D Devices D Endo Rotatory User manual

D_ENDO ROTATORY

EN_ User manual

ES_ Manual de instrucciones

2

Endo Pace

User manual

Model: D_Endo Rotatory

EN_

Contents

Preface 3

1. 3noitcudortnI

2. 6noitallatsnI

3. Function and operation of product 9

4. Operation instruction 11

5. Motor Operation 17

6. Cleaning, Disinfection and Sterilization 18

7. Storage and transportation 26

8. Environmental protection 27

9. After service 27

10. European authorized representative 27

11. Symbol instruction 27

12. Statement 28

13. EMC - Declaration of conformity 28

ENGLISH

3

Note: the description on reciprocating mode is only

applicable for the device that has reciprocating mode.

Preface

Guilin Woodpecker Medical Instrument Co., Ltd is a professional ma-

nufacturer researching, developing, and producing dental products.

Woodpecker owns a sound quality control system. Guilin Woodpec-

ker Medical Instrument Co., Ltd has two brands, Woodpecker and

DTE. Its main products include Ultrasonic Scaler, Curing light, Apex

locator, Ultrasurgery, Endo Motor, etc.

1 Product introduction

1.1 Product description

The device is mainly used in Endodontic treatment. It is a cordless

endo motor which can be connected to the matched Apex locator

to add an apex locator function. It can be used as a endo motor for

preparation and enlargement of root canals. By connecting the endo

the canal can be monitored during the procedure and many automa-

tic functions such as Apical Slow Down can be activated.

Features:

a) Use effcient brushless motor, bringing lower noise and longer

service life.

b) Cordless portable endo motor which can be connected to the

matched Apex locator.

c) The contra angle can be rotated for 360°.

The device

1.3 Performance and composition

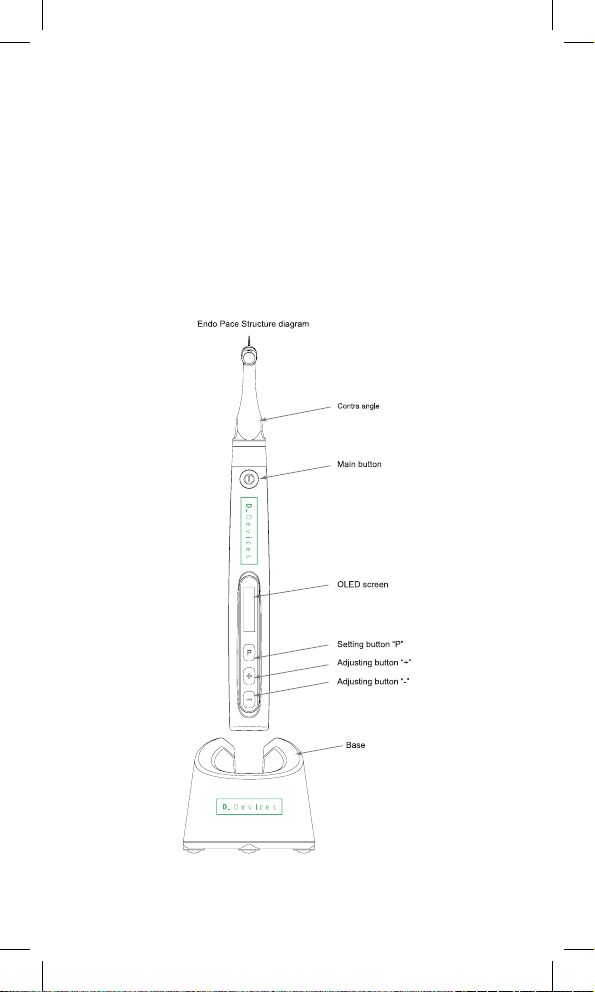

The device is composed of base, motor handpiece, contra angle,

USB wire, power adapter, protective silicon cover, etc.

1.4 Indications for Use

The device is cordless endodontic treatment motorized handpie-

ce with root canal measurement capability. It can be used for

preparation and enlargement of root canals, or measuring the canal

length. And it can be used to enlarge the canals while monitoring the

1.5 Scope of application

1.5.2 The device must be operated in hospital and clinic by the

1.6 Caution

4

Federal law restricts this device to sale by or on the order of a

dentists.

