2

Index

REPLACEMENT PARTS..................................................................... 3

ORDERING PARTS .................................................................. 3

SAFETY INSTRUCTIONS................................................................... 3

TO THE INSTALLER.................................................................. 3

GENERAL INFORMATION................................................................ 5

TRANSPORTATION DAMAGE ................................................. 5

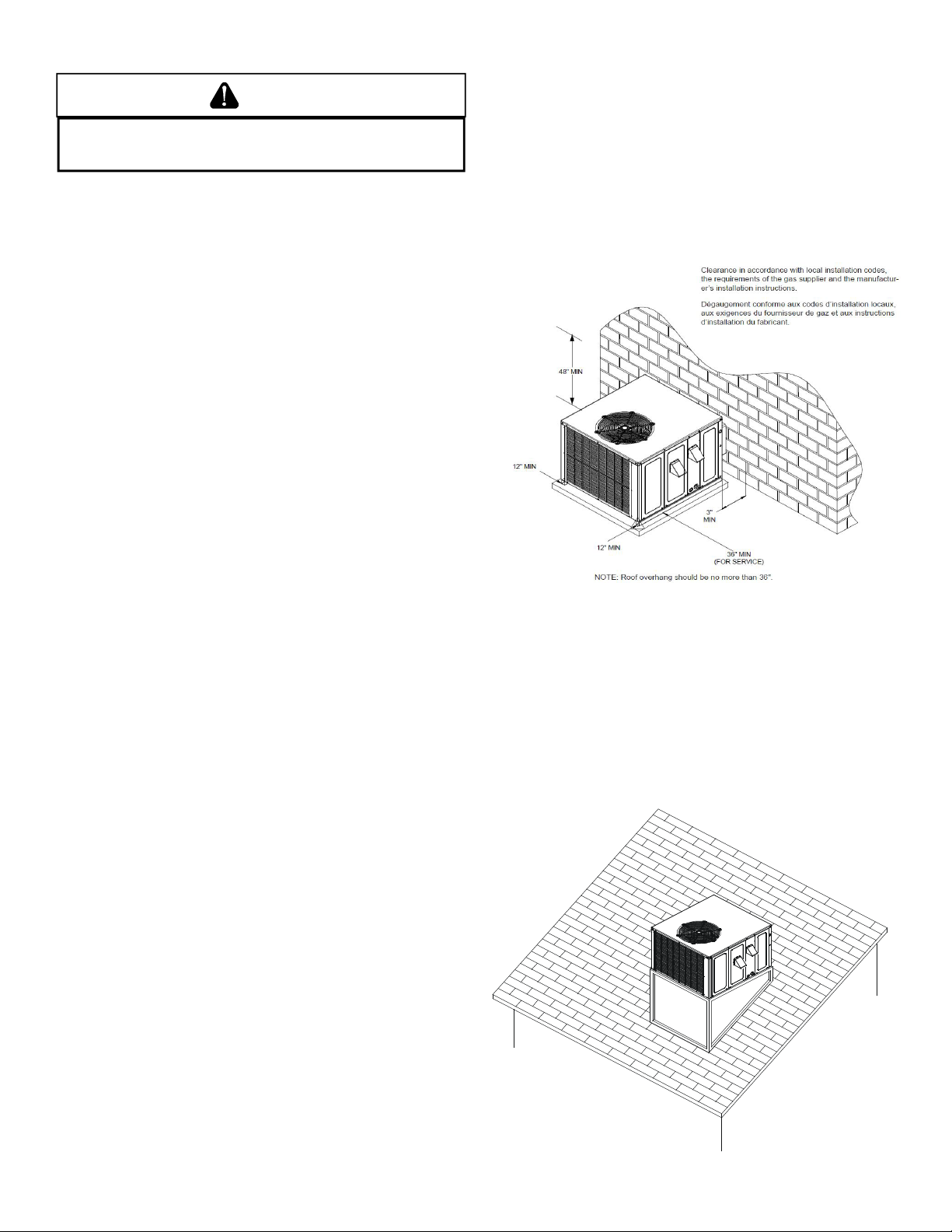

UNIT LOCATION .............................................................................. 6

ALL INSTALLATIONS: .............................................................. 6

GROUND LEVEL INSTALLATIONS ONLY: ................................. 6

ROOFTOP INSTALLATIONS ONLY:........................................... 6

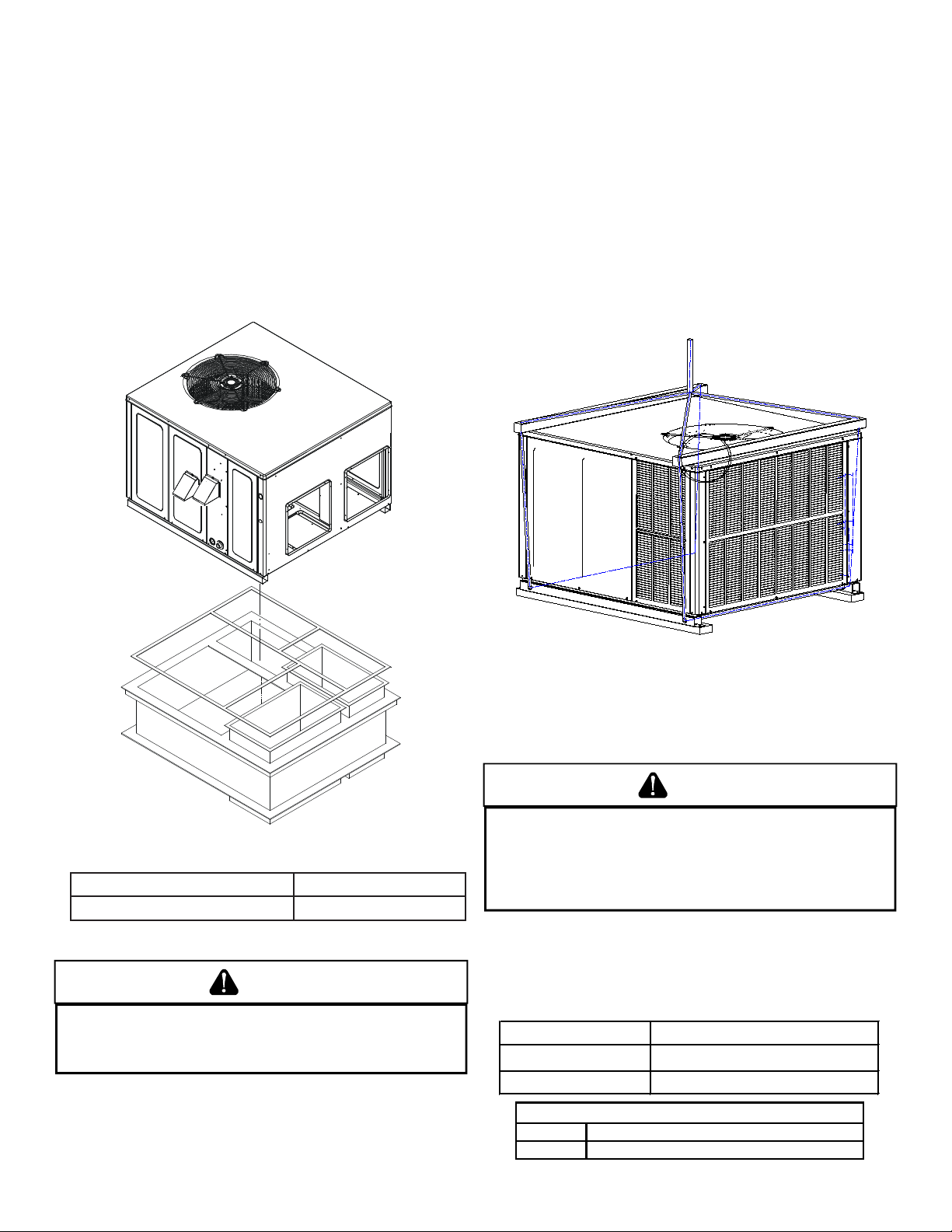

ROOF CURB INSTALLATIONS ONLY: ....................................... 7

RIGGING DETAILS............................................................................ 7

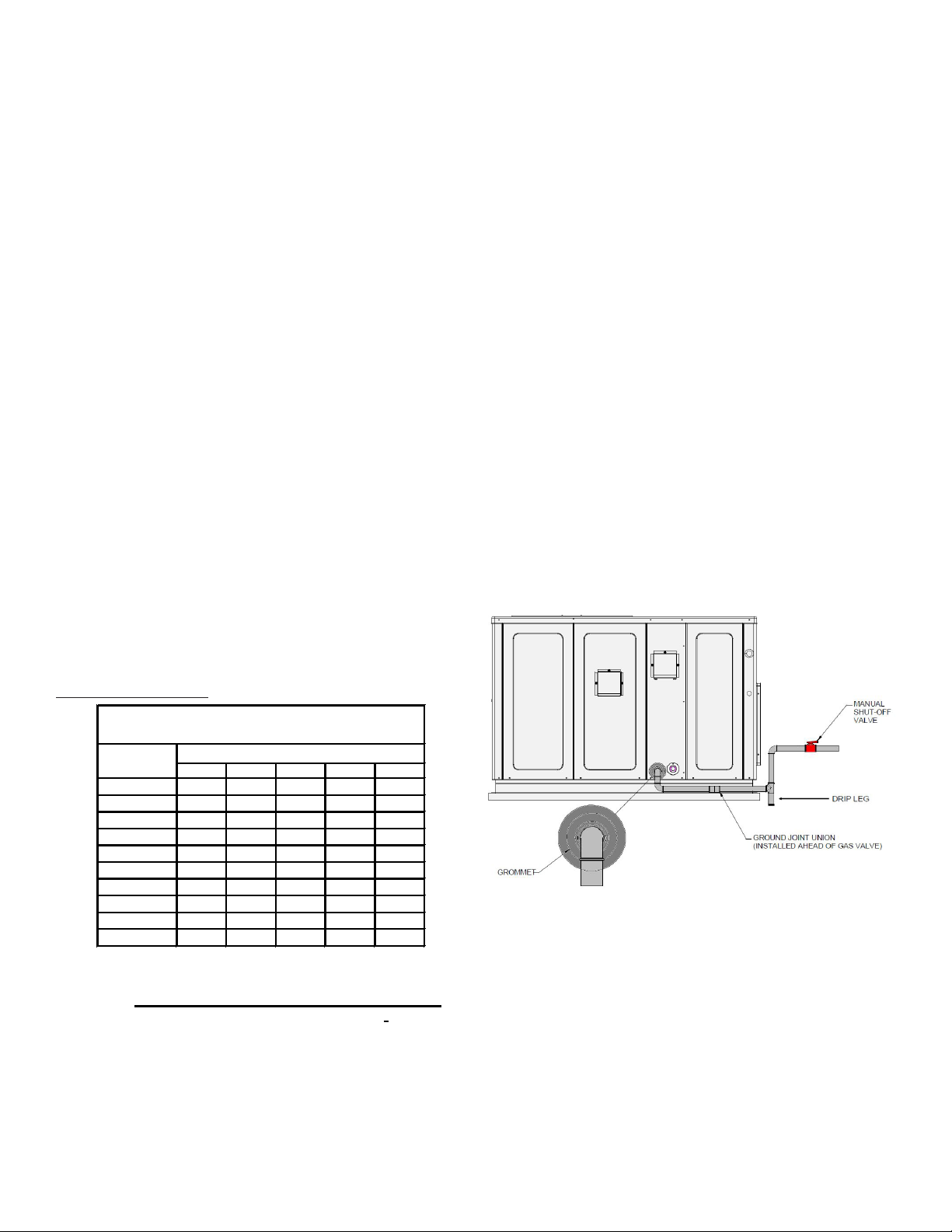

GAS PIPING ..................................................................................... 7

.......... 8

PIPING.................................................................................... 8

GAS PIPING CHECKS .............................................................. 9

