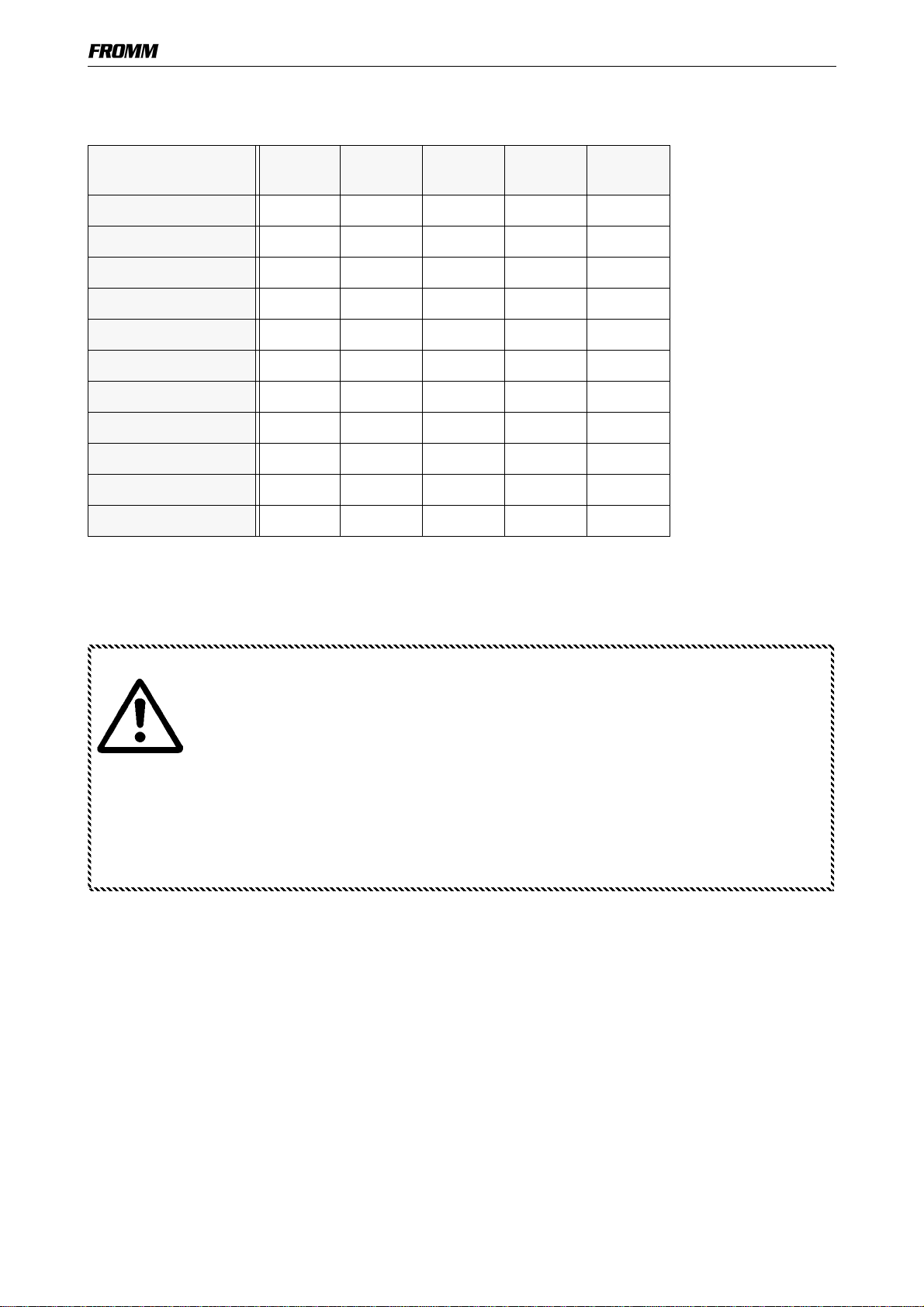

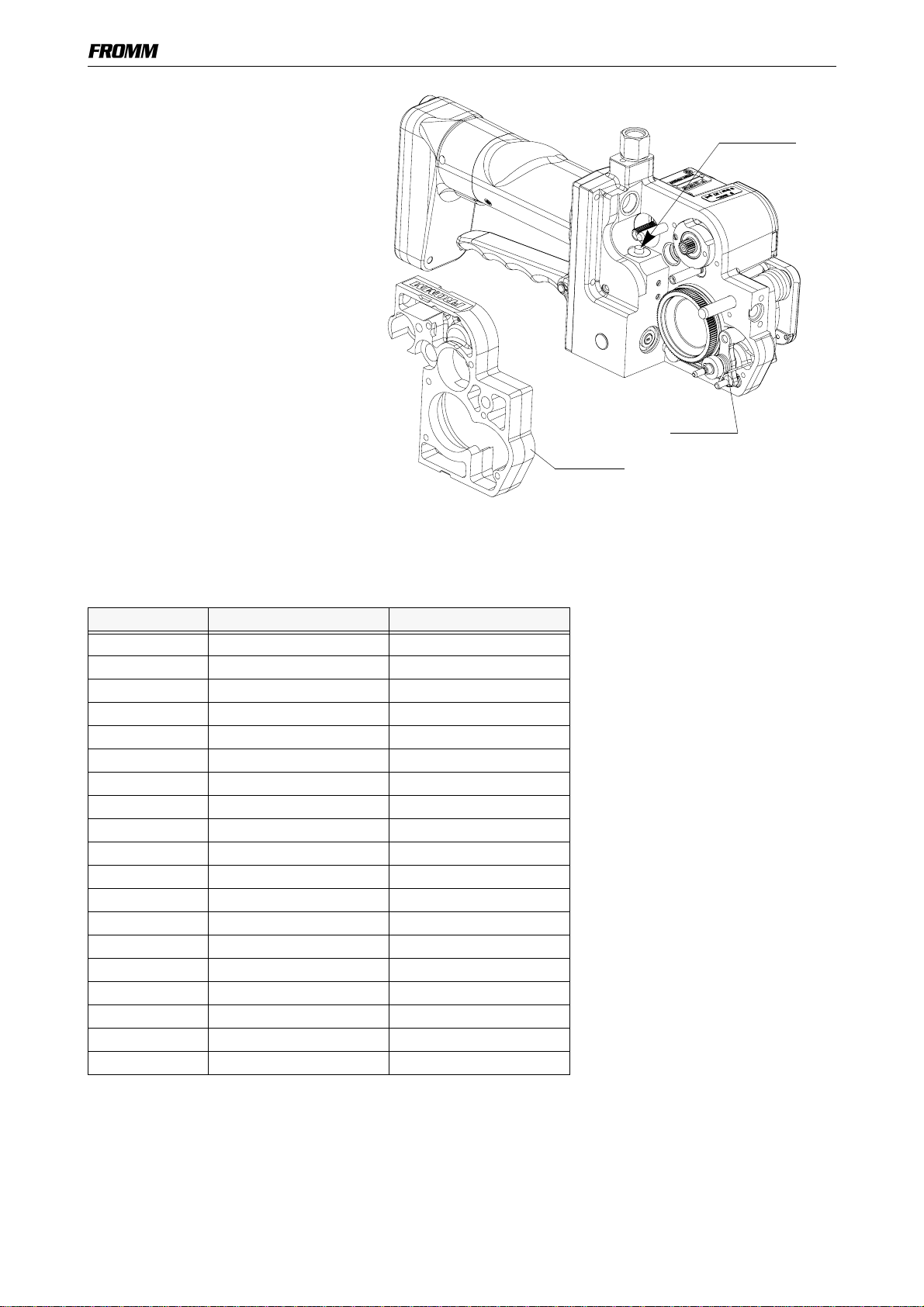

ACCESSORY TOOLS

1-17

1.5 ACCESSORY TOOLS

* a) These tools are also included in the P320 tool set.

b) These tools are also included in the P321 tool set.

c) These tools are also included in the P350 tool set.

d) These tools are also included in the P355 tool set.

Item

number Field Use

N71.3235 *a,d F5 Press in and press out arbor for N3.4509/P35.3118

N71.3238 *a,d F3 Press in and press out pressure pad for N3.1159/P32.1037

N71.3239 *a,d F7 Press in arbor for N3.2347/P32.1510

N71.3240 *a,d F7 Press out arbor for N3.2347/P32.1510

N71.3241 *a,d F7 Press in and press out pressure pad for N3.2347/P32.1510

N71.3266 *b F8 Press out arbor for N3.2356/P35.3211

N71.3237 *a,b,d F3, F8 Press in and press out arbor for N3.1159/P32.1037

and for N3.2356/P35.3211

N71.3243 *a,d F6 Press in arbor for N3.1134, P32.1023/P35.3123

N71.3244 *a,d F6, F9 Press out arbor for N3.1134, P32.1023/P35.3123; P35.0140/P32.1023

N71.3245 *a,d F6, F8 Pressure pad for N3.1134, P32.1023/P35.3123; N3.2356/P35.3211

