DCM SOLUTION ESV710 User manual

Versión: 1.0 05/01/2021

DCM Solution S.A.

Sanitizing tunnel

ESV710

Installation Manual

All information contained in this document, including illustrations and specifications are reliable

at the date of its publication but is subject to change without notice.

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 2of20

© 2021 DCM Solution S.A.

This publication or any part thereof, must not be reproduced or transmitted in

any form or by any means, electronic or mechanical, including photocopying,

recording, storage in an information retrieval system, or otherwise, without the

prior written permission of DCM Solution SA.

The information contained in this manual, including illustrations and

specifications, has been carefully checked and is reliable as of the date of its

publication but is subject to change without prior notice.

DCM Solution S.A., assumes no liability for any inaccuracy, error or omission in

this manual.

Under any circunstances, DCM Solution S.A., will be liable for direct, indirect,

special, incidental or consequential damages resulting from any defect or

omission of this manual, even if the possibility of damage was advised.

In the interest of product development, DCM Solution S.A., reserves the right to

make improvements to this manual and the products described at any time,

without prior notice or obligation.

2021 –Sanitizing tunnel ESV710–Installation Manual

.

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 3of20

Table of contents

1Introduction _______________________________________________ 4

2Object description__________________________________________ 4

2.1 General _______________________________________________ 4

2.2 Technical specification __________________________________ 4

2.2.1 Standard characteristics _______________________________ 4

2.2.2 Optionals___________________________________________ 4

2.2.3 Models ____________________________________________ 4

2.2.4 Electric power supply _________________________________ 5

2.2.5 Electric consumption__________________________________ 5

2.2.6 Environmental conditions ______________________________ 5

2.2.7 Weight_____________________________________________ 5

2.2.8 Dimensions_________________________________________ 6

3Technical information_______________________________________ 7

3.1 Location of the components______________________________ 7

4Installation________________________________________________ 8

4.1 Required tools _________________________________________ 8

4.2 Preliminary work on site _________________________________ 8

4.3 Unpacking_____________________________________________ 9

4.4 Assembly ____________________________________________ 12

5Wiring___________________________________________________ 15

5.1 Pre requisites _________________________________________ 15

5.2 Power supply _________________________________________ 15

6Start up__________________________________________________ 16

6.1 Filling the tank ________________________________________ 16

6.2 Purge________________________________________________ 16

6.3 Pressure valve ________________________________________ 17

7Operation________________________________________________ 18

8Maintenance _____________________________________________ 19

8.1 Spray nozzle cleaning __________________________________ 19

8.2 Platform draining ______________________________________ 20

8.3 Principal tank draining _________________________________ 20

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 4of20

1 Introduction

Please carefully read this manual which contains information that will assist you

in the operation and commissioning of the unit.

2 Object description

2.1 General

The ESV is a sanitizing tunnel for supermarket carts that allows a quick

sanitization to provide users hygienic safety before starting their purchases.

