5

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

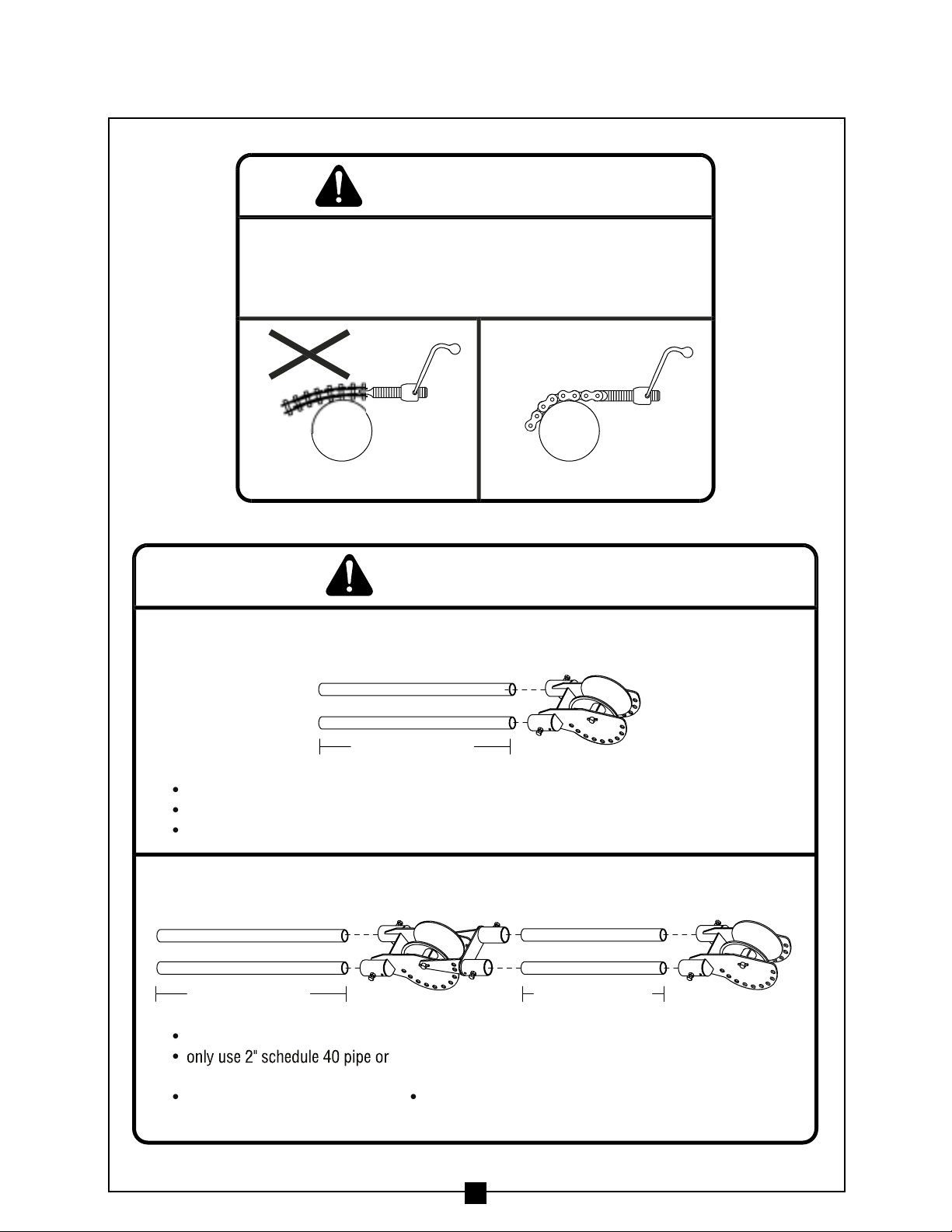

Pulling Rope should be the only thing to contact the capstan.

NEVER let swivels, grips, etc. come in contact with the capstan.

Keep as much rope confined in conduit as possible. This will

help prevent injury should the rope break and whip violently.

Rope must ALWAYS be pulled over a rotating sheave. If

a sheave does not rotate, turn cable puller off immediately

and determine problem before continuing the pull.

This cable puller is equipped with an anti-reversing pawl.

The pawl will make a clicking sound when the capstan is

rotating. If you can not hear the clicking sound as the capstan

rotates, immediately turn the cable puller off and do not

use until repaired.

ONLYuse 3/4” or larger double-braided composite pulling

rope with an average breaking strength of 26,000 lbs.

NEVER allow the rope to slip on a rotating capstan for more

than a couple of seconds. The rope will wear in that spot and

the rope could break under pressure. If you need to stop the

pull, turn the cable puller off and tie the rope off to hold it

in place until you restart your pull.

