Installation GuideDaintree®Wireless High Bay Sensor (WHS100)

6

10

13

Joining the ZigBee Lighting Control Network

11

Default Functionality

12

PIR Sensitivity Adjustment

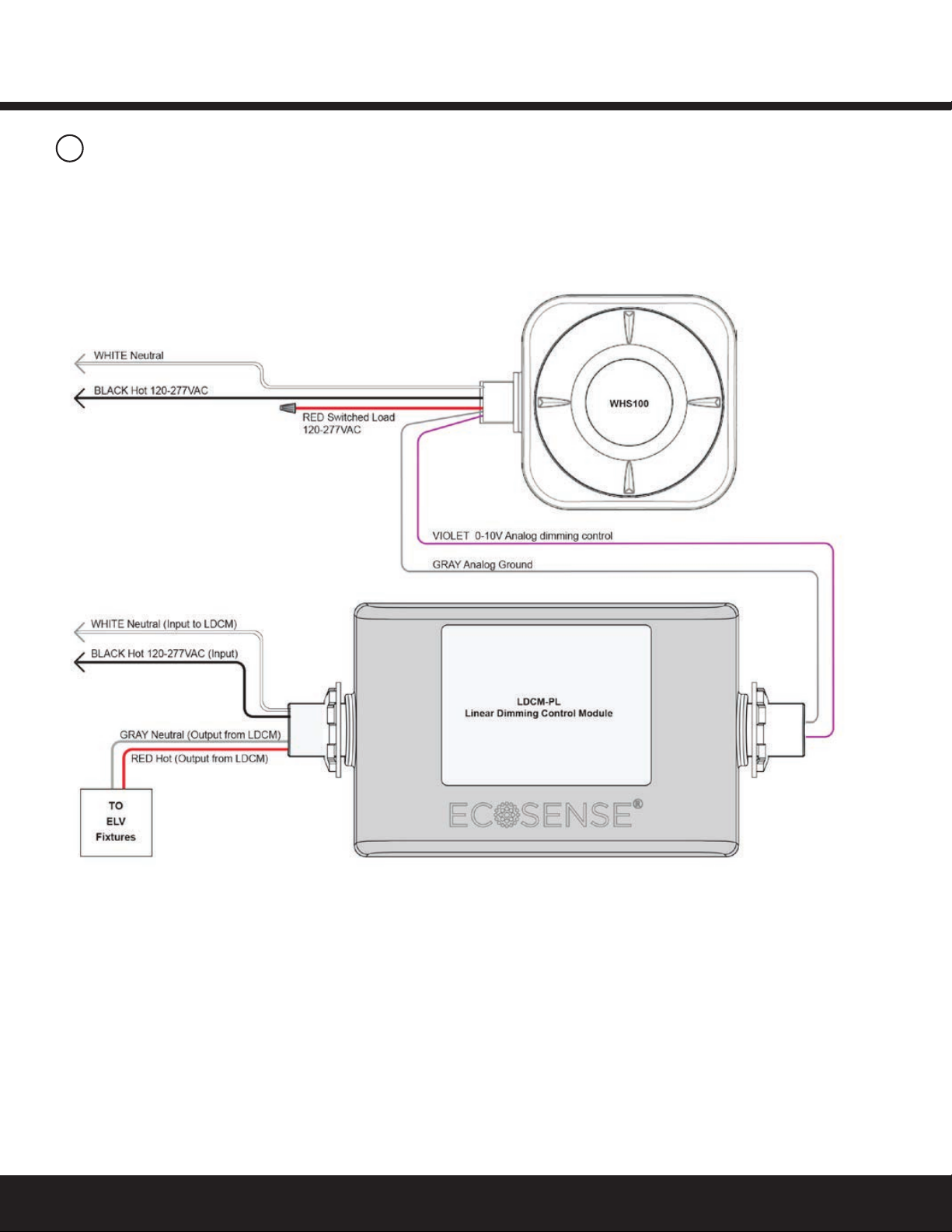

Redusing noise on low voltage (0-10V) wiring

After successfully completing the Installation Test the WHS100 is

ready to communicate with the Daintree Wireless Area Controller

(WAC) and the Daintree Controls Software (DCS) web-based

building controls management user interface.