2.2 Technical specification

2.2.1 Standard characteristics

SAE1010 epoxy painted Steel cabinet

Exposure time from 6 to 10 sexonds

Capacity of more than 500 cars/hour

2 rows of 4 industrial spray nozzles with anti-drip

1 liquid tank 45liters

System consumption: 10 liters per 2500 cars

Pressurizing unit

Low voltaje supply

Easy installation and operation

Does not include sanitizing liquid

It MUST be used with sanitizing products approved by an oficial entity

2.2.2 Optionals

Stainless steel cabinet

Automatic ignition by presence sensor

2.2.3 Models

ESV710 : SAE 1010 painted with epoxy sanitizing tunnel for supermaket

carts

ESV711 : Stainless steel sanitizing tunnel for supermarket carts

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 5of20

2.2.4 Electric power supply

Voltage

12VDC @ 5A

2.2.5 Electric consumption

Electric consumption

50 W max

2.2.6 Environmental conditions

Operating Temperature

+0 °C to +40 °C

Storage Temperature

-10 °C to +55 °C

Relative Humidity

95% non-condensible maximum

2.2.7 Weight

Weight

250 Kg

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 6of20

2.2.8 Dimensions

Characterist

mm

Length

1290

Width

1320

Height

1480

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 7of20

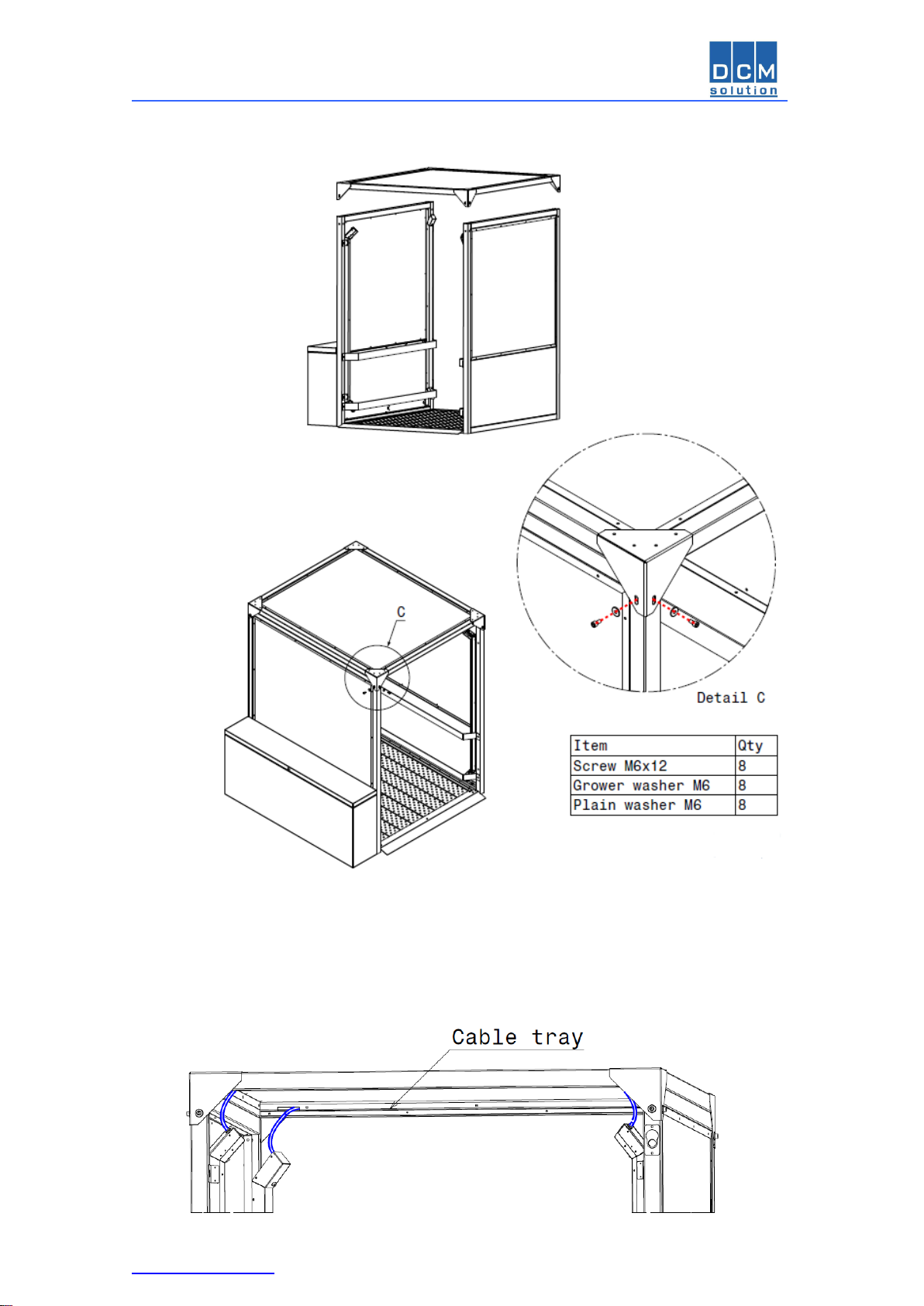

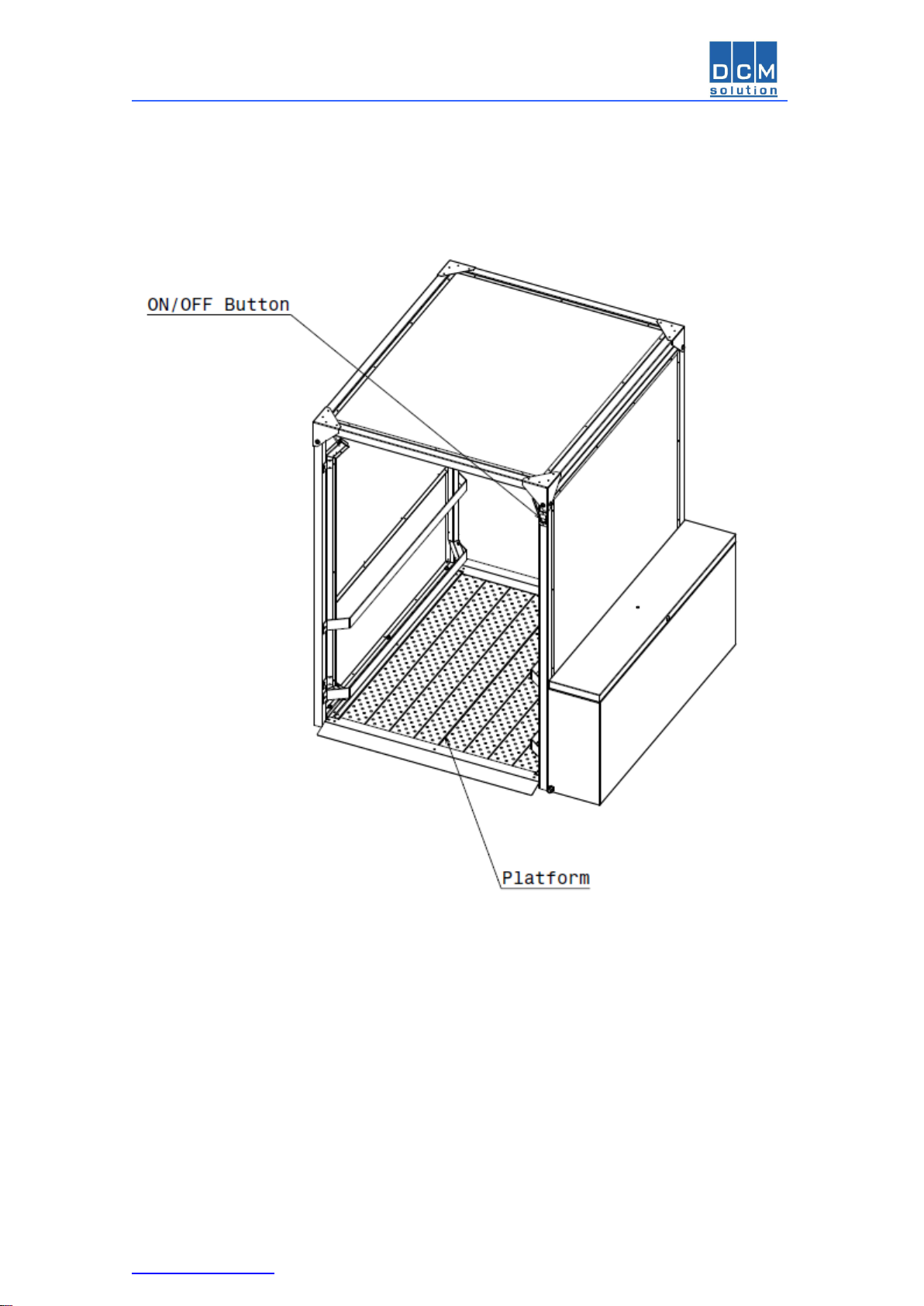

3 Technical information

3.1 Location of the components

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 8of20

4 Installation

4.1 Required tools

Industrial hammer drill

10mm Widia Solid CarbideDrill for concrete

4 10mm expansion metal plugs (type FISCHER steel MR10).

14 and 17mmwrench.

Mm Hexkey set.

Please carefully read all sections before starting the installation.

4.2 Preliminary work on site

Verify the position and location of the equipment according to the general

installation.

Depending on the area of installation of the equipment, there are two posible

variants.

1. If the floor is concrete, the installation can be carried out, with the help of

steel or chemical drills, by placing the drills in a position that matches

with the anchoring holes of the cabinet, either by means of the

installation plane or with a template.

2. In all the cases where the floor is not concrete, the installation should be

done on a bulk head plate. It must be made with threaded rods ØM10,

according to the installation blueprint, and tacked to the existing ground

with cement. It has to be 10cm below the level of the floor. It must also

be taken into account in this instance, that the threaded rods that are part

of the plate exceed the level of the floor by 5 cm.

Check that the floor or concrete base where the cabinets will be mounted is

even and leveled +/- 5mm in the area of attachment of the cabinets.

