GENERAL INFORMATION BEFORE YOU START

HELPFUL HINTS:

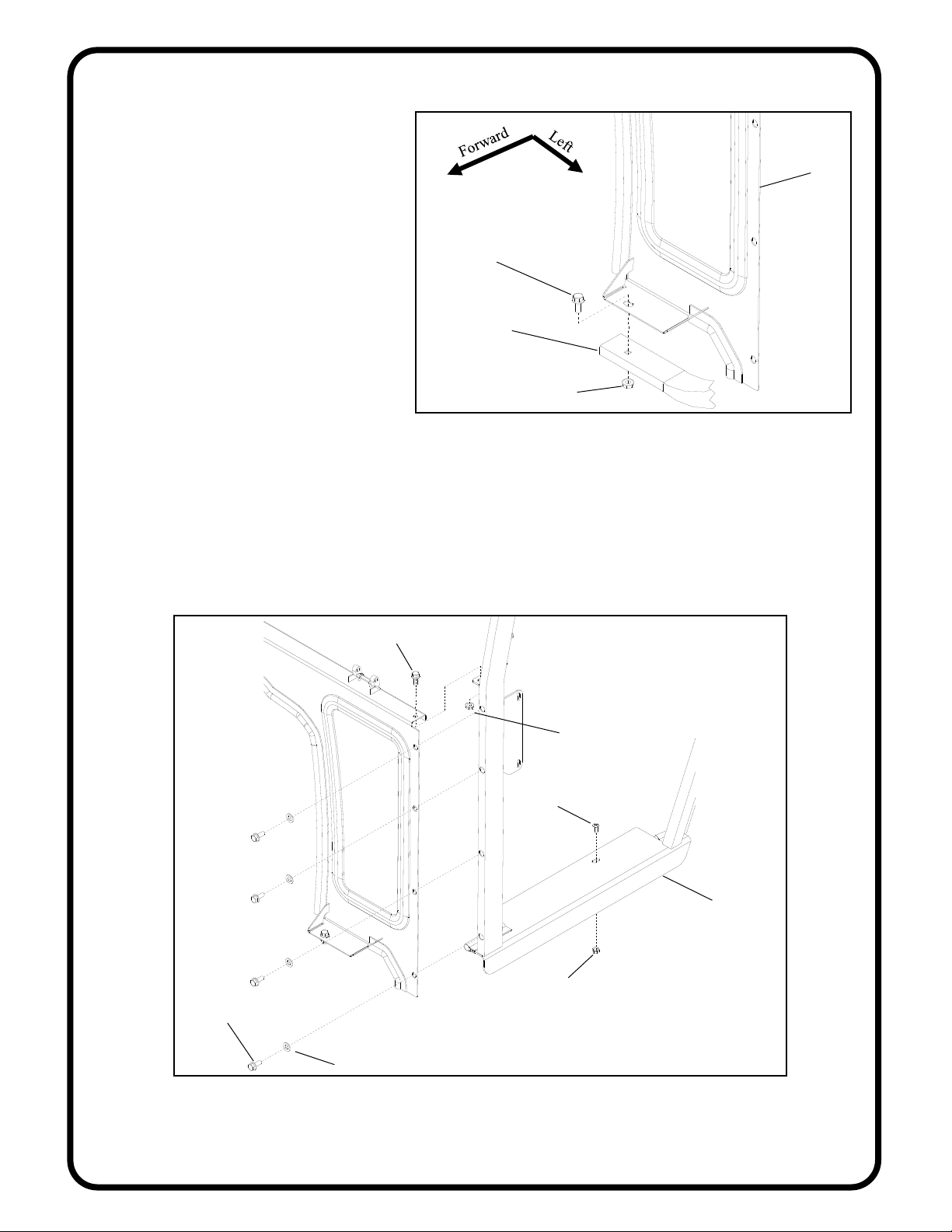

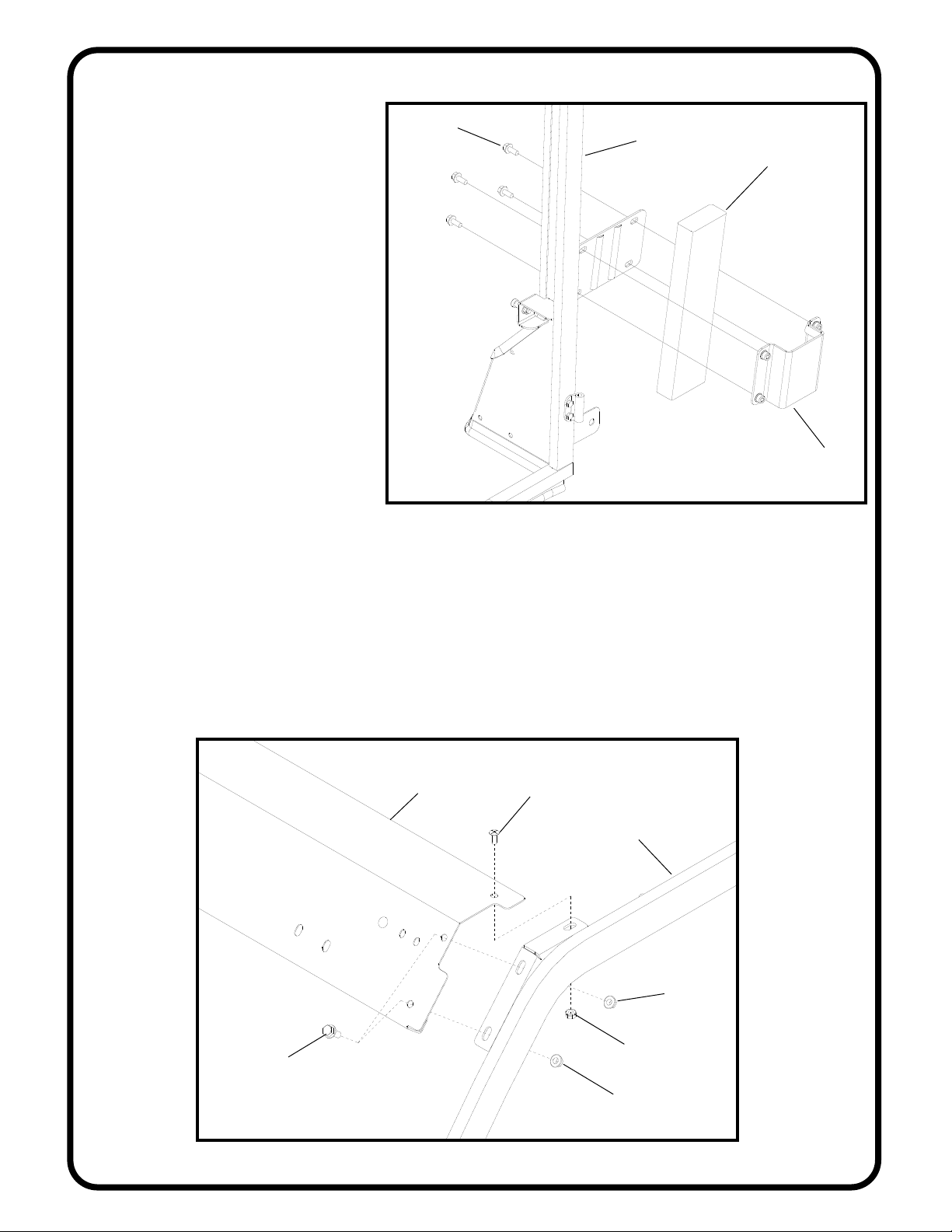

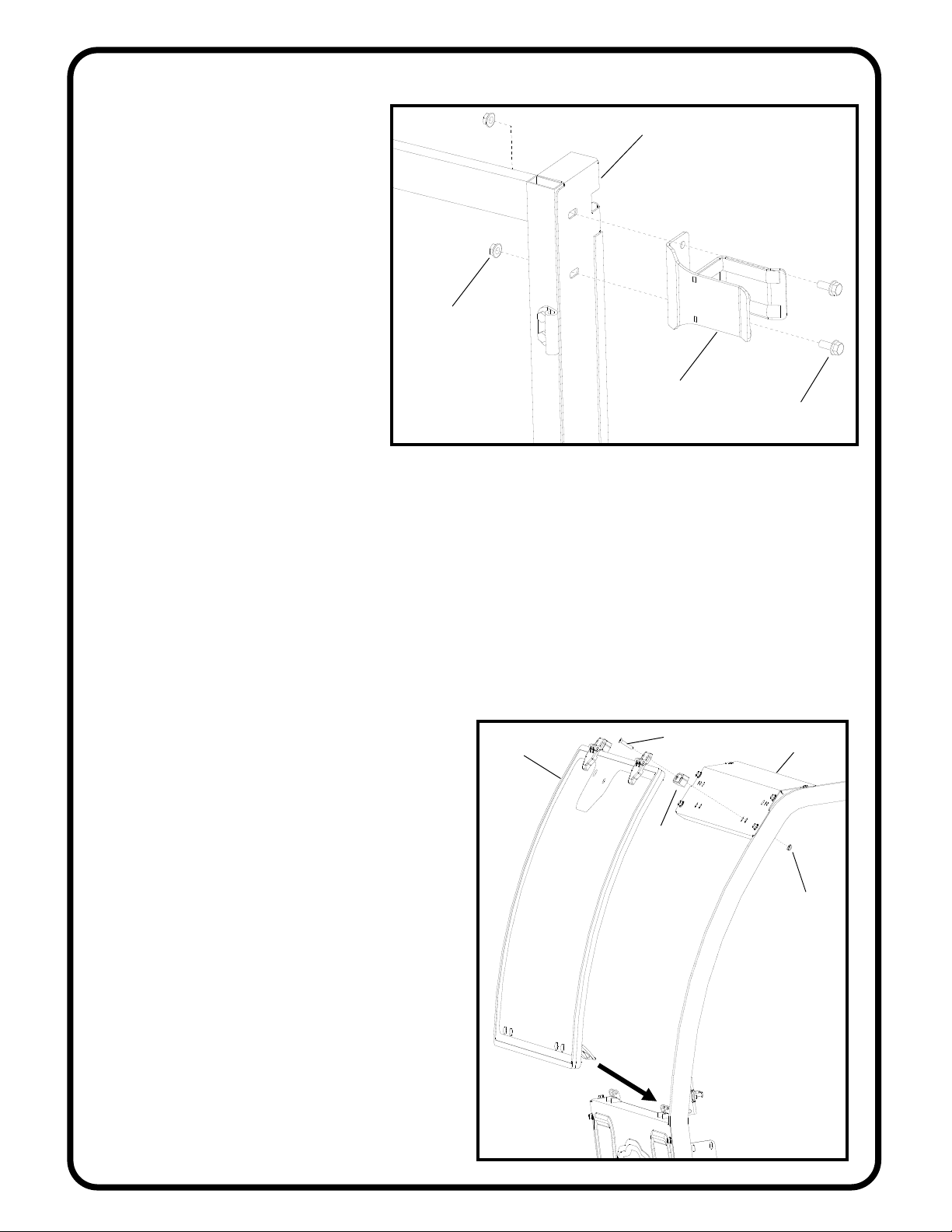

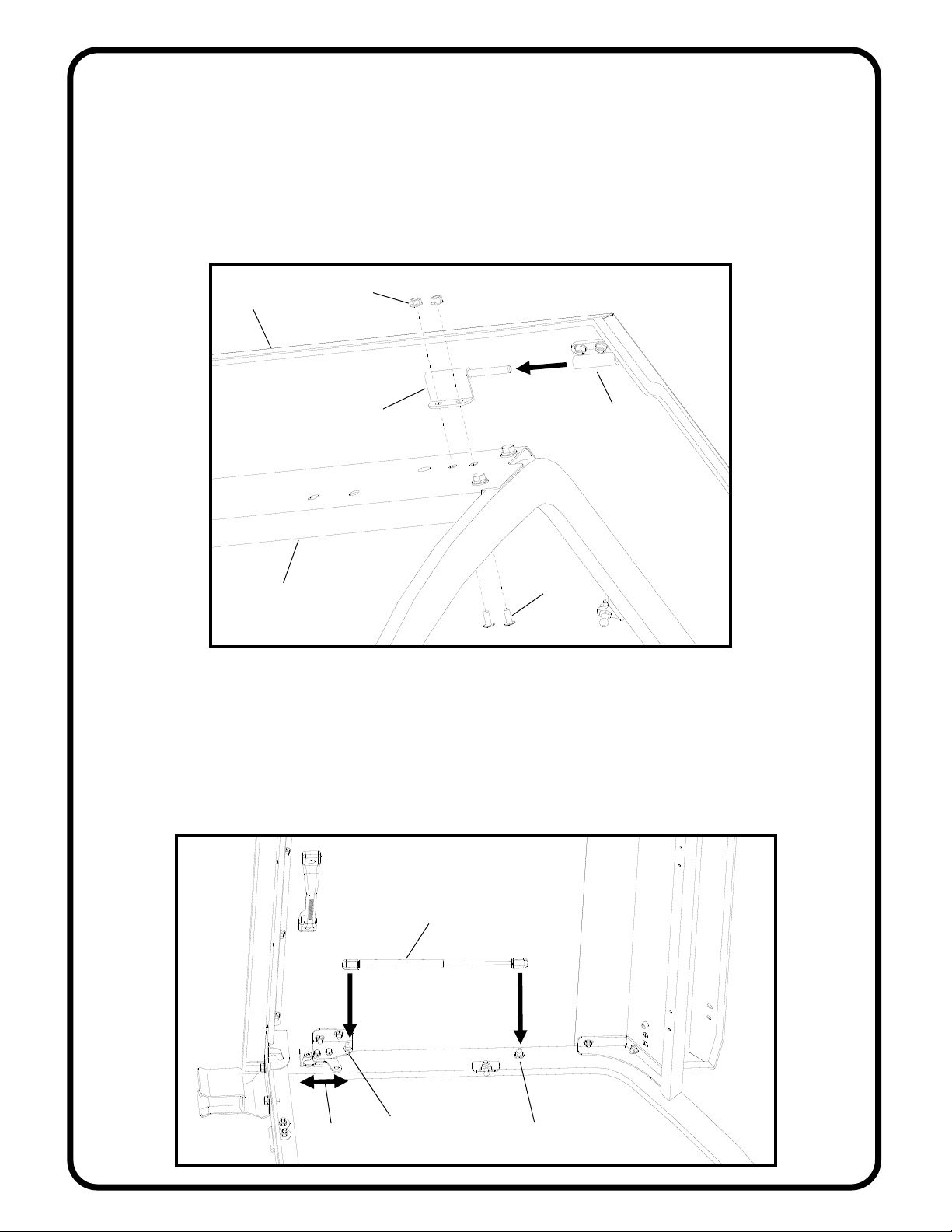

