4

Installation

Procedure

Installation

Built-inbreaker

model

Built-intank

model

Different-voltage

model

CEmodel

Built-inheater

model

Installation

Models

OilCooling Unit and Accessories

4

Precautionsfor Installation 5

Referencefor Pipe Selection 6

ElectricWiring 7

CONTENTS

1

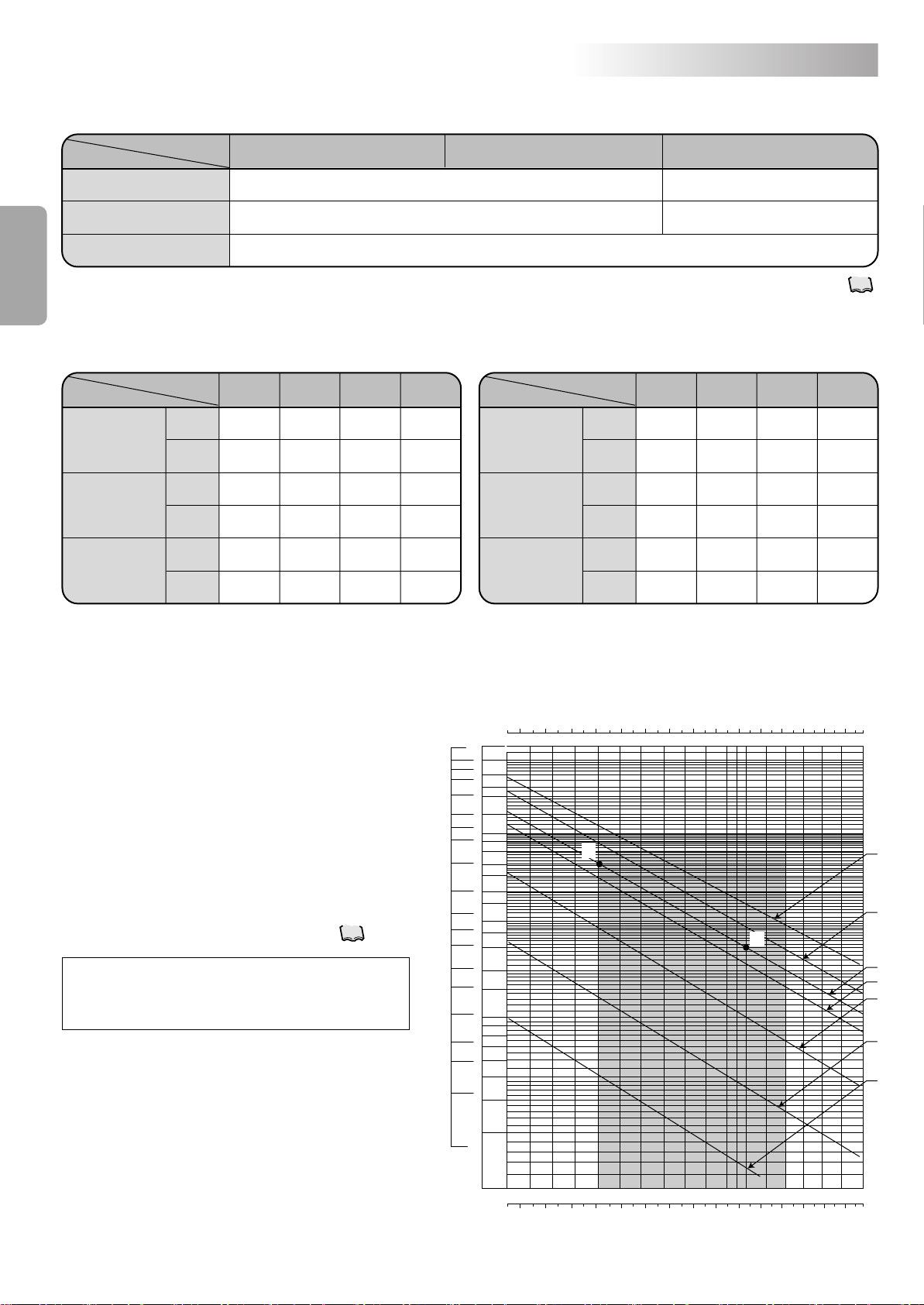

Circulating type

Standard

model

Menu

Series

Built-in

breaker

model(–B)

CEmodel

(–C)

Built-in

heater

model(–H)

Built-in

tankmodel

(–T1,–T)

Different-

voltage

model(–E)

AKZ148

AKZ328

AKZ438

AKZ568

AKZ908

Instruction Manual

AKZ8 Series

Ifthe air filter is clogged, the cooling performance deteriorates,

causingexcess power consumption.