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 9of20

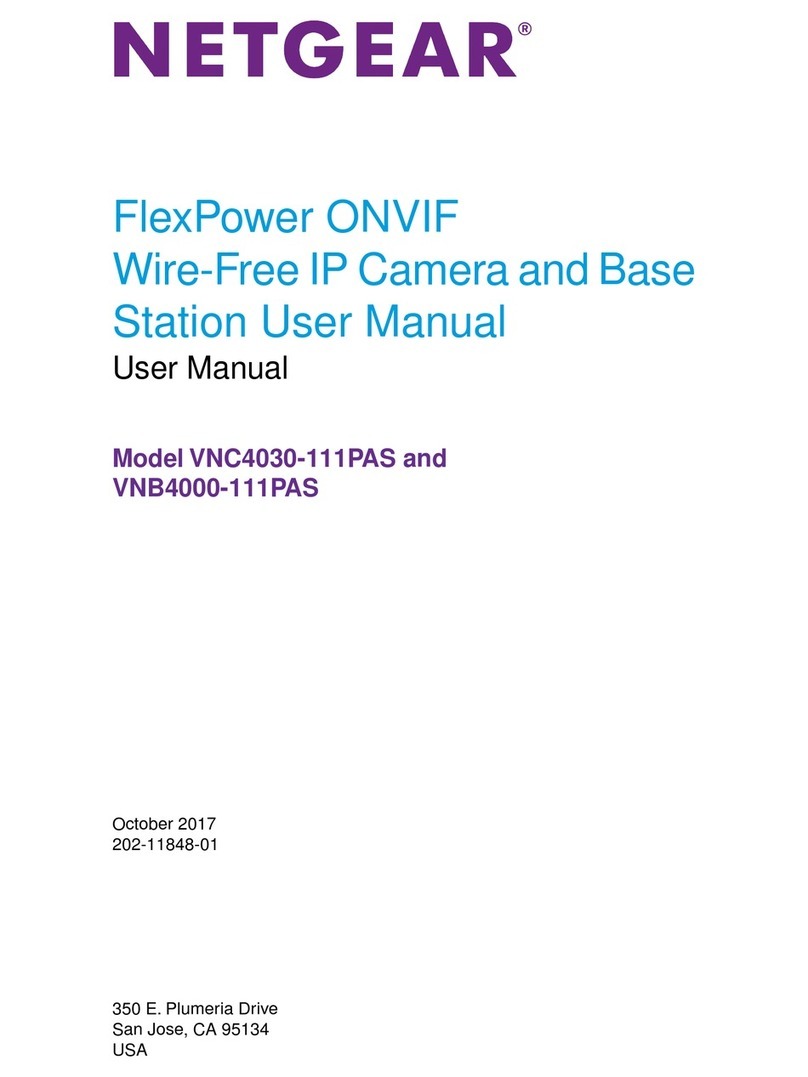

4.3 Unpacking

1. Place the package on the floor without turning it around.

2. Take the upper cover off.

3. Remove the styrofoam and grasp the platform.

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 10of20

4. Place the platform where the sanitizer will be installed.

5. Take the ceiling out of the box and leave it aside.

6. Remove the sidewalls from the box.

7. Discard packaging.

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 11of20

NOTE: You will find each item in its position. For each step you will have to

unscrew it, put the part and screw it back.