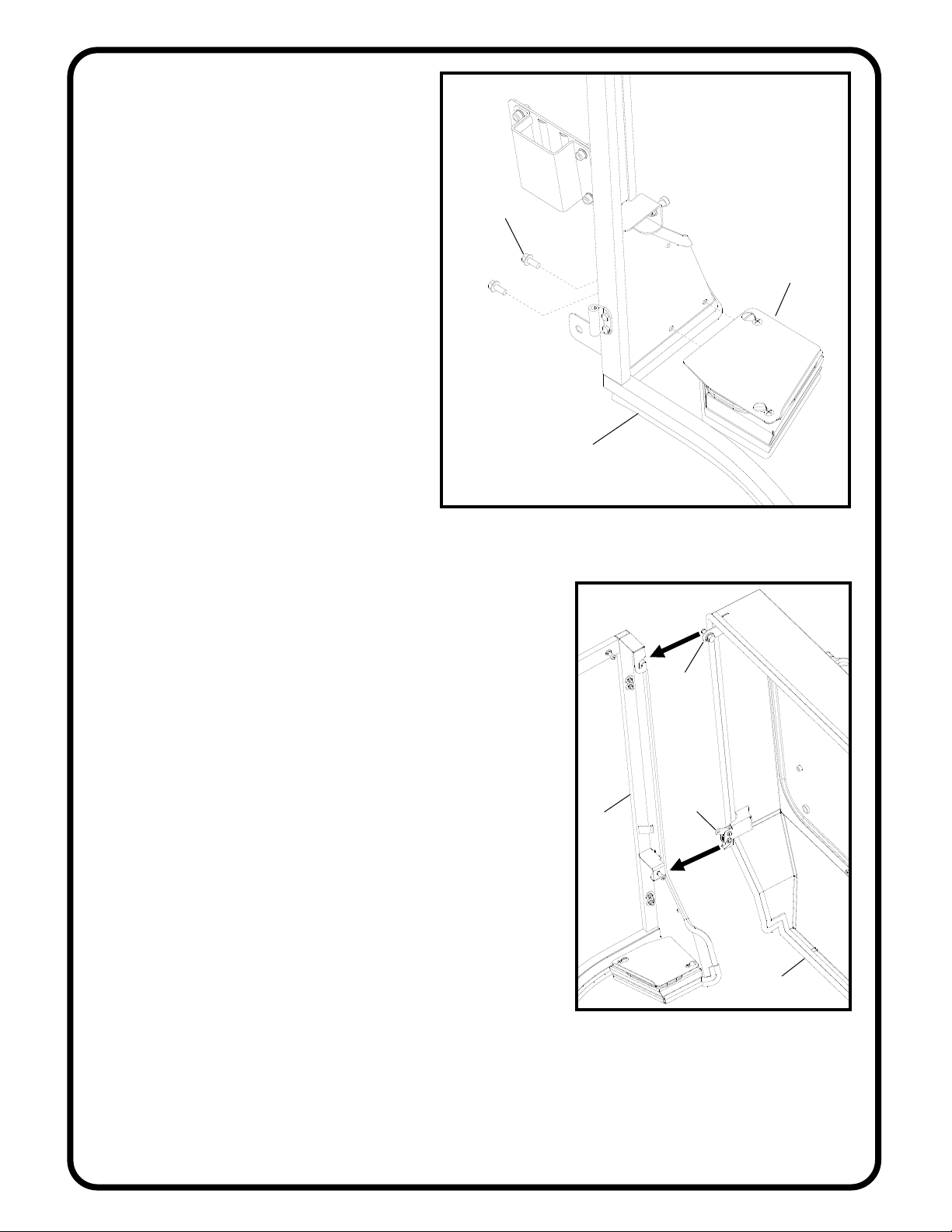

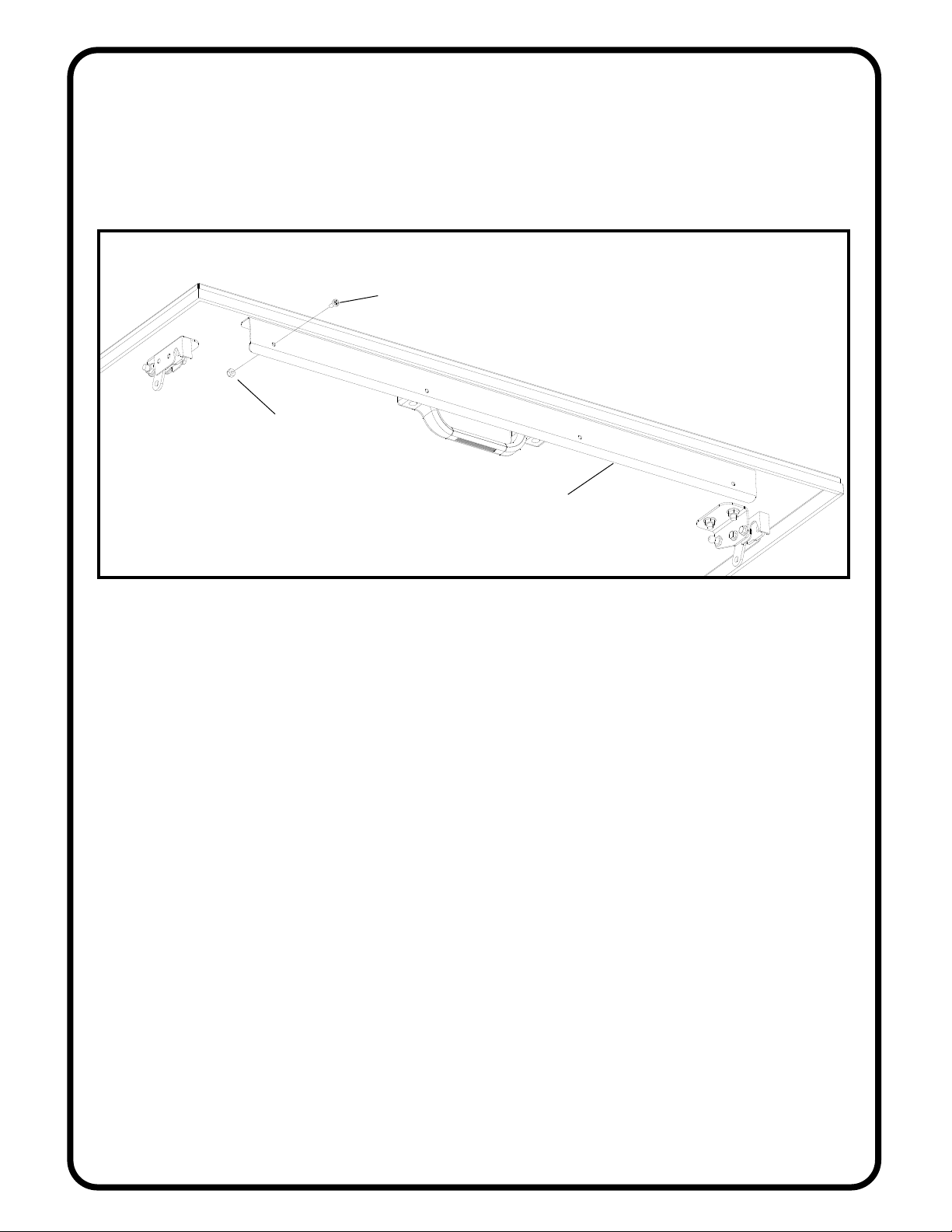

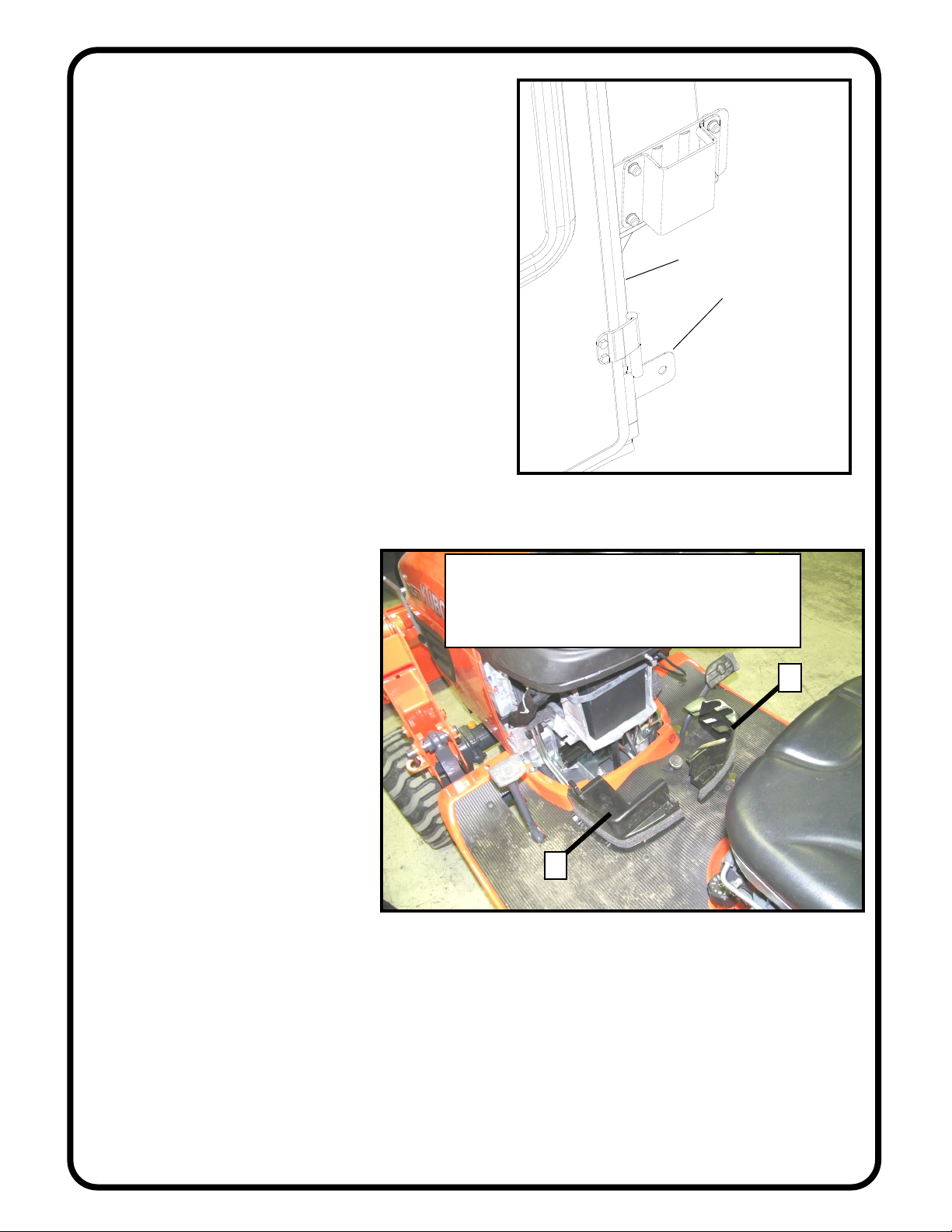

A. Refer to parts diagram toward the back of this manual to help identify parts during the assembly process.

B. To assist with the cab installation, leave all bolts loose for later adjustment unless otherwise specified.

C. Read and understand all instructions before beginning.

D. Apply a silicone sealant to seal any minor gaps that may occur due to vehicle variations.

E. Use caution to avoid damaging the factory installed threaded inserts. Begin the bolt engagement by hand

to guard against potential cross threading.

F. Verify all hardware and cab parts are accounted for before beginning.

TOOLS REQUIRED:

Set of Standard Sockets (3/8” Drive)

One 3/8” Drive Ratchet

Long Socket Extension

Set of Standard Open End Wrenches

Set of Metric Open End Wrenches

Set of Standard Allen Wrenches

#2 and #3 Phillips Head Screwdrivers

Grease

Bar Clamp

CARE AND MAINTENANCE:

Check and tighten hardware after 40 hours of operation. Periodically inspect and tighten hardware for the remainder of the unit’s

life.

Wash with a mild soap or detergent using your bare hands to free or dislodge any caked-on dirt or other foreign particles.

Do Not use Windex or any other chemicals to clean plastic windows or vinyl components.

