PRODUCT DESIGN

4

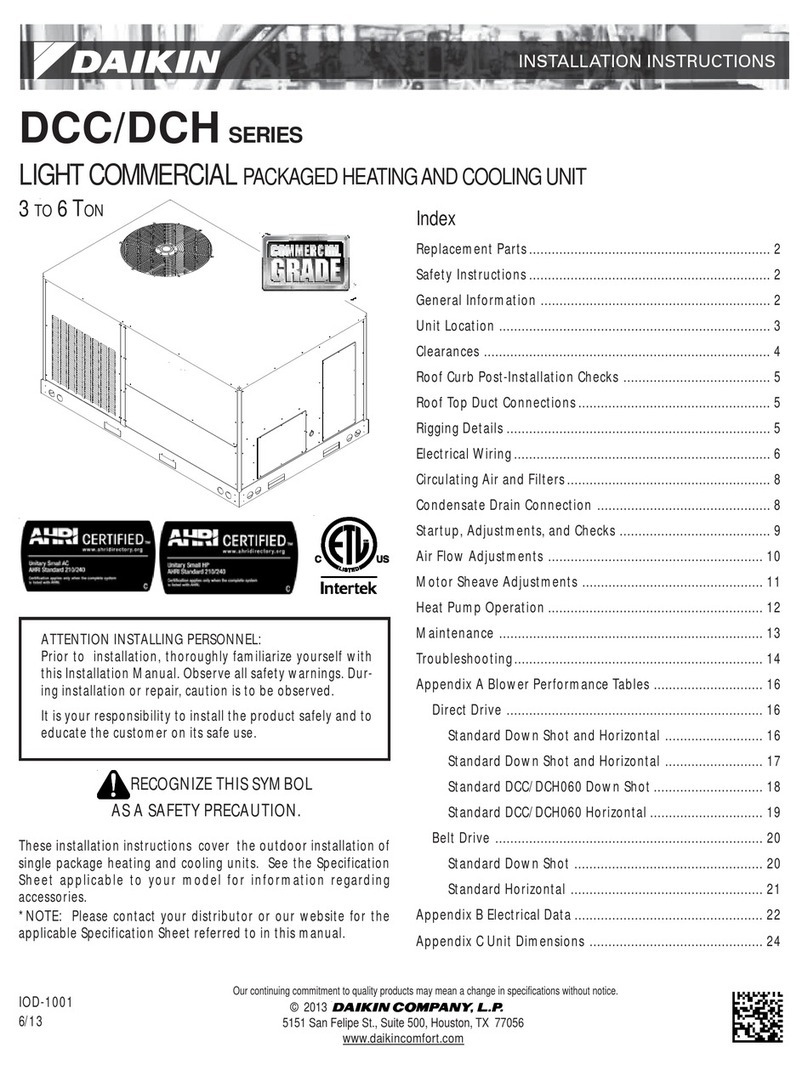

DP13GM Package Gas Units are designed for outdoor in-

stallationsonlyineitherresidentialor light commercial appli-

cations and are available in 2 through 5 ton sizes. They are

designedfor 208/230voltsinglephaseapplications. (DP13GM

3, 4 and 5 ton models are also available for 230V 3 phase

applications.See Technical Manual RTD6312005.)