1.7 Contraindication

a) The doctor with a pacemaker is disabled.

b) Patients with cardiac pacemakers (or other electrical equipment)

are warned not to use small appliances (such as Electric razors,

hair dryers, etc.) patients are disabled.

c) Hemophilia patients are banned.

d) Use with caution in patients with heart disease, pregnant women

and young children.

ENGLISH

5

1.8 Warnings

operation.

1.8.3 Do not directly or indirectly place this device near heat source.

Operate and store this device in reliable environment.

1.8.4 This device requires special precautions regarding electromag-

netic compatibility (EMC) and must be in strict accordance with the

EMC information for installation and use. Do not use this equipment

especially in the vicinity of fuorescent lamps, radio transmitting de-

vices, remote control devices, handheld and mobile high- frequency

communication devices.

1.8.5 Long time use of Reciprocating Mode may result in motor

handpiece overheat, thus it should be left to cool for use. If the motor

handpiece is overheated frequently, please contact local distributor.

1.8.6 Please use the original contra angle. Otherwise it will not be

used or cause adverse consequences.

1.8.7 Please do not make any changes to the device. Any changes

may violate safety regulations, causing harm to the patient. There

1.8.8 Please use original power adapter. Other power adapter will

result in damage to lithium battery and control circuit.

1.8.9 The motor handpiece cannot be autoclaved. Use disinfectant of

neutral pH value or ethyl alcohol to wipe its surface.

1.8.10 Before the contra angle stopping rotating, do not press the

push cover of contra angle. Otherwise the contra angle will be

broken.

1.8.11 Before the motor handpiece stopping rotating, do not remove

the contra angle. Otherwise the contra angle and the gear inside

motor handpiece will be broken.

before starting the motor handpiece.

-

1.8.14 Error in replacing lithium batteries can lead to unacceptable

risks, so please contact local distributors to replace the battery if

necessary.

1.8.15 Don’t place the device in a position diffcult to disconnect

fromthe network power.

1.8.16 Don’t maintain the machine while in use.

6

1.9.1 Type of operation mode: Continuous operating device

1.9.2 Type of protection against electric shock: Class II equipment

with internal power supply

1.9.3 Degree of protection against electric shock: B type applied part

1.9.4 Degree of protection against harmful ingress of water: Ordinary

equipment (IPX0)

1.9.5 Degree of safety application in the presence of a fammable

anesthetic mixture with air, oxygen, or nitrous oxide: Equipment

cannot be used in the presence of a fammable anesthetic mixture

with air, oxygen, or nitrous oxide.

1.9.7 The contact duration of applied part: 1 to 10 minutes.

1.9.8 The temperature of the surface of applied part may reach 41°C.

1.10.1 Battery

Lithium battery in motor handpiece: 3.6V /850mAh

1.10.2 Power adapter

Input: ~100V-240V 50Hz/60Hz 0.4A Max Output: DC5V/1A

1.10.3 Torque rang: 0.4N·cm-4.2N·cm

1.10.4 Speed rang: 100r/min~1500r/min

1.11 Working environment parameters

1.11.1 Environment temperature: +5°C ~ +40°C

1.11.2 Relative humidity: 30% ~ 75%

1.11.3 Atmospheric pressure: 70kPa ~ 106kPa

2 Installation

2.1 Basic accessories of product

USB Wire Disposable insulation sleeves Protective silicon cover

ENGLISH

7

2.2 Instructions for contra angle

2.2.1 The contra angle adopts precision gear transmission, and the

transmission ratio is 6:1.

disinfect contra angle with disinfectant of neutral PH value. After

under high temperature and high pressure (134°C, 2.0bar~2.3bar

(0.20MPa~0.23MPa)).

2.2.3 The contra angle can only be used cooperatively with this

device. Otherwise the contra angle will be damaged.

2.3 Installation and removal of contra angle.

2.3.1 Installation

Align any locating pin of the contra angle with the positioning slot

on the motor handpiece and push the contra angle horizontally. The

four locating pins on the contra angle are inserted into those four

positioning holes on the motor handpiece. A “click” sound indicates

that the installation is in place.

The contra angle can be rotated 360° freely.

The contra angle rotates 360° so that the OLED display can always

be viewed easily.

2.3.2 Removal

Pull out the contra angle horizontally when the motor handpiece

does not run.

