Data Sheet Radiator thermostats for one-pipe and two-pipe systems

2 VD.51.Q1.12 © Danfoss 10/2003 DKCD

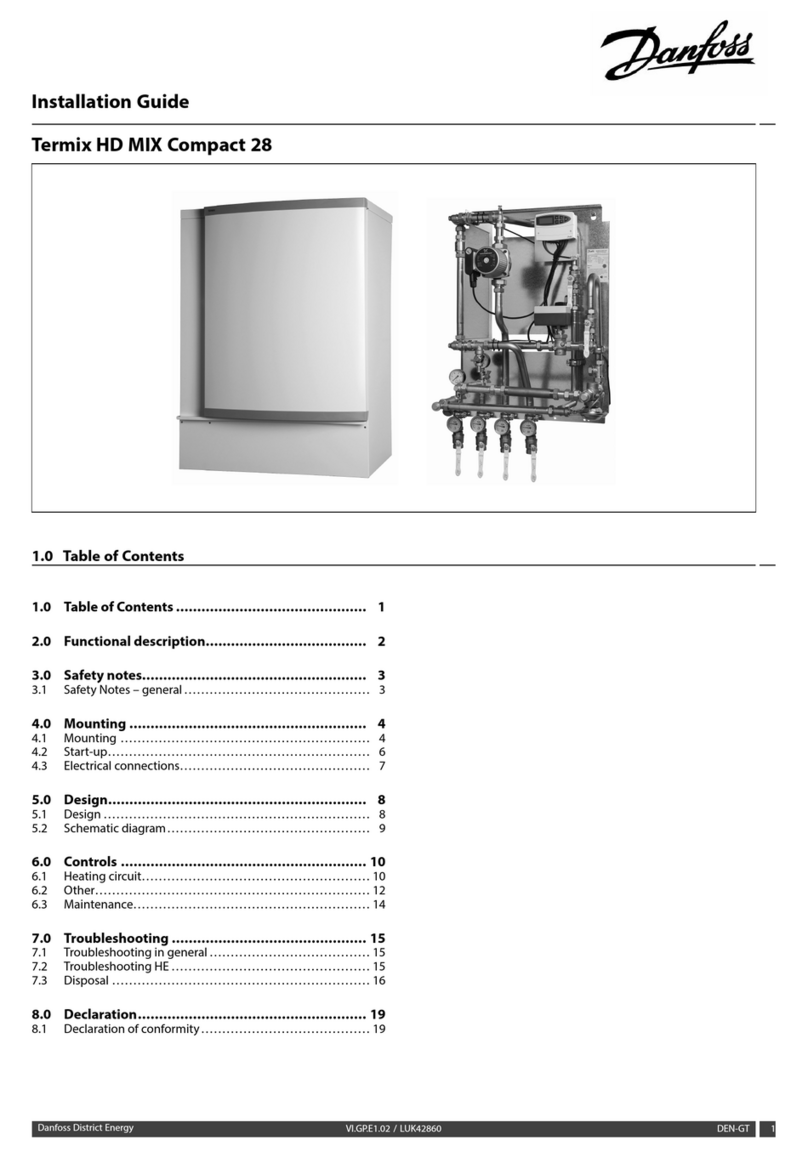

Valve bodies for two-pipe systems type RA-FN

1) Remote sensors are recommended

2) Kvs-maximum indicates the water flow (Q) with valve fully open

Selection and specification

Should water treatment be

used it is essential that dosing

instructions of the manufacturer

are strictly observed. It is

recommended that formulations

containing mineral oil are

avoided.

