INSTALLATION INSTRUCTIONS II2

Installation Instructions

Installation Requirements

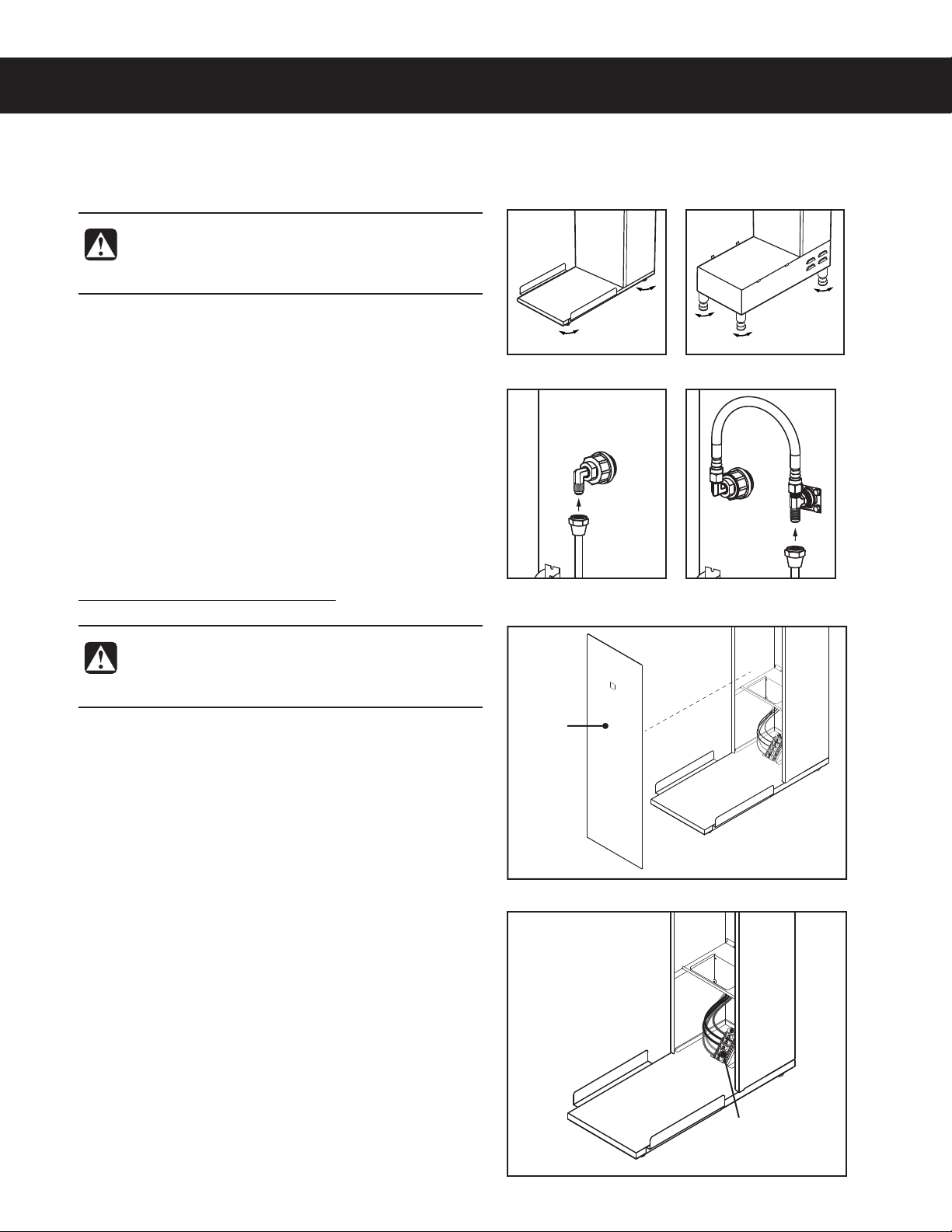

• A secure surface capable of supporting the weight of the brewer.

