Datakom DK-40 User manual

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 1 -

http://www.datakom.com.tr

Tel: +90 216 466 84 60

Fax: +90 216 364 65 65

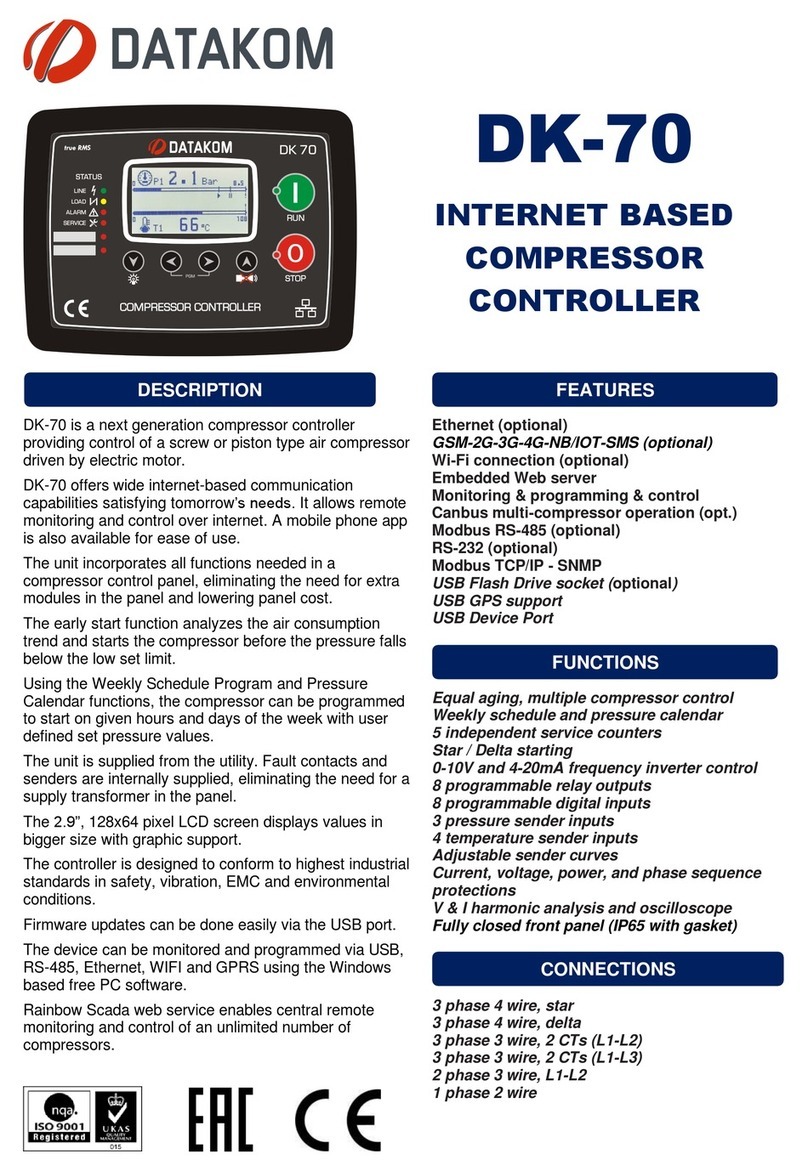

DK-40 COMPRESSOR CONTROLLER

INTRODUCTION

DK-40 is a state of the art unit for the control

of both screw and piston type compressors.

The unit integrates all functions needed in a

compressor system. Thus no extra units are

required in a compressor panel providing

cost reduction and simplicity.

The unit is directly powered from 230/400 volt

mains. It provides power supply for fault

switches and sensors. Thus external

transformer is not required in the panel.

The unit monitors mains phase voltages and

frequency. It features high/low voltage and

phase order protections.

The standard logic level serial port features

MODBUS communication. The unit allows

monitoring and programming through

computer.

