Danfoss KP 15A User manual

Other Danfoss Controllers manuals

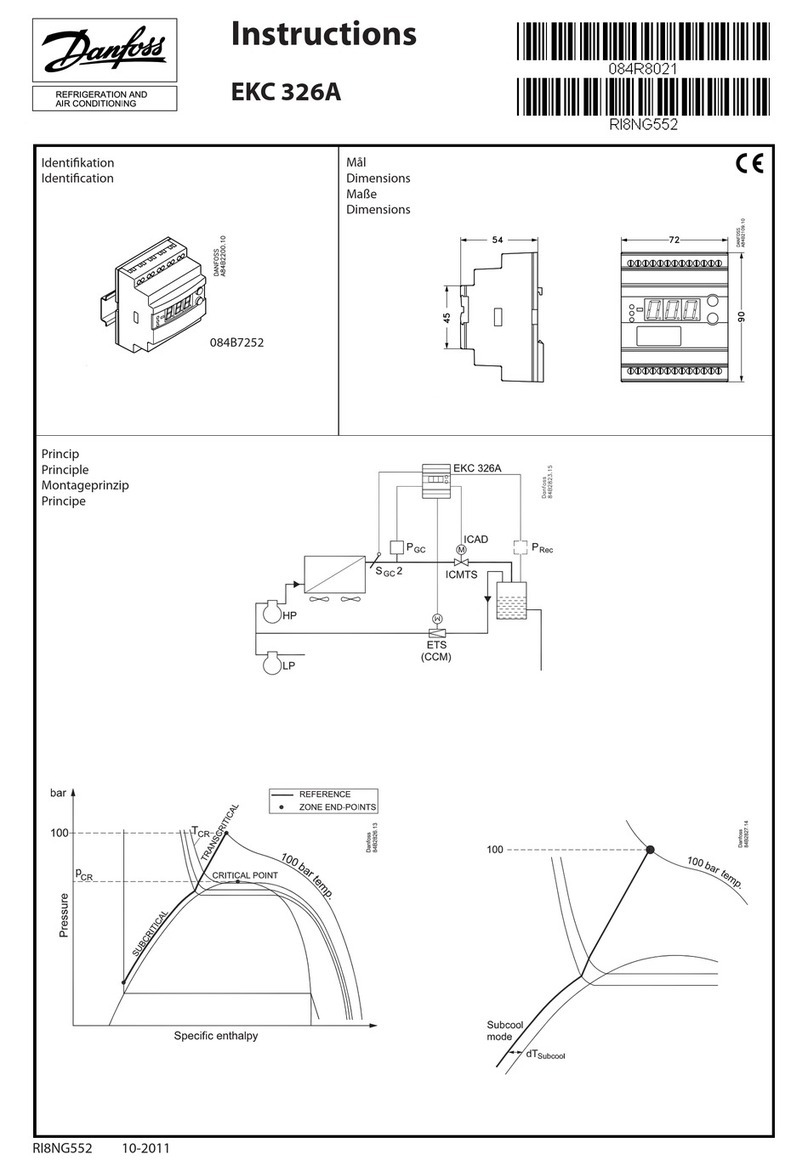

Danfoss

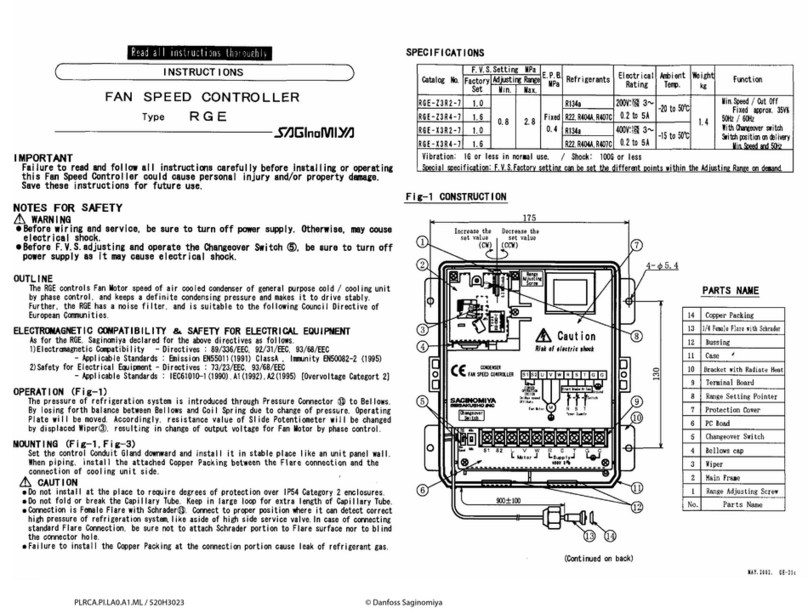

Danfoss Saginomiya RGE-Z3R2-7 User manual

Danfoss

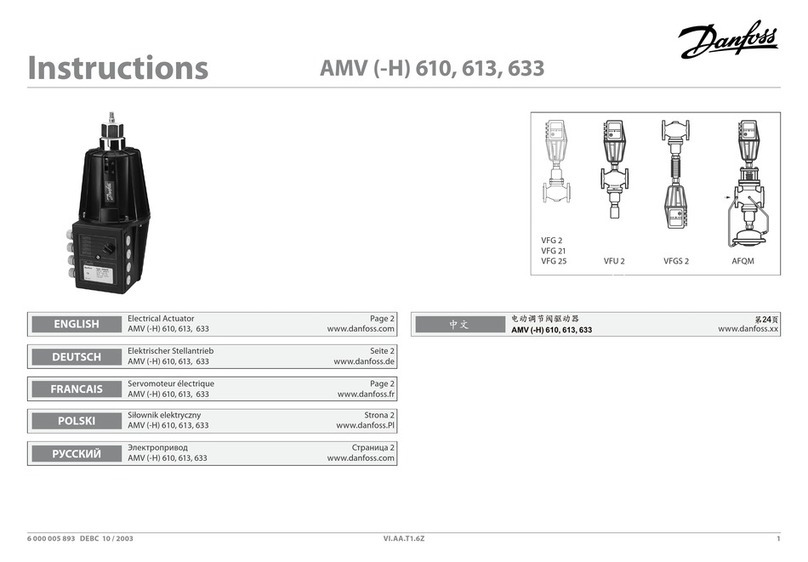

Danfoss AMV 610 User manual

Danfoss

Danfoss AMD 610 AS User manual