8

Warnings:

motor handpiece.

has been well installed.

head.

the contra angle.

chuck of contra angle.

02.334 – 2.350 mm)

Warnings:

stopped.

chuck of contra angle.

ENGLISH

9

3 Function and operation of product

3.3 Display Screens

3.3.1 Display Screens for 4 Operation Modes and Standby

3.3.1.1 CW Mode

The motor handpiece rotates forward 360°,clockwise direction. Used

10

3.3.1.2 CCW Mode

The motor handpiece rotates counterclockwise direction only. This

mode is used to inject calcium hydroxide and other medicant. When

this mode is being used, a double-beep sounds continuously.

3.3.1.3 REC Mode

F: Forward angle, R: Reverse angle F/R: Forward angle/ Reverse

angle

Forward Angle<Reverse Angle, such as F: 30/R: 150, effective cut-

ting angle is Reverse Angle, it is suitable for used the reciprocating

Forward Angle>Reverse Angle, such as F: 180/R: 30, effective cut-

ting angle is Forward Angle, it is suitable for used the reciprocating

SENDONELINE S1.

3.3.1.4 ATR Mode

ATR: Adaptive Torque Reverse function.

3.3.2 Torque Display

This appears when the motor is running. Meter shows the torque

ENGLISH

11

4 Operation instruction

4.1 Working environment parameters

4.1.1 Environment temperature: +5°C ~ +40°C

4.1.2 Relative humidity: 30% ~ 75%

4.1.3 Atmospheric pressure: 70kPa ~ 106kPa

4.2 Starting and stopping of motor handpiece

a) Under the power off state of motor handpiece, press Main but-

ton,and then the motor handpiece will enter Standby interface. The

interface displays are as follow:

Standby interface

b) Under Standby interface, press Main button, and then the motor

handpiece will enter Working interface. The interface displays are

as follow:

Working interface

Press the Main button again, and then the motor handpiece backs

to Standby interface.

c) Hold down the Setting button “P”, then press Main button to turn

off motor handpiece. In the standby interface without any key

down of the motor handle.

4.3 Selecting customized program sequence number

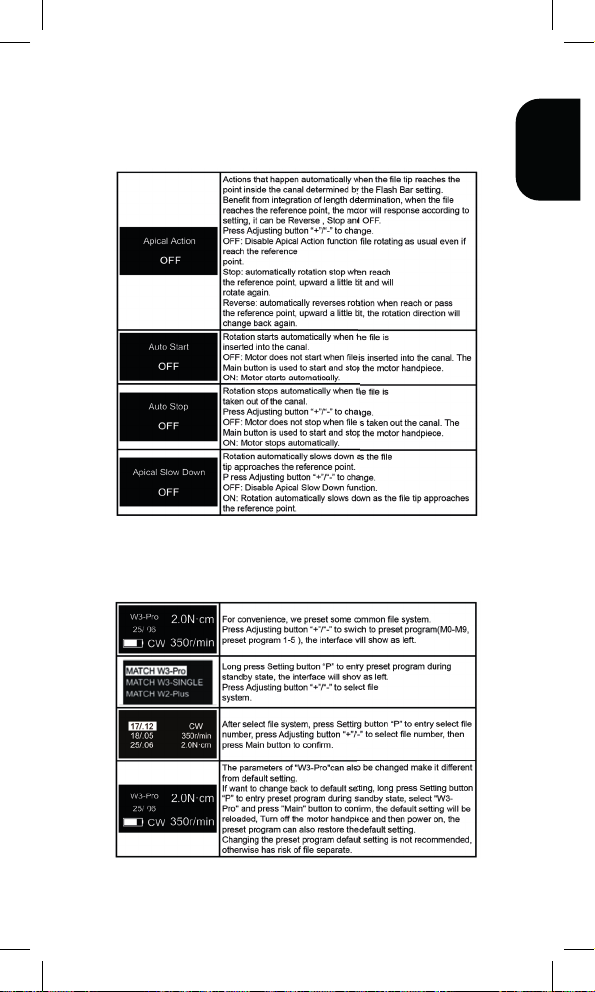

The motor handpiece has 10 memory programs(M0-M9) and 5

preset programs, press Adjusting button “+”/“-” to change customized

program sequence number during standby state.

M0-M9 is a memory program for canal shaping and measurement,

every memory program has its own parameters such as Operation

mode, speed and torque, all these parameters can be changed.

