3

-

-

-

NOTE: -

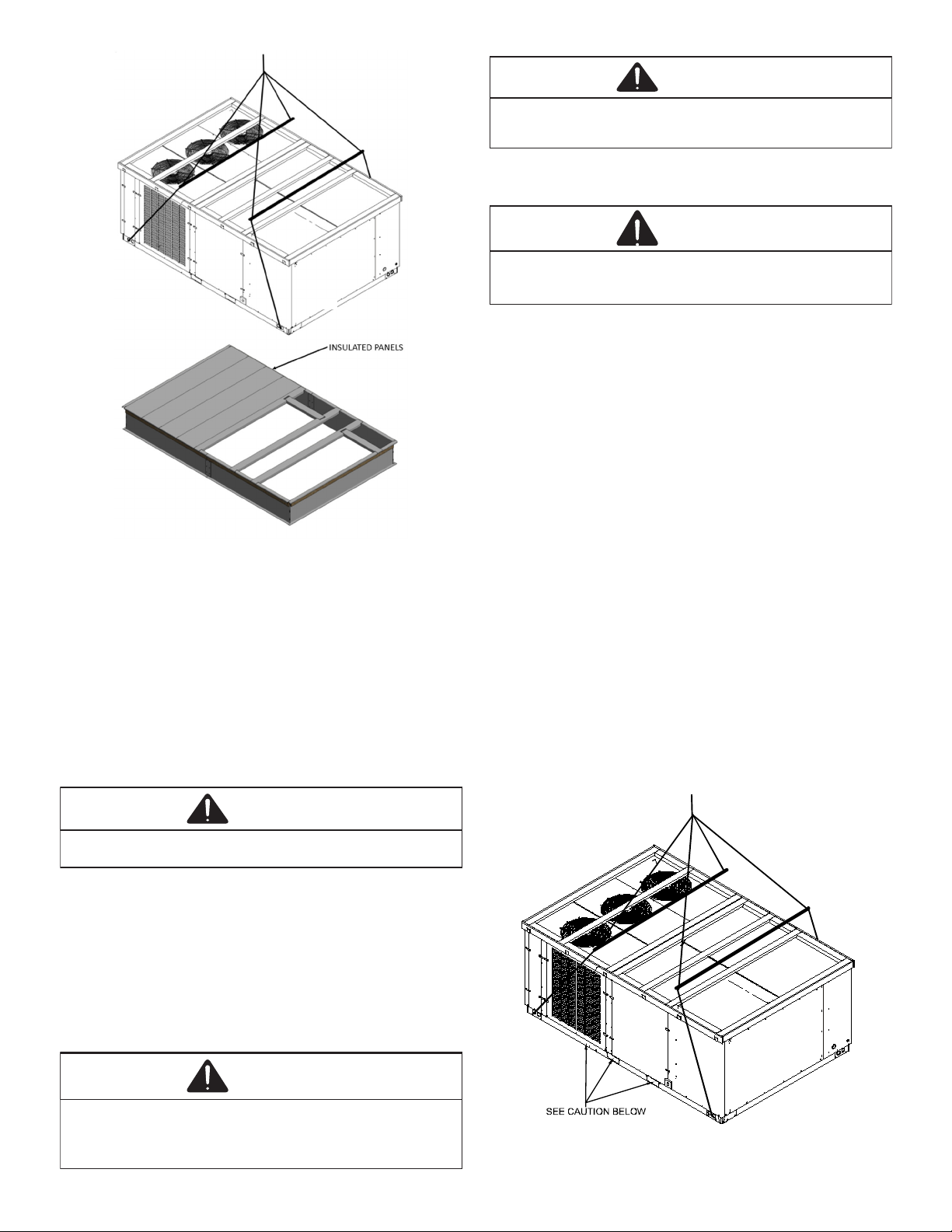

UNIT LOCATION

WARNING

To prevent possible equipment damage, property damage,

personal injury or death, the following must be observed

when installing the unit.

