3.0 Safety notes

3.1 Safety Notes – general

The following instructions refer to the standard design of

substation. Special versions of substations are available on

request.

T is operating manual s ould be read carefully before installation

and start-up of t e substation. T e manufacturer accepts no

liability for damage or faults t at result from non-compliance wit

t e operating manual. Please read and follow all t e instructions

carefully to prevent accidents, injury and damage to property.

Assembly, start-up and maintenance work must be performed by

qualified and aut orized personnel only.

Please comply wit t e instructions issued by t e system

manufacturer or system operator.

Corrosion protection

All pipes and components are made of stainless steel and brass.

T e maximum c loride compounds of t e flow medium s ould not

be ig er t an 150 mg/l.

T e risk of equipment corrosion increases considerably if t e

recommended level of permissible c loride compounds is

exceeded.

Energy source

T e substation is designed for district eating as t e primary

source of energy. However, also ot er energy sources can be used

w ere t e operating conditions allow it and always are comparable

to district eating.

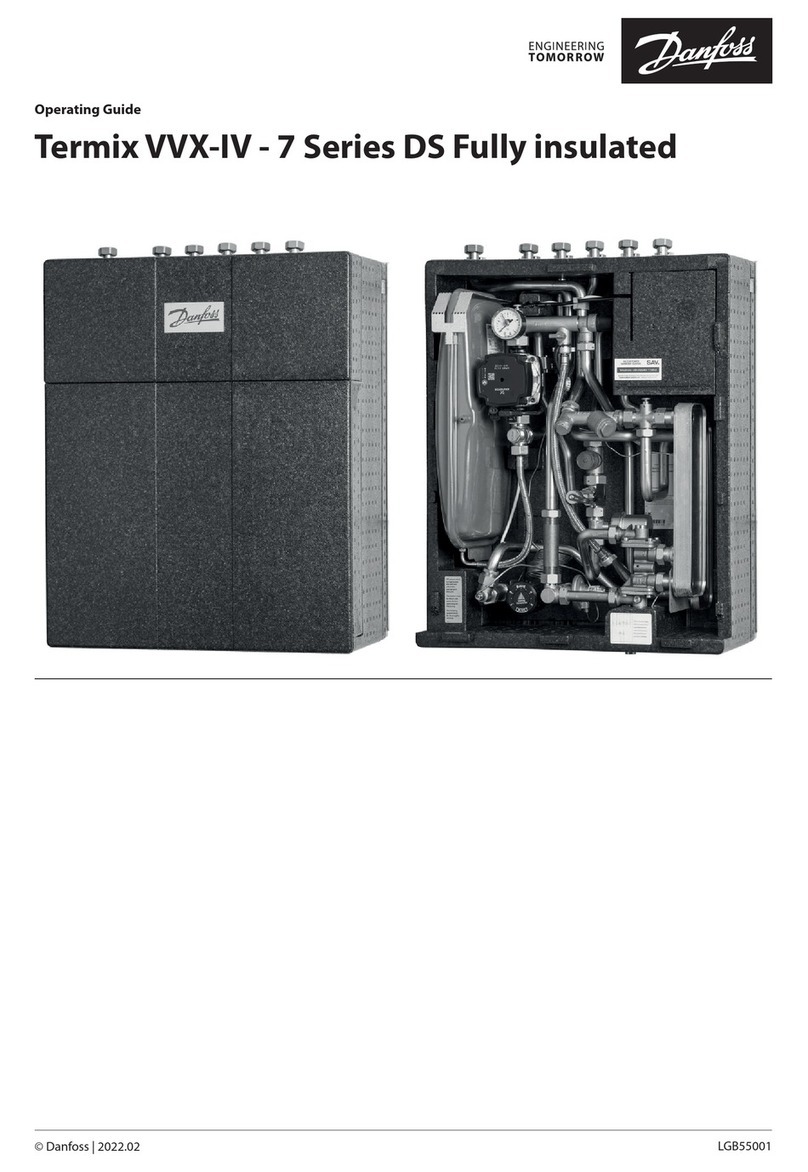

Application

T e substation is designed to be connected to t e ouse

installation in a frost-free room, w ere t e temperature does not

exceed 50 °C and t e umidity does not exceed 60%. Do not cover

or wall up t e substation or in any ot er way block t e entrance

to t e station.

Choice of material

C oice of materials always in compliance wit local legislation.

Safety valve(s)

We recommend mounting of safety valve(s), owever, always in

compliance wit local regulations.

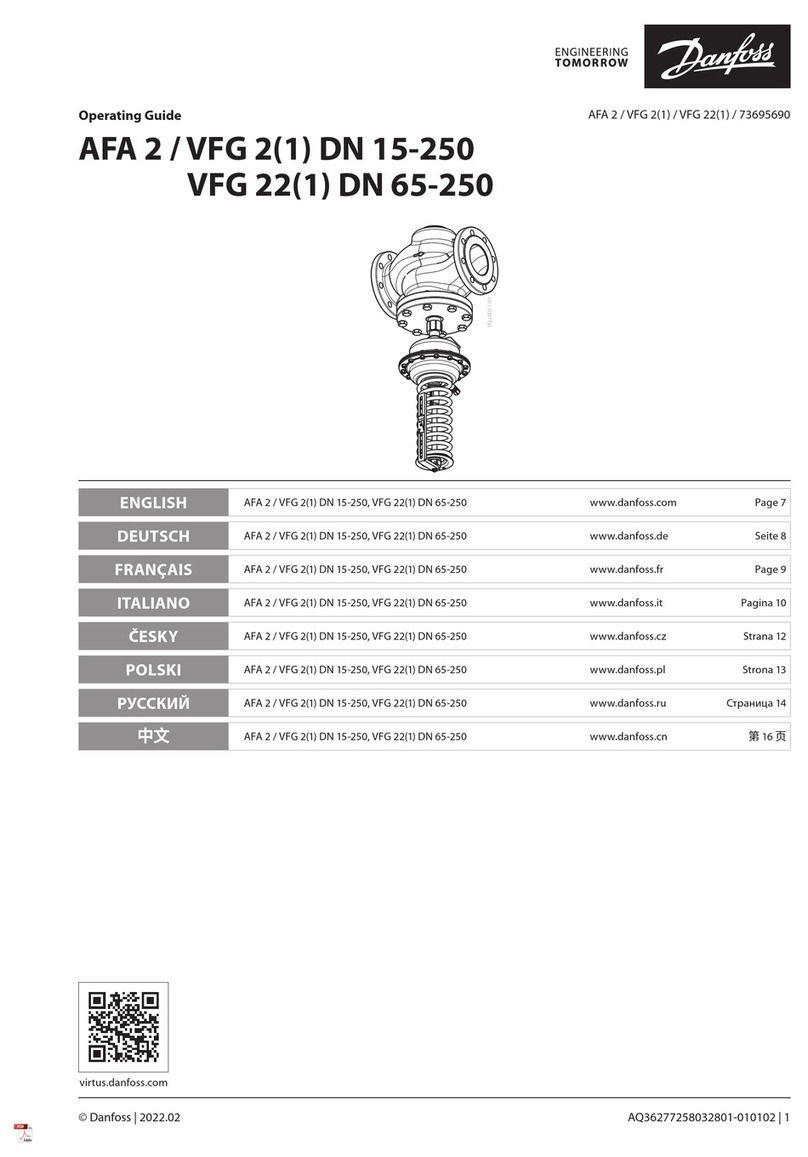

Connection

T e substation must be equipped wit features t at ensure t at

t e substation can be separated from all energy sources (also

power supply).

Emergency

In case of danger or accidents - fire, leaks or ot er dangerous

circumstances - interrupt all energy sources to t e station if

possible, and seek expert elp.

In case of discoloured or bad-smelling domestic ot water, close all

s ut-off valves on t e substation, inform t e operating personnel

and call for expert elp immediately.

REACH

All Danfoss A/S products fulfill t e requirements in REACH.

One of t e obligations in REACH is to inform customers about

presence of Candidate list substances if any, we ereby inform

you about one substance on t e candidate list: T e product

contains brass parts w ic contains lead (CAS no: 7439-92-1) in a

concentration above 0.1% w/w.

Storage

Any storage of t e substation w ic may be necessary prior to

installation s ould be in conditions w ic are dry and eated.

Authorized personnel only

Assembly, start-up and maintenance work must be performed by

qualified and aut orized personnel only.

Please observe instructions carefully

To avoid injury to persons and damage to t e device, it is absolutely

necessary to read and observe t ese instructions carefully.

Warning of high pressure and temperature

Be aware of t e installation’s permissible system pressure and

temperature.

T e maximum temperature of t e flow medium in t e substation is

120 °C.

T e maximum operating pressure of t e substation is 10 bar. PN 16

versions are available on enquiry.

T e risk of persons being injured and equipment damaged increases

considerably if t e recommended permissible operating parameters

are exceeded.

T e substation installation must be equipped wit safety valves,

owever, always in accordance wit local regulations.

Warning of hot surface

T e substation as got ot surfaces, w ic can cause skin burns.

Please be extremely cautious in close proximity to t e substation.

Power failure can result in t e motor valves being stuck in open

position. T e surfaces of t e substation can get ot, w ic can cause

skin burns. T e ball valves on district eating supply and return s ould

be closed.

Warning of transport damage

Before substation installation, please make sure t at t e substation

as not been damaged during transport.

IMPORTANT - Tightening of connections

Due to vibrations during transport all flange connections, screw joints

and electrical clamp and screw connections must be c ecked and

tig tened before water is added to t e system. After water as been

added to t e system and t e system as been put into operation,

re-tig ten ALLALL

ALL connections.

AQ082486478026en-010501/ LUK4044301 © Danfoss | 2023.10 | 3

Operating Guide Termix VVX-I with complete insulation