1 of 34

INSTALLATION & OWNER’S MANUAL

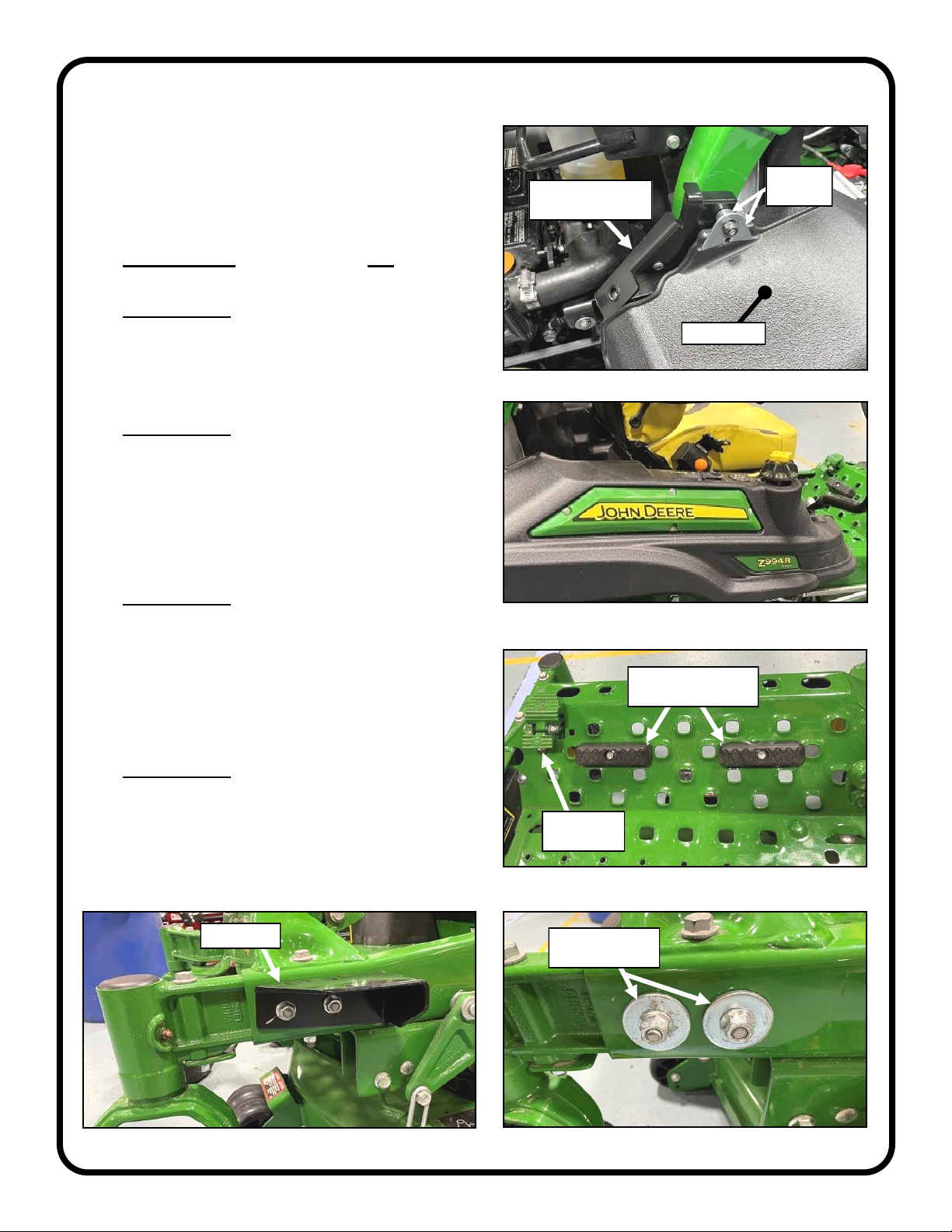

John Deere Z994R

(p/n: 1JDZ994RPR)

Cab with A/C

(fits both 60” and 72” mower decks.