FEATURES

Pressure driven automatic start and stop

Voltage Protection Relay function

Phase Order Protection Relay function

Mains phase voltages display

No need for external transformer

Star / Delta startup

Load solenoid control

1 programmable relay output

Optically isolated configurable digital inputs

2 pressure sensor inputs

2 temperature sensor inputs

Additional motor PTC input

Logic level serial port

MODBUS-RTU communication

Password protected front panel programming

Low panel depth, easy installation

Wide operating temperature range

Sealed front panel (IP54)

2 part connector system for easy installation

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 2 -

SAFETY NOTICE

Failure to follow below instructions will

result in death or serious injury

•

Electrical equipment should be installed only by qualified

specialist. No responsibility is assured by the

manufacturer or any of its subsidiaries for any

consequences resulting from the non-compliance to

these instructions.

•

Check the unit for cracks and damages due to

transportation. Do not install damaged equipment.

•Do not open the unit. There is no serviceable parts inside.

•

Fuses must be connected to the power supply and phase

voltage inputs, in close proximity of the unit.

•

Fuses must be of fast type (FF) with a maximum rating of

6A.

•

Disconnect all power before working on equipment.

•

When the unit is connected to the network do not touch

terminals.

•

Any electrical parameter applied to the device must be in

the range specified in the user manual.

•

Do not try to clean the device with solvent or the like.

Only clean with a dry cloth.

•

Verify correct terminal connections before applying

power.

•

Only for front panel mounting.

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 3 -

TABLE OF CONTENTS

Section

1. INSTALLATION

1.1. FRONT / REAR PANELS

1.2. MECHANICAL INSTALLATION

1.3. ELECTRICAL INSTALLATION

1.4. CONNECTION DIAGRAM

2. PUSHBUTTON FUNCTIONS

3. DISPLAY NAVIGATION

4. MODES OF OPERATION

5. ALARMS AND WARNINGS

6. OTHER FEATURES

6.1. RESETTING SERVICE COUNTERS

6.2. MODIFYING HOUR COUNTERS

6.3. SELECTION OF HOUR COUNTING METHOD

6.4. CONNECTION TOPOLOGIES

6.5. PREVENTING PRESSURE LOSS

6.6. ALARM HISTORY

7. INPUTS

8. RELAY OUTPUTS

9. PROGRAMMING

9.1. INTRODUCTION TO PROGRAMMING

9.2. PARAMETER LIST

10. MODBUS COMMUNICATIONS

10.1. DESCRIPTION

10.2. MODBUS REGISTER LIST

11. MULTIPLE CONTROLLER OPERATION

12. DECLARATION OF CONFORMITY

13. TECHNICAL SPECIFICATIONS

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 4 -

1. INSTALLATION

Before installation:

•Read the user manual carefully, determine the correct connection diagram.

•Remove all connectors and mounting brackets from the unit, then pass the unit through

the mounting opening.

•Put mounting brackets and tighten. Do not tighten too much, this can brake the enclosure.

•Make electrical connections with plugs removed from sockets, then place plugs to their

sockets.

•Note that the power supply terminal is separated from measurement terminals.

Below conditions may damage the device:

•Incorrect connections.

•Incorrect power supply voltage.

•Voltage at measuring terminals beyond specified range.

•Connecting or removing data terminals when the unit is powered-up.

•Overload or short circuit at relay outputs

•Voltage applied to digital inputs over specified range.

•High voltage applied to communication port.

Below conditions may cause abnormal operation:

•Power supply voltage below minimum acceptable level.

•Power supply frequency out of specified limits

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 5 -

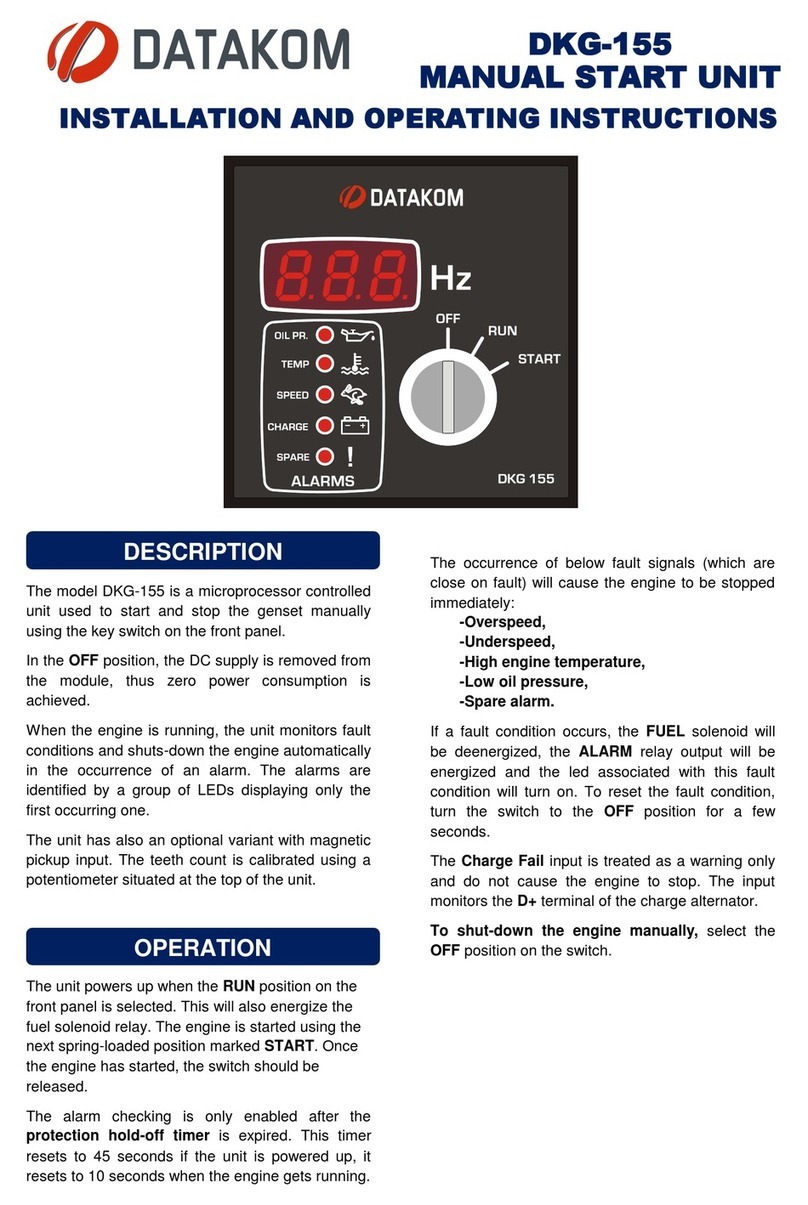

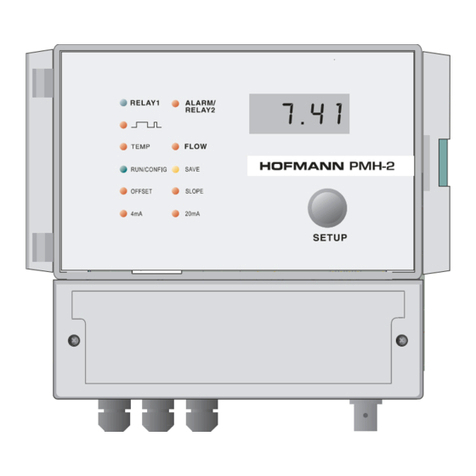

1.1 FRONT / REAR PANELS

1.2 MECHANICAL INSTALLATION

Panel Cutout Required Panel Depth

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 6 -

1.3 ELECTRICAL INSTALLATION

Do not install the unit close to high electromagnetic noise

emitting devices like contactors, high current busbars,

switchmode power supplies and the like.

Although the unit is protected against electromagnetic disturbance, excessive disturbance

can affect the operation, measurement precision and data communication quality.

•ALWAYS remove plug connectors when inserting wires with a screwdriver.

•Fuses must be connected to the power supply and phase voltage inputs, in close

proximity of the unit.

•Fuses must be of fast type (FF) with a maximum rating of 6A.

•Use cables of appropriate temperature range.

•Use adequate cable section, at least 0.75mm

2

(AWG18).

•Follow national rules for electrical installation.

•Use only the appropriate cable and connector for serial port connection.

