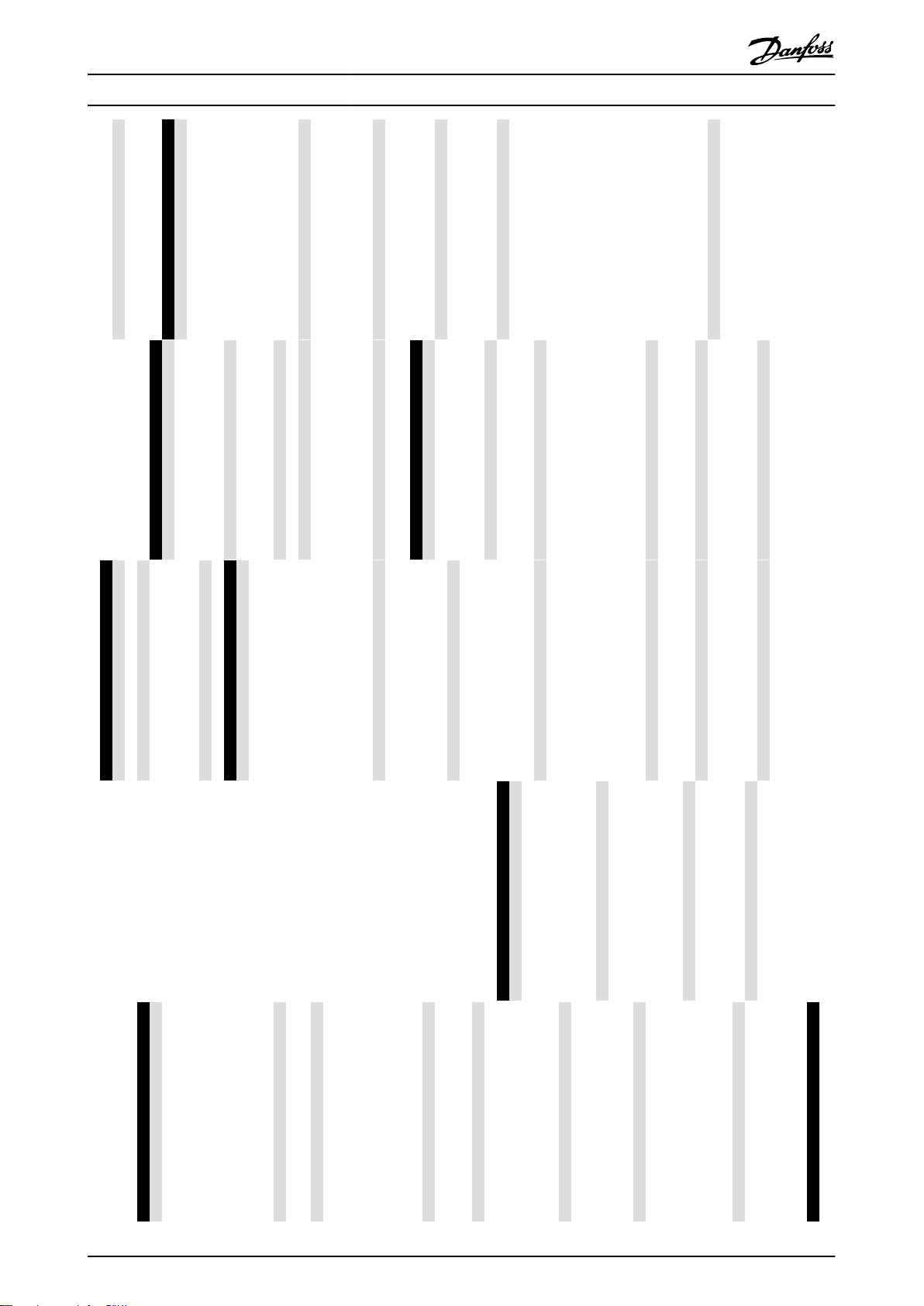

5.5.2 Main menu

structure

0-** Operation / Display

0-0* Basic Settings

0-01 Language

0-02 Motor Speed Unit

0-03 Regional Settings

0-04 Operating State at Power-up

0-05 Local Mode Unit

0-1* Set-up Operations

0-10 Active Set-up

0-11 Programming Set-up

0-12 This Set-up Linked to

0-13 Readout: Linked Set-ups

0-14 Readout: Prog. Set-ups / Channel

0-2* LCP Display

0-20 Display Line 1.1 Small

0-21 Display Line 1.2 Small

0-22 Display Line 1.3 Small

0-23 Display Line 2 Large

0-24 Display Line 3 Large

0-25 My Personal Menu

0-3* LCP Custom Readout

0-30 Custom Readout Unit

0-31 Custom Readout Min Value

0-32 Custom Readout Max Value

0-37 Display Text 1

0-38 Display Text 2

0-39 Display Text 3

0-4* LCP Keypad

0-40 [Hand on] Key on LCP

0-41 [Off] Key on LCP

0-42 [Auto on] Key on LCP

