DDS Calorimeters CALOK 3K-S User manual

3K-S

INSTALLATION GUIDE

VERSION NO: 1.2

DATE: 2023

MANUFACTURED BY:

CAL3K-S INSTALLATION GUIDE V1.2 Website: www.CAL3K-S.com i

Digital Data Systems (Pty) Ltd.

CAL3K Advanced Bomb Calorimeters

www.ddscalorimeters.com

Table of Contents:

1!INTRODUCTION .................................................................................................................... 1!

1.1!PURPOSE OF THIS MANUAL .......................................................................... 1!

1.2!HOW TO USE THIS MANUAL.......................................................................... 1!

1.2.1!WARNING SYMBOL................................................................................ 1!

1.2.2!INFORMATION (NOTE) SYMBOL .............................................................. 1!

2!USER INFORMATION AND HELP ............................................................................................ 1!

3!SYSTEM COMPONENTS ......................................................................................................... 2!

3.1!THE CAL3K-S SYSTEM CHECK LIST ................................................................ 2!

4!INSTALLATION ...................................................................................................................... 3!

4.1!UNPACKING AND INSPECTION ...................................................................... 3!

4.2!SETTING UP................................................................................................ 4!

4.2.1!PREREQUISITES ................................................................................... 4!

4.2.2!SITE SELECTION................................................................................... 4!

5!TESTING ............................................................................................................................... 5!

5.1!TEST CAL3K HARDWARE .............................................................................. 5!

5.2!TEST VESSEL HARDWARE............................................................................. 5!

6!SAFETY PRECAUTIONS .......................................................................................................... 5!

6.1!CALORIMETER (3K-S) .................................................................................. 5!

6.2!FILLING STATION (3K-3).............................................................................. 5!

6.2.1!HIGH PRESSURE OXYGEN ...................................................................... 6!

6.3!VESSEL (3K-5)............................................................................................ 6!

7!DAILY SAFETY STEPS ............................................................................................................. 8!

8!WARRANTY – FOR NEW PRODUCTS ...................................................................................... 9!

8.1!PURPOSE OF PRODUCT WARRANTY................................................................ 9!

8.2!OWNER’S WARRANTY................................................................................... 9!

8.3!EXCLUDED (NON-WARRANTY) PARTS ............................................................. 9!

8.4!WARRANTY – REPAIRED PRODUCTS..............................................................10!

8.5!GENERAL – WARRANTY VOID .......................................................................10!

8.6!WARRANTY REGISTRATION FORM.................................................................11!

CAL3K-S Installation Guide V 1.2 Website: www.ddscalorimeters.com 1

Digital Data Systems (Pty) Ltd.

CAL3K Advanced Bomb Calorimeters

www.ddscalorimeters.com

1 INTRODUCTION

Digital Data Systems (Pty) Ltd (dds) specializes in the design and manufacture of scientific bomb

calorimeter systems for various types of industries and applications from the coal mining industry to

educational institutes. dds bomb calorimeter systems are the most advanced combustion calorimeter

systems available today. The system is used to measure the calorific value of both solids and liquids. dds

has a wide range of systems to suit different applications and sample requirements. Please visit our

website: www.ddscalorimeters.com to find out more. You have chosen the CAL3K-S Bomb Combustion

Calorimeter System, which is best suited for fast and accurate calorimetry operations.

1.1 PURPOSE OF THIS MANUAL

It serves as a short introduction to the CAL3K-S system and the various components. It explains the very

basics of operation and guides you to perform hardware tests. It relies on the DEFAULT setting and the

factory calibration.

But there is more: Information and capability! This is not explained here but in the operations manual.

All functions can be exercised from the keyboard and a PC is not needed. However, a PC can show more

data and it can capture results.

1.2 HOW TO USE THIS MANUAL

This Manual makes use of some informative symbols or icons, to bring your attention to the text.

1.2.1 WARNING SYMBOL

This yellow triangle with an exclamation mark inside it indicates a WARNING message or a

message that is instructing you NOT to do something. Please take note of this message,

because if you ignore it you could damage the Calorimeter equipment.

