6

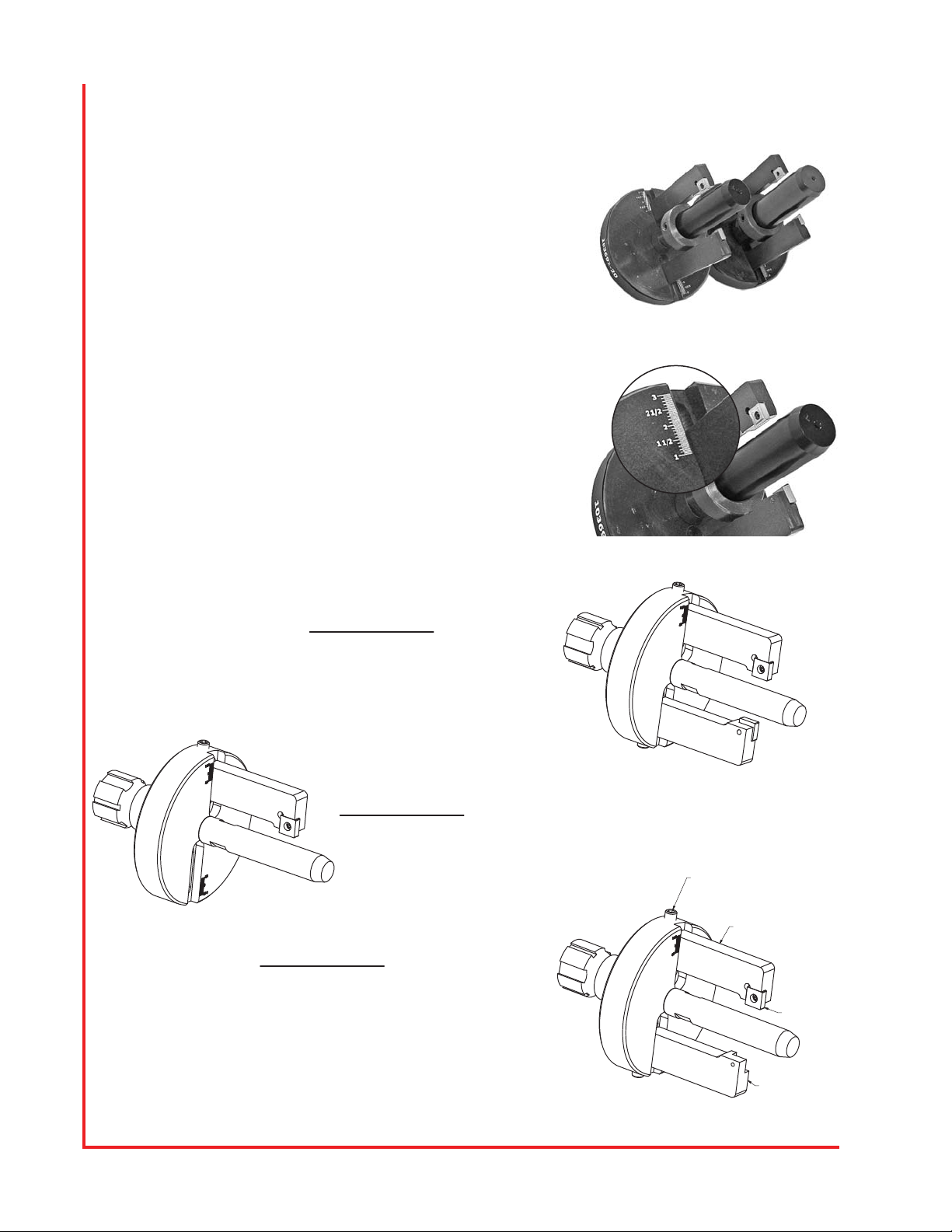

SM 300 HOSE SKIVER OD TOOLING FEATURES

The SM 300 Hose Skiver has the capacity and available tooling to

skive 2, 4, and 6 wire hoses from 1/2 inch thru 3 inches.

OD tools use readily available carbide cutting inserts. Carbide inserts

not only wear longer than conventional steel cutting tools, but they

never need sharpening. If an insert becomes dull, simply rotate it to

another cutting surface or install a new insert.

Note: No readjustment of the cutting tool is required.

The OD Skiving Tool is designed with two cutting arms. Both can be

adjusted to skive a single hose, but the real advantage of the two

arms is that one arm can be adjusted to skive diff erent wire hose.

For example: To switch from 2 wire skiving to 4 wire skiving, simply

remove the insert from the arm adjusted for 2 wire. The set up options

are shown in the panel below.