4.4 Parameter setting

12

ENGLISH

13

4.5 Preset program selection

14

4.6 Handpiece functions setting

With the motor handpiece turned off, hold down the Setting button

“P” and press Main button to entry handpiece functions setting, press

Setting button “P” till target setting, press Adjusting button “+”/“-” to

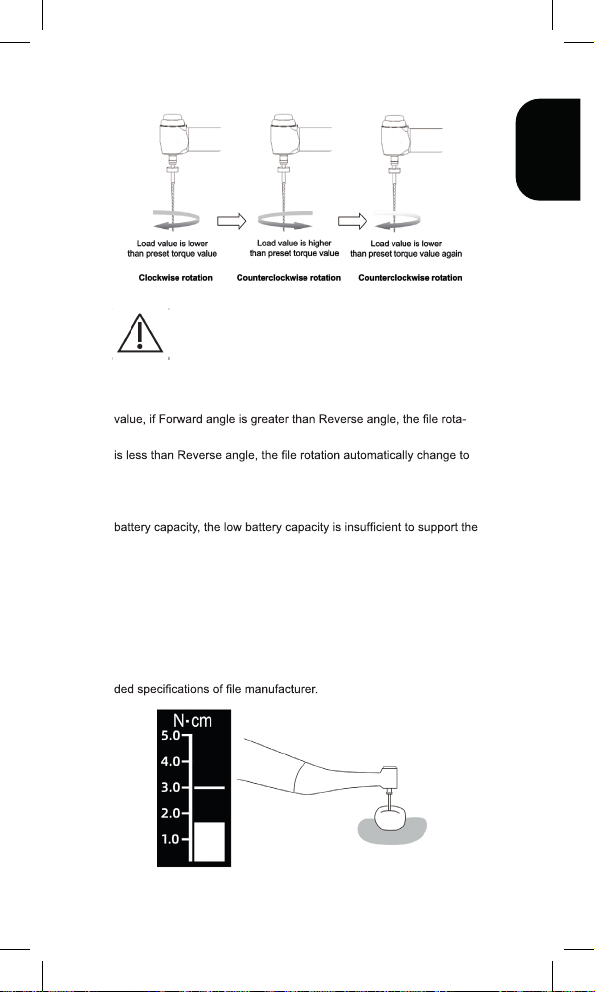

4.7 Protective function of automatic reverse

During operation, if the load value exceeds the preset torque value,

below the preset torque value again.

ENGLISH

15

Cautions:

1. Protective function of automatic reverse is ONLY suitable for CW

mode.

2. In REC mode, when the load value is higher than preset torque

tion automatically change to reverse rotation, and if Forward angle

forward rotation.

3. This function is forbidden under CCW mode, ATR mode.

4. When the motor handpiece battery indicator indicates a low

motor handpiece to reach the limit torque value, that is, the auto-re-

verse function will not work properly. Please charge it in time.

5. If the motor handpiece is under load all the time, the machine may

stop automatically as a result of overheat protection. lf it happens,

turn off the motor handpiece for a while until the temperature drops.