1.2.2 INFORMATION (NOTE) SYMBOL

This white hand with a finger pointing indicates a NOTE or INFORMATIVE message. It indicates

something that you need to pay attention to. Please take note of this message, as it provides

special or detailed information about a particular item.

2 USER INFORMATION AND HELP

Included in your shipment is this printed Installation Guide.

The on-line Help Guide for basic system operations, trouble-shooting and solutions, application notes as

well as how everything functions is available on-line and can be found at www.ddscalorimeters.com .

Please note the CAL3K-S Windows Software can be downloaded from the following link:

https://ddscalorimeters.com/dds-software/cal3k/

CAL3K-S Installation Guide V 1.2 Website: www.ddscalorimeters.com 2

Digital Data Systems (Pty) Ltd.

CAL3K Advanced Bomb Calorimeters

www.ddscalorimeters.com

3 SYSTEM COMPONENTS

3.1 THE CAL3K-S SYSTEM CHECK LIST

The system consists of the following:

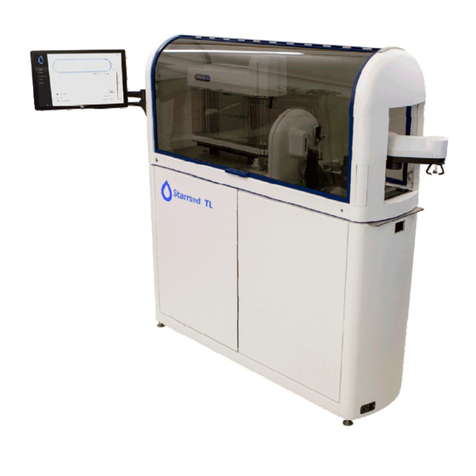

3K-S

CAL3K-S Calorimeter

1

Received

3K-S-KT

CAL3K-S Calorimeter Installation Kit

1

Included in Kit:

3K-1-055

Power Supply (12V)

1

3K-1-061

PC Keyboard (PS2)

1

3K-4-049

Preparation Stand

1

3K-1-081

Stainless Steel Tweezers

1

3K-4-084

Certified Benzoic Acid Tablets (150 x 0.5g Tablets per Bottle)

1

3K-4-106

Wire Brush

1

3K-1-043

USB with manuals, software etc

1

INSTALLATION-MANUAL

CAL3K-S Installation Guide Printed

1

3K-3

CAL3K Filling Station

1

3K-3-KT

CAL3K Filling Station Installation Kit

1

Included in Kit:

3K-3-29

Nozzle O-rings

5

3K-3-21

Oxygen Regulator Connection - Quick Fit

1

3K-3-27

High Pressure Oxygen Pipe 4mm (3.75m) (Clear)

3.75M

3K-3-22

De-filler Cap

1

3K-1-080

Nozzle O-rings

2

3K-3-32

Allen Key

1

3K-1-106

O-Ring Lubrication Grease tube

1

3K-5S

CAL3K-S Standard Vessel

1

3K-5S-KT

CAL3K-S Standard Vessel Installation Kit

1

Included in Kit:

3K-4-096

Centre Electrode

2

3K-4-037

Outside Electrode

2

3K-4-047

Crucibles

1

3K-4-092

Deflector Plate

2

3K-4-093

Firing Wire (1 packet of 5)

1

3K-4-065

Firing Cotton Packet (1 packet of 100)

2

3K-4-094

Lid O-Rings

5

3K-4-022

Top & Bottom O-ring

10

CAL3K-S Installation Guide V 1.2 Website: www.ddscalorimeters.com 3

Digital Data Systems (Pty) Ltd.

CAL3K Advanced Bomb Calorimeters

www.ddscalorimeters.com

4 INSTALLATION

4.1 UNPACKING AND INSPECTION

There are no special precautions to be taken when unpacking your system. The following check list is for

your convenience:

1. Locate and tick-off the various system components as indicated on the CAL3K-S Check List as

per above.