Keep all body parts, hair, loose clothing, etc. away from rotating

parts and pinch points. Keep hands away from capstan.

NEVER allow the rope to overlap on the capstan. If this condition

begins to occur, immediately release the tailing force on the rope

so that the rope can feed back toward the conduit or cable tray.

If this does not remedy the overlap, turn off the cable puller

immediately. There is no known solution for rope overlap.

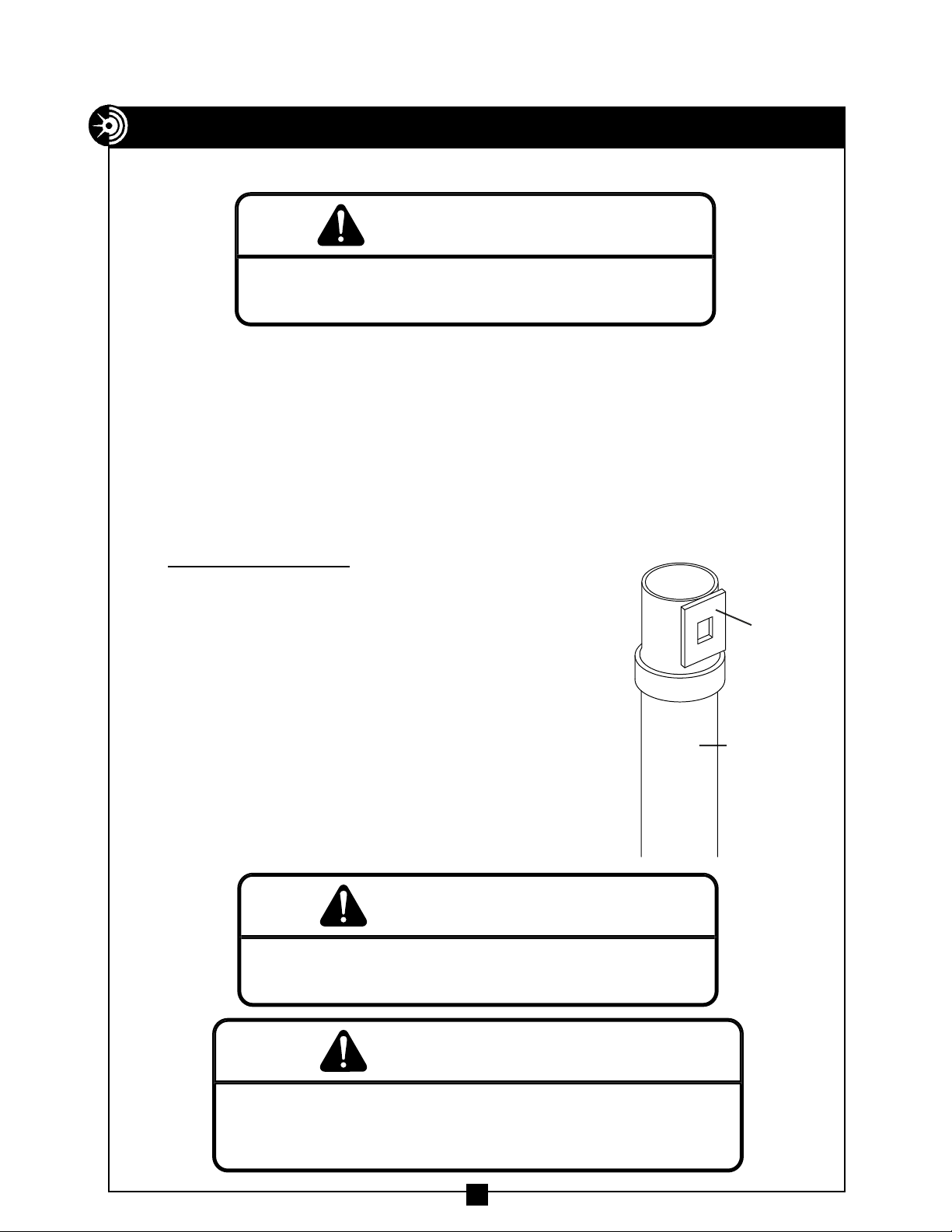

Rope should approach

capstan as shown in

figure 5a.

ALWAYS use black

roller to guide rope so

that operator stands at

90º angle to the cable

puller and out of the

direct line of tight pulling

rope. See figure 5b.

ALWAYS wrap rope begin-

ning at housing end of

capstan as shown in

figure 5b.

To help avoid rope overlap,

rope should approach

capstan at a 90º angle.

See figure 5b.