Danfoss

Danfoss WP75- RF Assembly Instructions

Danfoss

Danfoss VLT AutomationDrive FC 300 Guide

Danfoss

Danfoss MCV104A User manual

Danfoss

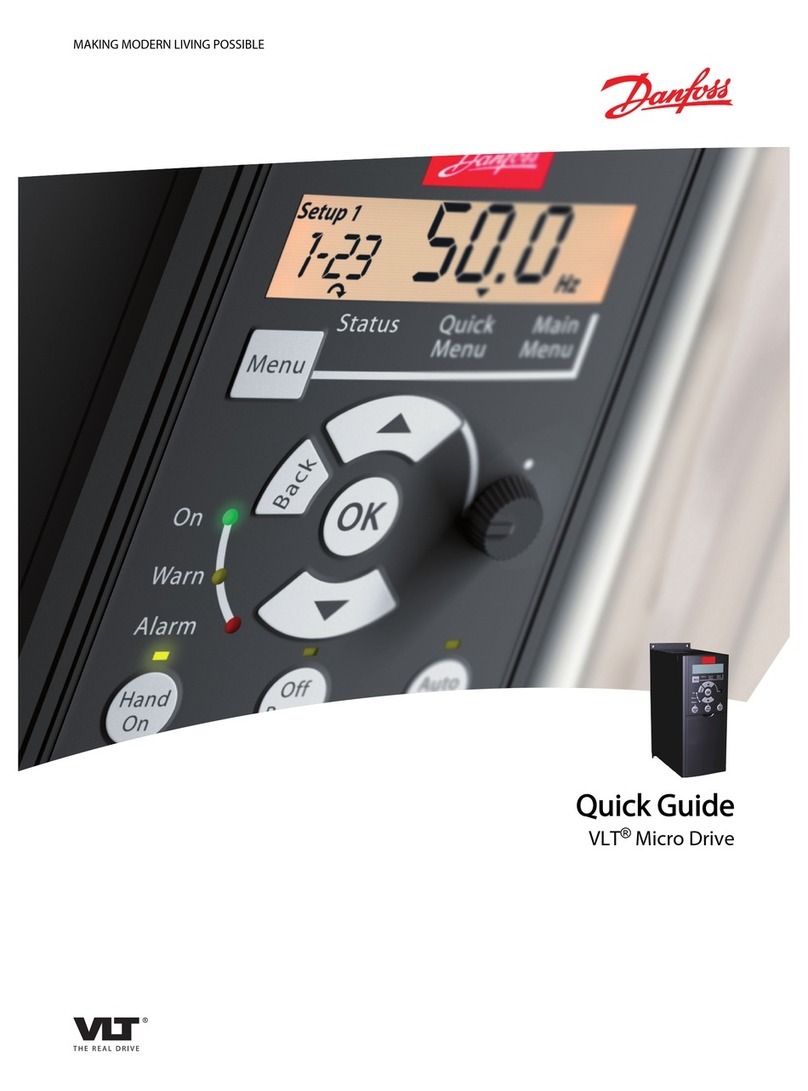

Danfoss VLT Micro Drive FC 51 Series User manual

Danfoss

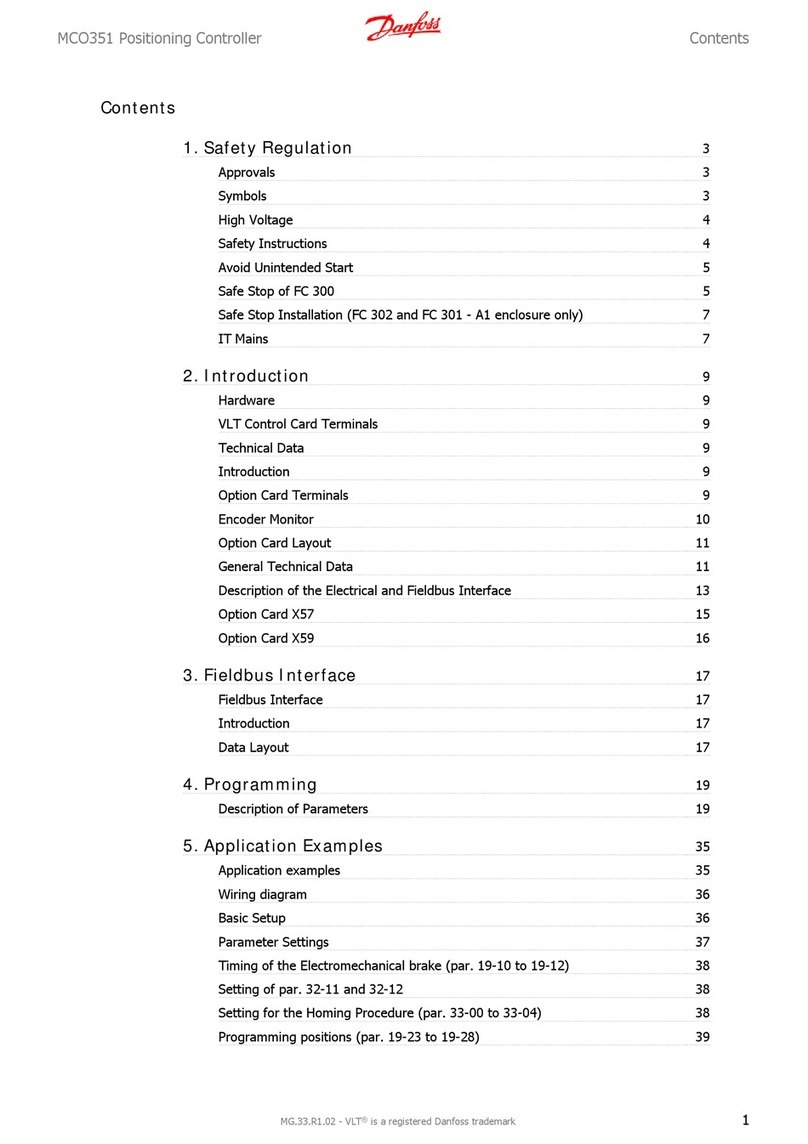

Danfoss MCO 351 Instruction manual