RA 2910 013G2910 Built-in 5 - 26 °C (1)

RA 2920 013G2920 Built-in, tamper proof 5 - 26 °C (1)

RA 2914 013G2914 Built-in, low temperature range model 5 - 22 °C (1)

RA 2912 013G2912 Remote sensor, 0 - 2 m capillary tube (2) 5 - 26 °C

RA 2922 013G2922 Remote sensor, 0 - 2 m capillary tube, tamper proof (2) 5 - 26 °C

RA 2916 013G2916 Remote sensor, 0 - 2 m capillary tube (2) 5 - 22 °C

RA 5062 013G5062 Remote temperature adjuster, 0 - 2 m capillary tube (3) 8 - 28 °C

RA 5065 013G5065 Remote temperature adjuster, 0 - 5 m capillary tube (3) 8 - 28 °C

RA 5068 013G5068 Remote temperature adjuster, 0 - 8 m capillary tube (3) 8 - 28 °C

Type Code no. Sensor (Max. sensor temperature 60°C) Temp. range

Xp = 2K

RA2000 thermostatic sensors (4) supplied in separate boxes

(1) Temperatures shown are for units with built-in

sensors which are subject to influence from

radiation and flow temperature. Without these

influences, max. temperature is 2 °C higher at de-

sign load condition.

(2) Remote sensors are supplied with all the

capillary tube coiled within the sensor. When

installing the sensor, only the length required

should be uncoiled.

(3) Remote temperature adjusters are supplied with

adapters for RA-valves. Adaptors for older valves

can be ordered separately:

RAVL-adaptor, code no. 013G5192

RAV-adaptor, code no. 013G5193

(4) Important note: Do not use any RA2000

sensors with RA-FR bi-directional valve bodies.

(1) These valve bodies are supplied with compression

fittings for copper tube to BS 864. When these

connections are removed, a standard BSP screwed

inlet BS 21 remains.

(2) Kvs-maximum indicates the water flow (Q) with valve

fully open.

(3) Remote sensors are recommended.

