Datakom DKG-379 User manual

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

DKG-379

VARIABLE SPEED DC

GENSET CONTROLLER

CANBUS AND MPU VERSIONS

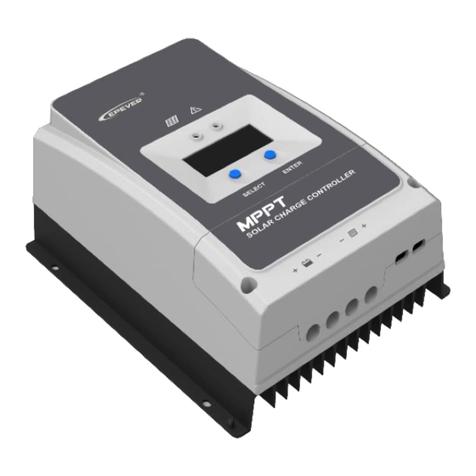

The DKG-379 is an advanced DC genset controller for both

variable and fixed speed systems. It is presented in 3 different

versions, as ANALOG DRIVE, POWER DRIVE and CANBUS

DRIVE.

The controller has a precision PID loop providing exact

matching of the optimal charging characteristics, as well as

overvoltage, overcurrent, overspeed, overheat protections.

The POWER DRIVE version provides a 7 Amp-DC output,

interfacing directly to the engine actuator or alternator

excitation winding without the need for a governor controller or

AVR. The CANBUS DRIVE version connects to ECU driven

electronic engines providing engine control, protection and

instrumentation without extra senders. ECU alarms are

displayed in text. All versions offer a 0-10V analog output for

speed or voltage control.

The fixed speed operation stops the genset precisely when

batteries are fully charged, providing fuel economy and

maintenance cost reductions.

The unit has precision, fully isolated measuring inputs for the

battery bank voltage and the charge current. It supports both

“positive to ground” and “negative to ground” installations.

The current is measured through a DC current shunt placed in

positive or negative output of the genset.

The genset starting is based on the precisely measured DC

battery bank voltage. Once started, the controller will perform

an optimal battery charging cycle and will stop the genset

when batteries are fully charged. The optimal charge algorithm

allows maximum battery life and minimal engine run time and

fuel consumption.

During the charge cycle, the unit controls the engine rpm (or

excitation) in order to apply the exact required DC voltage and

current to batteries. The rpm control over CANBUS-J1939 is

available for electronic engines.

The unit offers a PT100 type, battery temperature sensor

input. If used, the temperature protection will allow longer

battery life in hot environment and faster charge in cold

conditions.

Compatible with 12V, 24V and 48V DC systems

DC power drive output (7A-DC)

ECU connection through J1939 CAN option

0-10V analog control output

Isolated Volt - Amp measurements

Battery temperature input for PT100 sensor

Optimal charging, provides longer battery life

Temperature dependent battery charging

Thermal protection, short circuit protection

Dual genset mutual standby operation

100 event logs with time stamp and

measurements

Battery backed-up real time clock

Built in daily / weekly / monthly exerciser

Field adjustable parameters

RS-232 serial port

Free MS-Windows Remote monitoring SW

GSM and PSTN modem support

GSM SMS message sending on fault

MODBUS communications

Multiple language support

Customer logo display capability

Battery Volts

Battery temperature

Generator Volts

Generator Amps

Generator kW

Engine rpm

Engine battery Voltage

Engine Coolant Temperature

Engine Oil Pressure

Engine fuel Level

Engine Oil Temperature

MEASUREMENTS

FEATURES

DESCRIPTION

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 2 -

Any unauthorized use or copying of the contents or any part of this document is prohibited.

This applies in particular to trademarks, model denominations, part numbers and drawings.

This document describes minimum requirements and necessary steps for the successful installation of the

DKG-379 unit.

Follow carefully advices given in the document. These are often good practices for the installation of genset

control units which reduce future issues.

For all technical queries please contact Datakom at below e-mail address:

FILENAME

DESCRIPTION

379_INSTE

DKG-379 Installation Guide

REVISION

DATE

AUTHOR

DESCRIPTION

01

04.04.2012

MH

First issue, firmware version 12, hardware version 02

02

24.12.2012

MH

Updated for firmware version 15, hardware version 03

CAUTION: Potential risk of injury or death.

WARNING: Potential risk of malfunction or material damage.

ATTENTION: Useful hints for the understanding of device operation.

TERMINOLOGY

REVISION HISTORY

RELATED DOCUMENTS

ABOUT THIS DOCUMENT

COPYRIGHT NOTICE

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 3 -

The D-500 family units are available in various options and peripheral features. Please use below

information for ordering the correct version:

DKG-379

-MPU

-G

-T

-00

Screw type bracket

Stock Code=J10P01 (per unit)

Self Retaining type bracket

Stock Code=K16P01 (per unit)

Sealing Gasket, Stock Code= K44P01

SPARE PARTS

ORDERING CODES

Family Code

MPU: Magnetic pickup input

CAN: Canbus J1939 port

With Sealing

gasket

With Conformal

Coating

Variant

00: standard unit

01...99: customer

specific products

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 4 -

▪Electrical equipment should be installed only by qualified specialist.

No responsibility is assured by the manufacturer or any of its

subsidiaries for any consequences resulting from the non-

compliance to these instructions.

▪Check the unit for cracks and damages due to transportation. Do not

install damaged equipment.

▪Do not open the unit. There are no serviceable parts inside.

▪Fuses must be connected to the power supply and phase voltage

inputs, in close proximity of the unit.

▪Fuses must be of fast type (FF) with a maximum rating of 6A.

▪Disconnect all power before working on equipment.

▪Any electrical parameter applied to the device must be in the range

specified in the user manual. Although the unit is designed with a

wide safety margin, over-range parameters may reduce lifetime, alter

operational precision or even damage the unit.

▪Do not try to clean the device with solvent or the like. Only clean

with a dump cloth.

▪Verify correct terminal connections before applying power.

▪Only for front panel mounting.

SAFETY NOTICE

Failure to follow below instructions

will result in death or serious injury

Resistive Current Shunt must be used for current

measurement.

No direct connection allowed.

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 5 -

1.INSTALLATION INSTRUCTIONS

2.MOUNTING

2.1. DIMENSIONS

2.2. SEALING, GASKET

2.3. ELECTRICAL INSTALLATION

3. TERMINAL DESCRIPTIONS

3.1. BATTERY VOLTAGE INPUT

3.2. BATTERY BANK DC VOLTAGE INPUTS

3.3. BATTERY BANK CHARGE CURRENT INPUT

3.4. DIGITAL INPUTS

3.5. ANALOG SENDER INPUTS AND SENDER GROUND

3.6. CHARGE INPUT TERMINAL

3.7. DIGITAL OUTPUTS

3.8. LOAD CONTACTOR OUTPUT

3.9. ANALOG OUTPUT

3.10. MAGNETIC PICKUP INPUT

3.11. INPUT/OUTPUT EXTENSION

3.12. J1939-CANBUS PORT

3.13. RS-232 PORT (OPTIONAL)

4. CONNECTION DIAGRAM

5. TERMINAL DESCRIPTION

6. TECHNICAL SPECIFICATIONS

7. DESCRIPTION OF CONTROLS

7.1. FRONT PANEL FUNCTIONALITY

7.2. PUSHBUTTON FUNCTIONS

7.3. DISPLAY SCREEN ORGANIZATION

7.4. LED LAMPS

8. DISPLAYING EVENT LOGS

9. STATISTICAL COUNTERS

10. OPERATION OF THE UNIT

10.1. QUICK START GUIDE

10.2.STOP MODE

10.3. AUTO MODE

10.4. RUN MODE, MANUAL CONTROL

10.5. TEST MODE

11. OPTIMAL CHARGING, VARIABLE SPEED OPERATION

11.1. RELATED PARAMETERS

11.2. OPTIMAL CHARGE CYCLE DESCRIPTION

11.3. EFFECT OF BATTERY BANK TEMPERATURE

11.4. RPM CONTROL

12. UNCONTROLLED CHARGING, FIXED SPEED OPERATION

12.1. RELATED PARAMETERS

12.2. UNCONTROLLED CHARGE CYCLE DESCRIPTION

TABLE OF CONTENTS

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 6 -

13. PROTECTIONS AND ALARMS

13.1. SHUTDOWN ALARMS

13.2. LOADDUMP ALARMS

13.3. WARNINGS

14. PROGRAMMING

14.1. RESETTING TO FACTORY DEFAULTS

14.2. ENTERING THE PROGRAMMING MODE

14.3. NAVIGATING BETWEEN MENUS

14.4. MODIFYING PARAMETER VALUE

14.5. PROGRAMMING MODE EXIT

15. PROGRAM PARAMETER LIST

15.1. CONTROLLER CONFIGURATION GROUP

15.2. ELECTRICAL PARAMETERS GROUP

15.3. ENGINE PARAMETERS GROUP

15.4. ADJUST DATE AND TIME

15.5. WEEKLY OPERATION SCHEDULE

15.6. SENDER CHARACTERISTICS

15.7. INPUT CONFIGURATION

15.8. RELAY DEFINITIONS

15.9. INPUT FUNCTION SELECT

15.10. SITE ID STRING

15.11. MODEM1-2/SMS1-2-3-4 TELEPHONE NUMBERS

16. CRANK CUTTING

17. J1939 CANBUS ENGINE SUPPORT

18. SOFTWARE FEATURES

18.1. Charging the Engine Battery

18.2. Speed UP/DOWN Relay Outputs

18.3. Remote Start Operation

18.4. Disable Auto Start

18.5. Dual Genset Mutual Standby Operation

18.6. External Control of the Unit

18.7. Automatic Exerciser

18.8. Weekly Operation Scheduler

18.9. Engine Heating Operation

18.10. Engine Idle Speed Operation

18.11. Engine Block Heater

18.12. Fuel Pump Control

18.13. Gas Engine Fuel Solenoid Control

19. MODBUS SUPPORT

19.1. Modbus Register Map

20. DECLARATION OF CONFORMITY

21. MAINTENANCE

22. DISPOSAL OF THE UNIT

23. ROHS COMPLIANCE

24. TROUBLESHOOTING GUIDE

TABLE OF CONTENTS (continued)

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 7 -

Before installation:

•Read the user manual carefully, determine the correct connection diagram.

•Remove all connectors and mounting brackets from the unit, then pass the unit through the mounting

opening.

•Put mounting brackets and tighten. Do not tighten too much, this can brake the enclosure.

•Make electrical connections with plugs removed from sockets, then place plugs to their sockets.

•Be sure that adequate cooling is provided.

•Be sure that the temperature of the environment will not exceed the maximum operating temperature

in any case.

Below conditions may damage the device:

•Incorrect connections.

•Incorrect power supply voltage.

•Voltage at measuring terminals beyond specified range.

•Voltage applied to digital inputs over specified range.

•Overload or short circuit at relay outputs

•Connecting or removing data terminals when the unit is powered-up.

•High voltage applied to communication ports.

•Ground potential differences at non-isolated communication ports.

•Excessive vibration, direct installation on vibrating parts.

Below conditions may cause abnormal operation:

•Power supply voltage below minimum acceptable level.

•Current shunt polarity incorrect.

•Missing grounding.

Resistive Current Shunt must be used for current

measurement.

No direct connection allowed.

1. INSTALLATION INSTRUCTIONS

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 8 -

Dimensions: 172x134x76mm (6.8”x5.3”x3.0”)

Panel Cutout: 151x111mm minimum (6.0”x4.4”)

Weight: 450g (1 lb)

2.1. DIMENSIONS

2. MOUNTING

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 9 -

The unit is designed for panel mounting. The user should not be able to access parts of the unit other than

the front panel.

Mount the unit on a flat, vertical surface. Before mounting, remove the mounting brackets and connectors from

the unit, then pass the unit through the mounting opening.

Place and tighten mounting brackets.

Panel Cutout

Required Panel Depth

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 10 -

Two different types of brackets are provided:

Screw type bracket

Self retaining type bracket

Installation of screw type bracket

Installation of self retaining type bracket

Do not tighten too much, this may break the unit.

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 11 -

The rubber gasket provides a watertight means of mounting the module to the genset panel. Together with

the gasket, IEC 60529-IP65 protection can be reached from the front panel. A short definition of IP protection

levels is given below.

1st Digit Description of Protection Level

0 Not protected

1 Protected against solid foreign objects of 50 mm diameter and greater

2 Protected against solid foreign objects of 12,5 mm diameter and greater

3 Protected against solid foreign objects of 2,5 mm diameter and greater

4 Protected against solid foreign objects of 1,0 mm diameter and greater

5 Protected from the amount of dust that would interfere with normal operation

6 Dust tight

2nd Digit Description of Protection Level

0 Not protected

1 Protected against vertically falling water drops

2 Protected against vertically falling water drops when enclosure is tilted up to 15 °

3 Protected against water sprayed at an angle up to 60 ° on either side of the vertical

4 Protected against water splashed against the component from any direction

5 Protected against water projected in jets from any direction

6 Protected against water projected in powerful jets from any direction

7 Protected against temporary immersion in water

8 Protected against continuous immersion in water, or as specified by the user

2.2. SEALING, GASKET

Gasket

Panel

Module

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 12 -

Although the unit is protected against electromagnetic disturbance, excessive disturbance

can affect the operation, measurement precision and data communication quality.

•ALWAYS remove plug connectors when inserting wires with a screwdriver.

•Fuses must be connected to the power supply voltage inputs, in close

proximity of the unit.

•Fuses must be of fast type (FF) with a maximum rating of 6A.

•Use cables of appropriate temperature range.

•Use adequate cable section, at least 0.75mm2 (AWG18).

•Follow national rules for electrical installation.

•Current shunts must have 60mV output at nominal current.

For the correct operation of the exerciser and

weekly schedule programs, adjust the real time

clock of the unit through programming menu.

The engine body must be grounded. Otherwise faulty

voltage and frequency measurements may occur.

Resistive Current Shunts must be used for current

measurement.

No direct connection allowed.

Do not install the unit close to high electromagnetic

noise emitting devices like contactors, high current

busbars, switchmode power supplies and the like.

2.3. ELECTRICAL INSTALLATION

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 13 -

Supply voltage:

9 to 33VDC

Cranking dropouts:

Survives 0VDC during 100ms. The voltage before surge should be

9VDC minimum

Overvoltage protection:

Withstands 150VDC continuously.

Reverse voltage:

-33VDC continuous

Maximum operating

current:

250mA @ 12/24VDC. (All options included, digital outputs open.)

Typical operating current:

200mA @ 12/24VDC. (all options passive, digital outputs open)

Measurement range:

0 to 36VDC

Display resolution:

0.1VDC

Accuracy:

0.5% + 1 digit @ 24VDC

3.1. BATTERY VOLTAGE INPUT

3. TERMINAL DESCRIPTIONS

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 14 -

Measurement method:

Isolated DC voltage measurement

Sampling rate:

100K s/s

Input voltage range:

0 to 70 VDC

Measurement range:

0 to 70VDC

Input impedance:

215 K-ohms

Display resolution:

0.1VDC

Isolation:

500VAC, 1minute

Accuracy:

0.5% + 1 digit (±0.35V@50VDC)

Measurement method:

Isolated DC voltage measurement

Sampling rate:

100 Ks/s

Input voltage range:

0 to 100 mVDC

Measurement range:

0 to 100 mVDC

Input impedance:

1000 ohms

Isolation:

500VAC, 1minute

Accuracy:

0.5% + 1 digit (±0.6A@100ADC)

Current shunt range:

1A/60mV to 5000A/60mV

Display resolution:

0.1ADC (shunt < 250A/60mV)

1ADC (shunt > 250A/60mV)

Be careful about not to applying more than 100mVDC,

otherwise the unit may get damaged.

3.3. BATTERY BANK CHARGE CURRENT INPUT

3.2. BATTERY BANK DC VOLTAGE INPUTS

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 15 -

Number of inputs:

7 inputs, all configurable

Function selection:

from list

Contact type:

Normally open or normally closed (programmable)

Switching:

Battery negative or battery positive (programmable)

Structure:

47 k-ohms resistor to battery positive, 110k-ohms to battery negative.

Measurement:

Analog voltage measurement.

Open circuit voltage:

70% of battery voltage

Low level threshold:

35% of battery voltage

High level threshold:

85% of battery voltage

Maximum input voltage:

+100VDC with respect to battery negative

Minimum input voltage:

-70VDC with respect to battery negative

Noise filtering:

yes

Number of inputs:

4 inputs, with configurable curve

Structure:

667 ohms resistor polarizing to 3.3VDC

Measurement:

Analog resistor measurement.

Open circuit voltage:

+3.3VDC

Short circuit current:

5mA

Measurement range:

0 to 5000 ohms.

Open circuit threshold:

5000 ohms.

Resolution:

1 ohms @ 300 ohms or lower

Accuracy:

2 %+1 ohm (±7 ohms @300 ohms)

Noise filtering:

yes

3.5. ANALOG SENDER INPUTS AND SENDER GROUND

3.4. DIGITAL INPUTS

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 16 -

The Charge terminal is both an input and output.

When the engine is ready to run, this terminal supplies the excitation current to the charge alternator.

The excitation circuit is equivalent to a 2W lamp.

The threshold voltages for warning and shutdown alarm are adjustable through program parameter.

Structure:

•battery voltage output through 20 ohm PTC

•voltage measurement input

Output current:

160mA @12VDC

80mA @24VDC

Voltage measurement

resolution:

0.1VDC

Voltage measurement

accuracy:

2% + 0.1V (0.9V @30VDC)

Charge Fail Warning

Threshold:

adjustable

Charge Fail Shutdown

Alarm Threshold:

adjustable

Open circuit voltage:

battery positive

Overvoltage protection:

> 500VDC continuous, with respect to battery negative

Reverse voltage

protection:

-30VDC with respect to battery negative

The unit offers 4 digital outputs. Fuel and crank relays have fixed function. Other 2 relays have

programmable function, selectable from list.

Structure:

Negative pulling protected semiconductor output. One terminal is

connected to battery negative.

Max continuous current:

1.0 ADC

Max switching voltage:

33 VDC

Overvoltage protection:

40 VDC

Short circuit protection:

> 1.7 ADC

Reverse voltage

protection:

500 VDC

3.6. CHARGE INPUT TERMINAL

3.7. DIGITAL OUTPUTS

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 17 -

Structure:

Relay output, normally open contact. Both terminals provided

Max switching current:

16A @250VAC/30VDC

Max switching power:

4000VA

Structure:

linear output for rpm/voltage control

Functionality:

Precision PID control output, regulating rpm/voltage for voltage

matching, current control, temperature and rpm limiting.

Output impedance:

1 k-ohms

Output voltage:

0-10 V-DC

Frequency range:

10Hz to 10 kHz

Resolution:

0.1%

Accepted Load:

> 10 k-ohms

3.9. ANALOG OUTPUT

3.8. LOAD CONTACTOR OUTPUT

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 18 -

Structure:

Differential frequency measurement input, MPU or charging pulses

Input impedance:

100 k-ohms

Input voltage:

1.0VAC-RMS to 100VAC-RMS

Frequency range:

10Hz to 10 kHz

Resolution:

1 rpm

Accuracy:

0.2% + 1 rpm (±3rpm @1500 rpm)

Flywheel teeth range:

1 to 500

Do not share MPU with other devices.

If charge alternator pulses are used, please connect

only the MPU+ terminal and leave open the MPU-

terminal.

If MPU unit is used, then use a twisted cable pair or

coaxial cable for best results.

3.10. MAGNETIC PICKUP INPUT

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 19 -

The module provides resources for 16 additional

digital inputs and 16 additional digital outputs.

Digital inputs can be extended using DKG-188

Digital Input Extension modules, each one

providing 8 inputs. Digital inputs are programmable

through the main controller. The switching

characteristic is not programmable and must be

battery negative. Any function can be assigned to

digital inputs.

Digital outputs can be extended using DKG-186

Fet Extension modules, each one providing 8

outputs. Digital outputs have the same electrical

characteristics as on board outputs. They have

programmable functions through the main

controller. Any function can be assigned to any

output.

Input and output extension modules are connected

to the main controller in a cascade structure, in any

order. The connection cable is provided with each

extension module.

3.11. INPUT/OUTPUT EXTENSION

I/O Extension

Connector

DKG-379 User Manual Rev_02 V-15 (24-12-2012)

K43D01-EN - 20 -

Structure:

CANBUS, non isolated.

Connection:

3 wires (CANH-CANL-GND).

Data rate:

250 kbps

Termination:

Internal 120 ohms provided

Common mode voltage:

-0.5 VDC to +15 VDC, internally clamped by transient suppressors.

Max distance:

200m with 120 ohm balanced cable

Description:

RS-232, non isolated.

Functionality:

External modem, PC connection, PLC

connection

Connector:

RJ11-6pin

Connection:

6 wires (Rx-Tx-DTR-CxD-GND-+10V).

Full duplex.

Baud rate:

9600 bauds

Data type:

8 bit data, no parity, 1 bit stop

Max distance:

15m

Terminal

description:

1: DTR

output

2: Tx output

3: CxD input

4: GND

5: Rx input

6: +10V

Front view of RJ11 6 pin

connector

6 1

3.13. RS-232 PORT (OPTIONAL)

3.12. J1939-CANBUS PORT

RS-232

Connector

Table of contents

Other Datakom Controllers manuals

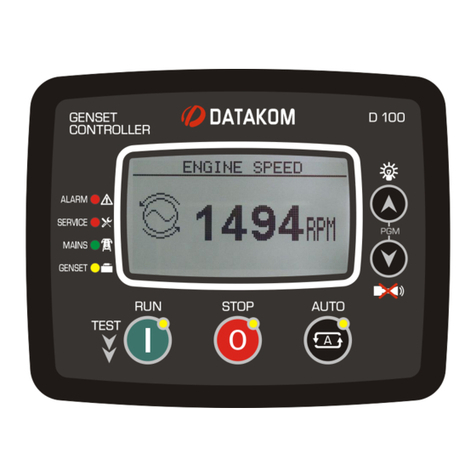

Datakom

Datakom DKG-108 User manual

Datakom

Datakom D-100 MK2 User manual

Datakom

Datakom D-500 MK2 User manual

Datakom

Datakom DK-40 User manual

Datakom

Datakom DKG-109 User manual

Datakom

Datakom DKG-225 User manual

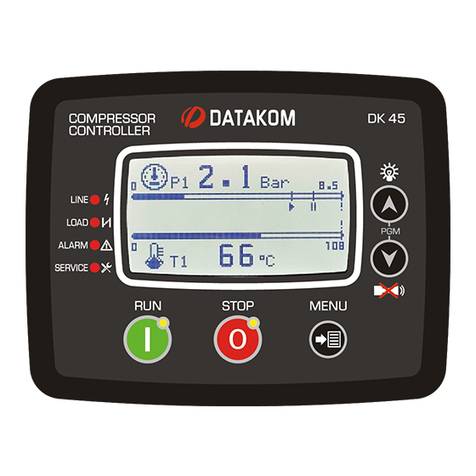

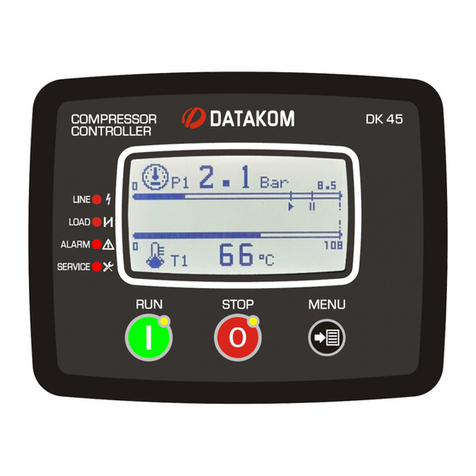

Datakom

Datakom DK-45 MK2 User manual

Datakom

Datakom D-500 MK3 User manual

Datakom

Datakom D-500 User manual

Datakom

Datakom D Series User manual

Datakom

Datakom DK-45 User manual

Datakom

Datakom DKG-509 User manual

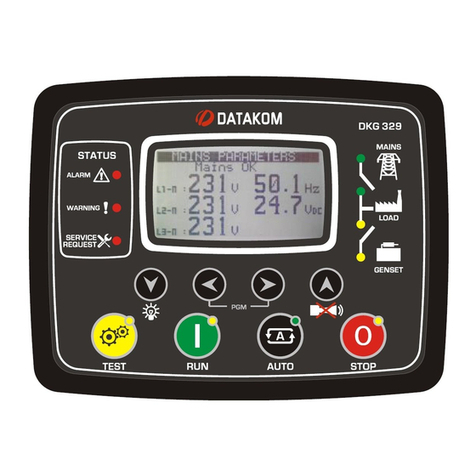

Datakom

Datakom DKG-329 User manual

Datakom

Datakom DKG-119 User manual

Datakom

Datakom D-200 MK2 User manual

Datakom

Datakom DKG-225 User manual

Datakom

Datakom DKG-255 User manual

Datakom

Datakom DKG-325 User manual

Datakom

Datakom D-700 MK3 User manual

Datakom

Datakom D-500 MK3 User manual