DAW Industries 4P10 KD User manual

Sitting Position

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01272021

®

DAW

Industries

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01272021

®

DAW

Industries

DAW

IMPORTANT:

Adjusting alignment beyond

recommended limits described within will

adversely affect patient’s gait, and could

cause premature wear.

PRACTITIONER’S

MANUAL

DAW Industries

CENTRAL/EASTERN

DISTRIBUTION CENTER:

5579-B Chamblee Dunwoody Road

Suite 227

Atlanta, GA 30338-4154

Orders: (800) 824-7192

Fax: (800) 865-8563

HEADQUARTERS:

6610 Nancy Ridge Road

San Diego, CA 92121-2252

Orders: (800) 252-2828 • (858) 622-4962

Fax: (800) 856-8563

www.daw-usa.com

Technical Support

(800) 242-8669

Stock#: TGK-4P10

4P10™KD

Engineered with True-KD™Biomechanics

Benefits:

✔Engineered specifically to serve the needs of KD Amputees

✔Ultra-Lite, high strength carbon fiber construction

✔Decades of proven reliability

✔Safe, natural toe-clearance in swing for added efficiency

✔Separate extension / flexion pneumatic adjustments

✔ Completely maintenance free

True-KD™ Biomechanics:

not only serves your KD Amputee’s unique cosmetic needs, True-KD

Knees are also engineered to maximize stability & efficiency by

exploiting your Patient’s distinct biomechanical advantages!

Learn more @ daw-usa.com/true-kd-biomechanics

IMPORTANT:

Read technical information

thoroughly before using knee.