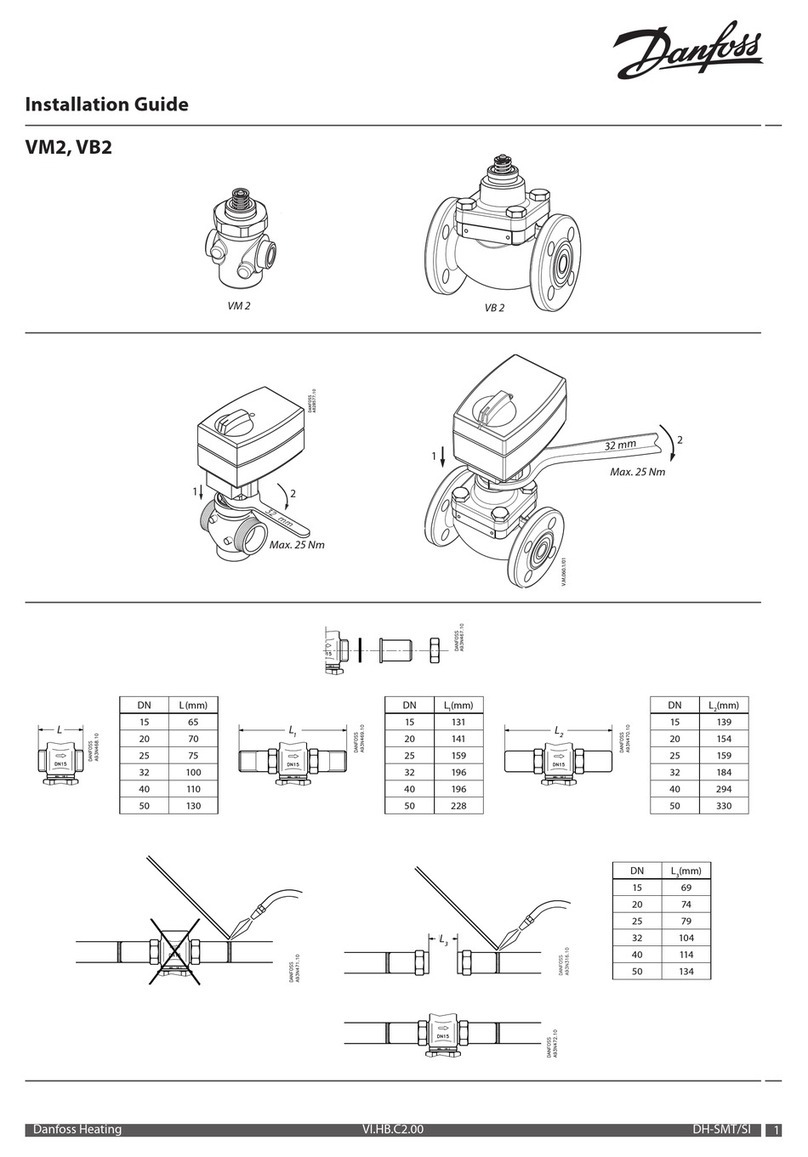

Working pressure = static + differential pressures. The

maximum differential pressure specified is the maximum

pressure at which the valves give satisfactory control. As with

any device which imposes a pressure drop in the system,

noise may occur under certain flow/pressure conditions. To

ensure quiet operation, maximum pressure drop should not

exceed 40 to 45 kPa. The differential pressure can be

reduced by the use of Danfoss differential pressure controls.

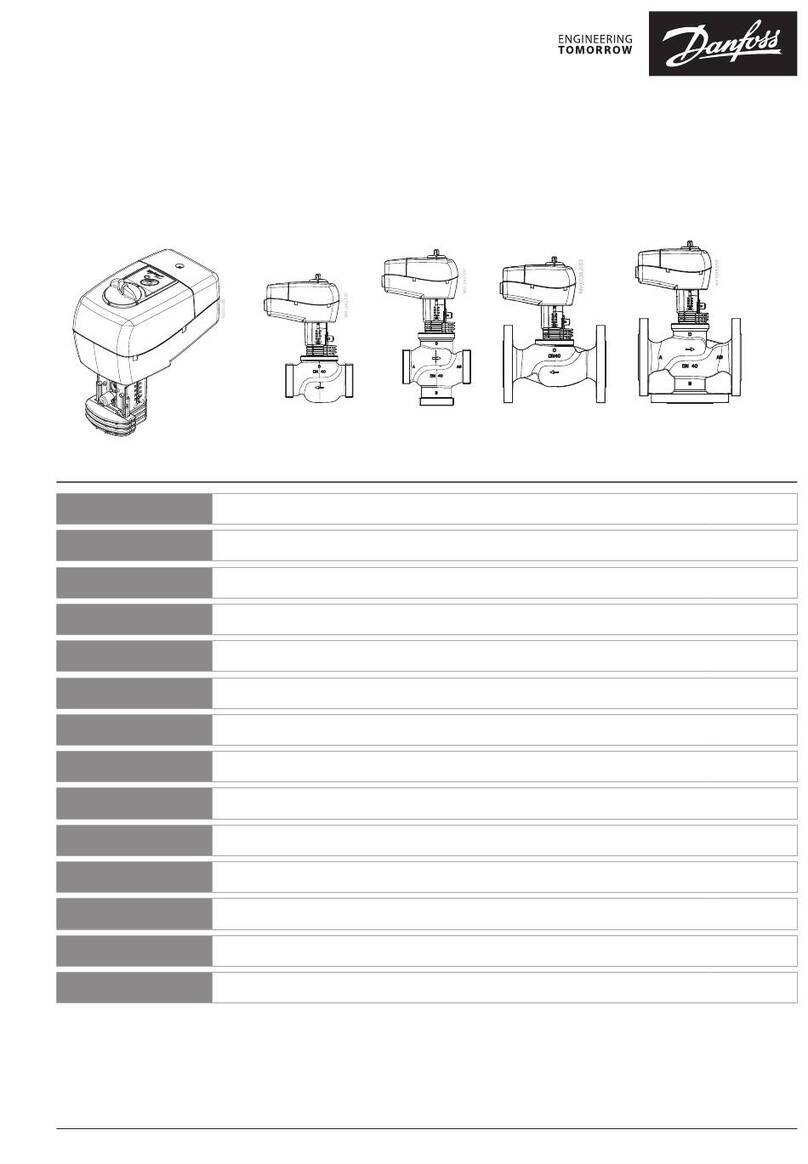

When using RA2000 remote temperature adjusters the kv-values stated in the table above must

be reduced by approximately 40% to take into account the different characteristics of these

sensors.

Valve bodies for one-pipe pumped or gravity systems, type RA-G

kv-value

(m3/h at 1 bar pressure drop)

P-band = K

013G3384

013G3386

013G3388