0-43 [Reset] Key on LCP

0-44 [Off/Reset] Key on LCP

0-45 [Drive Bypass] Key on LCP

0-5* Copy/Save

0-50 LCP Copy

0-51 Set-up Copy

0-6* Password

0-60 Main Menu Password

0-61 Access to Main Menu w/o Password

0-65 Personal Menu Password

0-66 Access to Personal Menu w/o

Password

0-7* Clock Settings

0-70 Date and Time

0-71 Date Format

0-72 Time Format

0-74 DST/Summertime

0-76 DST/Summertime Start

0-77 DST/Summertime End

0-79 Clock Fault

0-81 Working Days

0-82 Additional Working Days

0-83 Additional Non-Working Days

0-89 Date and Time Readout

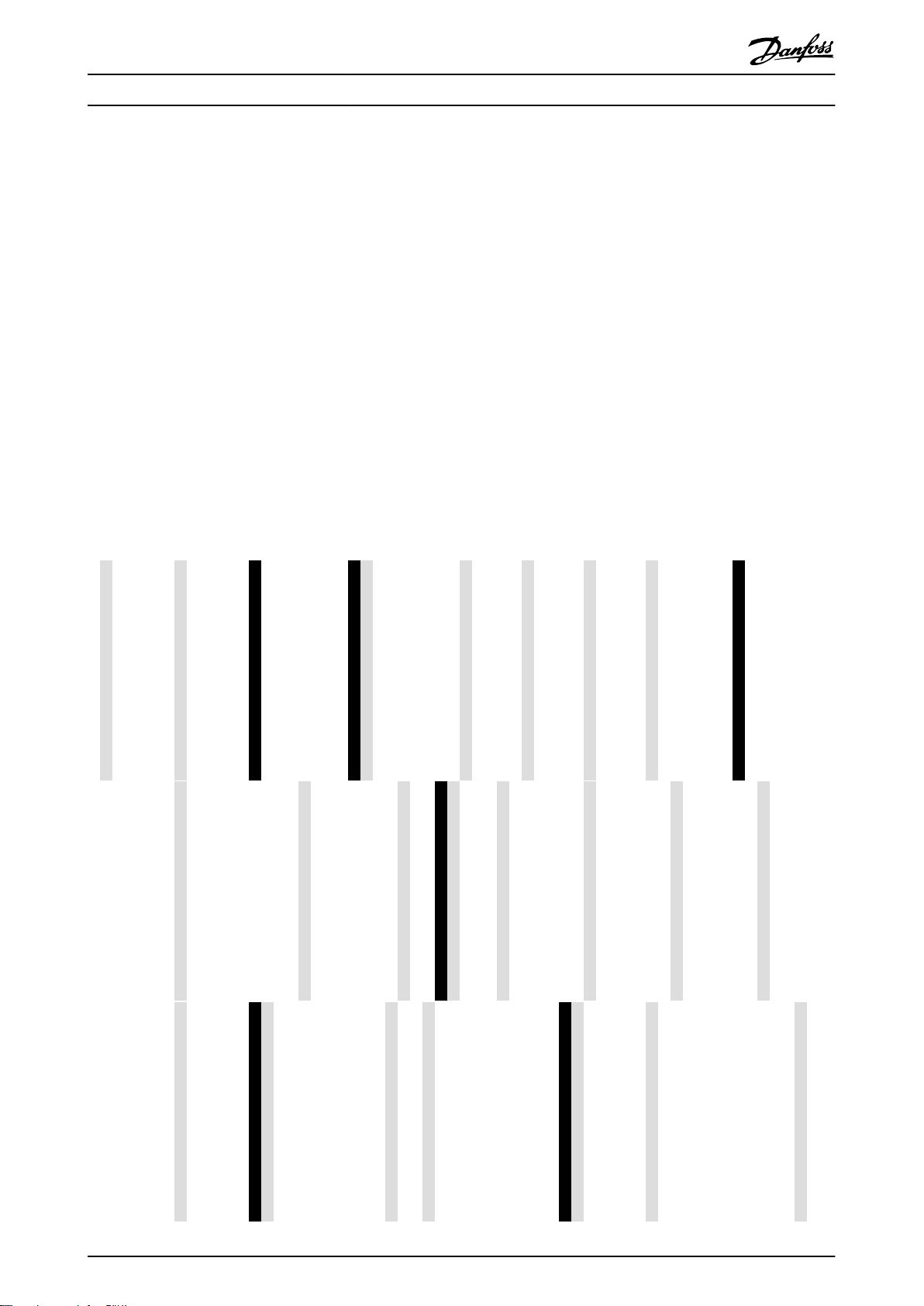

1-** Load and Motor

1-0* General Settings

1-00 Configuration Mode

1-03 Torque Characteristics

1-06 Clockwise Direction

1-1* Motor Selection

1-10 Motor Construction

1-1* VVC+ PM

1-14 Damping Gain

1-15 Low Speed Filter Time Const.