Tip: While the guide lines etched on the face of the OD Skiving Tool

will be very close to the correct setting, fine adjustment can be made

by leaving the hex bolt on the back face of the tool slightly loose and

adjusting the set screw on the edge of the tool before finally tightening

the hex bolt on the back face of the tool.

OPTION #1

Both Insert Arms can be set to the same

diameter on the etched scale and both

arms will work together.

OPTION #2

Only one Insert Arm may be installed and dialed

to the correct diameter on the etched scale.

OPTION #3

One Insert Arm can be dialed to skive a 4 spiral

hose and the other Insert Arm can be dialed to a

6 spiral hose of the same size.

If a 4 spiral hose is being skived, remove the 6

spiral Skiving Insert. If a 6 spiral hose is being

skived, remove the 4 spiral Skiving Insert.

SET UP FOR A 6 SPIRAL HOSE.

SET UP FOR A 4 SPIRAL HOSE.

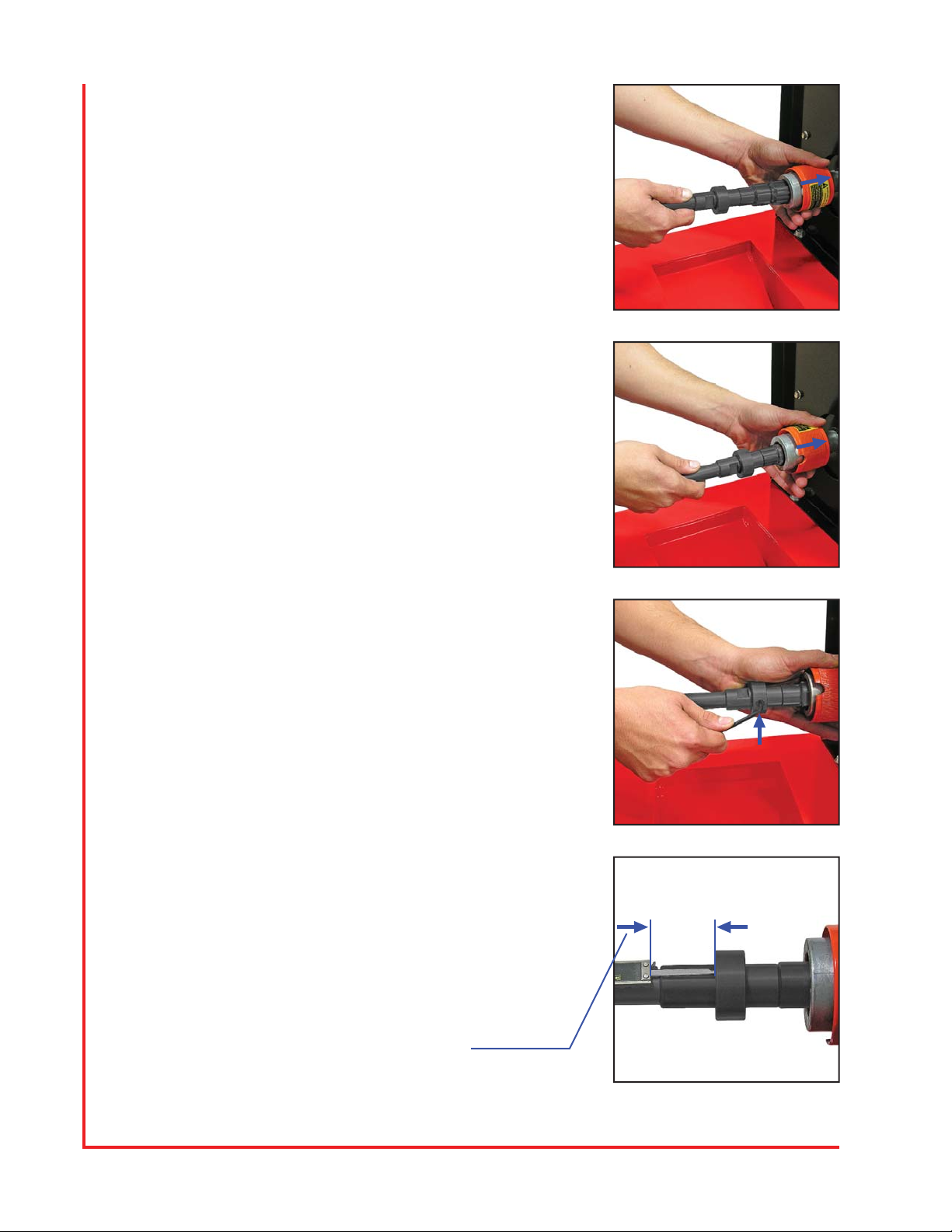

SKIVING INSERT

5/16-18 Set Screw