Danfoss

Danfoss AK-CC55 User manual

Danfoss

Danfoss 140F1089 User manual

Danfoss

Danfoss EKC 202C-MS User manual

Danfoss

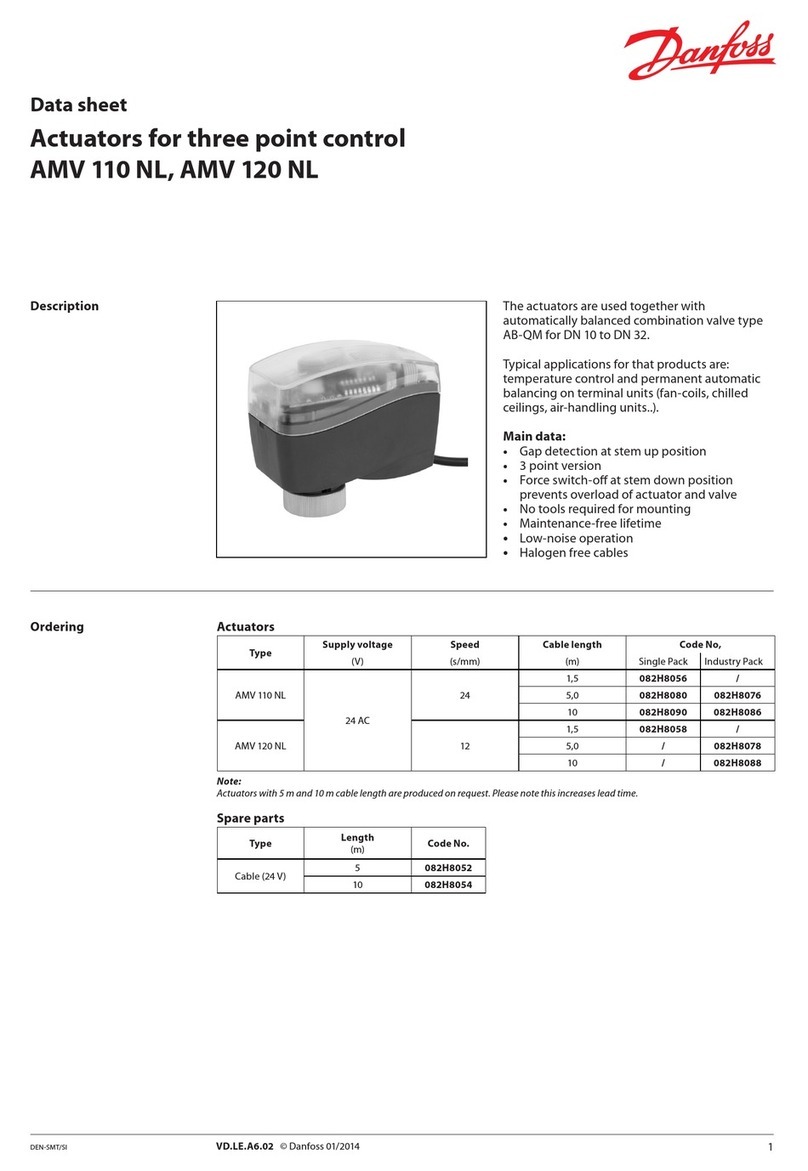

Danfoss AMV 110 NL AQT User manual

Danfoss

Danfoss AK-PC 551 User manual

Danfoss

Danfoss AMI 120 NL-1 User manual

Danfoss