Cleanthe air filter periodically to reduce power consumption.

Thankyou for purchasing DAIKIN Oil Cooling Unit (“OILCON”).

Thisinstruction manual includes instr uctions forusing the Oil

CoolingUnit.

Toensure proper use of this product, be sure to read through this

instructionmanual before using it.

Afterreading this manual, keep it handy for your future reference.

MonitorItems 23

TimerOperation 24

AdditionalSetting Functions 25

SettingAdditional Function 27

ForTemperature Control Improvement 30

Alarm/WarningOutput Logic 33

AlarmSettings for Optional Protection

Devices(Installed by User) 33

Handling

BeforeOperation

12ModelIdentification and Specifications

14

PartNames and Functions 15

Namesand Functions of the Control Panel Parts

16

CheckingInitial Operating Conditions 18

OperationSetting 19

HoldingConstant Oil Temperature 20

TuningOil Temperatureto Room Temperature

(orMachine Temperature)

21

CoolingOil at Constant Capacity (%) 22

Optional Parts

Machinetemperature tuning control 34

Returnedoil temperature control 35

Communicationwith main machine 36

Maintenance

37

38

Maintenance/Inspection

•Daily maintenance/inspection

•Periodic maintenance/inspection

•To leave the unit unused fora long period

Troubleshooting

•When the unit operation seems abnormal

althoughno alarm is activated

•When an alarm is activated

SafetyPrecautions

Installation

Procedure

Before

Operation

Useful

Functions

Maintenance

Troubleshooting

Optional

Functions

Operating

Procedure

DAIKIN Oil Cooling Unit

(“OILCON”)

Proper use results in power saving

PIM00116A

Built-inbreaker

model

Built-intank

model

Different-voltage

model

CEmodel

Built-inheater

model

Installation

Models

OilCooling Unit and Accessories

4

Precautionsfor Installation 5

Referencefor Pipe Selection 6

ElectricWiring 7

CONTENTS

1

Circulating type

Standard

model

Menu

Series

Built-in

breaker

model(–B)

CEmodel

(–C)

Built-in

heater

model(–H)

Built-in

tankmodel

(–T1,–T)

Different-

voltage

model(–E)

AKZ148

AKZ328

AKZ438

AKZ568

AKZ908

Instruction Manual

AKZ8 Series

Ifthe air filter is clogged, the cooling performance deteriorates,

causingexcess power consumption.

Cleanthe air filter periodically to reduce power consumption.

Thankyou for purchasing DAIKIN Oil Cooling Unit (“OILCON”).

Thisinstruction manual includes instr uctions forusing the Oil

CoolingUnit.

Toensure proper use of this product, be sure to read through this

instructionmanual before using it.

Afterreading this manual, keep it handy for your future reference.

MonitorItems 23

TimerOperation 24

AdditionalSetting Functions 25

SettingAdditional Function 27

ForTemperature Control Improvement 30

Alarm/WarningOutput Logic 33

AlarmSettings for Optional Protection

Devices(Installed by User) 33

Handling

BeforeOperation

12ModelIdentification and Specifications

14

PartNames and Functions 15

Namesand Functions of the Control Panel Parts

16

CheckingInitial Operating Conditions 18

OperationSetting 19

HoldingConstant Oil Temperature 20

TuningOil Temperatureto Room Temperature

(orMachine Temperature)

21

CoolingOil at Constant Capacity (%) 22

Optional Parts

Machinetemperature tuning control 34

Returnedoil temperature control 35

Communicationwith main machine 36

Maintenance

37

38

Maintenance/Inspection

•Daily maintenance/inspection

•Periodic maintenance/inspection

•To leave the unit unused fora long period

Troubleshooting

•When the unit operation seems abnormal

althoughno alarm is activated

•When an alarm is activated

SafetyPrecautions

Installation

Procedure

Before

Operation

Useful

Functions

Maintenance

Troubleshooting

Optional

Functions

Operating

Procedure

DAIKIN Oil Cooling Unit

(“OILCON”)

