3Danfoss T-420 Crimp machine operator´s manual December 2022

CAUTION: The above pumps have the pressure relief valve

set at 4,000 - 4,200 PSI, Damage to the press may result and

warranty may be voided if higher pressures are used.

Specifications and equipment

T-420 Crimp machine and accessories

T-420 Crimp machine

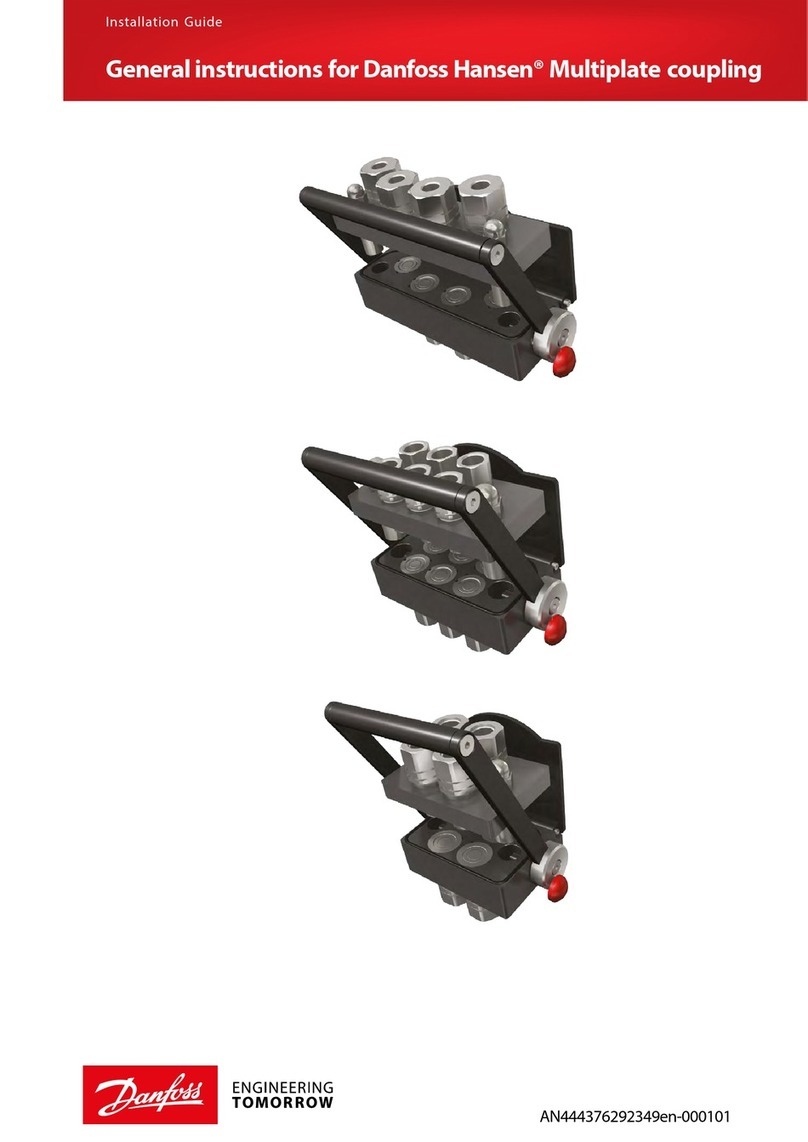

The T-420 is a versatile machine ideal for your shop,

factory, construction, and mine locations. Large

capacity combined with lever-activated crimping gives

you wide coverage and a quick and simple way to

make factory-quality hose assemblies. The T-420 press

offers crimping capabilities through 1-1/4”. I.D. four

spiral hose.

Weight 210 lbs.

Size 22”high, 20-1/2”deep, 10”wide

T-421U Electric pump (220 volt)

T-421UCSA CSA approved

Dimensions 7½” high, 10” wide, 22” long

Weight 75 lbs.

Pressure 4000-4200 psi

Reservoir capacity 6 Quarts

Outlet port size ¾-16 Straight thread

Motor 1HP, 3450 RPM, 220 volts, 60 cycle,

Single Phase

Hydraulic oil ISO 32 (SAE 10W)

Flow 2.5 GPM to 750 psi. 0.5 GPM above

4000 psi

*For low temperature applications automatic transmission fluid

can be substituted.

Note: It is recommended that the electric pump be used on a

15 amp. fused circuit. Pump wired for 220 volts, single phase.

T-421U-110 Electric pump (110 volt)

For dimensional data other than voltage information,

refer to T-421U see above.

T-421U-110CSA CSA approved

Note: It is recommended that the electric pump be used on an

individual 30 amp. fused circuit. Pump wired for 100 volts, single phase

Pump kit part numbers

ET420-007 110 volt electric pump kit with hose assembly

ET420-007CSA 110 volt electric pump kit with hose assembly,

CSA approved

ET420-008 220 volt electric pump kit with hose assembly

ET420-008CSA 220 volt electric pump kit with hose assembly,

CSA approved

Crimp machine part numbers

T-420-1 Base T-420 machine

T-420-1CSA Base T-420 machine, CSA approved

Crimp machine and tooling package part numbers

T-420-001 Contains T-420 crimper, 220v pump kit,

T420TP-1001 tooling package

T-420-002 Contains T-420 crimper, 110v pump kit,

T420TP-1001 tooling package

T-420-001CSA Contains T-420 crimper, 220v pump kit,

T420TP-1001 tooling package, CSA approved

T-420-002CSA Contains T-420 crimper, 110v pump kit,

T420TP-1001 tooling package, CSA approved

Crimp machine and tooling package part numbers

T420TP-1001 New placement tooling package

Capabilities: Braided -4 thru -20, Spiral -8 thru -20

T420TP-1002 Winner tooling package

Capabilities: Braided -4 thru -20, Spiral -6 thru -20

*both packages exclude -5 and -10 sizes