Does not fit with mulching or 54” deck)

Requires Premium Seat

Rev. B, 10/25/2022

p/n: IM-1JDZ994RPR

(*=Not including accessories)

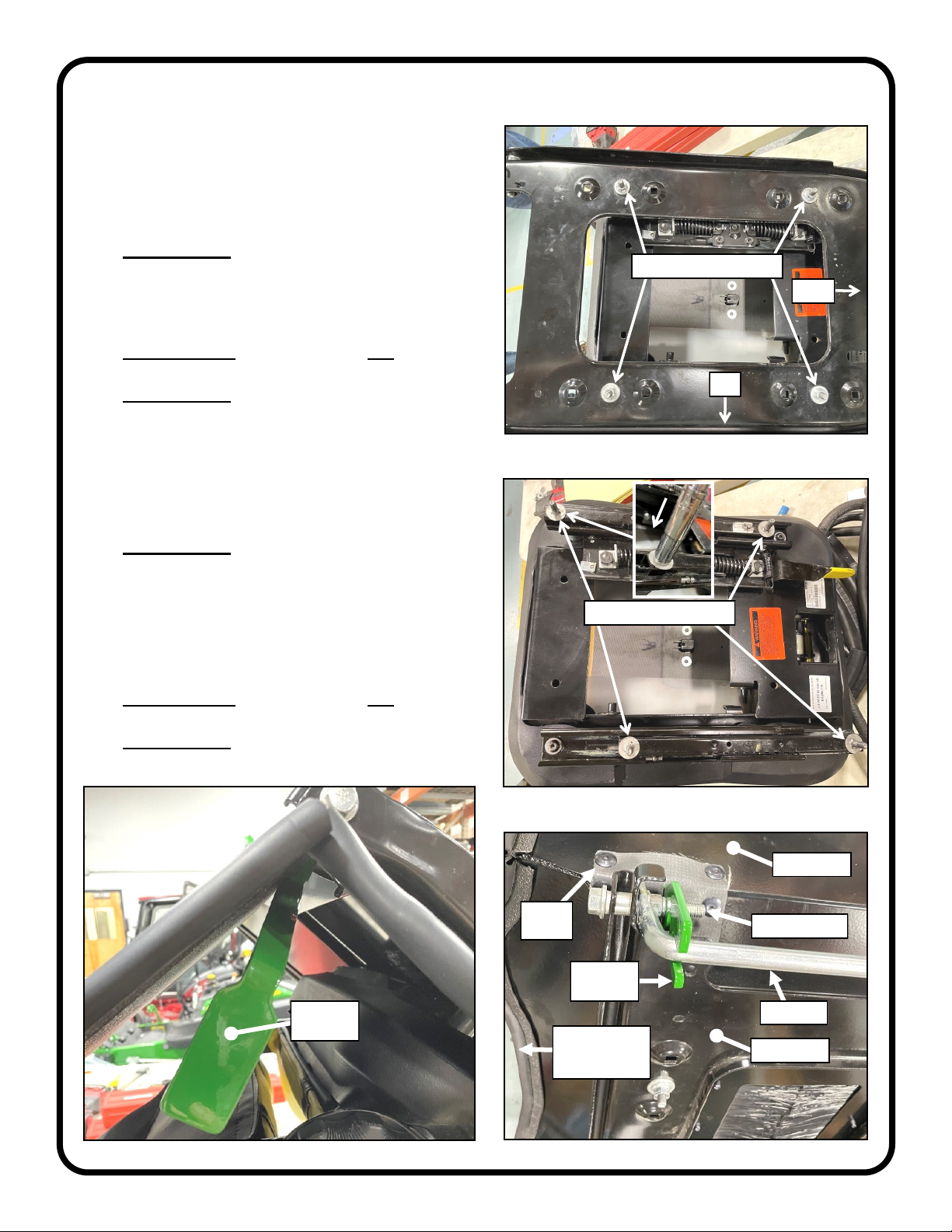

Approximate Installation Time *

Experienced Dealer Technician – 4 Hours

Average Dealer Technician – 6 Hours

Do-It-Yourself – 6-8 Hours

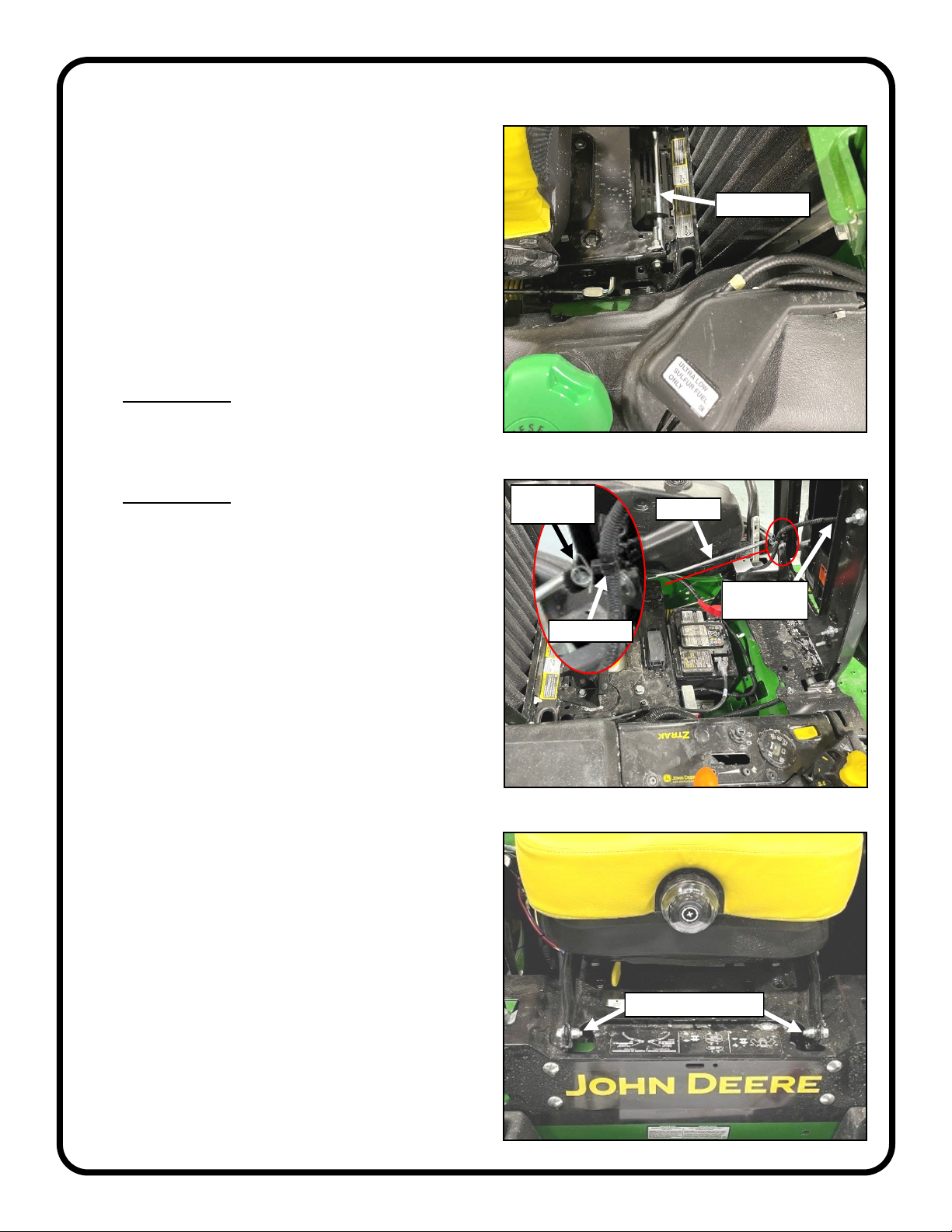

Approximate Product Specifications

Floorboard to Roof Height: 59 inches

Weight: 332 lbs.

Cab Width: 50 inches

The contents of this envelope are the property of the owner. Leave with the owner when installation is complete.

Register your new product quickly online at

Curtiscab.com/product-registration/

Download a digital copy of your installation

instructions online at Curtiscab.com/literature/

Curtis encourages all customers to register their

Curtis products. However, failure to do so will not

diminish right to warranty. Curtis Industries does not

sell or share your information with anyone else.

Curtis strives to continuously improve our products,

technical documentation, etc. Therefore, the

installation manual for this product may have been

updated after your product was packaged. The

latest revision of the installation manual can always

be found at the website above.

Premium Cab Shown with Options

Available Options:

1. Side View Mirrors (P/N: 9PM5)

2. Switch Panel (P/N: 1JDZ994RCK) (req’d for following 2 items)

3. Front LED Work Lights (P/N: 1ZTRLK)

4. Front Wiper/Washer Kit (P/N: 1ZTRWK)

While this cab kit was designed to fit on the vehicle listed above, manufacturing tolerances and vehicle

assembly may affect cab fitment. It is the responsibility of the cab installer to check all vehicle pedals and

levers for full functionality and, as required, adjust the cab fitment to prevent any interference of the cab

components with the travel of pedals or levers.