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01272021

®

DAW

Industries

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01272021

®

DAW

Industries

Includes: Adjustment Wrench, Washer & Lock Washer

Browse our complete selection of Unique Components at

daw-usa.com/all-connectors

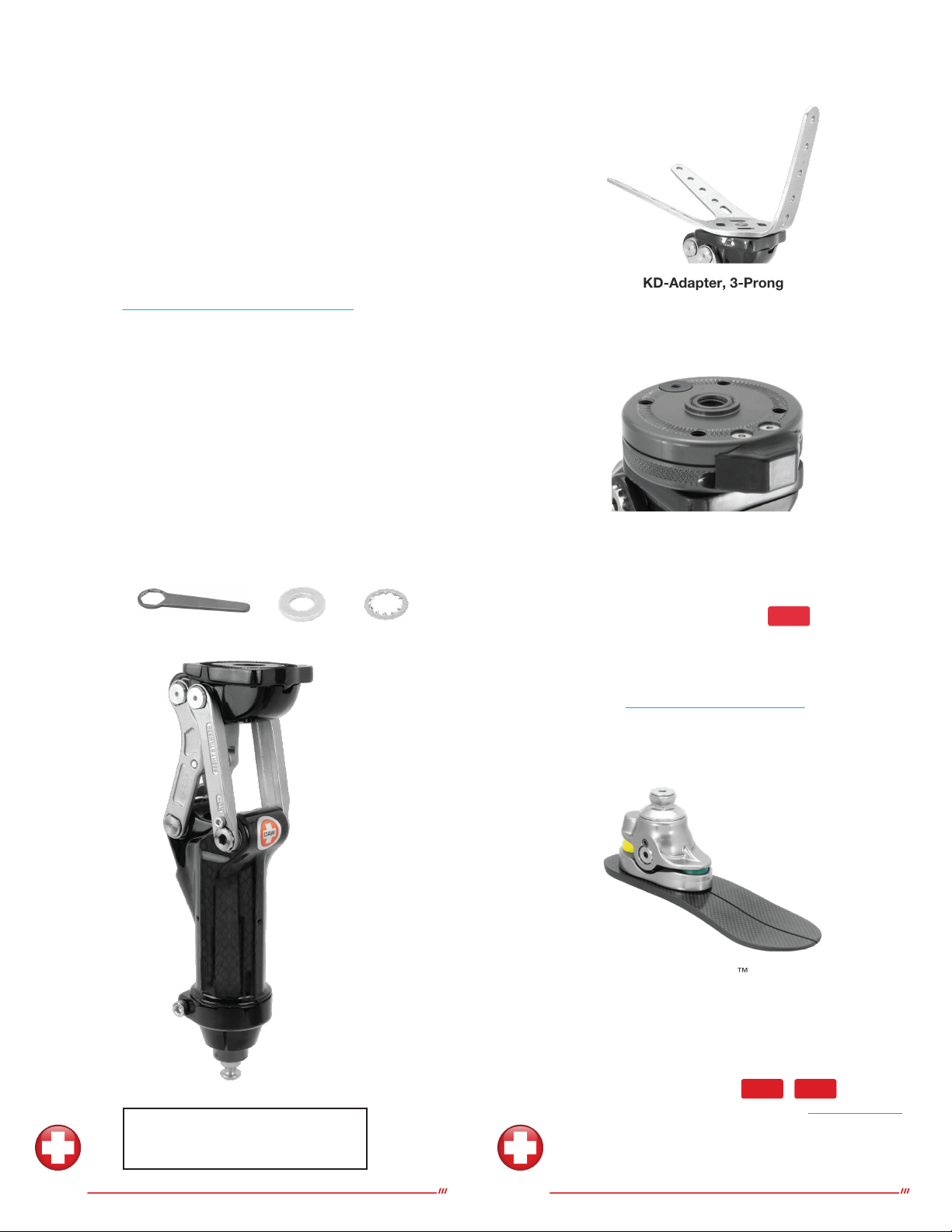

Popular Proximal Options

Lo-Pro Rotator™

(#: TKR-01)

Provides Rotational Adjustment

Attach any 4-Hole connector

Suggested L-Codes*: L5984

K3 Pro-Action™Foot

Engineered for the low to moderately active K3 Individual

Provides 3 Dynamic Energy Returning Carbon Keel Options

& Multi-Axial Ankle Motion with Rotation.

Suggested L-Codes*: L5981 L5986

*Please refer to the complete reimbursement disclaimer at www.daw-usa.com

Recommended K3 Foot

KD-Adapter, 3-Prong

Stainless Steel (#: TSC-KDL)

Provides Rotational Adjustment

Stock#: TGK-4P10

4P10™KD

Engineered with True-KD™Biomechanics

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01082021

®

DAW

Industries

For Technical Support call (800)242-8669

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01082021

®

DAW

Industries

For Technical Support call (800)242-8669

Patient Notes Contents

16 1

Page #

Recommended Order of Adjustments ................1 (Below)

KD Adapter Lamination / Connection Procedure ............2-3

Build Height .......................................... 4

Torque Settings ....................................... 4

Alignment ............................................ 5

Extension Stop (Stability & Swing Phase Trigger Point) . . . . . . . 6

Swing Phase Adjustments (Flexion & Extension Dampening) 7

Returning Flexion & Extension to Factory Setting ............. 8

Extension Assist Adjustment ........................... 9

Replacing or Trimming the Extension Assist Spring . . . . . . . . . . 10

Cleaning Pneumatic Components ........................ 11

DAW Prosthetic Knee Limited Warranty ................... 12

Specifications........................................ 13

Patient Notes ......................................14-16

Popular Proximal Options ................. (inside back cover)