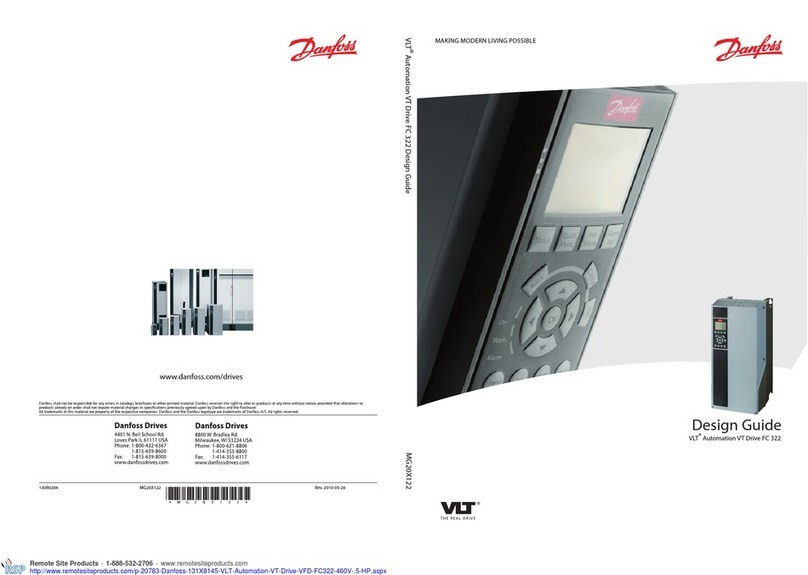

Danfoss VLT FC 322 Guide

Danfoss

Danfoss Optyma Plus User manual

Danfoss

Danfoss VLT 5000 User manual

Danfoss

Danfoss PN 25 User manual

Danfoss

Danfoss EKE 1B User manual

Danfoss

Danfoss vlt soft starter mcd 500 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions