Datakom DKM-046 User manual

DKM-046 User Manual V-2.0

1

DKM-046

TEMPERATURE &

HUMIDITY

CONTROLLER

DKM-046 is a DIN Rail mounted precision

unit capable of measuring temperature and

humidity in three different locations, provide

protection with 4 relay outputs and serve data

to remote monitoring and control systems.

Sensing modules are separated from the

base unit, connecting with cables. One

sensor comes together with the base unit.

Additional sensors may be purchased

separately.

Two different auxiliary supply versions are

available. The AC model accepts 85 to

305VAC and the DC model accepts 19 to

150VDC.

The module provides data to automation and

BMS systems through its isolated RS-485

Modbus port.

The programming is performed through

pushbuttons on the unit.

Sensor modules incorporate ST-HTS221

polymer dielectric planar capacitive sensors.

Relay functions are programmable with

functions selected from a list.

● Supports 3 temperature & humidity sensors

● AC and DC auxiliary supply versions

● Programmable relay outputs: 4

● Temperature and relative humidity control

● Independent cooling / heating / humidification

/ dehumidification functions for each sensor

● Temperature measuring range: -40...+80°C

● Humidity measuring range: 0% ... 100%

● Humidity accuracy: ±3.5% , 20 ... +80%

● Temperature accuracy: ± 1°C, 0 ... +60 °C

● Factory calibrated sensors

● Front panel programming

● Supports Modbus programming

●DIN rail mounted, easy installation

● Operating temp range: -20°C ... +70 °C

● Two part connection system

DESCRIPTION

FEATURES

DKM-046 User Manual V-1.0

2

Electrical equipment should be installed only by qualified

specialist. No responsibility is assured by the manufacturer or

any of its subsidiaries for any consequences resulting from the

non-compliance to these instructions.

Check the unit for cracks and damages due to transportation.

Do not install damaged equipment.

Do not open the unit. There are no serviceable parts inside.

Fuses must be connected to the power supply inputs, in close

proximity of the unit.

Fuses must be of fast type with a maximum rating of 6A.

Disconnect all power before working on equipment.

When the unit is connected to the network do not touch

terminals.

Any electrical parameter applied to the device must be in the

range specified in the user manual. Although the unit is

designed with a wide safety margin, over-range parameters may

reduce lifetime, alter operational precision or even damage the

unit.

Do not try to clean the device with solvent or the like. Only

clean with a dump cloth.

Verify correct terminal connections before applying power.

SAFETY NOTICE

Failure to follow below instructions will result in

death or serious injury

DKM-046 User Manual V-1.0

3

Section

1. INSTALLATION INSTRUCTIONS

1.1 FRONT PANEL VIEW

1.2 ELECTRICAL INSTALLATION

1.3 INSTALLATION DIAGRAM

2. PUSHBUTTON FUNCTIONS

3. SCREEN NAVIGATION

3.1 LAMP TEST

4. PROGRAMMING

4.1 ENTERING THE PROGRAMMING MODE

4.2 RESETTING ALARMS

4.3 SELECTING THE DEFAULT SCREEN

4.4 ADJUSTING TEMPERATURE LOW AND HIGH LIMITS

4.5 ADJUSTING RELATIVE HUMIDITY LOW AND HIGH LIMITS

4.6 ENABLING / DISABLING SENSORS

4.7 CONFIGURING RELAY OUTPUTS

4.8 ALARM DELAY

4.9 ALARM LOACK

4.10 MODBUS PARAMETERS

4.11 ADJUSTING TEMPERATURE OFFSET VALUES

4.12 ADJUSTING RELATIVE HUMIDITY OFFSET VALUES

4.13 ADJUSTING TEMPERATURE DIFFERENCE ALARM LIMITS

4.14 ADJUSTING COOLING START TEMPERATURE UPPER LIMITS

4.15 ADJUSTING HEATING START TEMPERATURE LOW LIMITS

4.16 ADJUSTING TEMPERATURE HYSTERESIS FOR COOLING AND

HEATING

4.17 ADJUSTING DE-HUMIDIFICATION START HUMIDITY

4.18 ADJUSTING HUMIDIFICATION START HUMIDITY

4.19 ADJUSTING HUMIDITY HYSTERESIS FOR HUMIDIFICATION

AND DE-HUMIDIFICATION

4.20 DISPLAYING THE FIRMWARE VERSION

4.21 RETURN TO FACTORY SETTINGS

TABLE OF CONTENTS

DKM-046 User Manual V-1.0

4

5. MODBUS COMMUNICATIONS

5.1. DESCRIPTION

5.2. COMMANDS

5.3. PROGRAM PARAMETERS

5.4. MEASUREMENTS AND CONTROLLER RECORDS

6. TECHNICAL SPECIFICATIONS

DKM-046 User Manual V-1.0

5

Before installation:

Read the user manual carefully, determine the correct connection diagram.

Install the unit to the DIN rail.

Make electrical connections with plugs removed from sockets, then place plugs to their sockets.

Be sure that adequate cooling is provided.

Be sure that the temperature of the environment will not exceed the maximum operating temperature in any

case.

Be sure that the unit is not subject to water spill.

Below conditions may damage the device:

Incorrect connections.

Incorrect power supply voltage.

Connecting or removing data terminals when the unit is powered-up.

Connecting or removing sensors when the unit is powered-up.

High voltage applied to communication ports.

Overload or short-circuit at relay outputs.

Excessive vibration, direct installation on vibrating parts.

Below conditions may cause abnormal operation:

Power supply voltage below minimum acceptable level.

Power supply frequency outside acceptable limits.

1. INSTALLATION INSTRUCTIONS

DKM-046 User Manual V-1.0

6

1.1 FRONT PANEL VIEW

DKM-046 User Manual V-1.0

7

Although the unit is protected against electromagnetic disturbance, excessive disturbance

can affect the operation, measurement precision and data communication quality.

ALWAYS remove plug connectors when inserting wires with a screwdriver.

Fuses must be connected to the power supply inputs, in close proximity of the unit.

Fuses must be of fast type with a maximum rating of 6A.

Use cables of appropriate temperature range.

Use adequate cable section, at least 0.75mm2 (AWG18).

Follow national rules for electrical installation.

Do not install the unit close to high electromagnetic

noise emitting devices like contactors, high current

busbars, switchmode power supplies and the like.

1.2 ELECTRICAL INSTALLATION

DKM-046 User Manual V-1.0

8

1.3 INSTALLATION DIAGRAM

DKM-046 User Manual V-1.0

9

BUTTON

FUNCTION

PROGRAMMING: Select related parameter / save adjusted

parameter.

Switch to the upper screen.

PROGRAMMING: increase value

Switch to the lower screen.

PROGRAMMING: decrease value

HELD PRESSED TOGETHER FOR 2 SECONDS:

Selects programming mode. If held pressed in programming

mode, then returns to normal mode.

NO KEY PRESSED DURING 1 MINUTE:

Returns to the main display screen.

2. PUSHBUTTON FUNCTIONS

DKM-046 User Manual V-1.0

10

Buttons allow navigation between measurement values. (Temp_1, Humidity_1,

Temp_2, Humidity_2, Temp_3, Humidity_3, Alarms)

Leds related to the currently displayed values will turn on, other leds will turn off.

Temperature display: Temperature is displayed with 0.1 °C accuracy. The related Modbus

register has 0.01 °C accuracy.

Humidity display: The relative humidity is displayed with 1% accuracy. The related

Modbus register has 0.01% accuracy.

HELD PRESSED FOR 2 SECONDS:

Enters lamp test mode. When released returns to

normal operating mode.

3.1 LAMP TEST

3. SCREEN NAVIGATION

DKM-046 User Manual V-1.0

11

In order to offer the maximum flexibility to the customer, the module has several

programmable parameters.

Device configurations

Default screen configuration

Measurement configurations

Alarm reset

Alarm high/low limit adjustments

Input/Output Configurations

Relay configuration

Alarm delays

Modbus configuration

Unit Calibration

Modbus configuration

Return to factory settings

In order to enable the programming menu,

hold both MENU buttons pressed for 2 seconds.

In order to exit programming menu,

hold both MENU buttons pressed for 2 seconds.

If no button is pressed during 1 minute, then the unit will

automatically close the programming mode.

Parameters may be scrolled with these buttons.

When SET button is pressed:

The parameter value is displayed

The value on the screen is recorded and the next

parameter is displayed.

Parameter values are modified with UP and DOWN Menu

buttons. If the button is held pressed, the the value will change

with larger steps.

After adjusting the parameter value this button saves the value

on the screen and switched to the next parameter.

4. PROGRAMMING

4.1 ENTERING THE PROGRAMMING MODE

DKM-046 User Manual V-1.0

12

Parameter value:

0: No operation

1: Reset alarms

Setting this parameter to 1 causes alarms to be reset.

The parameter value is not saved and always reads 0.