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 7 -

1.4 CONNECTION DIAGRAM

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 8 -

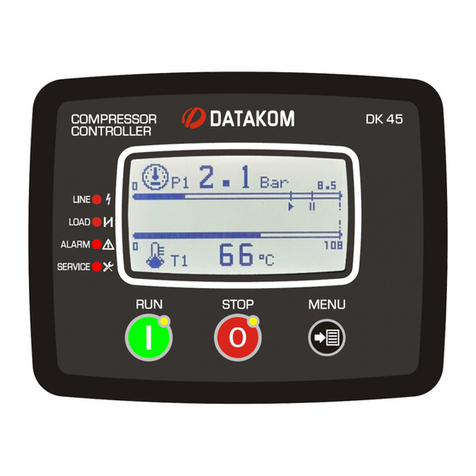

2. PUSHBUTTON FUNCTIONS

Programming and measurement displays are visualized using below buttons:

BUTTON DESCRIPTION

FUNCTION

MENU

Displays next parameter.

Resets faults.

Saves adjusted value.

RUN

Run the compressor and reset existing

alarms.

Increase value.

STOP

Stop the compressor and reset existing

alarms.

Decrease value.

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 9 -

3. DISPLAY NAVIGATION

Usually the upper display shows the pressure-1 value or the pressure switch-1 position.

The lower display shows the temperature-1.

Other values are scrolled by pressing the MENU

button. For better clarity, the upper

display will show the parameter name and the lower display will show the parameter value.

Some parameters are longer than 1 display. For these parameters, when MENU

button

is presssed the parameter name apeears on the upper display. When MENU button is

released, the parameter value is shown on both displays.

Display of some parameters are selectable with program parameters and

may differ following compressor manufacturers.

In the occurrence of a fault condition, the fault code will appear on the

upper display.

Below is a list of messages shown on the upper display in normal operation,

programming and alarm display modes:

MESSA

GE DESCRIPTION MODE

bar

barbar

bar

set

setset

set

Start pressure and stop pressure set

values Display

FrQ

FrQFrQ

FrQ

Mains frequency Display

L12

L12L12

L12

L1-L2 phase-to-phase voltage Display

L23

L23L23

L23

L2-L3 phase-to-phase voltage Display

L31

L31L31

L31

L3-L1 phase-to-phase voltage Display

SH

SHSH

SHA

AA

A

Hours remaining to service A Display / Program / Alarm

SHB

SHBSHB

SHB

Hours remaining to service B Display / Program / Alarm

SHC

SHCSHC

SHC

Hours remaining to service C Display / Program / Alarm

SHD

SHDSHD

SHD

Hours remaining to service D Display / Program / Alarm

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 10 -

MESSA

GE DESCRIPTION MODE

SHE

SHESHE

SHE

Hours remaining to service E Display / Program / Alarm

C-H

C-HC-H

C-H

Total compressor hours

(ON_LOAD+OFF_LOAD+STOP) Display

R-H

R-HR-H

R-H

Total Run Hours

(ON_LOAD+OFF_LOAD) Display

L-H

L-HL-H

L-H

Total load time (load contactor active) Display

o/o

o/oo/o

o/o

Load hours / Run hours percentage Display

E-t

E-tE-t

E-t

Motor PTC value or switch position Display

t-

t-t-

t-2

22

2

Temperature-2 value or switch position Display

d-p

d-pd-p

d-p

Differential Pressure Display

n--

n--n--

n--

Remaining starts for the last hour Display

rEL

rELrEL

rEL

Software version Display

Ah1

Ah1Ah1

Ah1

Alarm history 1 Display

n-C

n-Cn-C

n-C

Switch closed Display

N-O

N-ON-O

N-O

Switch open Display

SEP

SEPSEP

SEP

Waiting for separator filter pressure drop Display

S P

S PS P

S P

Remote Stop mode Display

RUN

RUNRUN

RUN

Remote Start mode Display

aL1

aL1aL1

aL1

Alarm code 01 Display

a99

a99a99

a99

Alarm code 99 Display

p99

p99p99

p99

Program parameter 99 Program

usr

usrusr

usr

Enter password Program

seL

seLseL

seL

Select parameter Program

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 11 -

4. MODES OF OPERATION

Selecting the operating mode:

At power-up, the unit will turn all lights on for 3 seconds in order to allow lamp check. Then

it goes in the STOP mode and the stop led turns on.

The compressor may be run through Remote Start signal (upper display shows

rUn

rUnrUn

rUn

for 5

seconds) or by pressing the RUN

button.

