1

Gateway Installation manual

READ THIS MANUAL ATTENTIVELY BEFORE

STARTING UP THE UNIT. DO NOT THROW IT AWAY.

KEEP IT IN YOUR FILES FOR FUTURE REFERENCE.

IMPROPER INSTALLATION OR ATTACHMENT OF

EQUIPMENT OR ACCESSORIES COULD RESULT IN

ELECTRIC SHOCK, SHORT-CIRCUIT, LEAKS, FIRE OR

OTHER DAMAGE TO EQUIPMENT. BE SURE ONLY TO

USE ACCESSORIES MADE BY DAIKIN THAT ARE

SPECIFICALLY DESIGNED FOR USE WITH THE

EQUIPMENT AND HAVE THEM INSTALLED BY A

PROFESSIONAL.

IF UNSURE OF INSTALLATION PROCEDURES OR

USE, ALWAYS CONTACT YOUR DAIKIN DEALER FOR

ADVICE AND INFORMATION.

INTRODUCTION

Thank you for purchasing the Gateway EKBMSMBA or

EKBMSBNA Kit. This Gateway will enable you to communicate

with your chiller or chillers through a Building Management

System (BMS) or other supervisory system. More specifically, it

functions as a translator between the BMS or supervisory system

and the address cards of the actual chiller or multiple chillers.

As such, the Gateway ensures the connection of all address cards

— and thus also of the chillers — with systems that can

communicate in Modbus or BACnet protocol.

YOUR GATEWAY KIT

The kit you have just purchased consists of:

■1 Gateway

■1 PC diskette with an MS-DOS-formatted program for the initial

configuration of the Gateway

■a cable terminal (resistor)

GENERAL OVERVIEW OF THE SYSTEM

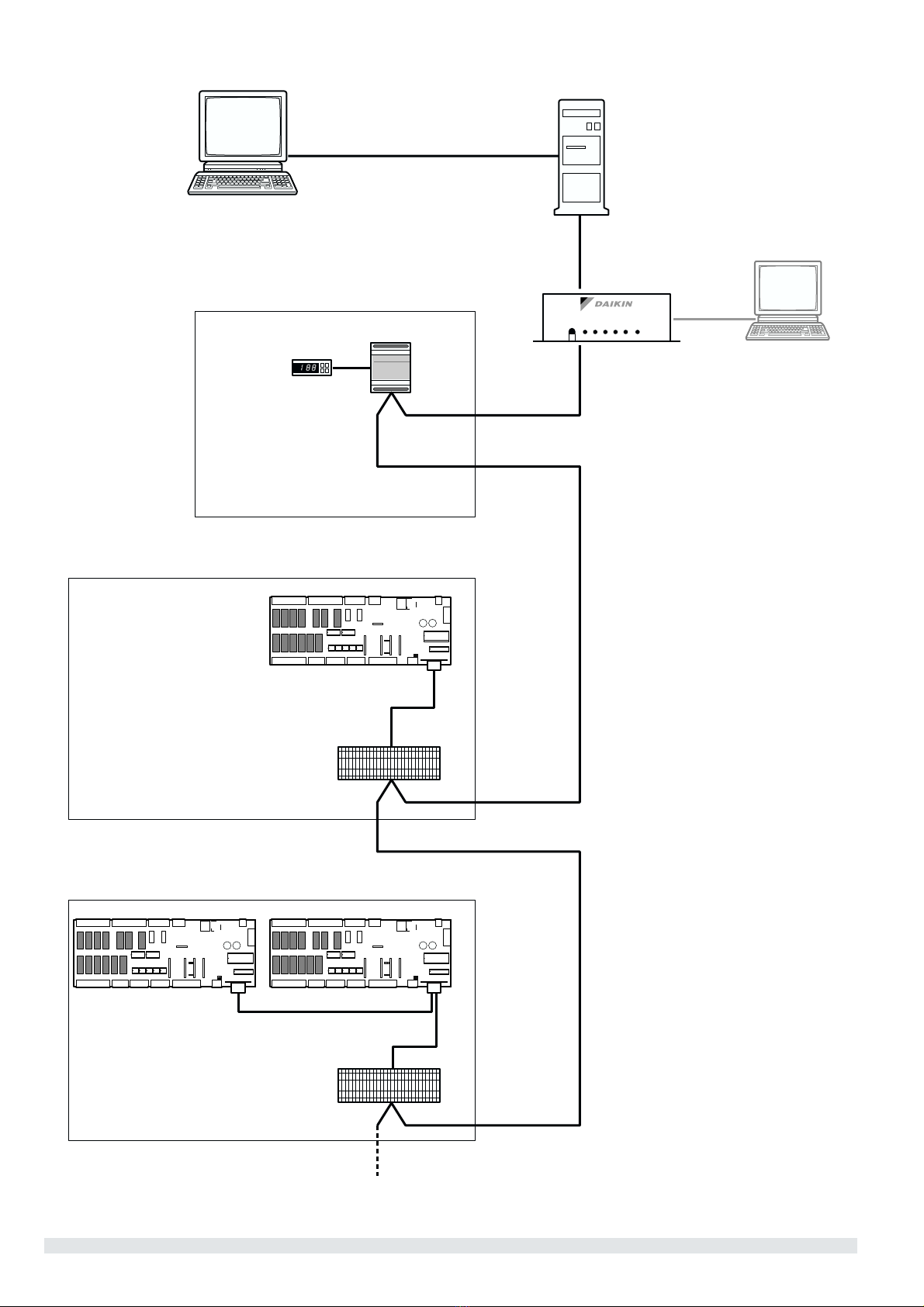

Different parts of the communication network

The communication network consists of two major players:

■The Building Management System or supervisory system.

■The chiller or multiple chillers.

The BMS or other supervisory system is able to communicate with

the chillers through two communication devices:

■The Gateway, a separate device that functions as a translator

between the Modbus/BACnet signals of the BMS or

supervisory system and the protocol used by the chiller’s

address card.

■The address card, a card placed on each PCB of the chiller or

a module placed inside the switchbox, depending on the range

of the chiller. It identifies the chiller. The Gateway can

communicate with up to 16 address cards using the Modbus-

Jbus protocol or up to 8 address cards using the BACnet

protocol. Mind that each PCB needs one address card!

(Refer to figure 1.)

DESCRIPTION OF THE GATEWAY

Technical data

■Intel 8032 microprocessor, 12 MHz

■240Vac factory standard power supply (can be changed into

24Vac or 120Vac)

■resident program, EPROM, 64 KB

A front view: Keys and LED’s

Key Purpose

print out No function

reset Press this key to reset the Gateway. It will restart the internal

configuration and external inquiry process of the address cards

LED Colour Indication

line yellow Power supply on

alarm 1 red Error in the configuration stored in the buffered RAM

alarm 2 red Malfunction in the communication between thegateway and the

address card, probably due to an inconsistency with the initial

configuration

rx green Communication OK (blinking)

tx green Communication OK (blinking)

A rear view: Connectors

The rear panel of the gateway has the following series of

connectors:

Connector name Connects to… Type

modem BMS/supervisory system with RS-232 standard 9 standard way male

RS-422/485 BMS/supervisory system with RS-485 standard 9 standard way female

config. Configuration PC 9 standard way male

Carel Net. Address cards with RS-485 standard 9 standard way female

fuse

line

print out

alarm 1

alarm 2

rx

tx

reset

Gateway

config.

Carel Net. relay fuse

cod.

modem

rs422/485

EKBMSMBA

EKBMSBNA