The description of alarm codes visible on the screen are below:

Alarm Code

Description

AL1

Sensor-1 low temperature

AL2

Sensor-1 high temperature

AL3

Sensor-1 low relative humidity

AL4

Sensor-1 high relative humidity

AL5

Sensor-2 low temperature

AL6

Sensor-2 high temperature

AL7

Sensor-2 low relative humidity

AL8

Sensor-2 high relative humidity

AL 9

Sensor-3 low temperature

A10

Sensor-3 high temperature

A11

Sensor-3 low relative humidity

A12

Sensor-3 high relative humidity

A13

T1-T2 or T2-T1 temperature difference alarm

A14

T2-T3 or T3-T2 temperature difference alarm

A15

T3-T1 or T1-T3 temperature difference alarm

When an alarm occurs, the display switches automatically to alarm display mode. If any key

is pressed then it resumes normal operation.

This parameter selects the screen menu where the unit returns

when no pushbutton is pressed during 1 minutes.

Param.

değeri

Ekran

0

Auto-scroll screens

1

Temperature_1 measurement

2

Humidity_1 measurement

3

Temperature_2 measurement

4

Humidity_2 measurement

5

Temperature_3 measurement

6

Humidity_3 measurement

4.3 SELECTING THE DEFAULT SCREEN

4.2 RESETTING ALARMS

DKM-046 User Manual V-1.0

13

These parameters adjust the low temperature alarm limit for the

related sensor.

Adjustment range is between -20°C and +80°C.

If the parameter is set to -20°C then low temperature alarm is

not monitored for the related sensor.

As the default factory set, the alarm is passive.

These parameters adjust the high temperature alarm limit for

the related sensor.

Adjustment range is between -20°C and +80°C.

If the parameter is set to +80°C then high temperature alarm is

not monitored for the related sensor.

As the default factory set, the alarm is passive.

These parameters adjust the low relative humidity alarm limit for

the related sensor.

Adjustment range is between 1% and 99%.

If the parameter is set to 1% then low relative humudity alarm is

not monitored for the related sensor.

As the default factory set, the alarm is passive.

These parameters adjust the high relative humidity alarm limit

for the related sensor.

Adjustment range is between 1% and 99%.

If the parameter is set to 99% then high relative humudity alarm

is not monitored for the related sensor.

As the default factory set, the alarm is passive.

4.5 ADJUSTING RELATIVE HUMIDITY LOW AND HIGH LIMITS

4.4 ADJUSTING TEMPERATURE LOW AND HIGH LIMITS

DKM-046 User Manual V-1.0

14

Parameter value:

0: Sensor disabled

1: Sensor enabled

These parameters enable/disable sensors 2 and 3.

The factory set value is 0 (sensor disabled).

When a sensor is disabled, the temperature and relative alarm

limits related to this sensor cannot be adjusted.

Sensor 1 cannot be disabled. It is always active.

4.6 ENABLING / DISABLING SENSORS

DKM-046 User Manual V-1.0

15

The unit provides 4 relay outputs. Each output reflects the

combination of 4 different relay functions. The combination

options are explained in the next parameter.

The total number of relay functions are 16. They are presented

as in the picture at left.

As an examle, 1r4 means function_4 of relay_1, 3r2 means

function_2 of relay_3.

Unused funtions should be left as 0.

Value

Relay Function

0

-

1

Sensor-1 low temperature

2

Sensor-1 high temperature

3

Sensor-1 low relative humidity

4

Sensor-1 high relative humidity

5

Sensor-2 low temperature

6

Sensor-2 high temperature

7

Sensor-2 low relative humidity

8

Sensor-2 high relative humidity

9

Sensor-3 low temperature

10

Sensor-3 high temperature

11

Sensor-3 low relative humidity

12

Sensor-3 high relative humidity

13

Function active if any alarm exists

14

Through Modbus registers:

If any non-zero value is written in related

register, then the function is active.

Relay-1: address 48

Relay-2: address 49

Relay-3: address 50

Relay-4: address 51

15

T1-T2 temperature difference alarm

16

T2-T3 temperature difference alarm

17

T3-T1 temperature difference alarm

18

T1 temperature cooling active

19

T1 temperature heating active

20

H1 sensor de-humidification active

21

H1 sensor humidification active

22

T2 temperature cooling active

23

T2 temperature heating active

24

H2 sensor de-humidification active

25

H2 sensor humidification active

26

T3 temperature cooling active

27

T3 temperature heating active

28

H3 sensor de-humidification active

29

H3 sensor humidification active

4.7 CONFIGURING RELAY OUTPUTS

DKM-046 User Manual V-1.0

16

The factory set value for all relay functions is 0.