2. Unpack and inspect all the system components such as the 3K-S Calorimeter, 3K-3 Filling

Station and the 3K-5S Standard Vessels according to the instructions in the relevant sections in

this document.

3. Inspect everything for any physical damage during transit. If damaged, consult your Agent

immediately.

4. The Calorimeter has a GROUND (SAFETY EARTH) lug at the rear panel. This lug MUST be

connected to the EARTH supply to ensure operating personal safety in case the power supply

fails.

5. Connect the power supply to the mains power and to the Calorimeter. Any power supply with

12V output, 1000mA capacity, centre pin POS, can be used.

6. Observe that the Display on the Calorimeter comes ON. If not, check the mains connections or

consult your Agent immediately.

CAL3K-S Installation Guide V 1.2 Website: www.ddscalorimeters.com 4

Digital Data Systems (Pty) Ltd.

CAL3K Advanced Bomb Calorimeters

www.ddscalorimeters.com

4.2 SETTING UP

4.2.1 PREREQUISITES

Prior to installation of the CAL3K-S System, the User must provide the following:

1. A mains outlet for the 3K-S Calorimeter and a mains outlet power supply.

2. A supply of oxygen at a pressure of 3.0Mpa (30bars) (3000Kpa) within 4 meters of the 3K-S

Calorimeter. If bottled oxygen is used, a suitable high-pressure oxygen regulator must be

supplied. Digital Data Systems can supply a single stage high-pressure oxygen regulator; contact

your agent for more information.

3. If a balance is supplied, ensure that a sturdy, stable weighing surface is available. A mains outlet

and Balance connecting cable will also be required (balance cable supplied as part of kit).

4.2.2 SITE SELECTION

The 3K-S Calorimeter is a desktop unit, which can be installed wherever the laboratory space permits,

with two restrictions:

1. The CAL3K-S system, consisting of 3K-S Calorimeter, should be connected to a mains circuit

without heavy inductive or SCR switched equipment. It is safe to have balances or other small

electronic apparatuses on the same circuit. Good installation practice would be to have a

separate fused mains circuit with separate earth leakage supply (or an earth current monitor, if

applicable) for every system component. Future computers and peripherals installed can be

connected to the same circuit.

2. The unit should be in a place with a stable temperature, not in direct sunlight or in the outlet

path of an air conditioner.

Please see above for the dimensions, weights, and power requirements per unit. The BALANCE

data would be dependent on the make and model that you will be using.

CAL3K-S Installation Guide V 1.2 Website: www.ddscalorimeters.com 5

Digital Data Systems (Pty) Ltd.

CAL3K Advanced Bomb Calorimeters

www.ddscalorimeters.com

5 TESTING

It is recommend to run a calorimeter hardware test and a vessel hard ware test after installation

and before operation of the system.

5.1 TEST CAL3K HARDWARE

The test is activated by F9 or by:

13 CAL3K-TEST: 0

This command tests the CAL3K hardware. Once started the unit will cycle through all tests and will

‘hang’ on any fault. Individual test can be executed (without cycling through all preceding test) by

replacing the ‘YES’ entry by the test number.

This test should be repeated once a day. The vessel must not be in the well.

5.2 TEST VESSEL HARDWARE

This test is activated by F7 or:

14 VESSEL-TEST: 0

The vessel must be in the well.

6 SAFETY PRECAUTIONS

6.1 CALORIMETER (3K-S)

• Connect the safety earth to the EARTH STUD on the back of the instrument. This is required

when the external power supply fails.

• Do not open the CAL3K for any reason whatsoever! There are no serviceable parts inside the

unit.

DO NOT TAMPER WITH THE EARTHING - CONSULT A QUALIFIED ELECTRICIAN SO THAT THE

EARTHING CAN BE CHECKED.

6.2 FILLING STATION (3K-3)

• Install the flexible high-pressure pipe supplied without any sharp bends.

• Check the nylon high-pressure pipe supplied for any mechanical damage before putting it under

pressure.