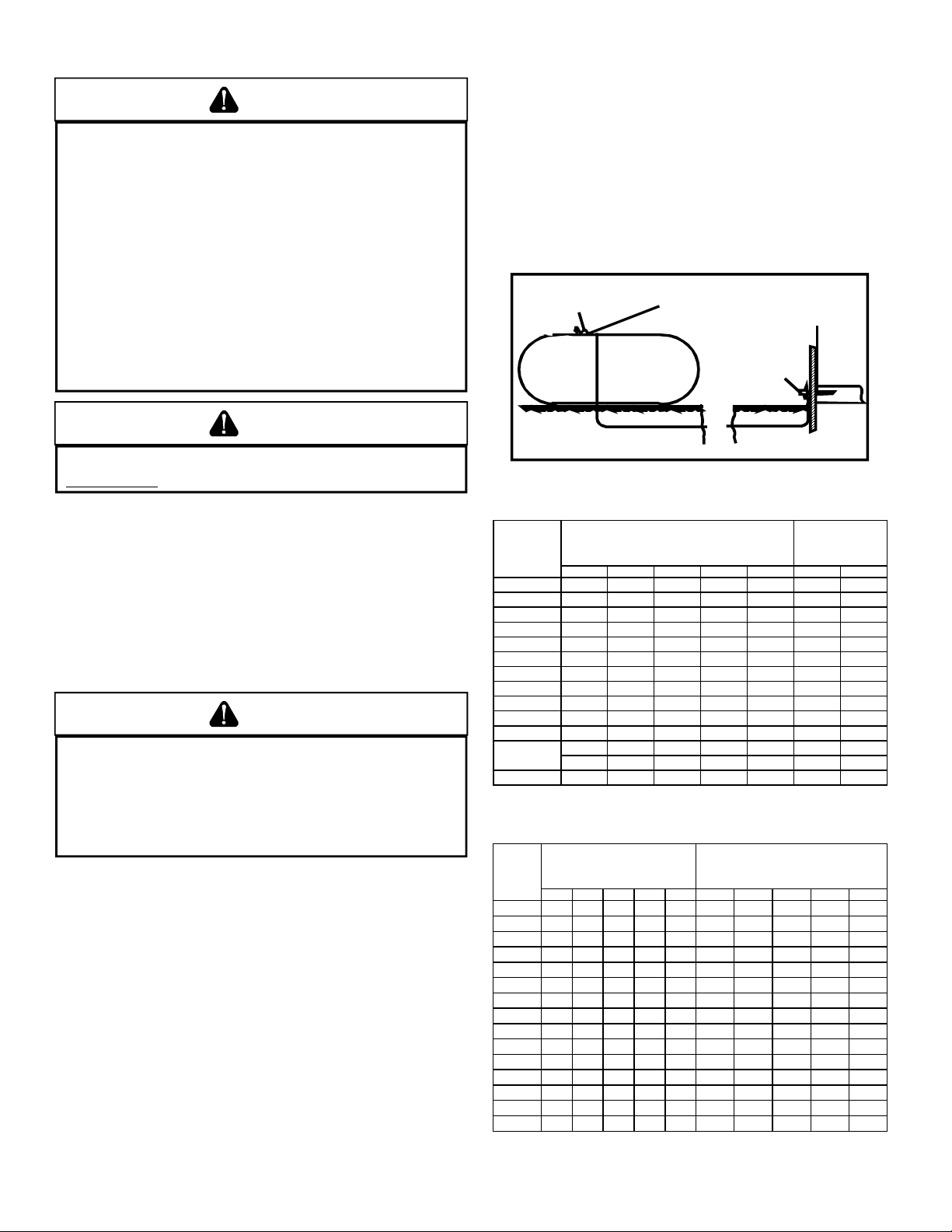

PROPANE GAS INSTALLATIONS ...................................................... 9

TANKS AND PIPING................................................................ 9

ELECTRICAL WIRING..................................................................... 10

THERMOSTAT LOCATION ..................................................... 10

......... 10

UNIT VOLTAGE...................................................................... 11

CIRCULATING AIR AND FILTERS.................................................... 11

AIRFLOW CONVERSION ....................................................... 11

DUCTWORK.......................................................................... 12

FILTERS ................................................................................. 12

VENTING ....................................................................................... 12

FLUE HOOD INSTALLATION.................................................. 12

............................... 12

............. 13

CONDENSATE DRAIN .................................................................... 13

CONDENSATE DRAIN CONNECTION .................................... 13

NORMAL SEQUENCE OF OPERATION........................................... 13

HEATING............................................................................... 13

COOLING .............................................................................. 14