4.8 Motor operation

Please set operation mode, torque and speed as per the recommen-

16

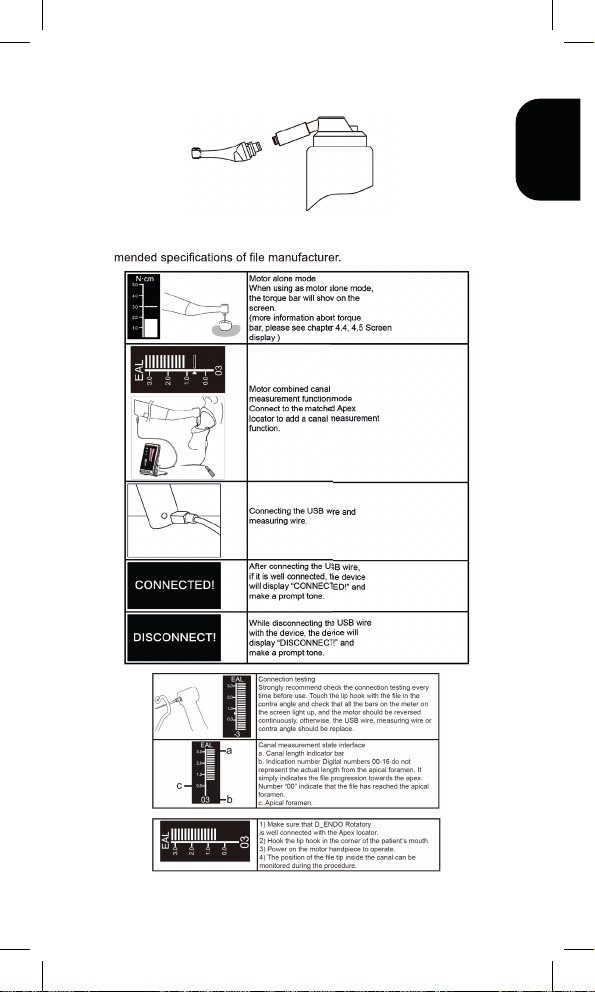

When using as motor alone mode, the torque bar will show on the

screen.

4.9 Battery Charging

There is a built-in rechargeable lithium battery in the motor han-

dpiece.Insert the power adapter plug into the Motor handpiece and

When the screen battery indicator fashes, it is charging. After char-

ging, please unplug the power adapter.

This device must use the original power adapter.

4.10 Replacing Battery

If the battery needs to be replaced,please contact local distributors.

Here is how to replace the battery.

a) Turn the motor handpiece power off.

b) Use tweezers etc. to open the rubber cover and then remove the

screw.

c) Gently separate the upper and lower cover of the Motor handpie-

ce.

d) Remove the old battery and disconnect the connector.

e) Connect the new battery and put it in the motor handpiece.

f) Fasten the upper and lower cover of the Motor handpiece, tighten

the screws and install the rubber cover.

4.11 Oiling of contra angle

Only the original oil injection nozzle can be used for oiling of contra

angle. The contra angle needs to be lubricated after cleaning and

disinfection, but before sterilization.

1. Firstly, screw the injecting nozzle into jet of oil bottle. (Around 1 to

3 circles)

2. Next, plug the nozzle into the end part of contra angle, and then

grease the contra angle for 2-3s till the oil fow out of contra angle

head part.

3. Vertically place the end part of contra angle more than 30 minutes

to let go the redundant oil under gravity.

Warnings

Cautions

a: To avoid the contra angle from fying out for the pressure use hand

to safely hold the contra angle while greasing.

b: Do not use a swirling nozzle. Swing nozzle can only be used for

injection of gas, not for oiling.