The adjustment range is from 0 to 14.

Each relay output is activated by the combination of 4 different

functions as explained above. Thus relay may be assigned to

complex functions.

Parameters at left adjust the function combination method for

each relay output.

0: Functions are combined with logical OR operation. Thus if

any of the function is active, then the relay output is active.

1: Functions are combined with logicalAND operation. Thus the

relay output will be active only if all functions are active.

This parameter adjusts the delay for relay activation after all

conditions for relay operation are met.

The factory set value is 0.

Adjustment range is between 0 and 999 seconds.

This parameter adjusts the delay for alarm activation after an

alarm condition occurs. It also determines the delay for alarm

deactivation after the alarm condition is removed.

The factory set value is 0.

Adjustment range is between 0 and 999 seconds.

4.8 ALARM DELAY

DKM-046 User Manual V-1.0

17

0: Alarm lock disabled

1: Alarm lock enabled

When this parameter is set to 1, even if the alarm cause is

removed, alarms will persist until manually reset.

When this parameter is set to 0, when the alarm cause is

removed, alarms automatically disappear.

Factory set value is 0.

Adjustment range is 0 to 1.

This parameter determines the Modbus node address of the

unit. Every unit in the same Modbus loop must have a different

node address.

Factory set value is 1.

Adjustment range is 0 to 255.

This parameter determines the data rate (baud rate) used in the

Modbus communication. Every unit in the same Modbus loop

must use the same data rate.

0: Baud rate = 2400

1: Baud rate = 4800

2: Baud rate = 9600

3: Baud rate = 19200

4: Baud rate = 38400

5: Baud rate = 57600

6: Baud rate = 115200

Factory set value is 2.

Adjustment range is 0 to 6.

4.9 ALARM LOCK

4.10 MODBUS PARAMETERS

DKM-046 User Manual V-1.0

18

These parameters determine respectively the offset value to be

added to temperature sensors 1, 2 and 3.

Factory set value is 0.

Adjustment range is between –9.9 and + 9.9 °C.

These parameters determine respectively the offset value to be

added to relative humidity sensors 1, 2 and 3.

Factory set value is 0.

Adjustment range is between –9.9% and + 9.9%.

4.11 ADJUSTING TEMPERATURE OFFSET VALUES

4.12 ADJUSTING RELATIVE HUMIDITY OFFSET VALUES

DKM-046 User Manual V-1.0

19

These parameters determine respectively the high alarm limits

for temperature differences T1-T2, T2-T1, T2-T3, T3-T2, T3-T1,

T1-T3.

Adjustment range is between 0°C and 100°C.

Factory set value is 0 and the alarm is passive.

When this parameter is set to 0, the temperature difference

alarm is de-activated.

These parameters determine respectively the cooling start

upper limits for temperature sensors 1 , 2 and 3.

When the temperaure measured from the related sensor goes

over the programmed limit, then the cooling relay function will

become active. When the measured temperature goes below

the limit more than the programmed hysteresis value, then the

cooling relay function will become passive.

Adjustment range is between -21°C and +80°C.

Factory set value is +40°C.

4.14 ADJUSTING COOLING START TEMPERATURE UPPER LIMITS

4.13 ADJUSTING TEMPERATURE DIFFERENCE ALARM LIMITS

DKM-046 User Manual V-1.0

20

These parameters determine respectively the heating start

temperature limits for temperature sensors 1 , 2 and 3.

When the temperaure measured from the related sensor goes

below the programmed limit, then the heating relay function will

become active. When the measured temperature goes above

the limit more than the programmed hysteresis value, then the

heating relay function will become passive.

Adjustment range is between -21°C and +80°C.

Factory set value is +20°C.

These parameters determine respectively the hysteresis values

for stopping the heating or cooling for temperature sensors 1 , 2

and 3.

Adjustment range is between 0°C and 100°C.

Factory set value is 5°C.

These parameters determine respectively the de-humidification

start upper limits for humidity sensors 1 , 2 and 3.

When the relative humidity measured from the related sensor

goes over the programmed limit, then the de-humidification

relay function will become active. When the measured relative

humidity goes below the limit more than the programmed

hysteresis value, then the de-humidification relay function will

become passive.

Adjustment range is between 0% and +100%

Factory set value is 70%.

