6. Programming Notes

10 Quick User Guide DCM014A51

6.4 Setpoints Range Limitation

“Maximum Cooling Setpoint – Minimum Cooling Setpoint – Maximum Heating Setpoint – Minimum Heating

Setpoint” are the points used to set the setpoints range limitations.

•The Out_Of_Service property for those points is true by default, which will need to change to false in

order to set the range values or enable setpoint range limitation from the iTM.

•The Out_Of_Service properties of Min Cooling Setpoint or Max Cooling Setpoint are synced, if one of

them changes (to True or False), the other will change and the same is true for the Min Heating setpoint

and Max Heating setpoint.

•Suggested setpoint range is 70-74°F for cooling and 66-70°F for heating.

6.5 Schedule

“Enable iTM Schedule Operation” point allows the BMS to enable or disable all schedule programs configured

on the ITM.

•The iTM can handle the everyday scheduling of the indoor unit groups.

•There are 4 types of schedules that can be set in the iTM 7 day, Weekday/Weekend, Weekday/Saturday/

Sunday and Everyday.

6.6 Timed Override

“Time Override Minutes” is number of minutes that can be set from the BMS, which represent the timer

extension on the iTM. This function sets up the time to stop the indoor unit.

“Time Override Operation” Monitors the status of the Timer Extension, and configures it for the indoor unit.

When the timed override function is enabled for an indoor unit group, the units will be turned off automatically

after the preset timer has expired if the unit is turned on during the unoccupied period.

6.7 Remote Controller Prohibits

Remote controller prohibits (On/Off, Mode and Setpoint) may be enabled/disabled by the objects provided to

the BMS or the iTM.

•If the BMS sets the Setpoint Range Limitation, prohibiting the remote controller setpoint adjustment

should not be enabled.

•The Remote Controller On/Off and Mode adjustment can be prohibited during the occupied hours, but

the On/Off may need to be permitted during the unoccupied period for the Timed Override operation.

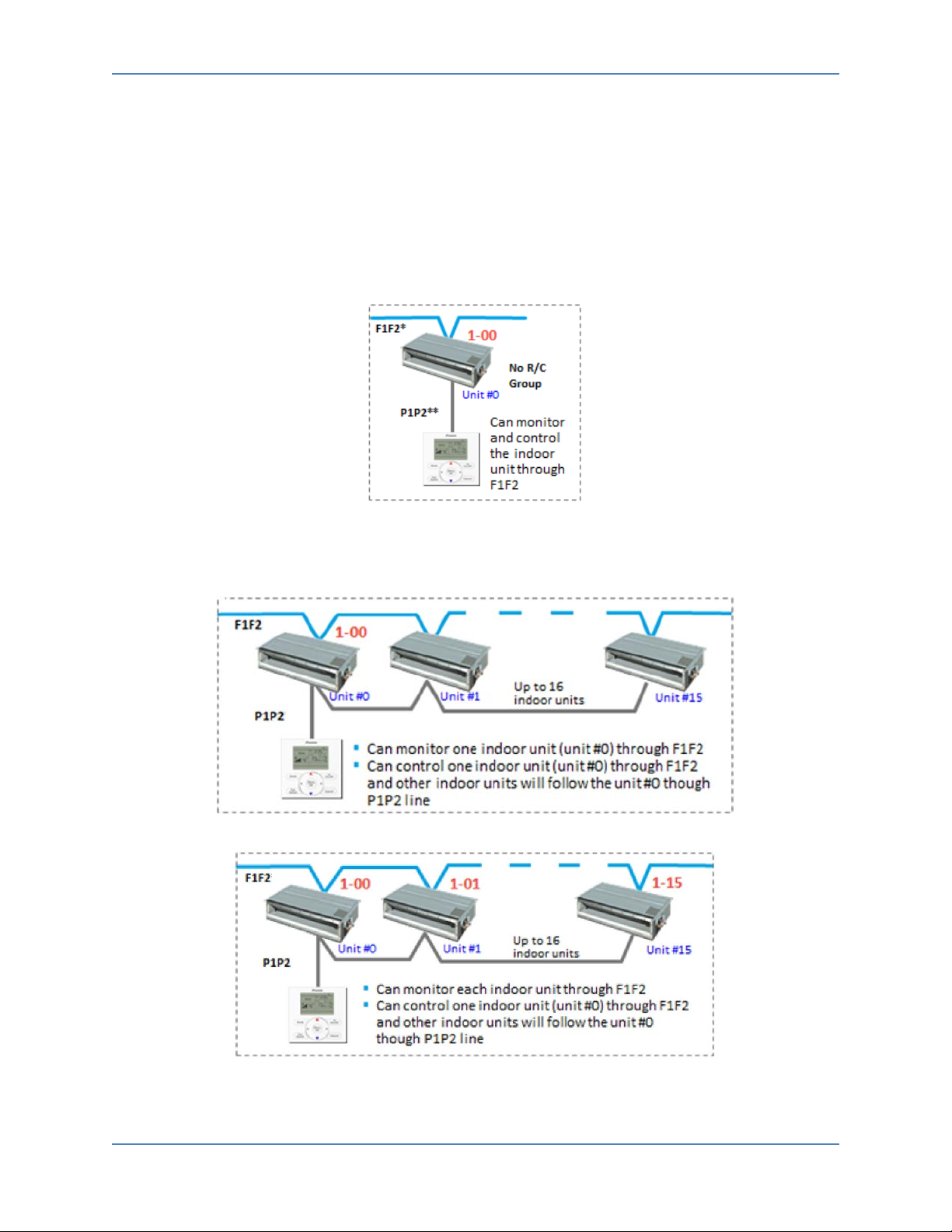

•When more than one indoor unit is connected to a single remote controller group, the BMS should only