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 12of20

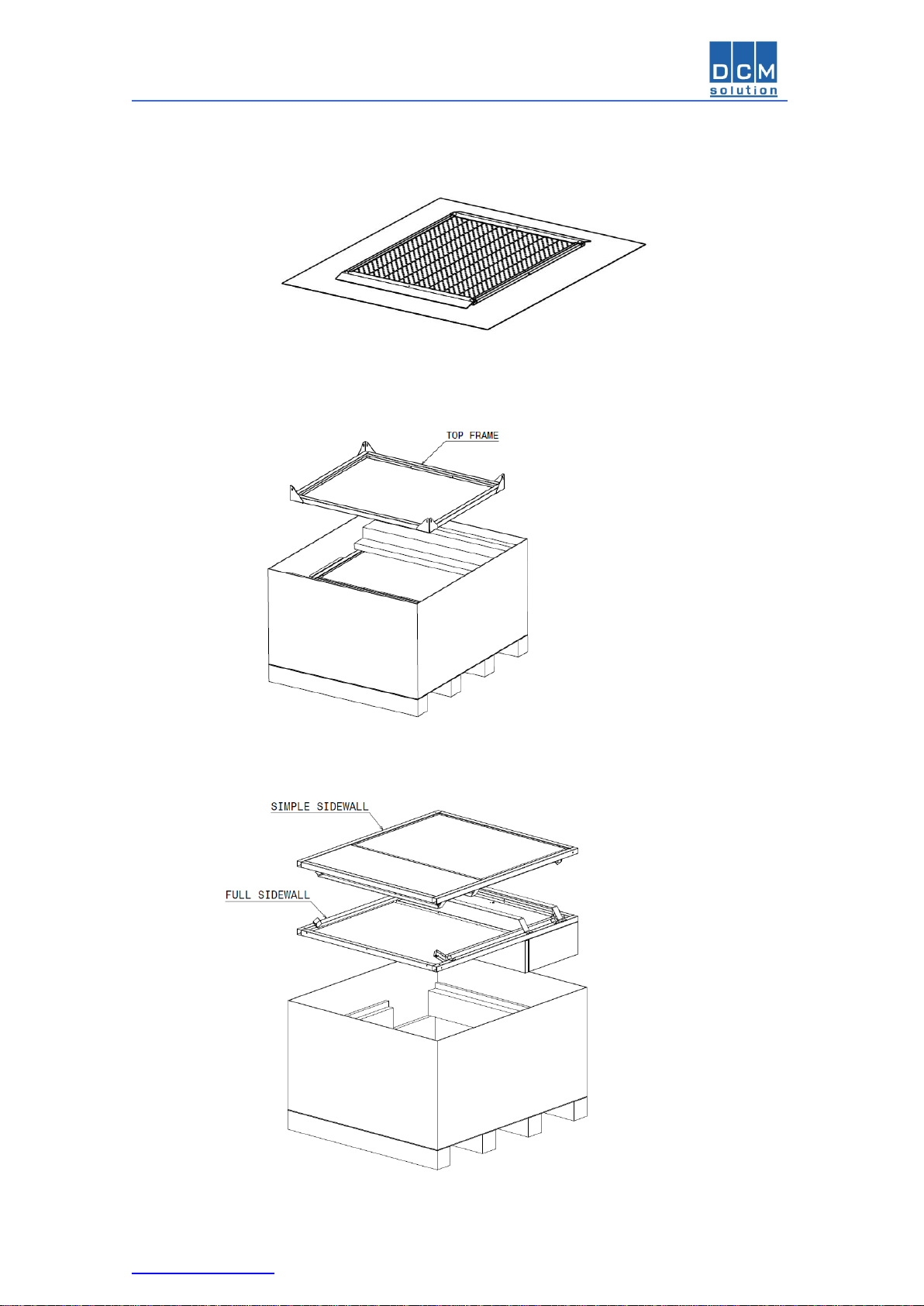

4.4 Assembly

1. Join the sidewalls to the platform as shown in the illustrations and

screw.

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 13of20

2. Place the ceiling in position and screw.

3. Take the hoses located at each inferior corner of the top frame and

connect them to their respective coupling.

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 14of20

To connect the hose to the coupling push the blue part of the coupling and hold

it down while inserting the hose.

4. Connect the draining hose coming out from the full sidewall to the

platform ecoupling.

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 15of20

5 Wiring

5.1 Pre requisites

For equipment a power supply of 12Vdc 5Amp (not provided) should be used.

For greater electrical safety of the installation it is necessary to comply with the

following:

Power to equipmentmust come from an electrical board (not

provided).

The electric panel must be equipped with:

oConnection terminal block.

oCircuit Breaker.

o10A termal key.

oHave an excellent land fill.