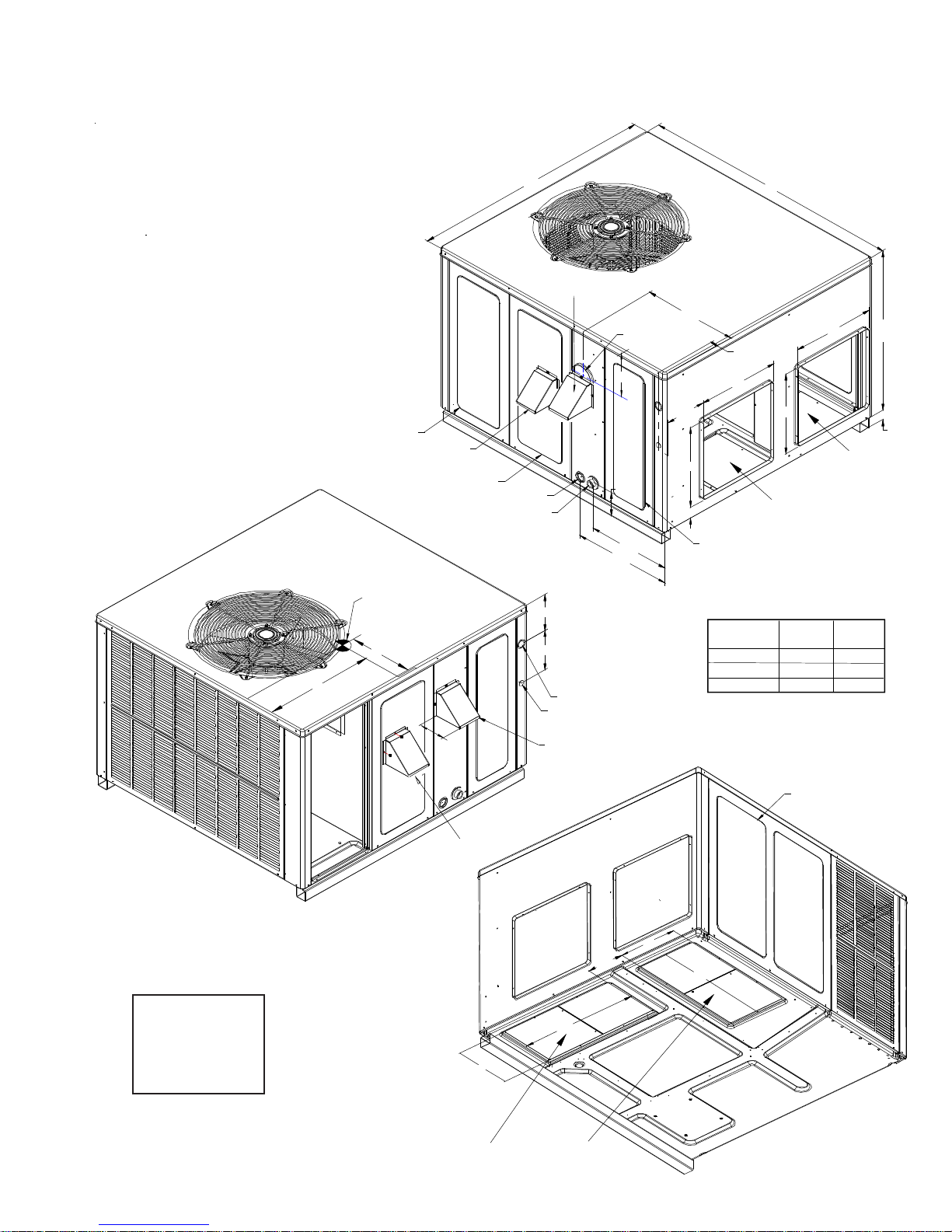

The connecting ductwork (Supply and Return) can be con-

nected for either horizontal or vertical airflow. In the vertical

application,amatching Roof Curb is recommended.

Areturnairfilter mustbeinstalledbehindthe returnairgrille(s)

or provision must be made for a filter in an accessible loca-

tionwithinthereturnairduct.Theminimumfilterareashould

not be less than those sizes listed in the Specification Sec-

tion. Under no circumstances should the unit be operated

withoutreturn air filters.

A3/4"pipeisprovidedforremovalofcondensatewaterfrom

the indoor coil. (Do not reduce the drain line size).

NOTE: Tightendrain to a maximum torqueof 10 in-lbs.

Refrigerant flow control is achieved by use of restrictor ori-

fices. DP13GM units use the FasTest Access Fitting Sys-

tem which consists of a saddle that is either soldered to the

suction and liquid lines or is fastened with a locking nut to

theaccessfittingbox (core)andthen screwedintothesaddle.

NOTE: The core must not be removed from the saddle

until the refrigerant charge has been removed. Failure

to do so could result in property damage or personal

injury.

Thesingle phase units use permanentsplitcapacitors(PSC)

designcompressors.Startingcomponents are therefore not

required. A low MFD run capacitor assists the compressor

to start and remains in the circuit during operation.

The outdoor fan and indoor blower motors are single phase

permanent split capacitor type motors. DP13GM48***41**

and DP13GM60***41** models are equipped with EEM in-

door blower motors. EEM motors are constant torque mo-

torswith verylowpowerconsumptionand are energizedbya

24V signal from the ignition control. The EEM features an

integratedcontrolmodule.

Air for condensing (cooling cycle) is drawn through the out-

door coil by a propeller fan, and is discharged vertically out

the top of the unit. The outdoor coil is designed for .0 static.

Noadditionalrestriction (ductwork) shall beapplied.

Conditioned air is drawn through the filter(s), field installed,

across the coil and back into the conditioned space by the

indoorblower.

Some models of the DP13GM series package units use the

Compliant Scroll compressor, there are a number of design

characteristicswhich are different fromthe traditional recip-

rocatingcompressor.

- DuetotheirdesignScrollcompressorsareinherentlymore

tolerantofliquidrefrigerant.NOTE:Even thoughthecom-

pressor section of a Scroll compressor is more tolerant

ofliquid refrigerant, continued floodbackorflooded start

conditionsmaywashoil from the bearing surfacescaus-

ingpremature bearing failure.

- These Scroll compressors use "POE" or polyester oil

whichisNOTcompatiblewith mineraloilbasedlubricants

like 3GS. "POE" oil must be used if additional oil is

required.

- Compliantscroll compressors perform "quiet"shutdowns

thatallow the compressor torestartimmediately without

the need for a time delay. This compressor will restart

even if the system has not equalized.

- Operatingpressuresandamp drawsmaydifferfromstan-

dardreciprocating compressors.Thisinformationmaybe

foundinthe "Cooling Performance Data" section.