• Secure the pipe into the ferrule connector and screw the connector to the pressure regulator

side. Secure the pipe nuts to the pressure regulator side, then clamp the ferrule to the high-

pressure pipe on the gauge block side.

CAL3K-S Installation Guide V 1.2 Website: www.ddscalorimeters.com 6

Digital Data Systems (Pty) Ltd.

CAL3K Advanced Bomb Calorimeters

www.ddscalorimeters.com

• If the oxygen bottle is not situated close to the Filling Station or if it is in another room or

perhaps outside, then a solid, permanent installation of pressure piping should be installed, as

well as a shut off valve and pressure gauge within easy reach of the 3K-3 Filling Station.

• If bottled oxygen is used, a suitable High Pressure oxygen regulator must be supplied by your

Agent or sourced locally. Ordering this item from the factory ensures that the necessary

modifications have been made to fit the 3K-3 Filling Station.

• The oxygen bottle should be secured according to regulations.

• Secure the pipe to the side of the filling through the supplied device.

• Do not use any oil or grease on any of the oxygen fittings or the O-rings. A very small amount of

high-pressure (vacuum) grease is allowed on the O-ring to make them pliable. Wipe them clean

afterwards.

• DO NOT USE ANY OTHER PIPE OTHER THAN THE HIGH-PRESSURE PIPE SUPPLIED FOR OXYGEN

FILLING.

• DO NOT USE THE HIGH-PRESSURE PIPE IF IT HAS A SHARP BEND OR KINK, DISCARD

IMMEDIATELY

• ALWAYS FILL THE VESSEL WITH OXYGEN TO A MAXIMUM PRESSURE OF 3000KPA (30 bar).

• NOTE: With some applications you may need to fill the Vessel to less than 3000KPA e.g.

1500KPA (15 bar), however this is only applicable when you have a sample which is highly

combustible, for example with wood related samples.

• REMEMBER: You may fill the Vessel LESS than 3000KPA but NEVER more than 3000KPA.

6.2.1 HIGH PRESSURE OXYGEN

• The type of Oxygen to be used is the standard Industrial Oxygen used for welding. A purity

of 99.5% will be suitable.

• Conform to the industry standard of handling procedures for oxygen bottles.

• Secure the bottle against a wall.

• Should the Oxygen supply be in another room, make sure there is a high pressure shut off

valve near the 3K-3 Filling Station installation.

6.3 VESSEL (3K-5)

• Handle the vessel over a table or solid surface.

• Do not drop a vessel.

• Do not overfill a vessel with oxygen: The maximum oxygen filling pressure is 30bar / 3000kPA, which

is the standard for bomb calorimetry.

• Use the provided De-filler cap only, part number: 3K-3-22.

CAL3K-S Installation Guide V 1.2 Website: www.ddscalorimeters.com 7

Digital Data Systems (Pty) Ltd.

CAL3K Advanced Bomb Calorimeters

www.ddscalorimeters.com

• Do not use any oil or grease on any of the oxygen fittings or the O-rings. A very small amount of

high-pressure (vacuum) grease is allowed on the O-ring to make them pliable. Wipe them clean

afterwards.

• Store the vessel with the lid open. Never store a vessel under pressure, always deflate using the de-

filler cap.

• Clean the inside of the vessel with paper towel after every use.

• Weigh the crucible every week and discard it when it has lost 10% of its original mass.

• Discard the crucible when the bottom is distorted and extremely discoloured.

• Remove the deflector plate every week and clean the top surface. It does accumulate residue and

must be clean regularly.

• Make sure to use the pipe-clamping device on the right side of the filing station for safe use.

• NEVER OPERATE ANY UNSAFE VESSEL.

• NEVER IMMERSE THE VESSEL INTO COLD WATER WHEN COOLING. ALLOW THE VESSEL

TO COOL DOWN NATURALLY.