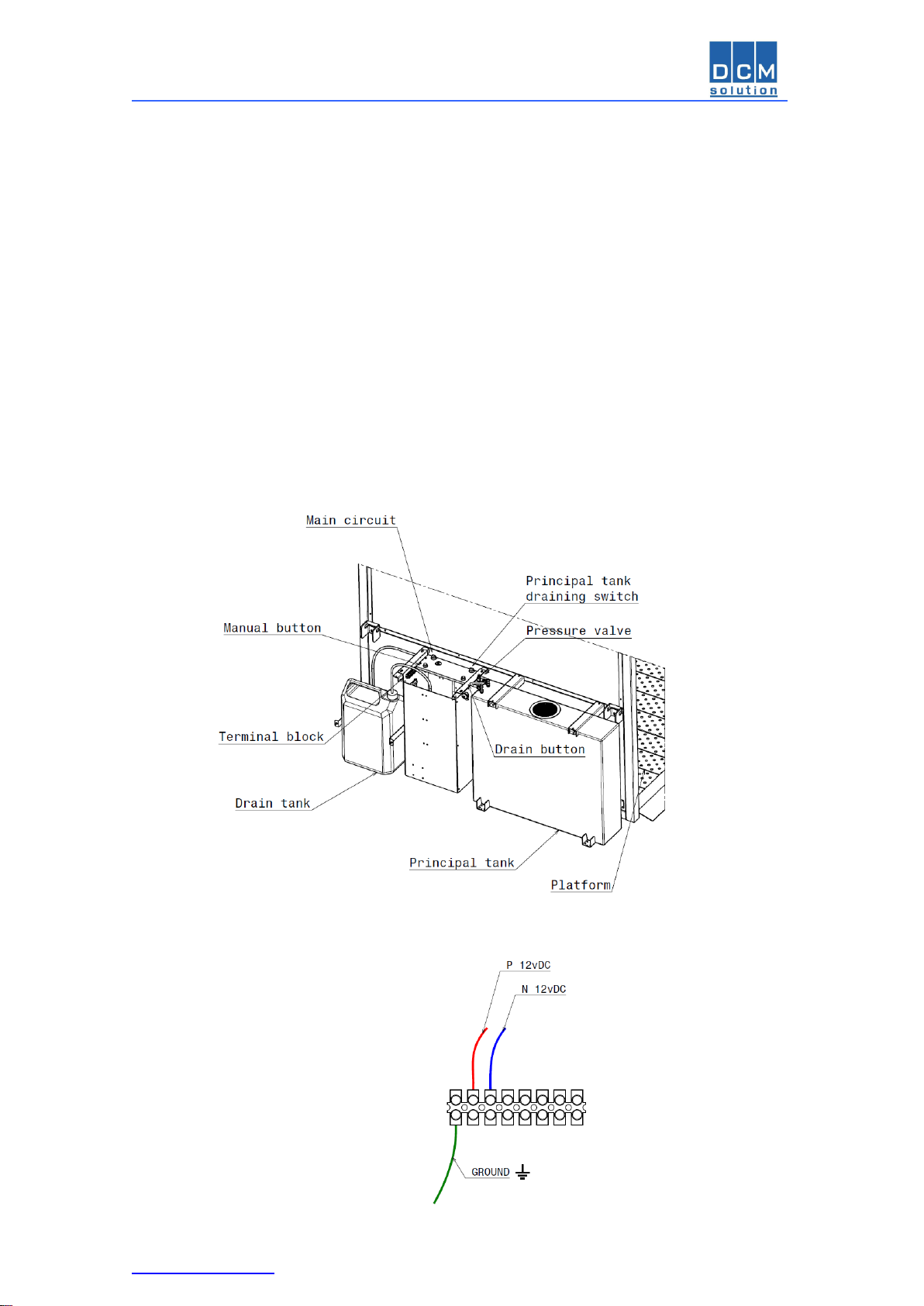

5.2 Power supply

1. Open the full sidewall's door and identify the terminal block.

2. Connect the electric supply to the terminal block as shown in the

illustration.

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 16of20

6 Start up

6.1 Filling the tank

Fill the tank directly through the filter placed on the top of the tank.

6.2 Purge

Connect the unit to the power source with 12vDC.

Check if the main circuitis in the same position as shown in the image.

Hold down the manual button, do not release until liquid comes from each of the

8 spray nozzles.