A network join can be retriggered manually at any time by

resetting the WHS100:

• Reset to factory defaults: Press and hold the Utility button for

5 seconds. Release the button when the LEDs begin to ash

rapidly. This causes the device to leave any network to which it

is currently joined. Following the reset, the device attempts to

join a network. For more information about conguring

the lighting control network, see the instructions and on-line

help provided with the Daintree Controls Software application.

For more information about conguring the lighting control

network, see the instructions and on-line help provided with

the Daintree Controls Software web application.

The WHS100 is designed to be part of the Daintree Networked.

It should not be left to operate outside of the network indenitely.

The Daintree Controls Software web application provides many

control efciencies not otherwise available, including changing

operational parameters.

As shipped from the factory, before it is joined to the DCS network,

and after it joins the network but before it is congured into a zone,

the WHS100 controls the connected light as follows:

• During occupancy light is ON at 100%

• During vacancy an on/off light turns OFF, a dimming

light is reduced to 10%.

• Vacancy delay (Off Delay) is 10 minutes.

Functionality after Congured into a Zone

After the WHS100 is congured into a zone, it follows the control

strategy for the zone, including delay time, light levels, and other

features. The delay time is whatever the strategy dictates plus 20

seconds. For example, if the strategy is set for 8 minutes, the

vacancy delay is 8 minutes and 20 seconds.

There are no senstivity adjustments on the WHS100.

Contact Daintree support for information on how to change

the sensor sensitivity.

• Keep wiring as short as practical.

• Keep the signal lines separate from the mains voltage lines.

• Reduce the area created by the signal lines and the

GND return (i.e., keep them close together).

• If possible twist the signal line with the GND return.

14

IEEE Address Labels

A small plastic bag containing two small labels and the lens mask

is included with every sensor. The larger label with the WHS100’s

full IEEE address is the Fixture label. Afx this label to the outside

of the xture or sensor in a standard location where it can be seen

after installation and mounting.

Record IEEE Addresses

A marked-up copy of the facility oor plan showing the identity

and location of each wireless adapter (including associated xtures

and sensors) should be available after installation. This will

simplify and expedite the commissioning process.

Be sure that each sensor’s IEEE address (last 5 digits) is

recorded on the facility oor plan. Use the Plan label supplied

with the adapter or write the last 5 digits on the oor plan. This

information will be used during thecommissioning process.

For factory installation by xture manufacturers:

• Remove the Fixture label from its plastic bag, and afx to the

outside of the xture or sensor in a consistent location where it

can be seen after installation and mounting.

• Leave the Plan label (smaller label) in its plastic bag. Tape the bag

to the Fixture label or next to it .

15

Troubleshooting

No LEDs turn on when I press the Utility button.

• Check line voltage wiring Light doesn’t operate as expected

in Installation Test Mode.

• Make sure power is turned on to the xture circuit .

• Check all wiring between the xture and the sensor.

• Press the blue Utility button for 5 seconds to reset the unit.

Green motion detection LED does not activate when

walking through the coverage area.

• Check to see if the green LED turns on when you wave your

hand directly in front of the lens.

• If the LED turns on, check for objects or barriers obstructing

the sensor’s view of the coverage area.

Green LED ashes when the coverage area is vacant.

• Check for sources of hot air ow in the coverage area.

• See Placement Guidelines. Eliminate false trigger sources.

Light doesn’t turn Off after WHS100 joins the ZigBee network.

• Once the WHS100 is congured into a zone through DCS it

follows the Off Delay for the zone’s control strategy.

Light doesn’t turn Off after WHS100 is congured into a zone.

• Check the “Off delay” for the zone in the DCS.

• Check for other DCS scheduled events or manual

overrides that may be keeping the lights On.