• For brewers without an attached cord set: Appropriately sized, UL listed, grounding type power cable to meet

UIFFMFDUSJDBMTQFDJmDBUJPOTGPSUIFCSFXFS*GZPVIBWFRVFTUJPOTBCPVUUIFDPSSFDUDBCMFTJ[FBOEMFOHUI

DPOTVMUBRVBMJmFEJOTUBMMFS*GUIFCSFXFSXJMMCFIBSEXJSFEUPBKVODUJPOCPYUIFQPXFSDBCMFNVTUCFMPOH

enoughTPUIBUUIFCSFXFSDBOCFNPWFEGPSDMFBOJOHVOEFSOFBUI

• "HSPVOEFEFMFDUSJDBMDPOOFDUJPOUPBOFMFDUSJDBMDJSDVJUUIBUNFFUTUIFFMFDUSJDBMTQFDJmDBUJPOTPGUIFCSFXFS

(see SPECIFICATIONS5IFDJSDVJUNVTUCFQSPUFDUFECZUIFBQQSPQSJBUFTJ[FEDJSDVJUCSFBLFS*GZPVBSFOPU

DFSUBJOUIBUUIFFYJTUJOHDJSDVJUNFFUTUIFSFRVJSFNFOUTGPSZPVSCSFXFSDPOTVMUBMJDFOTFEFMFDUSJDJBO

• 8BUFSmMUSBUJPOTZTUFN3FRVJSFEUPNBJOUBJOUSPVCMFGSFFPQFSBUJPO8JMCVS$VSUJT$P*ODSFDPNNFOETB

8JMCVS$VSUJTBQQSPWFEXBUFSmMUFS7JTJUwww.wilburcurtis.comUPTFFUIFGVMMMJOFPG8JMCVS$VSUJTBQQSPWFE

XBUFSmMUFST

• 1PUBCMFXBUFSTVQQMZMJOFDPOOFDUJPOGSPNUIFXBUFSmMUFSDBQBCMFPGTVQQMZJOHUIFNJOJNVNnPXSBUFSFRVJSFE

CZUIFTQFDJmDBUJPOT5IFXBUFSTVQQMZMJOFNVTUCFBCMFUPDPOOFDUUPUIFnBSFmUUJOHPOUIFCBDLPGUIF

brewer. See the SPECIFICATIONS section for the correct size. The water line should also be capable of being