ENGLISH

17

5 Motor operation

5.1 Please set operation mode, torque and speed as per the recom-

18

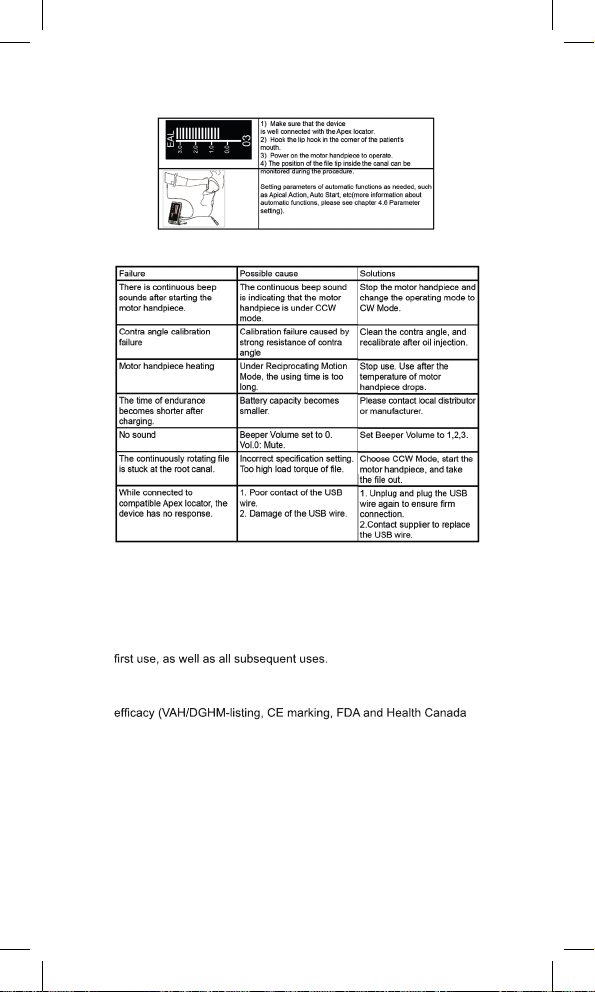

5.2 Trouble shooting

6 Cleaning, Disinfection and Sterilization

6.1 Foreword

For hygiene and sanitary safety purposes, the contra-angle, the

protective silicon cover must be cleaned, disinfected and sterilized

before each usage to prevent any contamination. This concerns the

6.2 General recommendations

6.2.1 Use only a disinfecting solution which is approved for its

approval) and in accordance with the DFU of the disinfecting solution

manufacturer.

6.2.2 Do not place the contra-angle in a disinfectant solution or in an

ultrasonic bath.

Do not use chloride detergent materials.

6.2.3 Do not use bleach or chloride disinfectant materials.

6.2.4 For your own safety, please wear personal protective equip-

ment(gloves, glasses, mask).

ENGLISH

19

6.2.5 The user is responsible for the sterility of the product for the

-

ged or dirty instruments where applicable after sterility.

6.2.6 The water quality has to be convenient to the local regulations

especially for the last rinsing step or with a washer-disinfector.

instructions for use.

6.2.8 The contra-angle needs to be lubricated after cleaning and

disinfection, but before sterilization.

6.3 Cleaning and disinfection steps for the motor handpiece, the AC

adapter and the base.

Before and After each use, all the objects that were in contact with

infectious agents should be cleaned using towels impregnated with

a disinfecting and detergent solution (a bactericidal, fungicidal and

aldehyde free solution) approved by VAH/DGHM-listing, CE marking,

FDA and Health Canada.

Warning: Do not sterilize the motor handpiece, the AC

adapterand the

base.

6.3.1 Pre-Op processing Before each use, the handpiece, charger,

as follows:

Warning: The handpiece, charger, and base cannot be

cleaned and

disinfected with automatic equipment. Manual cleaning and disinfec-

tion is required.

6.3.1.1 Manual cleaning steps:

1. Take out the handpiece, charger, and base on the workbench.

2. Wet the soft cloth completely with distilled water or deionized

water, and then wipe all the surfaces of the components such as the

handpiece, charger, base, etc. until the surface of the component is

not stained.

3. Wipe the surface of the component with a dry soft nap-free cloth.

4. Repeat the above steps at least 3 times. Note:

a)Use distilled water or deionized water for cleaning at room

temperature.

6.3.1.2 Manual disinfection steps:

1. Soak the dry soft cloth with 75% alcohol.

2. Wipe all surfaces of headpiece, charger, base and other compo-

20

nents with a wet soft cloth for at least 3 minutes.

3. Wipe the surface of the component with a dry soft nap-free cloth.

Note:

a) The cleaning and disinfection must be performed within 10min

before use.

b) The disinfectant used must be used immediately, no foaming is

allowed.

c) In addition to 75% alcohol, you can use non-residue disinfec-

tants such as Oxytech from Germany, but you must respect the

manufacturer.

d) After cleaning and disinfecting the handpiece, you must install a

disposable isolation sleeve before use.

6.3.1.3 Post-Op processing

After each use, clean and disinfect the handpiece, charger, and base

Tools: Nap-free soft cloth, tray

1. Remove the contra-angle from the handpiece, place it in a clean

tray, and then remove the disposable isolation sleeve from the

handpiece.

2. Soak the nap-free soft cloth with distilled water or deionized

water, and then wipe all the surfaces of the components such as the

handpiece, charger, base, etc. until the surface of the component is

not stained.

3. Wet the dry soft cloth with 75% alcohol, and then wipe all surfaces

of the handpiece, charger, base and other components for 3

minutes.

4. Put the handpiece, charger, base and other components back into

the clean storage area.

Note:

a) The cleaning and disinfection must be performed within 10min

before use.

b) The disinfectant used must be used immediately, no foaming is

allowed.

c) In addition to 75% alcohol, you can use non-residue disinfec-

tants such as Oxytech from Germany, but you must respect the

manufacturer.

d) After cleaning and disinfecting the handpiece, you must install a

disposable isolation sleeve before use.

Table of contents

Languages:

Other D Devices Dental Equipment manuals