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 17of20

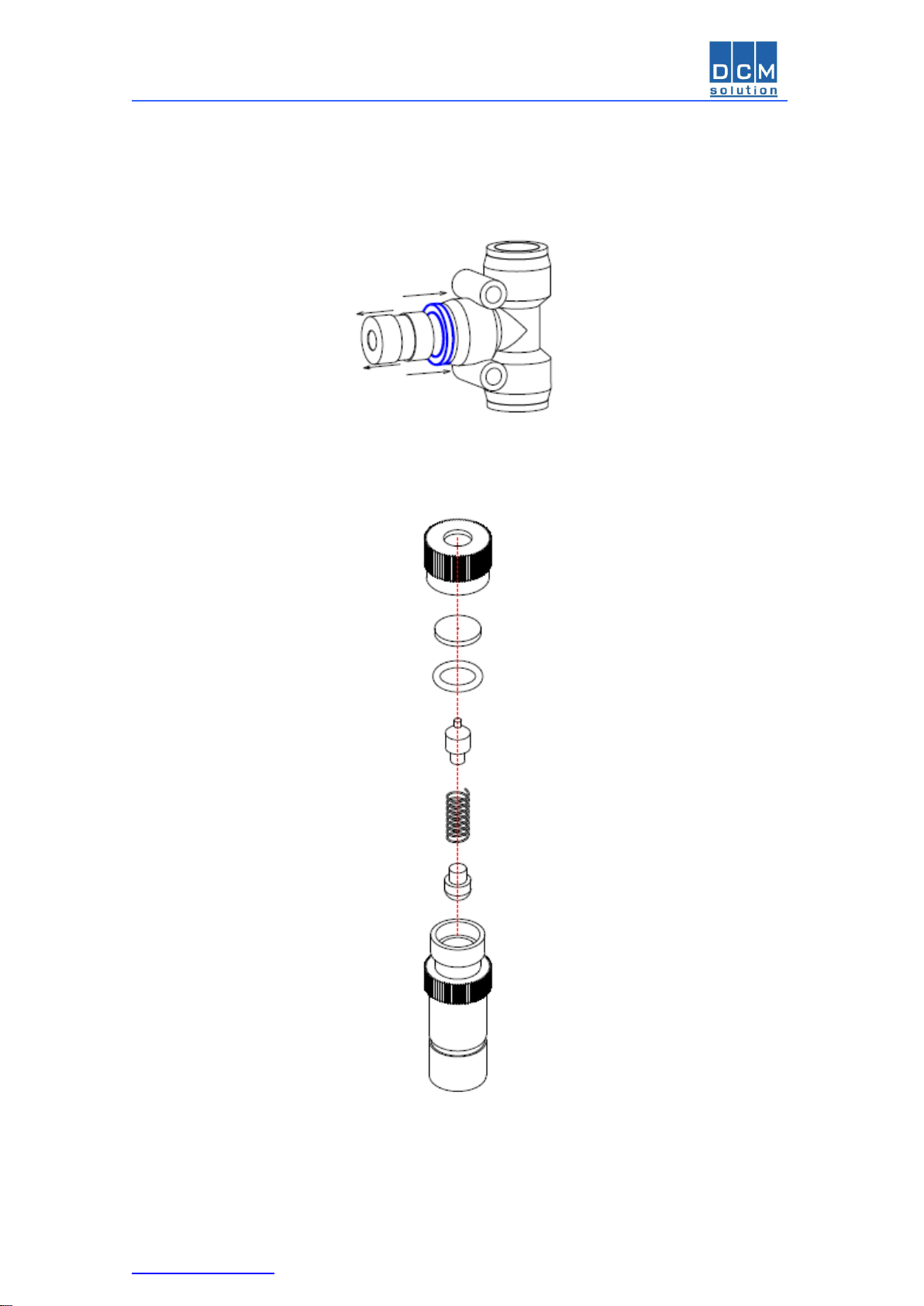

6.3 Pressure valve

In case of willing to correct the pressure, you can change it through the

pressure valve as shown in the pressure valve page.

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 18of20

7 Operation

Put the carton the platform and push the ON/OFF button. Wait until it finishes or

press the button again to stop it manually. Spraying duration: 7 seconds.

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 19of20

8 Maintenance

8.1 Spray nozzle cleaning

1. Pull out the nozzle from the product while holding down the blue part.

1. Disassemble the nozzle very carefully as it has tiny components

inside.