If P28 Safety Timer has not elapsed, the run led will flash until expiration of the timer. Then

if the pressure is below the limit set by P05 Start Pressure, then the compressor will run.

In the occurrence of an alarm the compressor stops

immediately and the upper display shows the alarm code.

A comprehensive list of alarm codes is given in chapter 5.

The compressor may be stopped with Remote Stop signal (upper display shows

StP

StPStP

StP

for 5

seconds) or the STOP button.

Stop procedure:

STOP led starts flashing.

If the compressor is loaded, then the LOAD relay will release and the compressor

continues to run during P28 Safety Timer or P26 Unload Timer (whichever is longer).

At this step, operation may be resumed by pressing the RUN

button. If STOP

button is pressed during unloaded operation, then the compressor stops immediately.

The stop led flashes until the compressor comes to complete stop.

When STOP

button is pressed, if the compressor is

running unloaded, then it will continue to run until

expiration of P26 Unload Timer.

The compressor may be immediately stopped by

pressing again the STOP

button.

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 12 -

Start procedure:

If mains phase voltages and frequency are between preset limits and the phase order is

correct, then the POWER led will turn on. The compressor may run only when the power

led is on. Otherwise it cannot run.

The Run mode of operation is selected by pressing the RUN button or by sending

REMOTE START/STOP signal (if enabled). At this position, when the pressure falls below

P05 Start Pressure (or pressure switch closes) the unit decides to run the compressor.

Befor running the compressor the STAR relay output becomes active. After P15 Delay

between Relays Timer LINE relay will be activated. Thus the motor starts in star mode.

After P23 Star Timer the STAR relay opens and after P24 Star/Delta Transition Timer the

DELTA relay operates.

After P25 Timer before Loading the LOAD relay operates and the compressor starts

producing compressed air.

Unloading and reloading:

When the pressure reaches P04 Stop Pressure (or pressure switch opens) then the LOAD

relay opens and the compressor runs unloaded during P26 Unload Timer. If the pressure

falls below P05 Start Pressure before the expiration of the timer, then the LOAD relay

energizes again.

Stopping and restarting:

If the pressure stays over the P05 Start Pressure limit (or pressure switch opened) during

P26 Unload Timer, then the DELTA relay will release. After P15 Delay between Relays

timer, the LINE relay releases.

In this situation, the RUN led starts flashing.

The maximum number of starts that the compressor may perform in one hour is adjusted

with P37 Maximum Starts per Hour parameter.

If the maximum start count is reached, then the compressor stopping is disabled and it will

continue to run unloaded until the end of 1 hour period.

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 13 -

5. ALARMS AND WARNINGS

Abnormal situations in the compressor are evaluated under 3 different categories as

ALARMS, WARNINGS and SERVICE REQUESTS.

Warnings are lowest level fault conditions and generate only visual warning, not affecting

the compressor operation.

Alarms are highest level fault conditions and cause the compressor to stop immediately,

the alarm relay to become active (if enabled by programming) and visual warning to occur.

If any fault condition occurs, the fault code will appear on the upper display and the related

fault category led turns on. (WARNING, ALARM or SERVICE)

Alarms and warnings may be reset by pressing the MENU button. The EMERGENCY

STOP alarm cannot be reset by pressing buttons, the alarm signal must be removed.

Service warnings may affect the compressor operation

depending on the amount exceeding the service period.

TIME REMAINING TO

SERVICE REACTION

> 100 hours No warning given.

100hours Service warning is given and SERVICE led turns on. The

compressor continues normal operation.

0 hour

The compressor stops. Service warning is given and

SERVICE led turns on. The compressor resumes normal

operation when RUN button is pressed.

-100 hours

The compressor stops. Service warning is given and

SERVICE led turns on. The compressor resumes normal

operation when RUN button is pressed.

-120 to -200 hours,

every 20 hours

The compressor stops. Service warning is given and

SERVICE led turns on. The compressor resumes normal

operation when RUN button is pressed.

-210 to -300 hours,

every 10 hours

The compressor stops. Service warning is given and

SERVICE led turns on. The compressor resumes normal

operation when RUN button is pressed.

-300 hours

The compressor stops. Service warning is given and

SERVICE led turns on. The compressor will not operate

again unless the service counter is reset.

