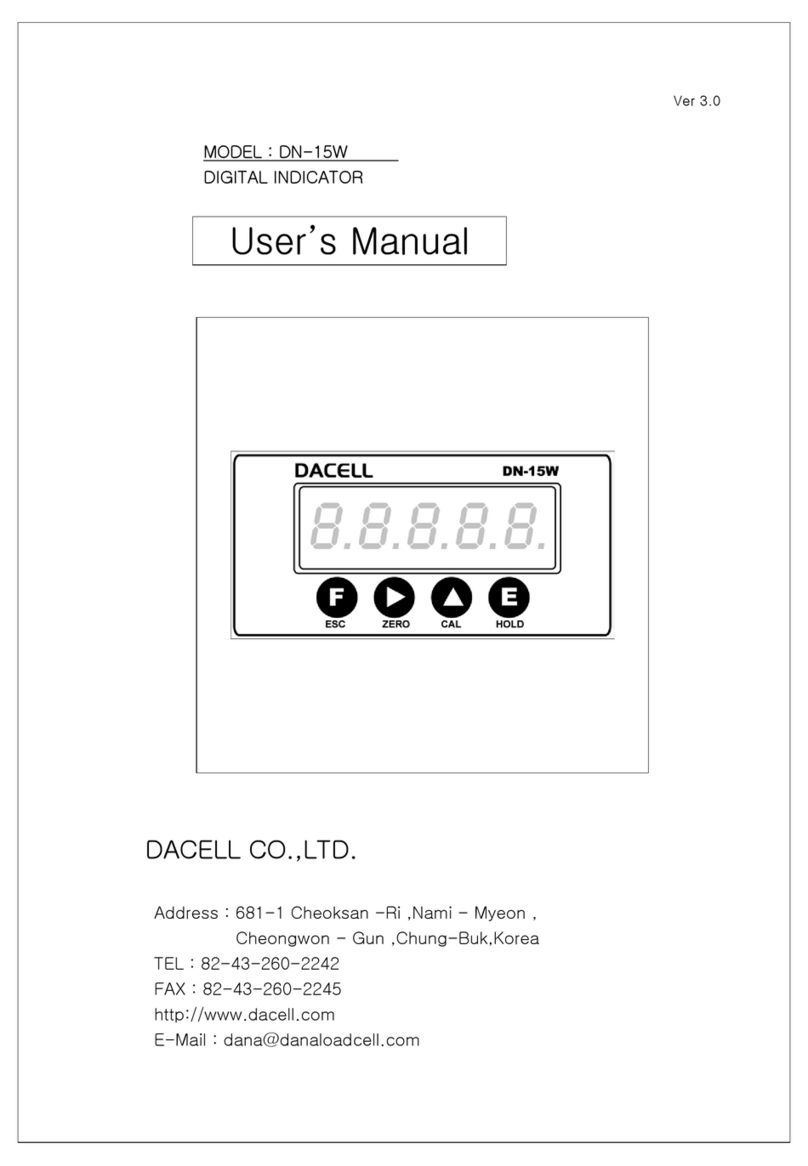

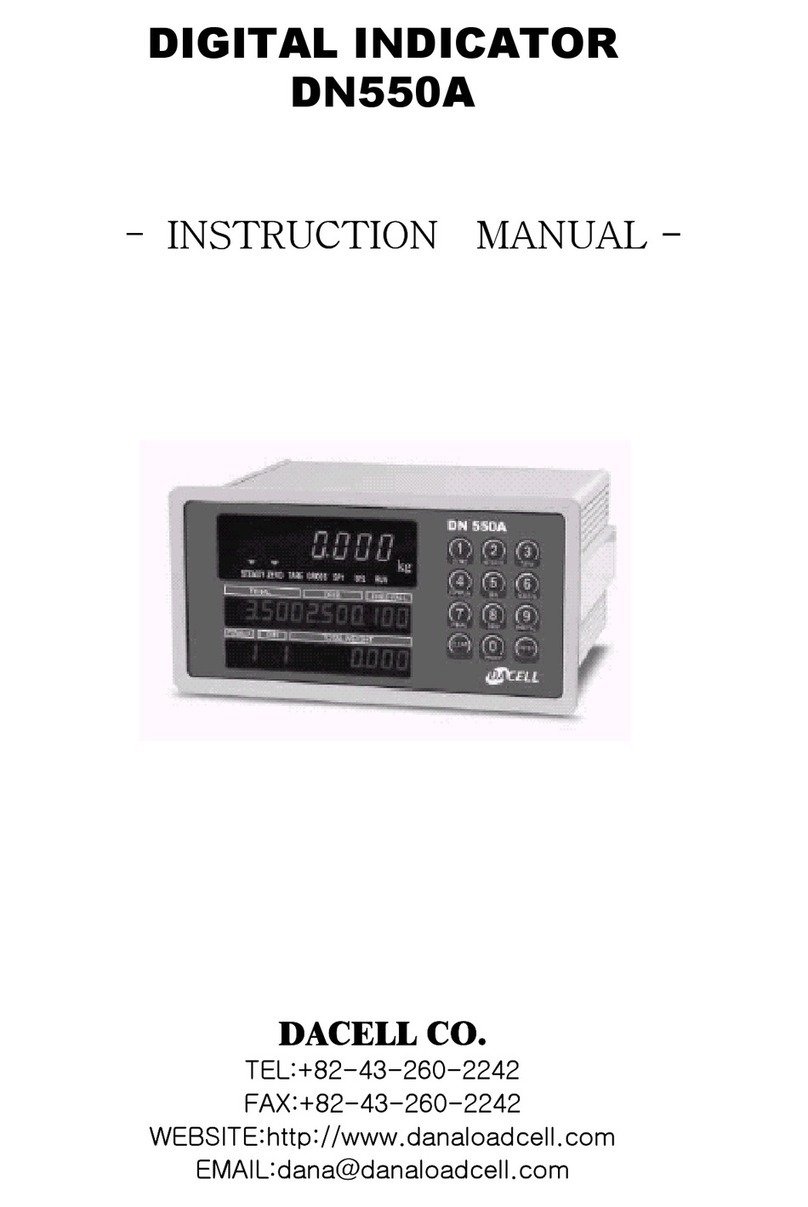

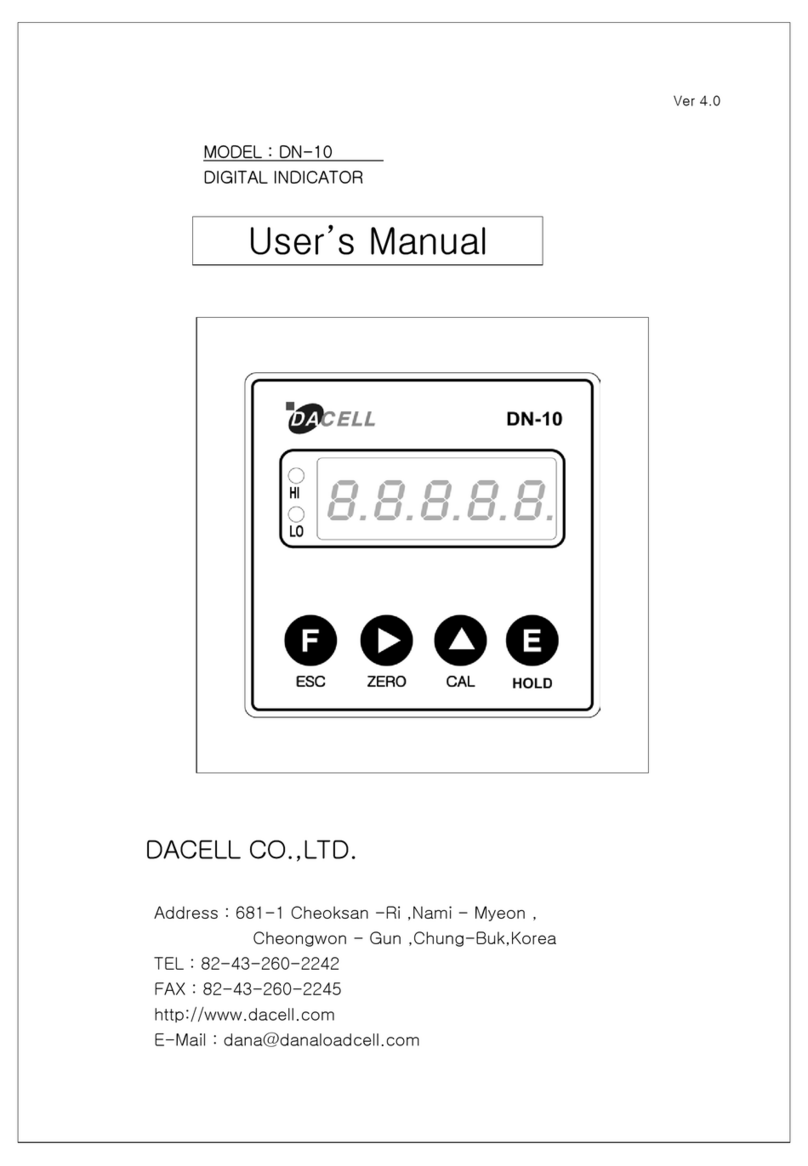

3. DISPLAY and KEY operation

1)DISPLAY : 4½ Digit LED

* Key operation start : press to key.

Key operation exit : press to key.