1-16 High Speed Filter Time Const.

1-17 Voltage filter time const.

1-2* Motor Data

1-20 Motor Power [kW]

1-21 Motor Power [HP]

1-22 Motor Voltage

1-23 Motor Frequency

1-24 Motor Current

1-25 Motor Nominal Speed

1-26 Motor Cont. Rated Torque

1-28 Motor Rotation Check

1-29 Automatic Motor Adaptation (AMA)

1-3* Adv. Motor Data

1-30 Stator Resistance (Rs)

1-31 Rotor Resistance (Rr)

1-35 Main Reactance (Xh)

1-36 Iron Loss Resistance (Rfe)

1-37 d-axis Inductance (Ld)

1-39 Motor Poles

1-40 Back EMF at 1000 RPM

1-5* Load Indep. Setting

1-50 Motor Magnetisation at Zero Speed

1-51 Min Speed Normal Magnetising [RPM]

1-52 Min Speed Normal Magnetising [Hz]

1-58 Flystart Test Pulses Current

1-59 Flystart Test Pulses Frequency

1-6* Load Depen. Setting

1-60 Low Speed Load Compensation

1-61 High Speed Load Compensation

1-62 Slip Compensation

1-63 Slip Compensation Time Constant

1-64 Resonance Dampening

1-65 Resonance Dampening Time Constant

1-66 Min. Current at Low Speed

1-7* Start Adjustments

1-70 PM Startmode

1-71 Start Delay

1-72 Start Function

1-73 Flying Start

1-77 Compressor Start Max Speed [RPM]

1-78 Compressor Start Max Speed [Hz]

1-79 Compressor Start Max Time to Trip

1-8* Stop Adjustments

1-80 Function at Stop

1-81 Min Speed for Function at Stop [RPM]

1-82 Min Speed for Function at Stop [Hz]

1-86 Trip Speed Low [RPM]

1-87 Trip Speed Low [Hz]

1-9* Motor Temperature

1-90 Motor Thermal Protection

1-91 Motor External Fan

1-93 Thermistor Source

2-** Brakes

2-0* DC-Brake

2-00 DC Hold/Preheat Current

2-01 DC Brake Current

2-02 DC Braking Time

2-03 DC Brake Cut In Speed [RPM]

2-04 DC Brake Cut In Speed [Hz]

2-06 Parking Current

2-07 Parking Time

2-1* Brake Energy Funct.

2-10 Brake Function

2-11 Brake Resistor (ohm)

2-12 Brake Power Limit (kW)

2-13 Brake Power Monitoring

2-15 Brake Check

2-16 AC brake Max. Current

2-17 Over-voltage Control

3-** Reference / Ramps

3-0* Reference Limits

3-02 Minimum Reference

3-03 Maximum Reference

3-04 Reference Function

3-1* References

3-10 Preset Reference

3-11 Jog Speed [Hz]

3-13 Reference Site

3-14 Preset Relative Reference

3-15 Reference 1 Source

3-16 Reference 2 Source

3-17 Reference 3 Source

3-19 Jog Speed [RPM]

3-4* Ramp 1

3-41 Ramp 1 Ramp Up Time

3-42 Ramp 1 Ramp Down Time

3-5* Ramp 2

3-51 Ramp 2 Ramp Up Time

3-52 Ramp 2 Ramp Down Time

3-8* Other Ramps

3-80 Jog Ramp Time

3-81 Quick Stop Ramp Time

3-82 Starting Ramp Up Time

3-9* Digital Pot.Meter

3-90 Step Size

3-91 Ramp Time

3-92 Power Restore

3-93 Maximum Limit

3-94 Minimum Limit

3-95 Ramp Delay

4-** Limits / Warnings

4-1* Motor Limits

4-10 Motor Speed Direction

4-11 Motor Speed Low Limit [RPM]

4-12 Motor Speed Low Limit [Hz]

4-13 Motor Speed High Limit [RPM]

4-14 Motor Speed High Limit [Hz]

4-16 Torque Limit Motor Mode

4-17 Torque Limit Generator Mode

4-18 Current Limit

4-19 Max Output Frequency

4-5* Adj. Warnings

4-50 Warning Current Low

4-51 Warning Current High

4-52 Warning Speed Low

4-53 Warning Speed High

4-54 Warning Reference Low

4-55 Warning Reference High

4-56 Warning Feedback Low

4-57 Warning Feedback High

4-58 Missing Motor Phase Function

4-6* Speed Bypass

4-60 Bypass Speed From [RPM]