Proper use results in power saving

PIM00116A

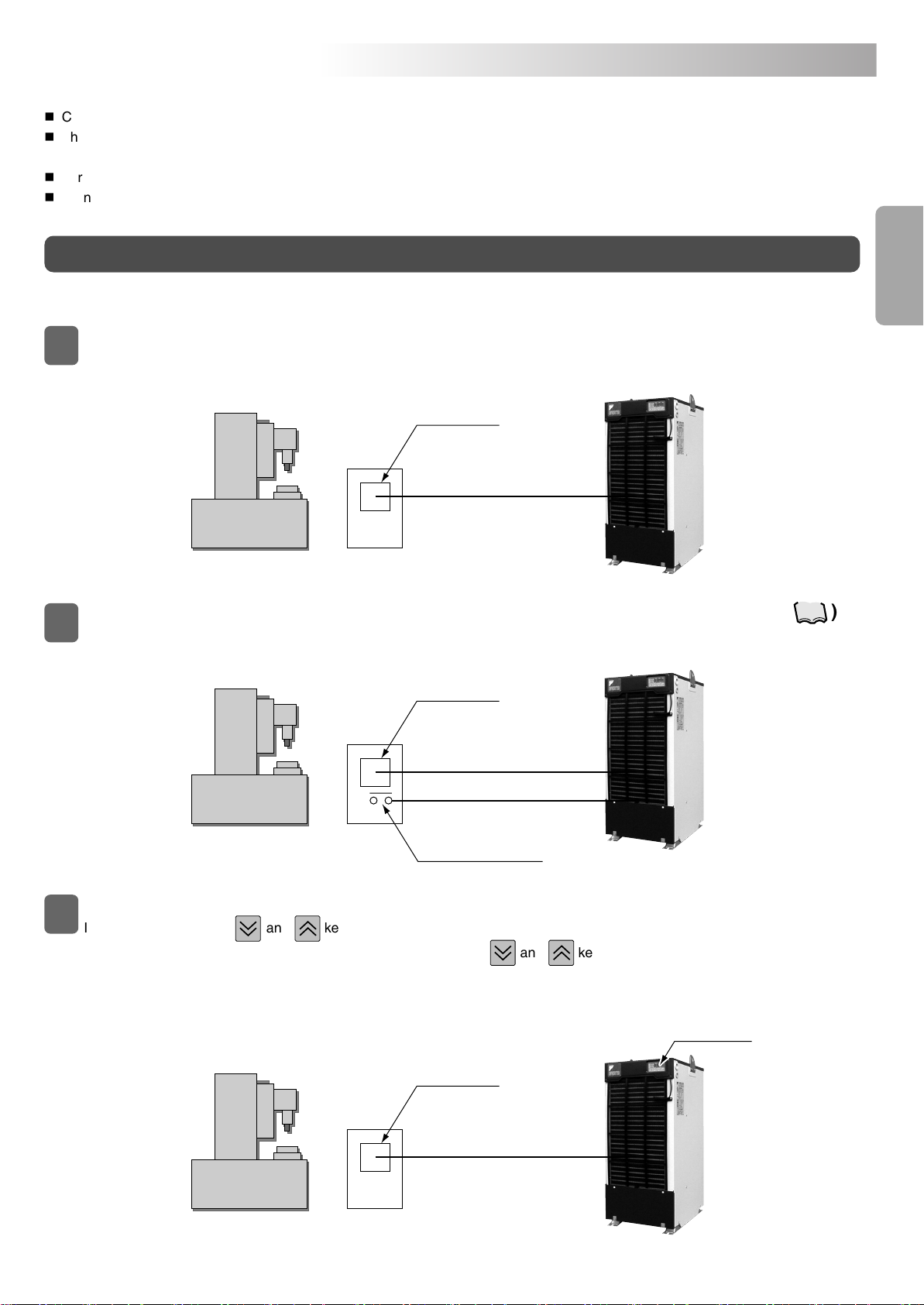

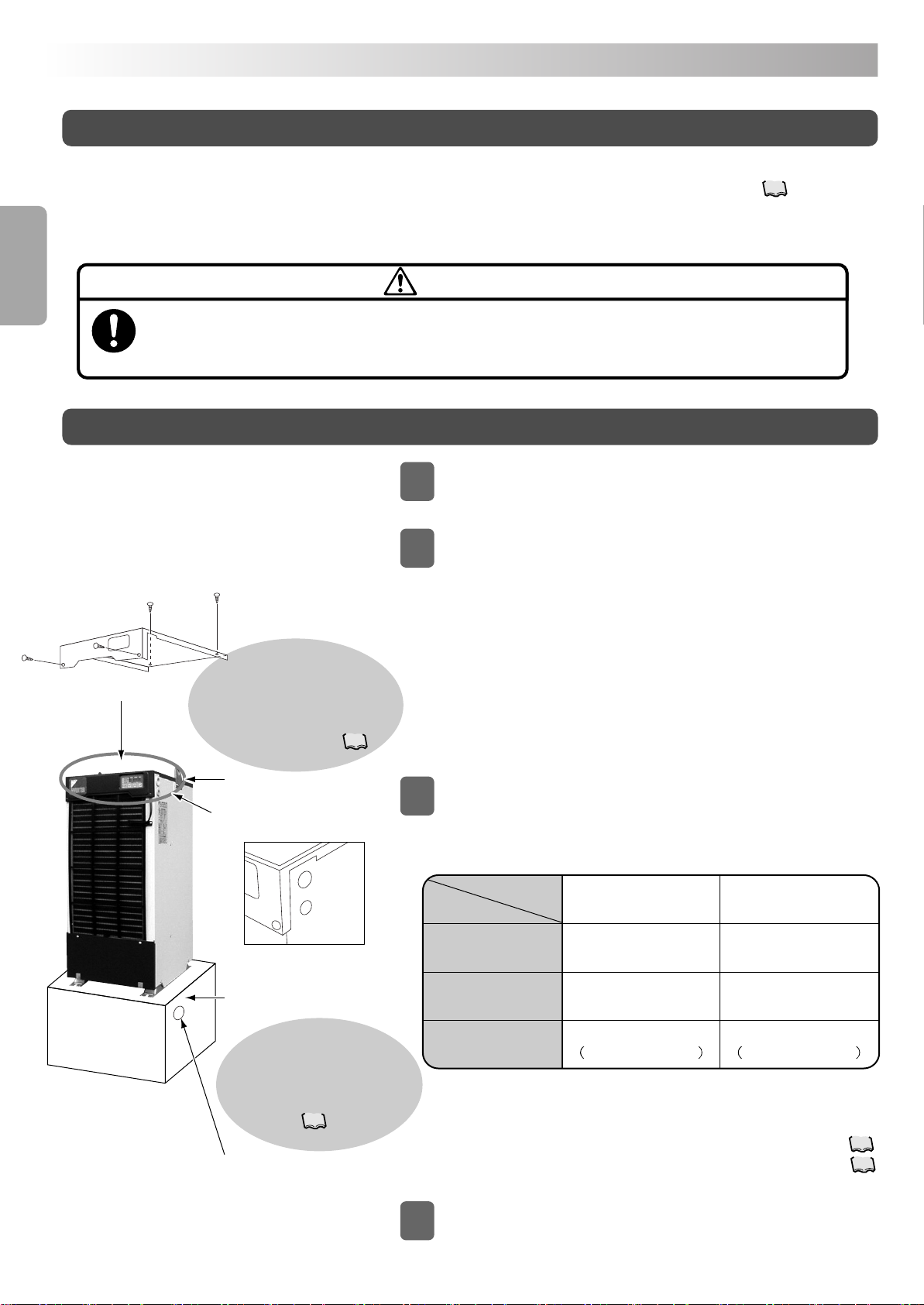

Oil Cooling Unit and Accessories

Check the following items:

Check the model name and serial No. (MFG. No.) on the nameplate attached to the right side of the Oil Cooling Unit.

Oil Cooling Unit

1

An accessory package

∗1

is attached to the top plate of the Oil Cooling Unit. Make sure that the following items are included

in the accessory package.

1.

Instruction manual (This document): 1 volume

Keep this manual in place where users can read it whenever required.

2.

Rubber bushing for electric wiring (Large size, with cross slit): 1 pc.

When connecting the power cable, remove the resin cable hole cap in the side plate of the unit, and attach the rubber

bushing. It is only for provisional use.

∗2

3.

Rubber bushing for electric wiring (Small size, with cross slit): 1 pc.

When connecting the signal cable, remove the resin cable hole cap in the side plate of the unit, and attach the rubber

bushing. It is only for provisional use.

∗2

Accessories

2

∗1: Before operation, be sure to remove the accessory package. Otherwise, the package blocks exhaust air flow, resulting in cooling

capacity deterioration.

∗2: When connecting each cable finally, place the cable in a conduit. If the rubber bushing is used, the dust-proof effect of the electrical

equipment box deteriorates, causing a fault. For details, refer to “Wiring procedure” on page .

8

+

Accessory package

Instruction manual

(This document)

Machine nameplate

Rubber bushing

(Large and small, 1 pc. each)

Model

name

Type of

refrigerant

Manufacture

No.

Oil Cooling Unit

PIM00116C_EN.fm 4 ページ 2008年9月29日 月曜日 午前11時51分