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 14 -

FAULT CODES LIST

SYMBOL

CODE

DESCRIPTION TİP

AL1 01 Security Pressure Switch Opened ALARM

AL2 02 High Pressure ALARM

AL3 03 Pressure Sensor Fail ALARM

AL4 04 High Temperature ALARM

AL5 05 High Temperature WARNING

AL6 06 Temperature Sensor Fail ALARM

AL7 07 Low Temperature ALARM

AL8 08 Fan Motor High Temperature ALARM

AL9 09 Motor PTC High Temperature ALARM

A10 10 Voltage Unbalance ALARM

A11 11 High Voltage ALARM

A12 12 Low Voltage ALARM

A13 13 High Frequency ALARM

A14 14 Low Frequency ALARM

A15 15 Phase Squence Fail ALARM

A16 16 Air Filter Clogged WARNING

A17 17 Maximum starts per hour exceeded WARNING

A18 18 Emergency Stop ALARM

A19 19 Internal Warning WARNING

A20 20 Pressure Difference ALARM

A21 21 High Pressure-2 ALARM

A22 22 Pressure-2 Sensor Fail ALARM

A23 23 High Temperature-2 / Delta (tS2-tS1) ALARM

A24 24 Temperature-2 Sensor Fail ALARM

A25 25 Low Temperature-2 ALARM

A26 26 Air In Separator WARNING

A27 27 Delta Temperature-2 Warning WARNING

A28 28 Main Motor thermal ALARM

A29 29 Low Pressure-2 ALARM

SHA 100 Service A Period Elapsed SERVICE

SHb 101 Service B Period Elapsed SERVICE

SHC 102 Service C Period Elapsed SERVICE

SHD 103 Service D Period Elapsed SERVICE

SHE 104 Service E Period Elapsed SERVICE

Stp 200 Remote Stop -

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 15 -

6. OTHER FEATURES

6.1. RESETTING SERVICE COUNTERS

Service counters can only be reset when the compresssor

is in STOP mode.

In order to reset service counters:

- Hold MENU and RUN buttons pressed for 3 seconds. If the high level

password is not entered in the last 90 minutes, the unit will ask the password.

- Enter the password.

- The upper display will show

sH

sHsH

sHA

AA

A

hours remaining for SERVICE A message.

- Press again the MENU button. The hours remaining for SERVICE A will appear

flashing on the display.

- In order to reset the hours remaining for SERVICE A, hold pressed MENU button

for 3 seconds.

- The upper display will show the next service counter which is

SHB

SHBSHB

SHB

hours remaining for

SERVICE B message.

- Press again the MENU button. The hours remaining for SERVICE B will appear

flashing on the display.

- In order to reset the hours remaining for SERVICE B, hold pressed MENU button

for 3 seconds.

- By pressing the MENU button again, below counters can be scrolled and reset:

SHC

SHCSHC

SHC

: hours remaining for SERVICE C

SHD

SHDSHD

SHD

: hours remaining for SERVICE D

SHE

SHESHE

SHE

: hours remaining for SERVICE E

After the last counter, the display will return to pressure-

temperature display mode.

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 16 -

6.2. MODIFYING HOUR COUNTERS

The unit holds 3 different run hour counters:

MESSAGE

DESCRIPTION

C-H

C-HC-H

C-H

Total compressor hours (ON_LOAD+OFF_LOAD+STOP)

This counter increments while the RUN led is on.

R-H

R-HR-H

R-H

Total motor run hours

(ON_LOAD+OFF_LOAD)

This counter increments while the motor runs.

L-H

L-HL-H

L-H

Total load time (load contactor active)

This counter increments while LOAD led is on.

Hour counters can only be modified while the compresor

is in STOP mode.

In order to modify hour counters:

- Hold pressed together MENU , RUN and STOP buttons for 3 seconds. If

the high level password is not entered in the last 90 minutes, the unit will ask password

(USR

USRUSR

USR).

- Enter password.

- The upper display will show

C-H

C-HC-H

C-H

message.

- Adjust required hour counter value with RUN and STOP buttons.

- Press MENU button for 3 seconds, the display wil show SEt message and the

counter will be adjusted to the new value. If MENU button is pressed for short

duration, then the value will not be modified and the next hour counter will be displayed.