2. Clean all the components (Do not use chemical solvents).

3. Put back in position.

4. Repeat with all of the nozzles.

Sanitizing tunnel ESV710

www.dcm.com.ar Installation Manual Page.: 20of20

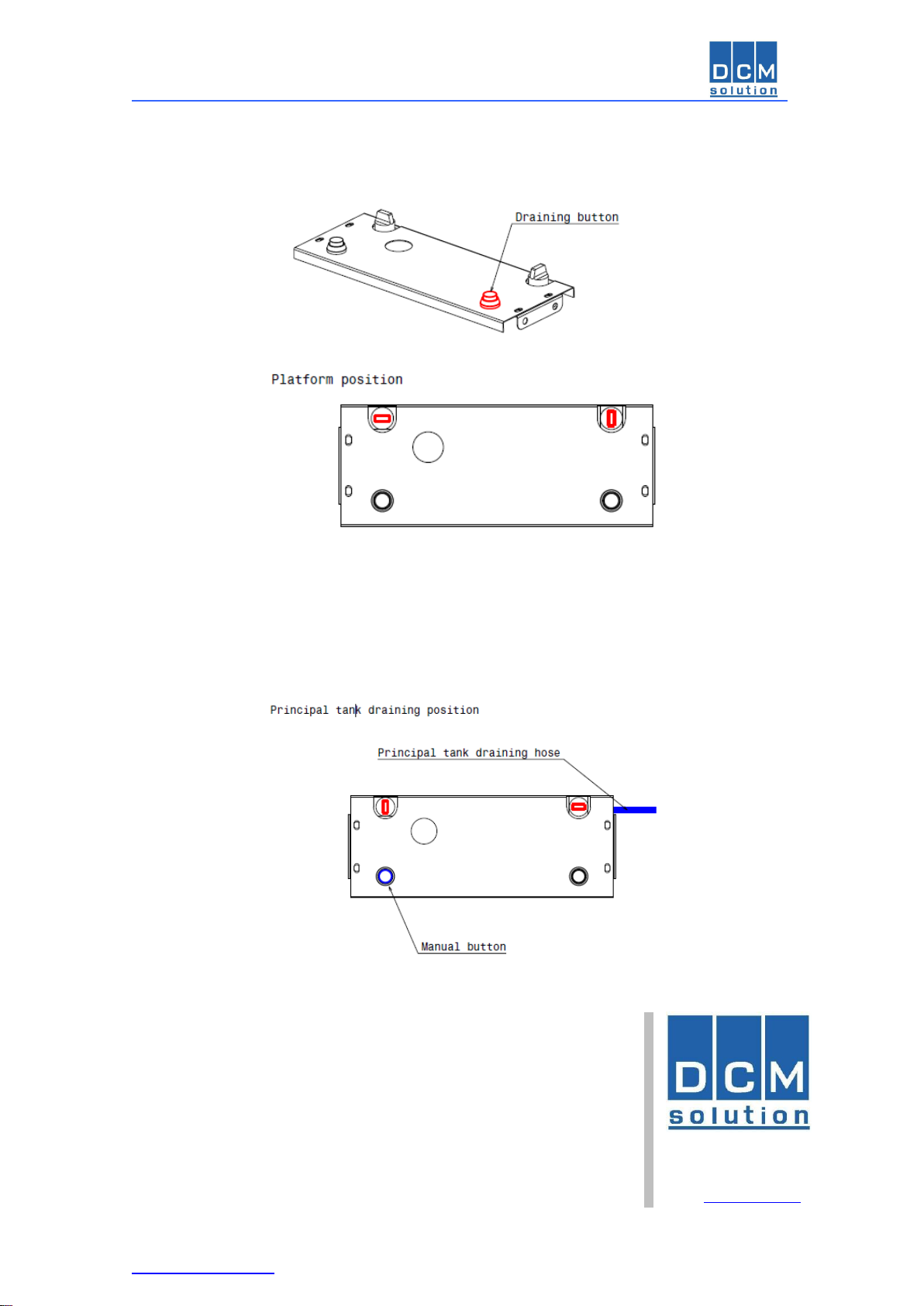

8.2 Platform draining

Check that the position of the knobs are in "platform position" and press the

draining button.

8.3 Principal tank draining

If it is needed to drain the principal tank put the knobs in "principal tank draining

position" and press the manual button.

Juan de Garay 3942

(1636) Olivos - Buenos Aires

República Argentina

Tel: (+54 11) 4005-5881/ 4711-0458

Email: info@dcm.com.ar

Table of contents

Other DCM SOLUTION Accessories manuals

Popular Accessories manuals by other brands

Omron

Omron Z4W-V manual

elsner elektronik

elsner elektronik KNX RW sl Technical specifications and installation instructions

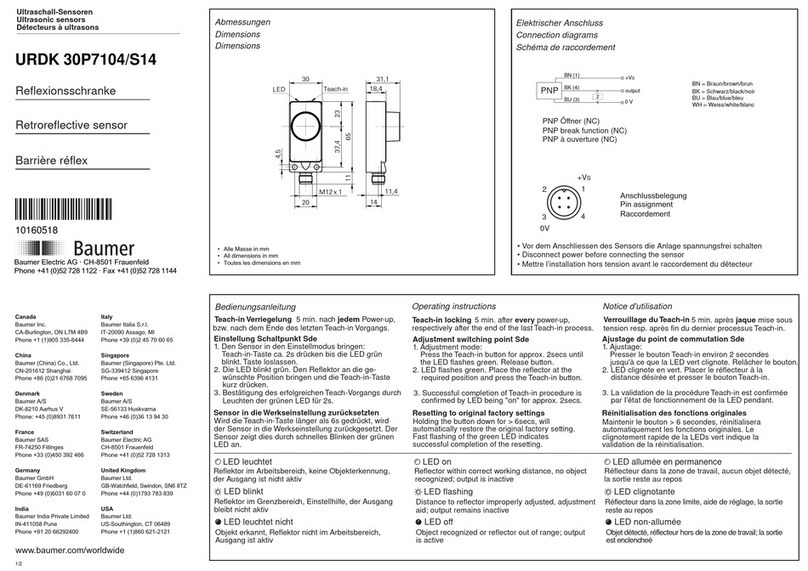

Baumer

Baumer URDK 30P7104/S14 quick start guide

Promate

Promate PowerPeak-10 user guide

Gedge Systems

Gedge Systems GS3100 Operating & installation manual

Steren

Steren TIM-305 instruction manual