Page 7

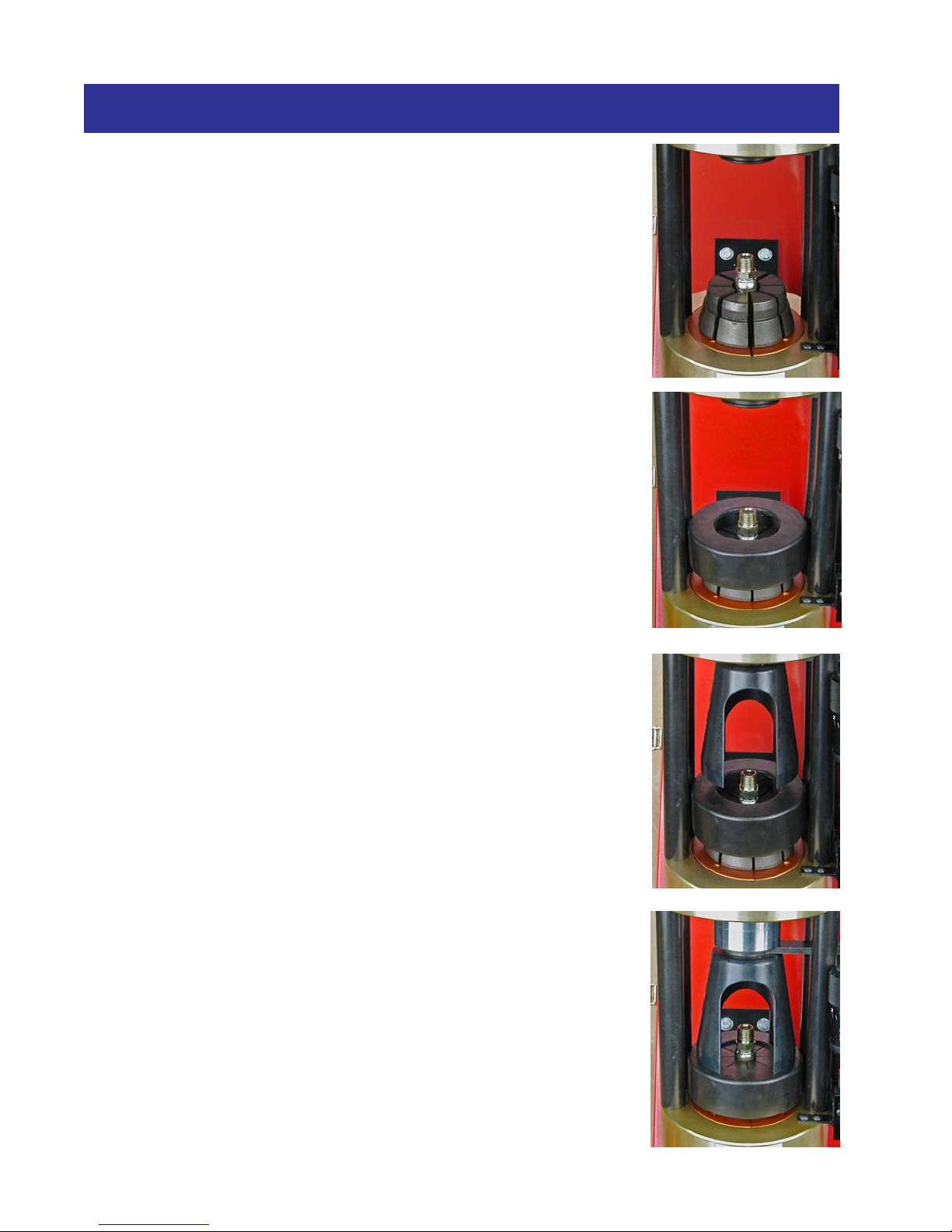

•The Double Angle Dies are special purpose dies designed to

double the crimping force thus allowing larger fittings to be

crimped with less vertical force.

The limitation, however, is that they must crimp to a near

fully closed position and therefore a given die set can crimp

only limited range above the diameter shown on the die ring.

•To use the Double Angle Die set, remove the flat pressure plate

from the cone base and replace it with the compression plate

labeled ‘DBL BASE’ whose angle matches that on the Double

Angle Die.

•Seat the Double Angle Die in the conical recess of the ‘DBL

BASE’ cone and position the hose and fitting as specified by the

fitting manufacturer.

•Place the ‘DBL TOP’ Compression Ring on top of the die set

making sure that the fitting is still correctly positioned. Slide the

pusher into place on the cylinder ram.

Note: the angles on the Double Angle compression ring and

the Standard Compression ring are not the same. The DBL

Top compression ring must be used with the Double Angle Die

set.

•Set the Micro-Crimp Adjuster at the recommended setting

specified by the hose and fitting manufacturer.

Note: The direct reading feature of the Micro-Crimp Adjuster is

not applicable with Double Angle Dies. Follow the hose and

fitting manufacturer’s recommendations

•Cycle the crimper until the white circumferential line on the

Micro-Crimp Sight Button just appears on the top of the Micro-

Crimp Adjuster or the power unit shuts off for the D101S unit.

Note that if the die is not brought to a near fully closed condition,

there is the possibility that the crimps will be tapered along the

length of the crimp diameter.

•Check the crimp diameter to be certain that it is within the specifications of the hose and

fitting manufacturer.

CRIMPING WITH A DOUBLE ANGLE DIE