send commands to the indoor unit that is designated to receive the command for the remote controller

group (unit#0). BMS should not send commands to other indoor units in the remote control group. If this

object is sent to the other indoor units in the remote controller group, the indoor unit will not execute

this command.

6.8 Forced System Shutdown

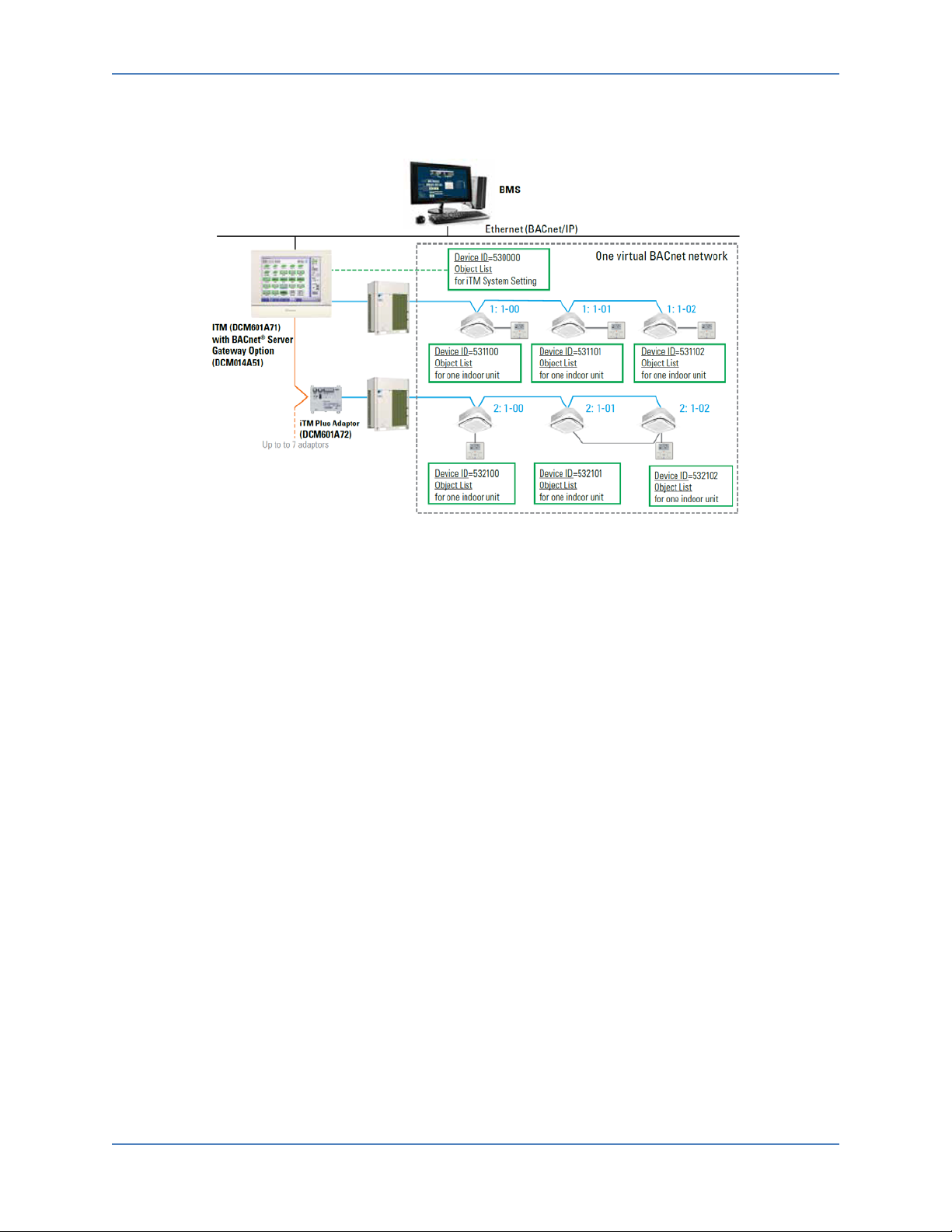

The “Forced System Off” point can be used to turn off all indoor unit groups connected to the iTM via the DIII-

Net communication bus when an emergency signal has been received by the BMS.

•Emergency Stop program should have been configured and enabled in advance on the iTM.

•Indoor unit groups cannot be restarted from the remote controller until the "Forced System Off" point has

been set to inactive.