• A SUITABLE INSPECTION WARNING PERIOD OF 2000 FIRINGS, AND A STOP OPERATING LIMIT OF

2500 FIRINGS ARE PRE-PROGRAMMED FROM THE FACTORY

THE VESSEL MUST BE INSPECTED AT REGULAR INTERVALS DEPENDING ON THE USE. A SUITABLE

INSPECTION PERIOD CAN BE SET (By your agent!) AND THE UNIT WILL ISSUE AN INSPECTION

WARNING AND SOON AFTER THIS IT WILL SHUT DOWN THE OPERATION.

NOTE: THE MANUFACTURER (DDS) AND ITS AGENTS CANNOT BE HELD RESPONSIBLE FOR

ANY LOSS OR DAMAGE RESULTING FROM NEGLIGENCE OR INCORRECT USE OF THEIR

EQUIPMENT. IT IS YOUR DUTY AND RESPONSIBILITY TO CHECK ALL SAFETY ASPECTS OF THE

CAL3K-S SYSTEM REGULARLY.

CAL3K-S Installation Guide V 1.2 Website: www.ddscalorimeters.com 8

Digital Data Systems (Pty) Ltd.

CAL3K Advanced Bomb Calorimeters

www.ddscalorimeters.com

7 DAILY SAFETY STEPS

The 3K-5 vessel is a high-pressure apparatus and should be treated with care.

• Handle the vessel over a table or solid surface.

• Do not drop a vessel.

• Do not overfill a vessel with oxygen: The maximum oxygen filling pressure is 30bar / 3000kPA, which

is the standard for bomb calorimetry.

• Use the provided De-filler cap only, part number: 3K-3-22.

• Do not use any oil or grease on any of the oxygen fittings or the O-rings. A very small amount of

high-pressure (vacuum) grease is allowed on the O-ring to make them pliable. Wipe them clean

afterwards.

• Store the vessel with the lid open. Never store a vessel under pressure, always deflate using the de-

filler cap.

• Clean the inside of the vessel with paper towel after every use.

• Weigh the crucible every week and discard it when it has lost 10% of its original mass.

• Discard the crucible when the bottom is distorted and extremely discoloured.

• Remove the deflector plate every week and clean the top surface. It does accumulate residue and

must be clean regularly.

• Make sure to use the pipe-clamping device on the right side of the filing station for safe use.

WATCH YOUTUBE VIDEO ON CAL3K-S UNPACKING

AND INSTALLATION!!

CAL3K-S Installation Guide V 1.2 Website: www.ddscalorimeters.com 9

Digital Data Systems (Pty) Ltd.

CAL3K Advanced Bomb Calorimeters

www.ddscalorimeters.com

8 WARRANTY – FOR NEW PRODUCTS

8.1 PURPOSE OF PRODUCT WARRANTY

Any part of a product is subject to ageing and eventual failure. These failures occur during normal use.

The purpose of a warranty is to protect the Owner against a part failure caused by manufacturing

defects in workmanship, material or design for a specific time.

8.2 OWNER’S WARRANTY

In the event of the Owner contracting directly with Digital Data Systems (Pty) Ltd “dds”, or in the event

of the installation of a unit arising out of a contract between the Owner’s Dealer or any other party on

his/her behalf and the said “dds”, the Owner records that not withstanding same, this warranty is the

only warranty applicable to “dds” units and is expressly in lieu of all other warranties, expressed or

implied, including any implied warranty of merchantability or fitness for a particular purpose. No

amendments or additions to this warranty shall be binding on “dds”, unless recorded in writing and

signed by a duly authorised officer of the company. “dds” agrees to repair and replace with a new or

remanufactured part, any part, other than those excluded below, which after inspection, upon its

return to the factory in Randburg, Johannesburg by the Owner or the authorised Dealer to which

he/she returns the unit, is proven to be defective.

Replacement of a defective part will be made only within the applicable warranty period of 12 (twelve)

months from date of shipment. Not withstanding anything to the contrary herein, any labour involved

in repairing or replacing a defective part will be charged at “dds” rates applicable at the time.

If upon inspection it is found that the pressure vessel was submerged in water the

warranty will automatically be null and void and the owner will be responsible for the

labour and parts charges.