FAN ONLY ............................................................................. 14

STARTUP, ADJUSTMENTS, AND CHECKS....................................... 14

HEATING STARTUP .............................................................. 14

GAS SUPPLY PRESSURE MEASUREMENT............................. 15

GAS MANIFOLD PRESSURE MEASUREMENT

AND ADJUSTMENT............................................................... 16

COOLING STARTUP .............................................................. 19

CHECKING SUBCOOLING ..................................................... 19

CHECKING SUPERHEAT ........................................................ 19

TROUBLESHOOTING ..................................................................... 20

IGNITION CONTROL ERROR CODES..................................... 20

ABNORMAL OPERATION - HEATING.................................... 20

ABNORMAL OPERATION - COOLING ................................... 22

MAINTENANCE ............................................................................. 22

FILTER REPLACEMENT OR CLEANING ................................. 22

CABINET FINISH MAINTENANCE......................................... 22

.......... 22

CONDENSER, EVAPORATOR,

..................................... 22

..................... 22

.................... 22

CLEANING FLUE PASSAGES

........................................... 23

.......... 23

CLEANING BURNERS............................................................ 23

ACCESSORIES AND FUNCTIONAL PARTS...................................... 23

SHEET METAL ACCESSORIES ............................................... 23

FUNCTIONAL PARTS............................................................. 24

GENERAL INFORMATION..................................................... 24

BLOWER PERFORMANCE DATA .................................................... 25

IGNITION CONTROL DIAGNOSTIC INDICATOR CHART

.................................................... 29

HEATING TIMING CHART.............................................................. 29

COOLING TIMING CHART ............................................................. 29

IGNITION CONTROL DIAGNOSTIC INDICATOR CHART

........................................................ 30

HEATING TIMING CHART.............................................................. 30

COOLING TIMING CHART ............................................................. 30

..................................................................................... 31

UNIT DIMENSIONS............................................................... 31

WIRING DIAGRAMS...................................................................... 32

HOMEOWNER’S ROUTINE MAINTENANCE.................................. 44

........................................................................... 45