OM 1039-1 • VAV ACTUATOR ROOM SENSOR 2 www.DaikinApplied.com

IntroductIon

IntroductIon

Revision History

Publication Date Release Notes

OM 1039 March 2010 Initial Release

OM 1039-1 January 2011 Claried BACnet

VAV Actuator

as the VAV box

controller

Reference Documents

Publication Company Title Source

IM 1040 Daikin Applied

Start-up

procedures

for the

BACnet VAV

actuator

www.

DaikinApplied.

com

IM 1093 Daikin Applied

Single

Duct VAV

Terminal Box

installation

manual

www.

DaikinApplied.

com

Limited Warranty

Consult your local Daikin representative for warranty details. To

nd your local Daikin representative, go to www.DaikinApplied.

com.

Notice

Copyright © 2010 Daikin Applied, Minneapolis MN. All rights

reserved throughout the world. Daikin Applied reserves the

right to change any information contained herein without prior

notice. The user is responsible for determining whether this

software is appropriate for his or her application.

® ™ The following are tradenames or registered trademarks of

their respective companies: BACnet from the American Society

of Heating, Refrigerating and Air-Conditioning Engineers,

Inc.; Windows from Microsoft Corporation; D-Net, Daikin and

MicroTech III from Daikin Applied.

General Information

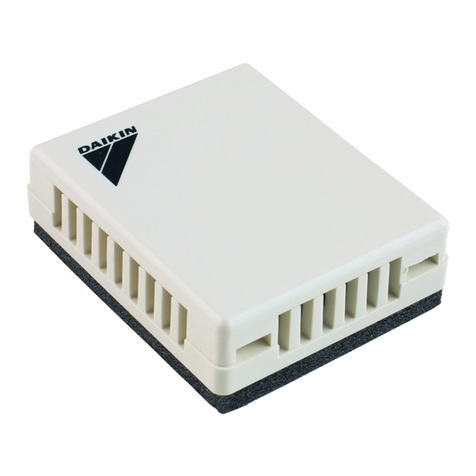

This document relates to the set up and operation of the

Daikin 2508032 Room Temperature Sensor. It explains the

various operating modes available and describes procedure for

programming the display, according to user preferences.

Table 1: Accessories

Description Product Number

25-foot (7.6 m) cable with connections 2508041

50-foot (15.2 m) cable with connections 2508042

100-foot (30.5 m) cable with connections 2508043

Replacement Housing Base 2508044

Passkey 2508045

Hazard Identication Messages

CAUTION

Cautions indicate potentially hazardous situations, which can

result in personal injury or equipment damage if not avoided.

WARNING

Warnings indicate potentially hazardous situations, which can

result in property damage, severe personal injury, or death if

not avoided.

DANGER

Dangers indicate a hazardous situation which will result in

death or serious injury if not avoided.

NOTICE

Notices give important information concerning a process,

procedure, special handling or equipment attributes.

DANGER

Electric shock hazard. Can cause personal injury or

equipment damage.

This equipment must be properly grounded. Connections and

service to the MicroTech III Chiller Unit Controller must be

performed only by personnel knowledgeable in the operation

of the equipment being controlled.

CAUTION

Static sensitive components. Can cause equipment damage.

Discharge any static electrical charge by touching the bare

metal inside the control panel before performing any service

work. Never unplug cables, circuit board terminal blocks, or

power plugs while power is applied to the panel.

NOTICE

This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance

with this instruction manual, may cause interference to radio

communications. It has been tested and found to comply with

the limits for a Class A digital device, pursuant to part 15 of the

FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment

is operated in a commercial environment. Operation of this

equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct

the interference at his or her own expense. Daikin Applied

disclaims any liability resulting from any interference or

for the correction thereof.