* Display : setting mode and operation mode.

1. Setting mode : data confirmation or correction.

2. Operation mode : normal operation state.

3. Press to key : setting mode.

Press to key : operation mode.

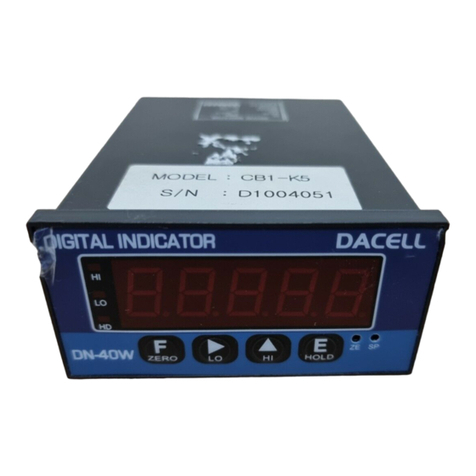

2) L.E.D Display

LED state Description

HI operation Display operation mode of high relay.

setting Confirm and adjust high data

LO operation Display operation mode of low relay.

setting Confirm and adjust low data

FS setting Confirm and adjust full scale data.

Input the full range or capacity of sensor.

DP setting Confirm and adjust decimal point.

CAL setting

key in sensor output data ( mV/V )

* refer to 6 - 1)

FS+

CAL

setting auto calibration execution mode.

cal data is adjusted automatically.

* refer to 3 - 6)

FS+

DP

setting Adjust display time and unit of

measurement data

* refer to 6 - 2)

DP+

CAL

setting Software adjustment mode.

* refer to 6 - 3)

FS+

DP+

CAL

operation Set or reset data lock mode

* refer to 3 - 4)

3) KEY operation

Mode

select

1. HI LO FS DP CAL FS+CAL FS+→→→→ → →

DP DP+CAL→

2. All FND of selected mode will blink.

Positio

n

select

3. Press key : 10000→1000→100→10→1

Selected digit position will blink

4. DP(decimal point mode) : decimal point

position movement key.

10.000 100.00 1000.0 10000→→→

Number

select

5. Data correction key.

6. 5 digit 1, -1, -, non→

7.Theothers123456789→→→→→→→→

0→

Input 8. Input data. After setting up must press

key therefore become input.

Auto

zero

9. Sensor : No load state(0V, 4 )㎃

10. Display : 0

Key result Description

+

Lock

mode

11. Protect setting data.

12. Reset lock mode to adjust data

4) PROTECTION mode

Use this mode for protection and security of System.

high, low data is possible to adjust irrespectively.

Mode confirm and setting

Unlock *Press and key during 5 sec at the same

time

FS, DP, CAL LED will light up and reset lock mode

(data correction enable)

Lock

*Press and key during 5 sec at the same

time in unlock mode : FS, DP, CAL LED turn off

(lock mode)

* power off : Set lock mode automatically.

5) AUTO ZERO mode

Initialize sensor and indicator.

Executethismodeatunlockmode.

Execution process (display : operation mode)

(1) Sensor : no load.

(2) Voluntary data display.

(3) Press key and key at the same time.

Zero display (ex : 0, 0.0, 0.00, 0.000)

(4) This data is memorized to indicator though power turn off.

(5) If operate mode with input signal to remain, this point is

memorized zero point.

6) AUTO CALIBRATION mode

Convenience to use when do not know calibration data of

sensor or displayed the measurement value differently.

EX) At sensor Supply : 100.00 kg/㎠

Display : 100.05 or 99.05 kg/㎠

Adjustment : 100.00 kg/㎠

(1) Adjust zero point of indicator.

(2) Apply known load to sensor. Large load is high safety.

(3) Press key : F.S and CAL L.E.D turn on at the same

time.

(4) As example table, 100.05 or 99.05 will blink.

(5) After correction of 100.00 using key and key,

press key.

(6) 100.05 is display correction of 100.00.

(7)Atthistime,caldataiscorrectedminutely.

(8)Ifcorrectedcaldataisoverlimitsof2-4),correctofDIP

S/W setting and again set the auto calibration.

4. Operating flow chart

Install and connection --Mount indicator to panel and make

connection. (Check AC POWER 110/220V)

Unlock mode -- Press +key(data protection unlock)

DATA Input --Setdata(high,low,F.S,DP,CAL),

refer to 6

DIP S/W setting --sensoroutputdata---DIPS/W1,2,3,4

analog output ---- DIP S/W 5

filter frequency ---- DIP S/W 6, 7, 8

Auto zero -- Sensor : no load

Press +key (auto zero)

AUTO CAL -- Execute auto calibration.

Mode Check -- Check function(Relay output,analog output,

reset, hold, peak).

Lock mode setting --Press +key(data protection mode)