1. Extension Stop

2. Flexion Dampening

3. Extension Dampening

4. Extension Assist

Recommended Order of Adjustments

adjustable functions

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01082021

®

DAW

Industries

For Technical Support call (800)242-8669

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01082021

®

DAW

Industries

For Technical Support call (800)242-8669

2 15

True-KD™Series

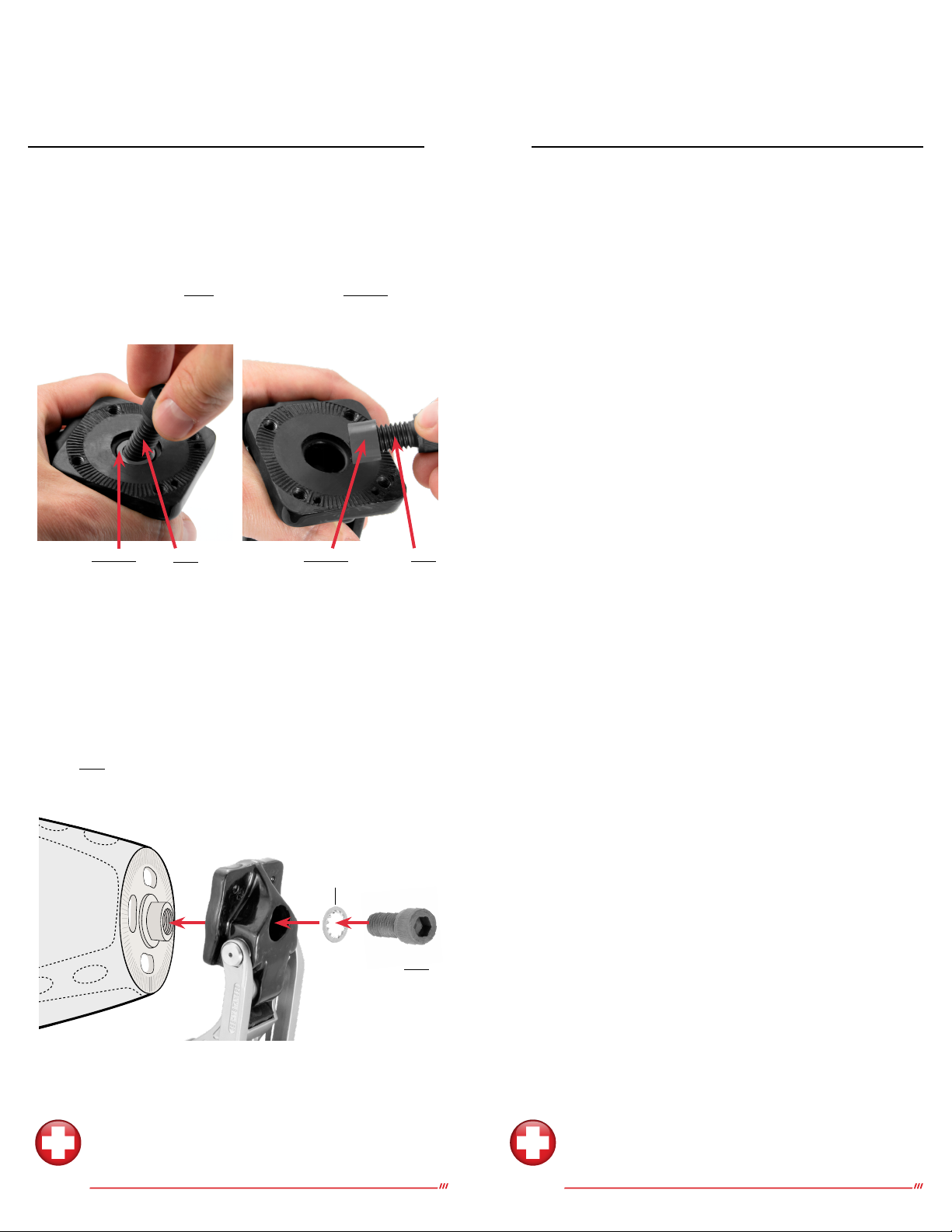

Knee Connection to KD Adapter (TSC-KDL)

7

/16 Bolt

(8mm hex)

Lock Washer

7

/16 Bolt

Spacer Spacer 7

/16 Bolt

The instructions below apply to True-KD™Series Knees, when

using the KD Adapter (TSC-KDL):

After lamination of the KD Adapter (TSC-KDL) is complete,

A. Use the included 7

/16 Bolt to remove the black Spacer from the

center of the top of the knee.

B. Remove the Kneecap.

C. Flex the 4P10 KD™True-KD Knee approx. 90-degrees.

D. Select your desired degree of external knee rotation.

Each notch of the KD Adapter and knee top is an adjustment

of 2 degrees.

E. Secure the knee to the KD Adapter using the included

7

/16 Bolt (8mm hex). Torque the bolt to 9ft-lb (12.2Nm).

Patient Notes

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01082021

®

DAW

Industries

For Technical Support call (800)242-8669

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01082021

®

DAW

Industries

For Technical Support call (800)242-8669

14 3

True-KD™Series Knee Connection to

Wire Basket Adapter (TSC-BX)

with Lo-Pro Rotator™

Threaded Side Unthreaded Side

Rubber Plug

7

/16 Bolt

(8mm hex)

M6 Buttonhead

Screw (4mm hex)

M4

Screw Rubber

Plug

Button

Lock Washer

The Lo-Pro Rotator attaches directly to the top of any DAW

True-KD™Series knee. It’s low build height allows KD Amputees

the convenience of knee rotation while still maintaining cosmetic

appearance in the sitting position.

The Lo-Pro Rotator features an

Unthreaded Side (with an unthreaded 4-Hole pattern) and a

Threaded Side (with a threaded 4-Hole pattern*Rubber Plug).

A. First, screw in the included M4 Screw

(by hand) partially into the Rubber Plug

and pull up to remove it.

B. Push and hold down the Button and rotate

until the Plug’s Hole lines up with one of

the unthreaded holes on the rotator’s other

side. If it is difficult to rotate, screw in 2

M6 Button Head Screws partially into the

Threaded Side to use as leverage.

C. With the Unthreaded Side against the

adapter, insert one of the included

M6 Button Head Screws (4mm hex)

through the 2 holes into a threaded hole

of the Wire Basket. Screw in, but do not

tighten. It’s recommended the button be

positioned facing forward.

D. Repeat steps B. & C. until all 4 M6 Button

Head Screws are screwed in. Torque each

screw to 7.4ft-lb (9.9Nm).

E. Return the Rubber Plug to its hole.

F. Now you may secure the knee to the bottom of the Lo-Pro

Rotator using the included 7

/16 Bolt (8mm hex). Torque the

bolt to 9ft-lb (12.2Nm).

Connection of the Lo-Pro Rotator to the 4P10 KD™:

After lamination of the Wire Basket Adapter (TSC-BX) is complete,

Patient Notes

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01082021

®

DAW

Industries

For Technical Support call (800)242-8669

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01082021

®

DAW

Industries

For Technical Support call (800)242-8669

4 13

TORQUE SETTINGS

BUILD HEIGHT

Single 7/16 SAE Bolt

(8mm hex)

9ft-lb (12.2Nm)

Pylon Clamp Screw

(5mm hex)

11ft-lb (15Nm)

Important:

Use blue Loctite™242 on all screws referenced here.

It is not recommended to use Ottobock Titanium Pylon.

Do not use a spacer for height adjustment.

Ensure pylon is cut straight.

It is recommended these torques be checked within 30 days

and then 6 months after your delivery of this prothesis.

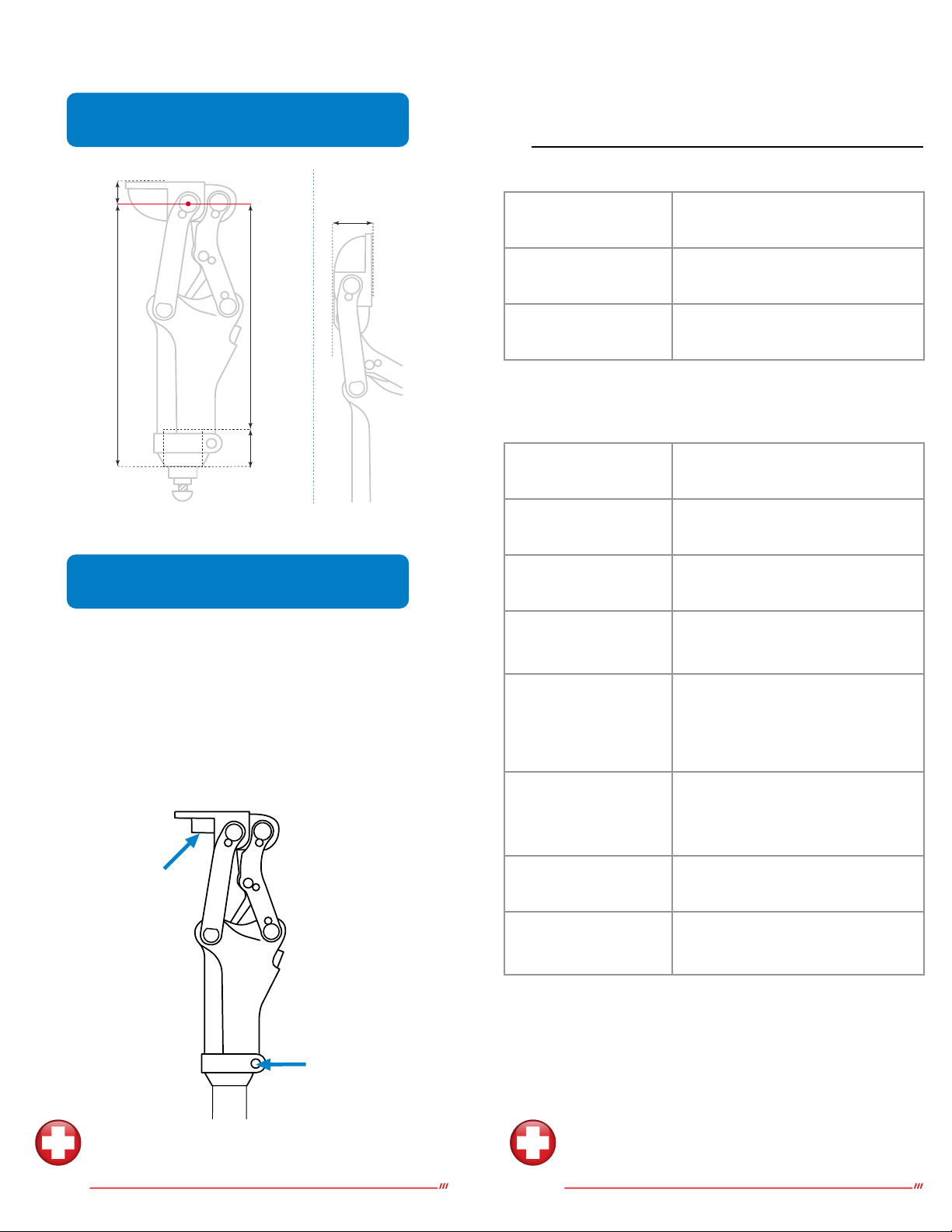

7

7

/

16 in

(189

mm

)

1

3

/

8in

(35

mm

)

8

13

/

16 in

(224

mm

)

3

/

4in

(18

mm

)

Knee Center

4P10 KD

TM

Sitting Position

1

3

/

16 in

(30

mm

)

Specifications

Patient profile:

Body weight Under 275lb (125kg)

Functional level K3 / K4

Amputation level Knee Disarticulation

Knee Specifications:

Stock number TGK-4P10

Max weight limit 275lb (125kg)

Knee weight 2.4 lb (1084g)

Proximal connection M6 threaded 4-hole or,

Unthreaded single hole

Swing Controls

Separate DAW Pneumatics™

Extension/Flexion Adjustments,

Extension Assist Adjustment &

Adjustable Swing Phase Trigger

Stability Controls True-KD™Biomechanics Stability,

Adjustable Extension Stop

Distal connection 30mm tube clamp

Warranty 2 years, upgrade

for additional 3 years

Knee Shown

w/ KneeCap

Removed

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01082021

®

DAW

Industries

For Technical Support call (800)242-8669

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01082021

®

DAW

Industries

For Technical Support call (800)242-8669

12 5

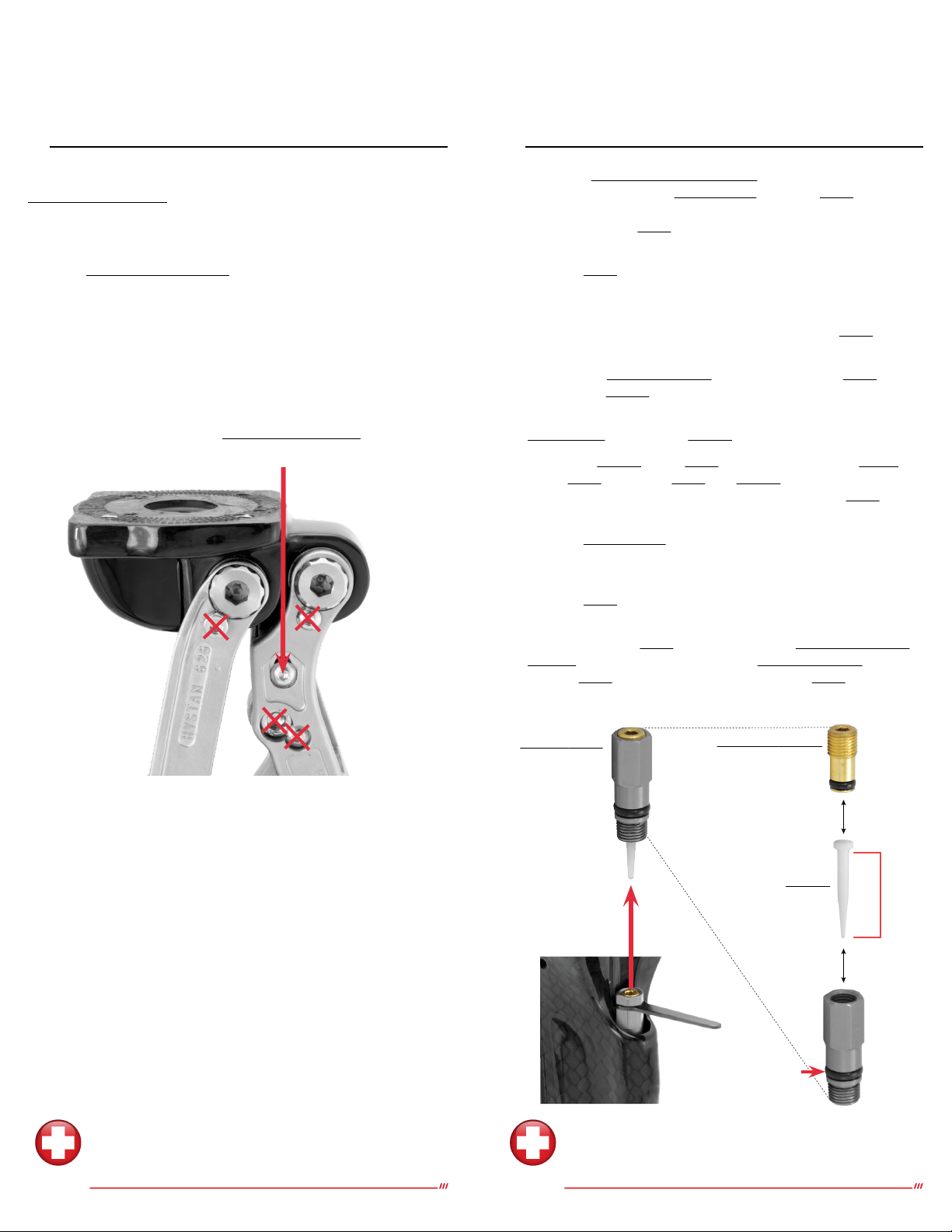

ALIGNMENT

RECOMMENDED

BENCH & STATIC

Standard alignment procedure must be observed to obtain the

maximum benefits offered by this knee. All alignment

references should be taken from the center of the anterior

superior knee axis (commonly referred to as the Knee Center).

Knee Center is

recommended 5-10mm

posterior to TKA

(15mm Maximum,

as illustrated here)

A socket flexion

angle of 5°

recommended

+10mm Heel

TKA

DAW Prosthetic Knee Limited Warranty

The knee comes with a Limited Warranty for 2-years. It covers

manufacturer defects (excluding wear & tear). An additional 3

years of warranty coverage can be purchased for +15% of the

original cost of the knee. See full warranty statement at:

www.daw-usa.com/practitioner-resources/

Weight limit of this knee is 275lb (125kg)

Bumpers are not under warranty.

Tight screws and a straight cut of the tubing are a must. Not

following recommended use of components, including weight

limit and alignment, will void the warranty. Make sure to read

all instructions enclosed with the knee unit.

All repairs on the knee module must be done by a factory-

trained DAW technician. Any disassembly done on the knee

during the warranty period(s) will void the warranty (excluding

dissasembly of the extension spring housing).

Service Under Warranty

For all component repairs call DAW Industries right away. We

will ship a replacement knee the same day, which will become

your patient’s new knee. The replacement component is under

warranty for the time remaining on the original component.

The overnight shipping charge will be credited upon receipt of

the failed knee component.

Service Outside of Warranty

Knees not under warranty may be repaired by DAW. While any

unwarranted knee is being serviced, DAW will provide a rental

knee subject to availability. The DAW rental fee is listed in the

price list under each knee. The rental fee covers the period

DAW takes to complete the repair with ten (10) days allowed

for shipping in both directions. The same rental fee will be

charged every 30 days passed the initial rental fee period.

For any repair you must first contact our Technical Services

at 1(800)242-8669. This will allow DAW to best understand

the issue. Our Technical Support will immediately asses if the

repair qualifies as a “minor” or “substantial” repair. A “minor”

repair will be completed, as a courtesy, free of charge (you

will just pay for return shipping). A “substantial” repair will be

billed at a flat rate according to knee model. Upon return of

your repaired knee, you will be invoiced for the repair charge, if

any. When DAW receives the rental knee, your account will be

credited for the value of the returned knee

(Gold Preferred+ = FREE rental; Preferred = 33% off).

In the event your knee is unrepairable, you will be

notified immediately. The rental must then be returned to

DAW, 2nd day, within five (5) working days. The rental fee may

be applied toward the purchase of a new DAW knee.

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01082021

®

DAW

Industries

For Technical Support call (800)242-8669

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01082021

®

DAW

Industries

For Technical Support call (800)242-8669

6 11

Adjusting the Extension Stop Bumper

(Stability & Swing Phase Trigger Point)

Extension Stop Screw

(2.5mm hex)

To customize the “trigger point” of swing-phase, adjust the

Extension Stop Screw. Max adjustment is 2°.

Note: This adjustment will affect socket flexion slightly.

Turn the Extension Stop Screw (2.5mm hex):

Clockwise for earlier swing-phase initiation

(& less stance phase stability)

Counter-clockwise for later swing-phase initiation

(& more stance phase stability)

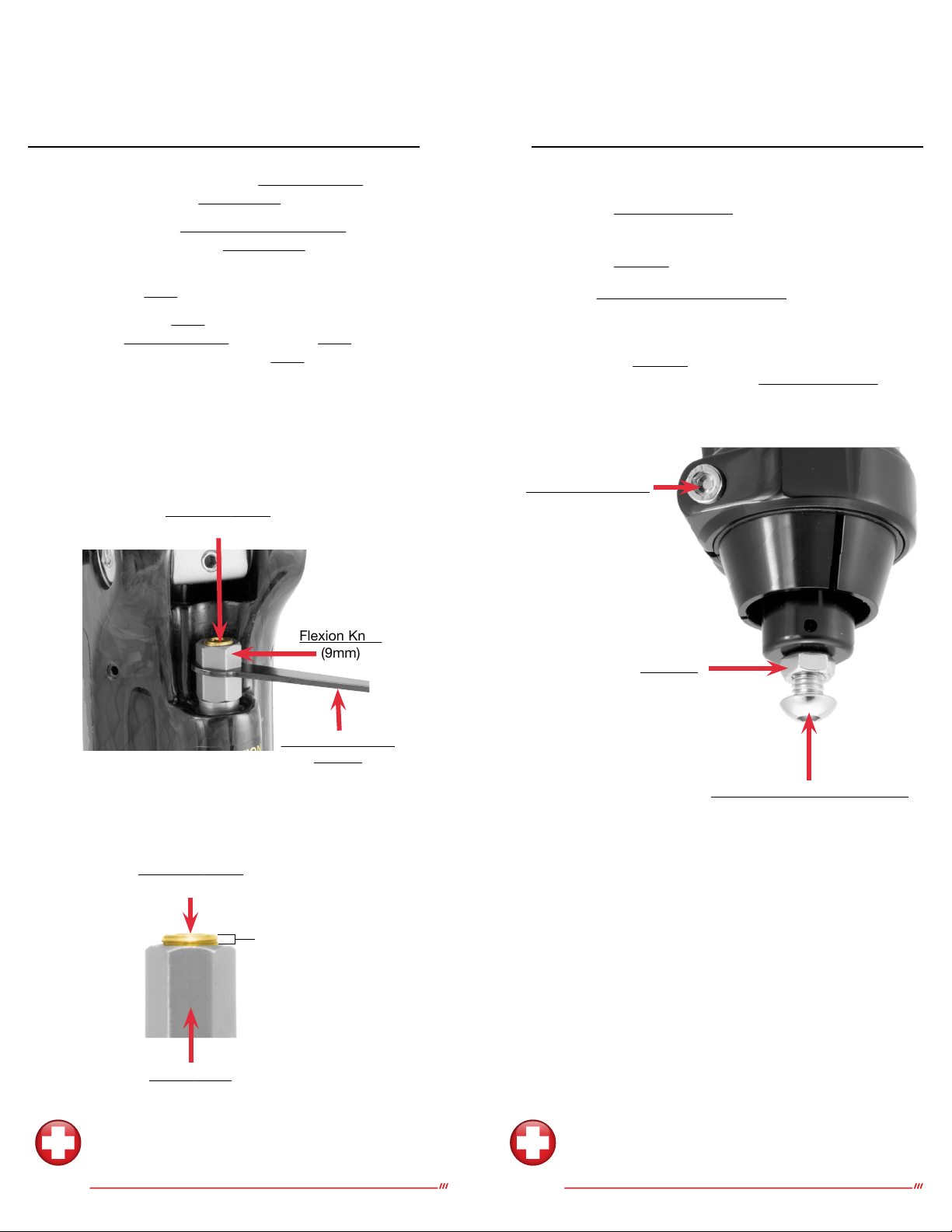

Cleaning Pneumatic Components

Using the Swing Adjustment Wrench (or 9mm wrench),

completely remove the Flexion Knob. Turn the Knob

counter-clockwise until it no longer appears to be

unthreading. The Knob pulls out of its chamber with a small

amount of force.

With the Knob removed, flex the Knee quickly & repeatedly

to clear out any debris from the air passage. Air should flow

smoothly with no restriction.

Using a Q-Tip, clean the chamber from which the Knob was

removed. The entire chamber should be dry.

Remove the Extension Screw (3mm Hex) from the Knob.

Remove the Needle and clean it of any debris or lubricant.

Apply a very light coat of wheel-bearing grease to the

Knob O-ring. Be sure the Needle remains dry.

Return the Needle to the Knob. Do not yet return the Screw

to the Knob. Press the Knob and Needle back into the

chamber of the knee. You will hear a “click” as the Knob

seats back into the chamber.

Turn the Flexion Knob clockwise. Initially, apply a small

amount of downward force while you turn to ensure the

threads catch. Gently screw it in until it stops. Do not tighten.

Turn the Knob counter-clockwise 2 rotations

(the factory setting for Extension).

While holding the Knob stationary with the Swing Adjustment

Wrench (or 9mm wrench), screw the Extension Screw back

into the Knob until 1 thread shows above the Knob

(the factory setting for Flexion).

A.

B.

C.

D.

E.

F.

G.

H.

I.

Needle

Clean

Flexion Knob

(9mm)

Extension Screw

(3mm)

Knob O-ring

Apply wheel

bearing grease

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01082021

®

DAW

Industries

For Technical Support call (800)242-8669

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01082021

®

DAW

Industries

For Technical Support call (800)242-8669

10 7

Replacing or Trimming

the Extension Assist Spring

To replace the current Extension Assist Spring with the

Stronger spring included with your knee:

Completely remove the Pylon Clamp Screw (5mm hex).

Remove the pylon.

Flex the knee to full flexion.

Using a 12mm wrench, or crescent wrench, twist the

Lock Nut clockwise, the Spring Housing will extend

out of the knee as you twist the Lock Nut.

You can now pull the Spring out of the Housing .

Insert your new Spring into the Housing .

Unflex the knee to full extension and return the housing

to the knee making sure the groove for the

Pylon Clamp Screw lines up properly.

After returning the Pylon. Retighten Pylon Clamp Screw

(5mm hex) to 11ft-lb (15Nm)

Too much Extension Assist even with the lighter spring?

Complete steps A. through E. above

Using a grinding wheel, trim one or two coils (maximum) off one

end of the Spring. Smooth the trimmed end. Return the Spring to

the housing, trimmed end down. Continue with step G. above.

A.

B.

C.

D.

E.

F.

G.

1

1

2

2

2

2

3

3

3

Groove for

Pylon Clamp Screw

Adjusting Swing Phase Controls

(Flexion & Extension Dampening)

It is recommended your Patient take their first steps slowly!

This knee is engineered to conserve your Patient’s energy &

strength throughout the day. Very little energy is required to

initiate gate.

The DAW Pneumatics™Knob-and-Screw-Adjustment

provides exceptionally precise control of heel rise and

extension dampening. Perform these adjustments in

1/8-turn increments.

Needed for This Adjustment:

✔3mm hex key

✔Swing Adjustment Wrench (included) or a 9mm wrench

It is recommended to make your Extension Adjustment first,

then your Flexion Adjustment. Repeat adjusting Extension

then Flexion as needed.

Adjusting Extension Dampening:

In 1

/8-turn increments, turn the brass Extension Screw:

Clockwise to increase resistance

Counter-Clockwise to decrease resistance

Adjusting Flexion Dampening:

While holding the Extension Screw stationary (3mm hex key),

in 1

/8-turn increments turn the Flexion Knob:

Clockwise to increase resistance

Counter-Clockwise to decrease resistance

NOTE: Excessive adjustment of Extension Screw can jam

needle pin, eliminating full range-of-motion resistance control.

Flexion Knob

(9mm)

(Posterior View)

Extension Screw

(3mm hex key)

Swing Adjustment

Wrench

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01082021

®

DAW

Industries

For Technical Support call (800)242-8669

DAW

© Copyright 2021, DAW Industries, San Diego, CA - All Rights Reserved 01082021

®

DAW

Industries

For Technical Support call (800)242-8669

8 9

Pylon Clamp Screw

(5mm hex)

11ft-lb(15nm)

Lock Nut

(12mm wrench)

Hand Tighten

Extension Assist Control Screw

(5mm hex)

To Adjust Extension Assist:

Loosen the Pylon Clamp Screw (5mm hex)

and remove the Pylon

Loosen the Lock Nut (12mm wrench)

Turn the Extension Assist Control Screw (5mm hex):

Clockwise to increase extension assist

Counter-clockwise to decrease extension assist

Re-tighten the Lock Nut, Hand Tighten (12mm wrench)

After returning the pylon, re-tighten Pylon Clamp Screw to

11ft-lb (15Nm).

A.

B.

C.

D.

Adjusting Extension Assist

Returning Flexion & Extension

Adjustments to Factory Settings

A.

B.

C.

D.

The knee’s Flexion & Extension Controls

are now at their factory settings.

Fig. 1

Fig. 2

Flexion Knob

(9mm)

(Posterior View)

Extension Screw

(3mm hex key)

Swing Adjustment

Wrench

1 Thread showing

above Knob

Flexion Knob

(9mm)

Extension Screw

(3mm hex)

Unscrew and remove the brass Extension Screw (3mm Hex)

from the center of the Flexion Knob.

Using the included Swing Adjustment Wrench (or a 9mm

wrench), gently screw the Flexion Knob clockwise until

it stops. Do not tighten.

Now turn the Knob counter-clockwise 2 full rotations.

While holding the Knob stationary,

screw the Extension Screw back into the Knob (fig. 1)

until one thread shows above the Knob (fig. 2).

This manual suits for next models

1

Other DAW Industries Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Mac Medical

Mac Medical SS32 instruction manual

BRASSELER USA

BRASSELER USA EndoPro 270 Operation, maintenance & instruction manual

Zeiss

Zeiss OPMI Lumera T Instructions for use

Handicare

Handicare SystemRoMedic Carina350EE user manual

Bistos

Bistos BT-350 Operator's manual

AmpliVox

AmpliVox Otosure operating manual