N71.3264 *a F1 Press in and press out arbor for N3.1157/P35.3103

N71.3247 *a,d F1 Press in and press out pressure pad for N3.1157/P35.3103

N71.3248 *a,d F4 Press in arbor for N3.3150/P35.3204 or P35.3205

N71.3268 *a F4 Press out pressure pad for N3.3150/P35.3204 or P35.3205

N71.3250 *a,d F2 Press in and press out arbor for N3.3172/P35.3101

N71.3254 *a,d F9 Press on arbor for P32.1023/P35.0140

N71.3267 *b F4 Press in arbor for N3.3150/P35.3204 or P35.3205

N71.3278 F5 Press in and press out pressure pad for N3.4509/P35.3118

N71.3274 *d F11,F12,

F13 Hook for exhaust ring P35.2005, P35.3129/P35.3101;

P35.2059 and P35.3142/P35.3141

N71.3281 *d F9 Press on pressure pad for P32.1023/P35.0140

N71.3276*dF10 Pressure pad for P35.3138 resp. P35.3106/P35.2023, N3.1174

N71.3277*dF10 Thrust piecefor P35.3138resp. P35.3106/P35.2023, N3.1174

N71.3280 *d F9 Press out pressure pad for P32.1023/P35.0140

N71.3214 *c F14 Hook for throttle seat P35.2057/P35.3141

-- -- For the slotted round nut N1.5602 take a commercially face spanner