& 1

11

hr

7

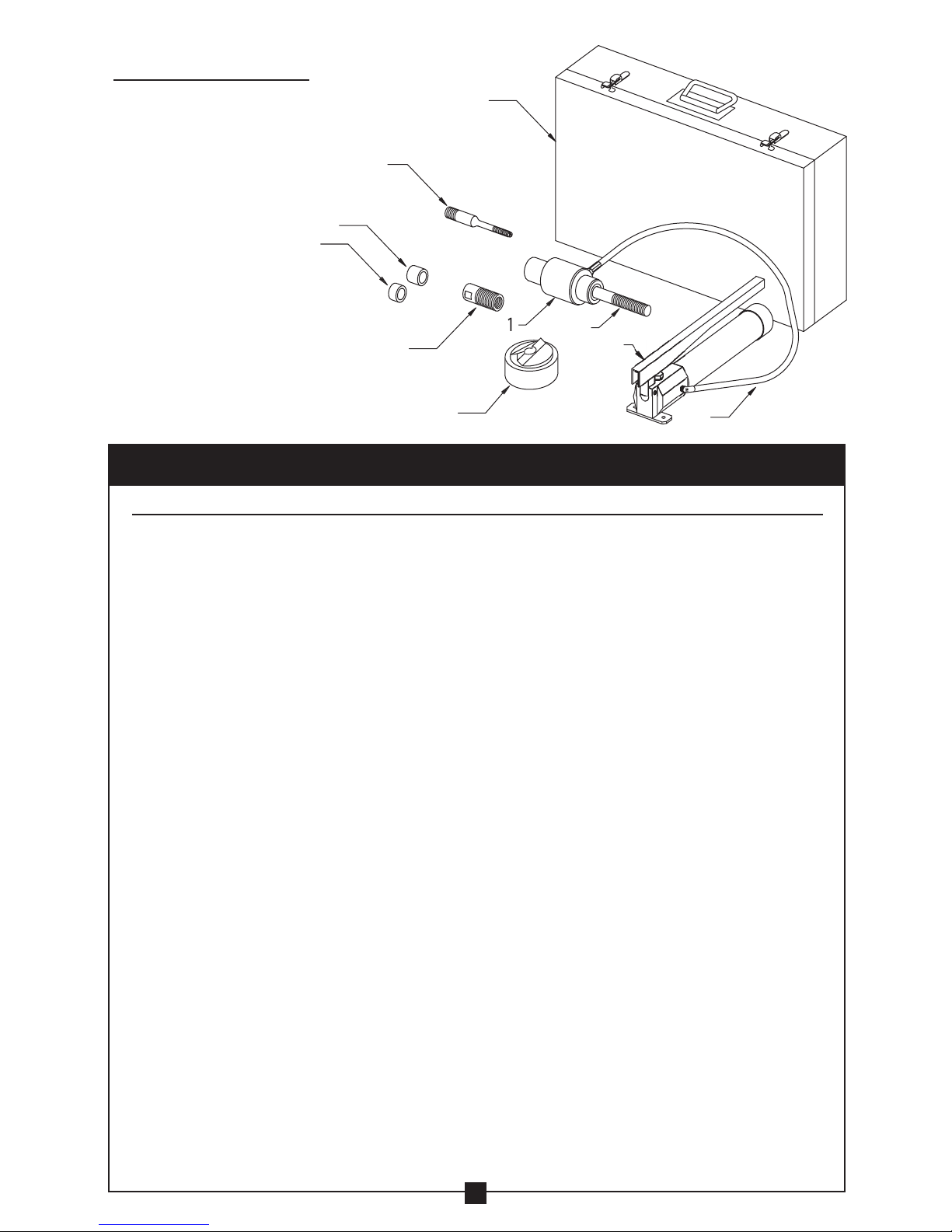

COMPONENTS LIST

ITEM# CATALOG# DESCRIPTION #152 #152PM #154 #154PM

1⁄2" to 2" 1⁄2" to 2" 1⁄2" to 4" 1⁄2" to 4"

1 ...............1522 ................... Ram (Includes #2) .................. 1 .................. 1 ................. 1 ................. 1

2 ...............1582 ........................3⁄4" Draw Stud ......................1 ..................1 ................. 1 ................. 1

3 ...............1552 ......................... 11⁄8" Adapter ................................................................1 ................. 1

4 ...............1581 ................ 3⁄8" Adapter Draw Stud ...............1 ..................1 .................1 ................. 1

5 ...............1553 ....................Short Spacer – S ................. 1 .................. 1 ................. 1 ................. 1

6 ...............1554 .................Medium Spacer – M .............. 1 .................. 1 ................. 1 ................. 1

7 ...............1521 .................Hydraulic Hand Pump ...............1 ..................1 .................1 ................. 1

8 ...............1523 ................ 1⁄4" x 3' Hydraulic Hose ..............1 ..................1 .................1 ................. 1

9 ............1500-PC ... Plastic Carrying Case –1⁄2" to 2" Set ....1 ..................1 ......................................

10 ..............1501 .......Metal Carrying Case –1⁄2" to 4" Set ..............................................1 ................. 1

11 ..............1524 ................1⁄2" Piece Maker™ Punch ...................................1 ..................................... 1

12 ..............1525 .............................. 1⁄2" Die ............................1 ..................1 .................1 ................. 1

13 ..............1526 ................3⁄4" Piece Maker™ Punch ...................................1 ..................................... 1

14 ..............1527 .............................. 3⁄4" Die ............................1 ..................1 .................1 ................. 1

15 ..............1528 ................ 1" Piece Maker™ Punch ...................................1 ..................................... 1

16 ..............1529 .............................. 1" Die............................. 1 .................. 1 ................. 1 ................. 1

17 ..............1530 ...............11⁄4" Piece Maker™ Punch ..................................1 ..................................... 1

18 ..............1531 ............................. 11⁄4" Die ...........................1 ..................1 .................1 ................. 1

19 ..............1532 ...............11⁄2" Piece Maker™ Punch ..................................1 ..................................... 1

20 ..............1533 ............................. 11⁄2" Die ...........................1 ..................1 .................1 ................. 1

21 ..............1534 ................ 2" Piece Maker™ Punch ...................................1 ..................................... 1

22 ..............1535 .............................. 2" Die .............................1 .................. 1 ................. 1 ................. 1

23 ..............1560 ................... 1⁄2" Standard Punch .................1 ......................................1 ..................

24 ..............1561 ................... 3⁄4" Standard Punch .................1 ......................................1 ..................

25 ..............1562 ....................1" Standard Punch .................. 1 ...................................... 1 ..................

26 ..............1563 .................. 11⁄4" Standard Punch ................1 ......................................1 ..................

27 ..............1564 .................. 11⁄2" Standard Punch ................1 ......................................1 ..................

28 ..............1565 ....................2" Standard Punch .................. 1 ...................................... 1 ..................

29 ..............1566 ...........................21⁄2" Punch ..................................................................1 ................. 1

30 ..............1567 ............................. 21⁄2" Die ....................................................................1 ................. 1

31 ..............1568 ............................3" Punch ...................................................................1 ................. 1

32 ..............1569 .............................. 3" Die ...................................................................... 1 ................. 1

33 ..............1570 ...........................31⁄2" Punch ..................................................................1 ................. 1

34 ..............1571 ............................. 31⁄2" Die ....................................................................1 ................. 1

35 ..............1572 ............................4" Punch ...................................................................1 ................. 1

36 ..............1573 .............................. 4" Die...................................................................... 1 ................. 1

COMPONENTS

KNOCKOUT SET