Same steps are repeated for further modification.

After modifications, the display will return to pressure-

temperature display mode.

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 17 -

6.3. SELECTION OF HOUR COUNTING METHOD

The unit offers the possibility of incrementing hour counters with a variable coefficient,

depending on air end temperature.

The use of variable coefficient is selected with P89 Variable Hour counting coefficient. If

this parameter is 0, all service and hour counters will increment with a fixed coefficient of

1.00.

If Variable Hour Counting is activated:

Running on load:

below 90 °C, coefficient = 1.00

between 90 and 95 °C, coefficient = 1.50

between 95 and 100 °C, coefficient = 2.00

above 100 °C, coefficient = 3.00

Running off load

below 90 °C, coefficient = 0.50

between 90 and 95 °C, coefficient = 0.75

between 95 and 100 °C, coefficient = 1.00

above 100 °C, coefficient = 1.50

These coefficients apply to both service and compressor

hour counters.

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 18 -

6.4. CONNECTION TOPOLOGIES

The unit supports various connection topologies. The topology is selected through

parameter P48.

Different topologies and terminal connections are as below:

P48 = 3

P48 = 1

P48 = 2

P48 = 3

The power supply and measuring terminals

of the unit are isolated. In order to enable

above topology, the unit must be specially

manufactured.

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 19 -

6.5. PREVENTING PRESSURE LOSS

If the pressure stays above the P05 Start Pressure, during P26 Unload Timer then

the unit will stop the motor. If the pressure falls below P05 Start Pressure then the motor

will run again.

Before the compressor is loaded, a timer equal to P23+P24+P25+P15x3 will be

elapsed.

During this period, depending on the air consumption, the pressure may fall below

P05 Start Pressure.

In most applications, it is required that the pressure never falls below the P05 Start

Pressure limit.

In order to prevent this unwanted situation, the unit offers 3 different operating

modes selected through program parameter P45. The unit calculates dynamically the

restart pressure (Pi)

P45 = 0 No special care taken. Pi = P05.

P45 = 1 When the compressor is loaded, if the pressure is below P05 Start Pressure,

then the Restart Pressure (Pi) is incremented by 0.1 bar.

When the compressor is loaded, if the pressure is above P05 Start Pressure, then the

Restart Pressure (Pi) is decremented by 0.1 bar. Thus the unit tries to load at exactly P05

Start Pressure.

P45 = 2

When the compressor reaches P04 Stop Pressure, the unit measures the air

consumption during 8 seconds, then calculates the Restart Pressure (Pi) again.

At the end of P26 Unload Timer, if the pressure is above

P05 Start Pressure and below Pi Restart Pressure, then the

motor will continue to run unloaded.

DK-40 USER MANUAL V2.6 (02.08.2011)

K13D01-E - 20 -

6.6. ALARM HISTORY

The unit keeps the list of 9 most recent alarm records.

A new occurring alarm will appear at the top of the list.

The alarm list may be visualized on the screen or read through Modbus.

The alarm list is kept in a non-volatile memory and is not affected by power failures.

The alarm will be added to the list only if it is different from the previous alarm or the

motor has run at least 6 minutes after its previous occurrence.

In order to visualize the latest alarm in the history press MENU button until

Ah

AhAh

Ah1

11

1

(alarm history 1) comes to the display.

To visualize previous alarms use RUN and STOP pushbuttons.

When the alarm history is scrolled the STOP

button

is always active and stops the compressor. However the

RUN

button is not active and does not run the

compressor. To scroll the alarm history when the

compressor is running please use only the RUN

button.