8.3 EXCLUDED (NON-WARRANTY) PARTS

“dds” shall be entitled to treat this warranty as void unless the relevant warranty form (attached) is sent

by registered post to “dds” by the Owner within 10 (ten) days from date of original installation.

Regardless of warranty-status, the Owner shall be responsible for labour charges connected with

periodic maintenance requirements involving visual and functional inspection of the systems.

This warranty expressly covers the unit(s) “dds” supplied only and does not cover any other part, which

may, as a consequence of the installation and operation of the unit, become damaged in any way

whatsoever.

Special attention should be given to the safe operation of the high-pressure Vessels. The published

rules are guidelines only and enclosed in this leaflet for the convenience of the User. The

manufacturer is not responsible for any damages, consequential, indirect or direct, or loss

whatsoever, resulting out of electrical shock, Vessel explosion, or any other cause.

CAL3K-S Installation Guide V 1.2 Website: www.ddscalorimeters.com 10

Digital Data Systems (Pty) Ltd.

CAL3K Advanced Bomb Calorimeters

www.ddscalorimeters.com

8.4 WARRANTY – REPAIRED PRODUCTS

Any “dds” scientific product that has been repaired has a warranty period of 30 Days from date of

shipment for the Repair request only. If something else goes wrong that is not part of the original

Repair, the warranty does not apply. Each product that is sent to “dds” for Repair is tested and checked

and leaves “dds’s” Factory in 100% working order. It is the Owner’s responsibility to inspect any repaired

product on receipt thereof and confirm in writing, any faults, errors or problems with the said product.

If a fault, error or problem is reported after the 30 Day warranty period, and “dds” finds that the

product has been damaged and requires another repair, the full cost of repair will be applicable and paid

for by the Owner.

8.5 GENERAL – WARRANTY VOID

All serial numbers on any relevant “dds” Scientific product need to remain on the product at all times, or

warranty will be void. Warranty will also be void if any of the branding stickers or decals have been

removed and/or the colour of the Scientific product has been changed in any way.

CAL3K-S Installation Guide V 1.2 Website: www.ddscalorimeters.com 11

Digital Data Systems (Pty) Ltd.

CAL3K Advanced Bomb Calorimeters

www.ddscalorimeters.com

8.6 WARRANTY REGISTRATION FORM

SERIAL NUMBERS (S/N): Calorimeter: _____________________________

Filling Station: _____________________________

Vessel(s): _____________________________

Other: _____________________________

DEALER NAME: _____________________________________________________________

OWNER’S/CUSTOMER’S COMPANY NAME: _______________________________________

AUTHORISED BY: _____________________________________________________________

INSTALLED AT: _____________________________________________________________

TEL NO: ____________________________ FAX NO: ______________________________

CONTACT PERSON: ________________________________________________________

INSTALLED BY: _____________________________________________________________

DATE INSTALLED: ____________________________ (REPRESENTATIVE OF DEALER/AGENT)

CUSTOMER ORDER NUMBER AND DATE: _______________________________________

INSTALLATION DETAILS (LOCATION, WATER SUPPLY, AIR-CONDITIONING ETC.):

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

ACCEPTED IN GOOD CONDITION:

DATE: ______________________ SIGNATURE: ____________________________

NAME (printed): ____________________________

WITNESS: ____________________________

I have read, understood and accepted the conditions of this warranty, the details of which are printed in this Manual.

CUSTOMER’S SIGNATURE: __________________________________________________

NAME (printed): __________________________________________________

DATE: ___________________________________________

Table of contents

Other DDS Calorimeters Laboratory Equipment manuals

DDS Calorimeters

DDS Calorimeters CAL3K-A User manual

DDS Calorimeters

DDS Calorimeters CAL3K-AP User manual

DDS Calorimeters

DDS Calorimeters CAL3K 3K-F User manual

DDS Calorimeters

DDS Calorimeters CAL3K Series User manual

DDS Calorimeters

DDS Calorimeters CAL3K-F User manual

DDS Calorimeters

DDS Calorimeters 3K-ST User manual