DPOUSPMMFECZBTIVUPGGWBMWF%POPUDPOOFDUUIFXBUFSMJOFUPBTBEEMFWBMWF

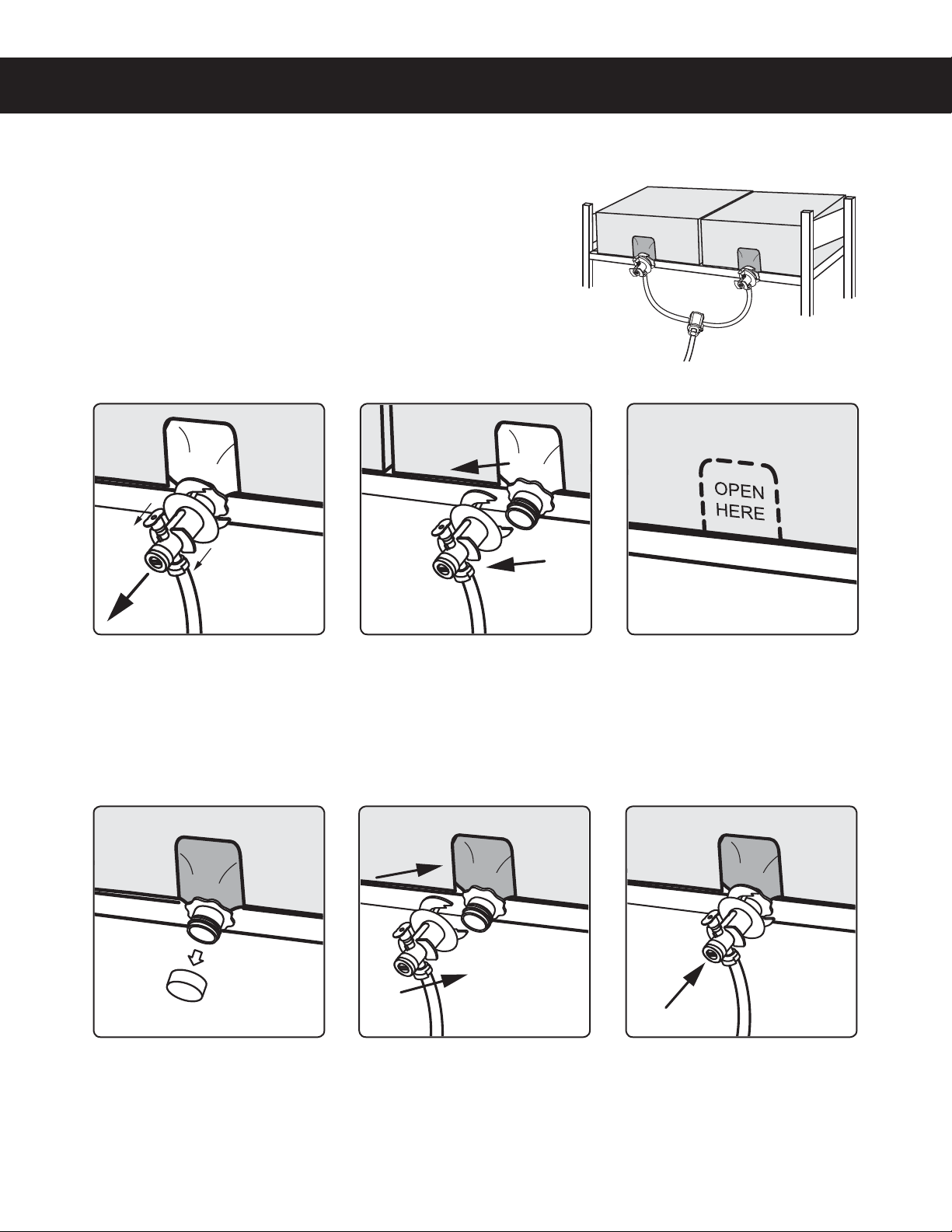

/4'*OUFSOBUJPOBMSFRVJSFTUIFGPMMPXJOHXBUFSDPOOFDUJPO

1 "RVJDLEJTDPOOFDUPSBEEJUJPOBMDPJMFEUVCJOHBUMFBTUUXPUJNFTUIFEFQUIPGUIFCSFXFSJTSFRVJSFE

TPUIBUJUDBOCFNPWFEGPSDMFBOJOHVOEFSOFBUI

2 5IJTFRVJQNFOUJTUPCFJOTUBMMFEXJUIBEFRVBUFCBDLnPXQSPUFDUJPOUPDPNQMZXJUIBQQMJDBCMF

federal, state and local codes.

8BUFSQJQFDPOOFDUJPOTBOEmYUVSFTEJSFDUMZDPOOFDUFEUPBQPUBCMFXBUFSTVQQMZTIBMMCFTJ[FE

installed and maintained in accordance with federal, state and local codes.

WARNING:*OTUBMMBUJPOJTUPCFQFSGPSNFEPOMZCZBRVBMJmFEJOTUBMMFS

WARNING: *NQSPQFS FMFDUSJDBM DPOOFDUJPO NBZ SFTVMU JO BO FMFDUSJD TIPDL IB[BSE 5IJT CSFXFS NVTU CF

properly grounded.

NOTICE:%0/05DPOOFDUUIJTCSFXFSUPBIPUXBUFSTVQQMZ5IFXBUFSJOMFUWBMWFJTOPUSBUFEGPSIPUXBUFS

%POPUFYDFFEUIFNBYJNVNXBUFSQSFTTVSFTUBUFEJOUIFSPECIFICATIONS section.

IMPORTANT:0CTFSWFBMMHPWFSOJOHDPEFTBOEPSEJOBODFT

#3&8&34(&/&3*$*/45"--"5*0/*/4536$5*0/4 /$

5IF*OUFSOBUJPOBM1MVNCJOH$PEFPGUIF*OUFSOBUJPOBM$PEF$PVODJMBOEUIF'PPEBOE%SVH"ENJOJTUSBUJPO

'%"'PPE$PEFNBOVBMEJSFDUUIBUUIJTFRVJQNFOUNVTUCFJOTUBMMFEXJUIBEFRVBUFCBDLnPXQSFWFOUJPO

in compliance with federal, state and local codes. For units installed outside of the U.S.A., make sure that

the installation is in compliance with the applicable plumbing/sanitation code for your area.