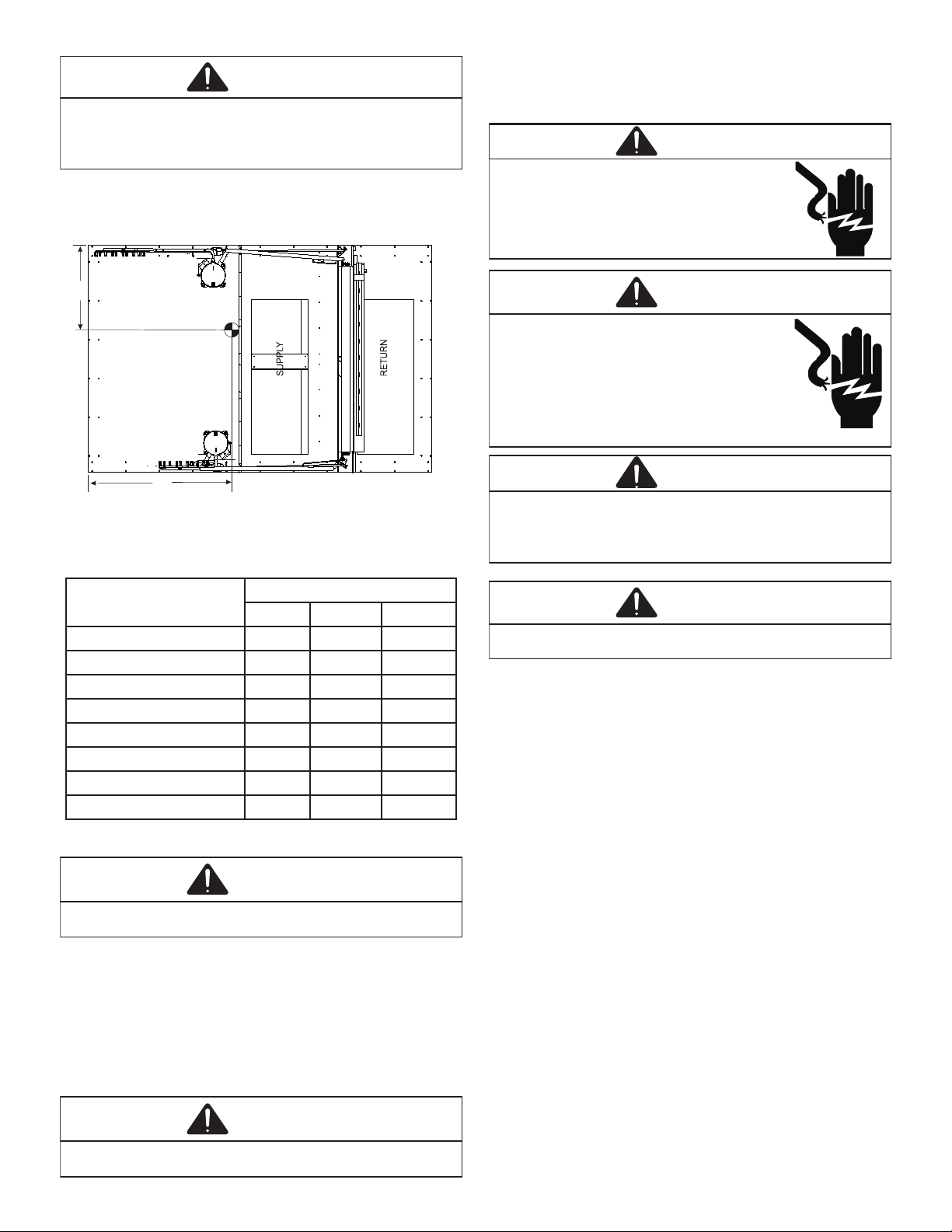

IMPORTANT NOTE:

See important note under Roof Curb Installaon Only.

Unit should be energized 24 hours prior to

compressor start up to ensure crankcase heater has suciently

warmed the compressors. Compressor damage may occur if

this step is not followed.

NOTE:

-