Be sure to regularly grease door hinge pins. Also lubricate moving parts in the door latches.

p. 2 of 13

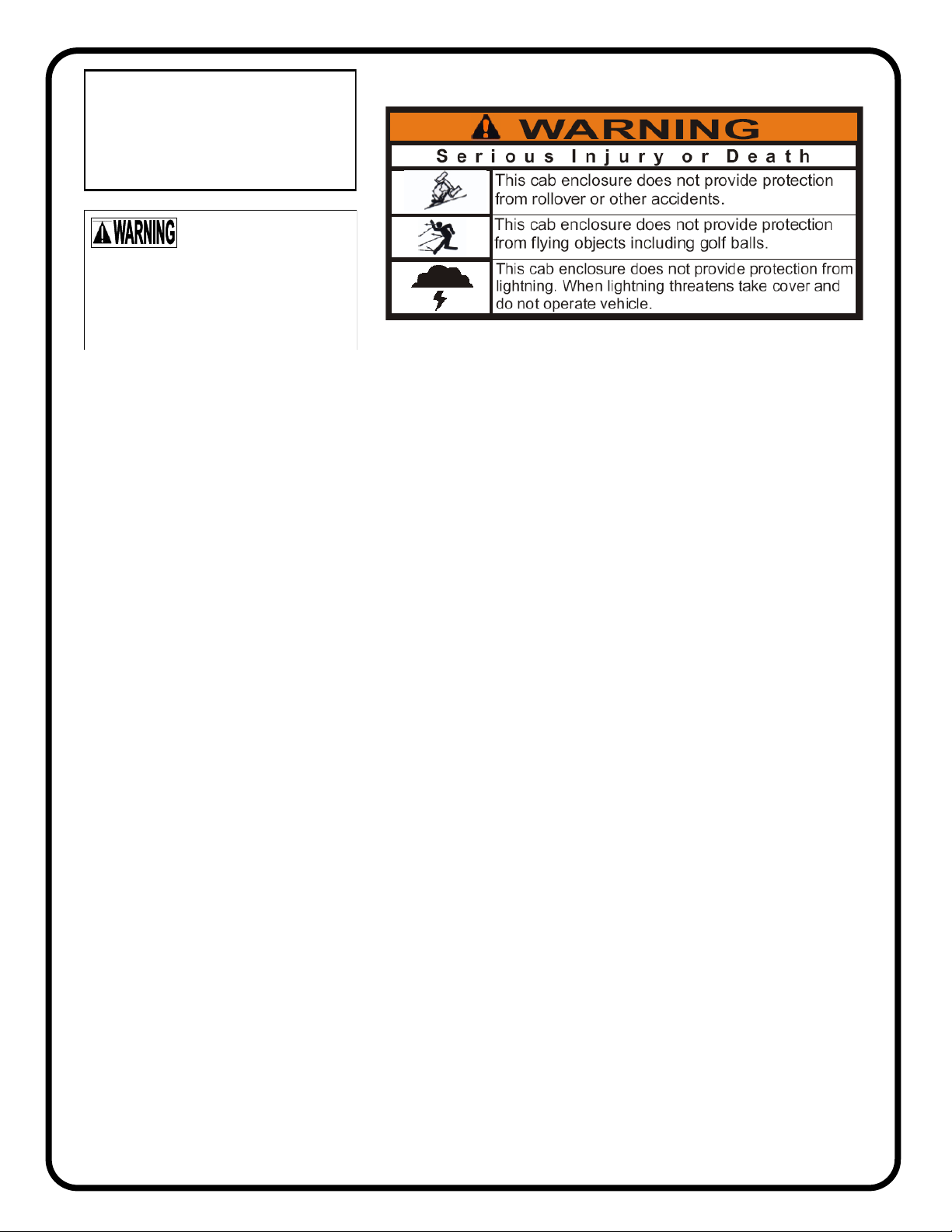

NOTICE

Cabs, blades, and general accessories add

additional weight to the base vehicle.

Deduct the accessory’s total weight from

the vehicle’s rated capacity including

driver and passenger.

Exposure to Carbon Monoxide

can Cause illness, serious injury

or death. Never operate vehicle if

suspicious of Carbon Monoxide. Inspect exhaust

system for leaks monthly. Leaks can result from

loose connections, corrosion, cracks or other dam-

age to the exhaust manifold. If leaks are found,

repair or replace exhaust system. Do not use vehicle

until repair or replacement is complete.