4.17 ADJUSTING DE-HUMIDIFICATION START HUMIDITY

4.16 ADJUSTING TEMPERATURE HYSTERESIS FOR COOLING

AND HEATING

4.15 ADJUSTING HEATING START TEMPERATURE LOW LIMITS

Table of contents

Other Datakom Controllers manuals

Datakom

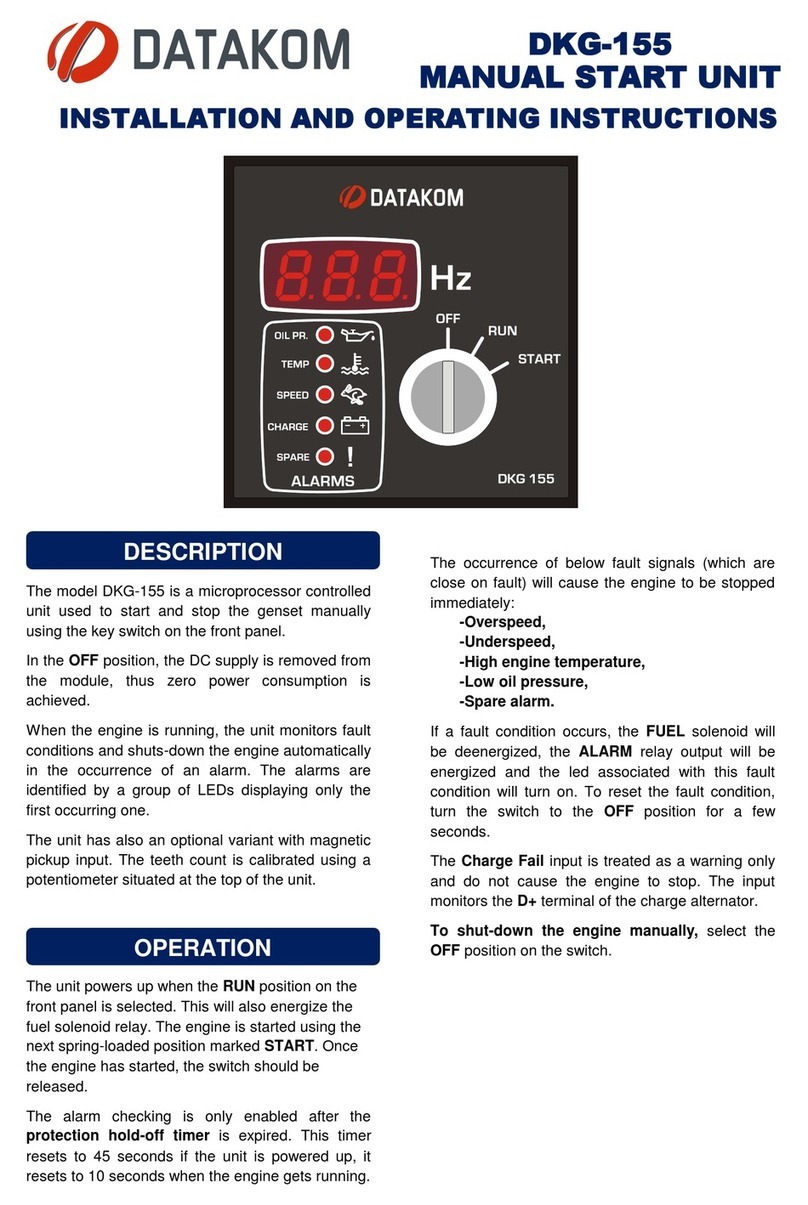

Datakom DKG-155 User manual

Datakom

Datakom DKG-109 User manual

Datakom

Datakom DKG-116 User manual

Datakom

Datakom DKG-225 User manual

Datakom

Datakom D Series User manual

Datakom

Datakom DKG-509 User manual

Datakom

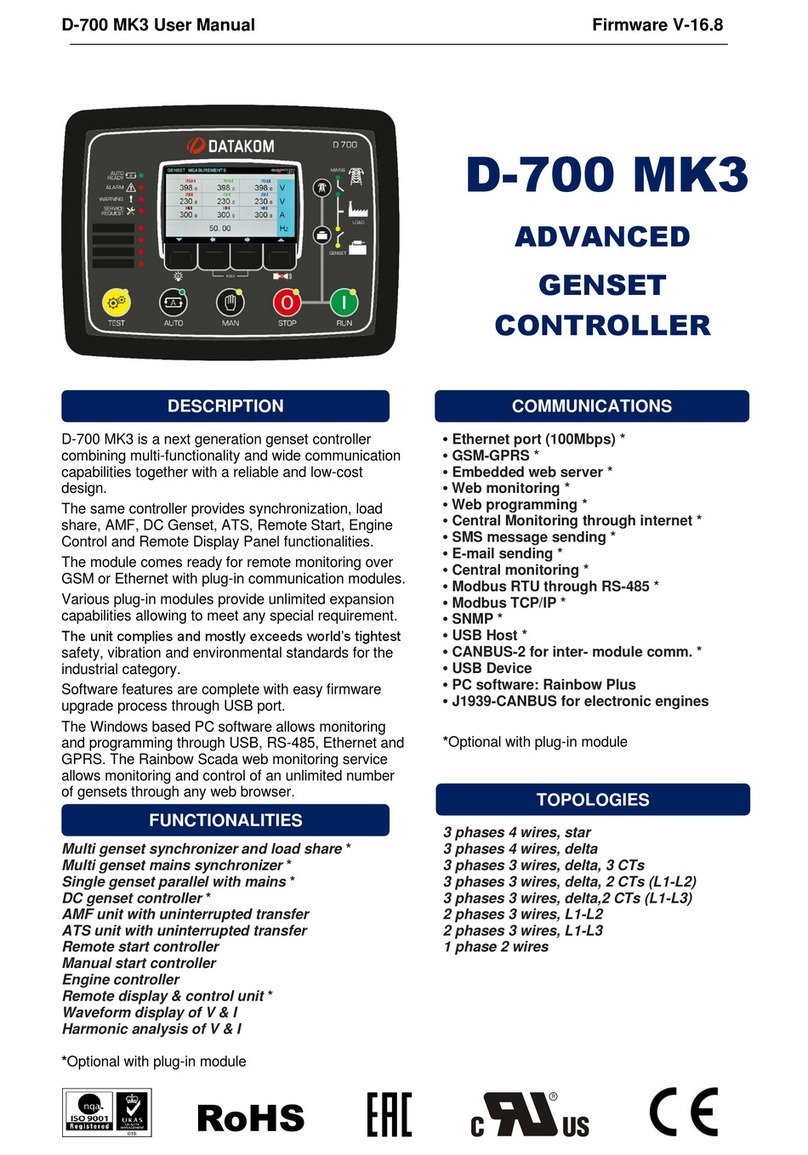

Datakom D-700 MK3 User manual