Table of contents

Other Datakom Controllers manuals

Datakom

Datakom DK-70 User manual

Datakom

Datakom DKG-225 User manual

Datakom

Datakom D-500 MK2 User manual

Datakom

Datakom DKG-119 User manual

Datakom

Datakom DKG-325 User manual

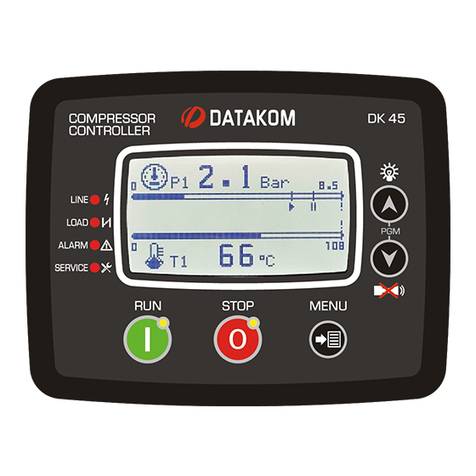

Datakom

Datakom DK-45 MK2 User manual

Datakom

Datakom D-100 MK2 User manual

Datakom

Datakom DKG-307 User manual

Datakom

Datakom DKG-109 User manual

Datakom

Datakom D-300 MK2 User manual

Datakom

Datakom DKG-209 User manual

Datakom

Datakom DKG-114 Manual

Datakom

Datakom D-500 MK3 User manual

Datakom

Datakom DKG-225 User manual

Datakom

Datakom D-200 MK2 User manual

Datakom

Datakom DKG-116 User manual

Datakom

Datakom DKG-190 User manual

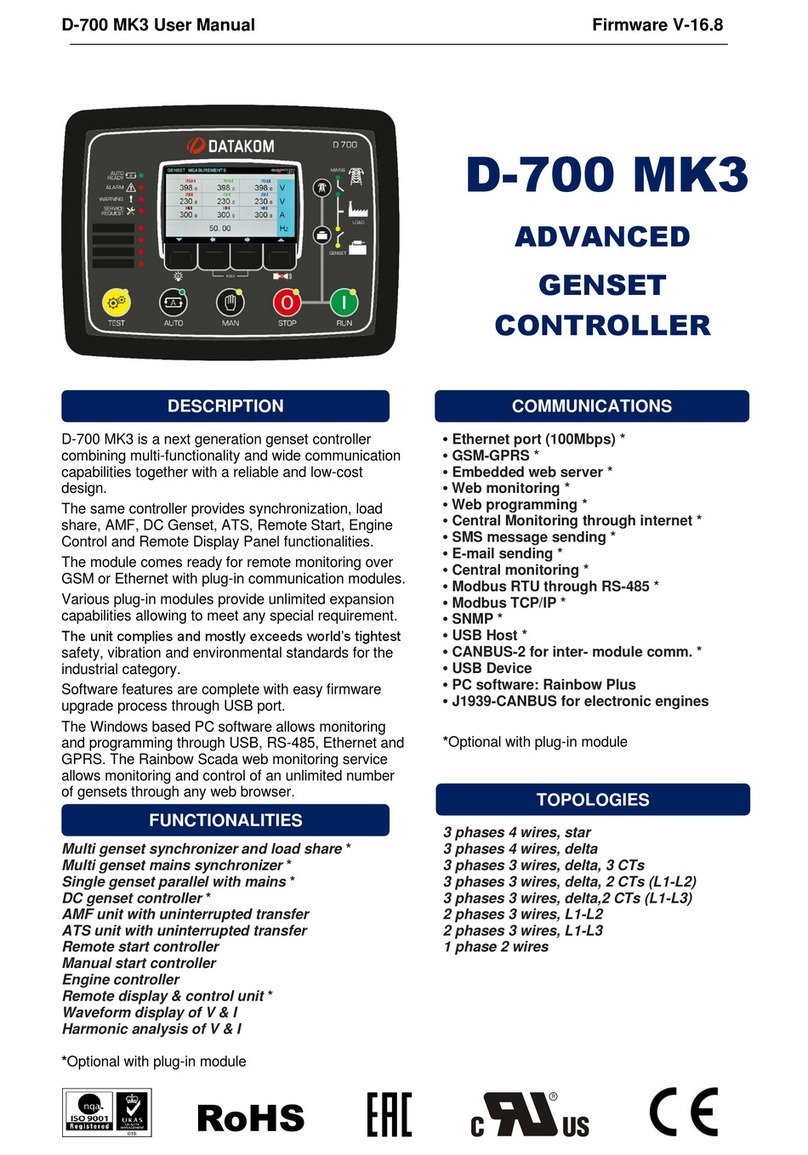

Datakom

Datakom D-700 MK3 User manual

Datakom

Datakom DK-45 User manual

Datakom

Datakom D-500 MK3 User manual