4-61 Bypass Speed From [Hz]

4-62 Bypass Speed To [RPM]

4-63 Bypass Speed To [Hz]

4-64 Semi-Auto Bypass Set-up

5-** Digital In/Out

5-0* Digital I/O mode

5-00 Digital I/O Mode

5-01 Terminal 27 Mode

5-02 Terminal 29 Mode

5-1* Digital Inputs

5-10 Terminal 18 Digital Input

5-11 Terminal 19 Digital Input

5-12 Terminal 27 Digital Input

5-13 Terminal 29 Digital Input

5-14 Terminal 32 Digital Input

5-15 Terminal 33 Digital Input

5-16 Terminal X30/2 Digital Input

5-17 Terminal X30/3 Digital Input

5-18 Terminal X30/4 Digital Input

5-19 Terminal 37 Safe Stop

5-3* Digital Outputs

5-30 Terminal 27 Digital Output

5-31 Terminal 29 Digital Output

5-32 Term X30/6 Digi Out (MCB 101)

5-33 Term X30/7 Digi Out (MCB 101)

5-4* Relays

5-40 Function Relay

5-41 On Delay, Relay

5-42 Off Delay, Relay

5-5* Pulse Input

5-50 Term. 29 Low Frequency

5-51 Term. 29 High Frequency

5-52 Term. 29 Low Ref./Feedb. Value

5-53 Term. 29 High Ref./Feedb. Value

5-54 Pulse Filter Time Constant #29

5-55 Term. 33 Low Frequency

5-56 Term. 33 High Frequency

5-57 Term. 33 Low Ref./Feedb. Value

5-58 Term. 33 High Ref./Feedb. Value

5-59 Pulse Filter Time Constant #33

5-6* Pulse Output

5-60 Terminal 27 Pulse Output Variable

5-62 Pulse Output Max Freq #27

5-63 Terminal 29 Pulse Output Variable

5-65 Pulse Output Max Freq #29

5-66 Terminal X30/6 Pulse Output Variable

5-68 Pulse Output Max Freq #X30/6

5-8* I/O Options

5-80 AHF Cap Reconnect Delay

5-9* Bus Controlled

5-90 Digital & Relay Bus Control

5-93 Pulse Out #27 Bus Control

5-94 Pulse Out #27 Timeout Preset

5-95 Pulse Out #29 Bus Control

5-96 Pulse Out #29 Timeout Preset

5-97 Pulse Out #X30/6 Bus Control

5-98 Pulse Out #X30/6 Timeout Preset

6-** Analog In/Out

6-0* Analog I/O Mode

6-00 Live Zero Timeout Time

6-01 Live Zero Timeout Function

6-02 Fire Mode Live Zero Timeout Function

6-1* Analog Input 53

6-10 Terminal 53 Low Voltage

6-11 Terminal 53 High Voltage

6-12 Terminal 53 Low Current

6-13 Terminal 53 High Current

6-14 Terminal 53 Low Ref./Feedb. Value

6-15 Terminal 53 High Ref./Feedb. Value

6-16 Terminal 53 Filter Time Constant

6-17 Terminal 53 Live Zero

6-2* Analog Input 54

6-20 Terminal 54 Low Voltage

6-21 Terminal 54 High Voltage

6-22 Terminal 54 Low Current

6-23 Terminal 54 High Current

6-24 Terminal 54 Low Ref./Feedb. Value

6-25 Terminal 54 High Ref./Feedb. Value

6-26 Terminal 54 Filter Time Constant

6-27 Terminal 54 Live Zero

6-3* Analog Input X30/11

6-30 Terminal X30/11 Low Voltage

6-31 Terminal X30/11 High Voltage

6-34 Term. X30/11 Low Ref./Feedb. Value

6-35 Term. X30/11 High Ref./Feedb. Value

6-36 Term. X30/11 Filter Time Constant

6-37 Term. X30/11 Live Zero

6-4* Analog Input X30/12

6-40 Terminal X30/12 Low Voltage

6-41 Terminal X30/12 High Voltage

6-44 Term. X30/12 Low Ref./Feedb. Value

6-45 Term. X30/12 High Ref./Feedb. Value

6-46 Term. X30/12 Filter Time Constant

6-47 Term. X30/12 Live Zero

6-5* Analog Output 42

6-50 Terminal 42 Output

6-51 Terminal 42 Output Min Scale

6-52 Terminal 42 Output Max Scale

6-53 Terminal 42 Output Bus Control

6-54 Terminal 42 Output Timeout Preset

6-55 Analog Output Filter

6-6* Analog Output X30/8

6-60 Terminal X30/8 Output

VLT®HVAC Drive Quick Reference Guide