Datakom

Datakom DKG-225 User manual

Datakom

Datakom D-500 User manual

Datakom

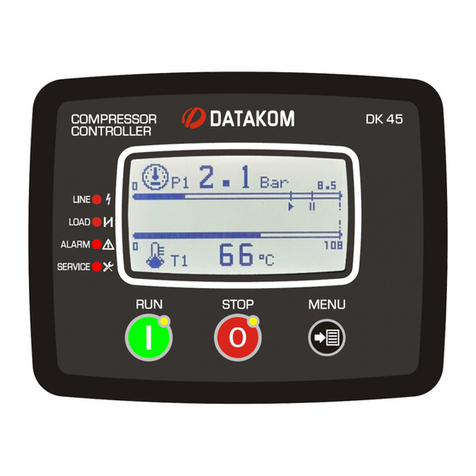

Datakom DK-45 User manual

Datakom

Datakom D-200 MK2 User manual

Datakom

Datakom DKG-190 User manual

Datakom

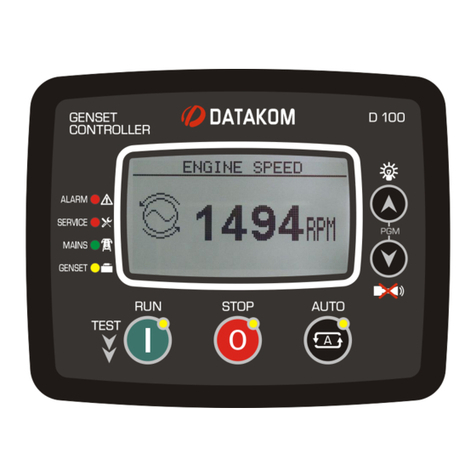

Datakom D-100 MK2 User manual

Datakom

Datakom DK-45 MK2 User manual

Datakom

Datakom DFC-0108 User manual

Datakom

Datakom D-300 MK2 User manual

Datakom

Datakom DKG-255 User manual

Datakom

Datakom DKG-108 User manual

Datakom

Datakom DKG-325 User manual

Datakom

Datakom DKG-379 User manual