Skytron SS2201-J2 User manual

OWNER'S MANUAL

WARMING

CABINETS MODELS SS2201-J2

THROUGH SS2207-J2

TEC-F-0007 REV8

9/13

Page 1

J2 WARMING CAB. OWNER'S • REV8

TABLE OF CONTENTS

TITLE PAGE

Although current at the time of publication, SKYTRON’S policy of continuous development makes this

manual subject to change without notice.

PRODUCT SAFETY LABELS .................................................................................................................2

SPECIAL USER ATTENTION..................................................................................................................4

SPECIFICATION DRAWINGS.................................................................................................................5

SECTION I INTRODUCTION..................................................................................................................8

SECTION II OPERATION.......................................................................................................................10

SECTION III MAINTENANCE & REPAIR...............................................................................................13

SECTION IV REPLACEMENT PARTS...................................................................................................20

WIRING DIAGRAM ................................................................................................................................22

TRANSPORT AND STORAGE REQUIREMENTS

• Ambient temperature range: -40° to +159°F (-40° to +70°C)

• Relative humidity range of 10% to 100% including condensation.

• Atmospheric pressure range of 50KPa to 106KPa

ELECTRICAL INFORMATION

SS2201-J2(G) SS2205-J2(G) SS2207-J2(G)

Electrical 120V, 50/60Hz,1PH 120V, 50/60Hz,1PH 120V, 50/60Hz,1PH

Amp Rating 2.0 Amps 6.5 Amps 8.8 Amps

Power Usage 240 Watts 720 Watts 1056 Watts

This manual has four main sections, each developed for a certain reader.

1. General Description: For all readers

2. Operation: For staff who use the warming cabinets

3. Service: For authorized SKYTRON trained personnel

4. Installation Instructions: For contractors and authorized SKYTRON service personnel who install

warming cabinets. (Refer to section 1-2.)

Model Identication

The data tag can be found on each warmer inside the uppermost compartment on the left hand side closest

to the door. Record your Model Number and Serial Number below. For prompt service, please have your

model and serial number ready when contacting SKYTRON for assistance.

Model #_______________________________

Serial #_______________________________

Page 2

J2 WARMING CAB. OWNER'S • REV8

Appliance must be located

a minimum of 6 feet

from patient.

1-ALWAYS DISCONNECT POWER WHEN SERVICING THIS DEVICE TO ELIMINATE RISK OF ELECTRIC SHOCK!

2-Refer to the Operating Manual provided prior to using this device, or anytime you have a question about safe operation.

3-Refer to the General Set-up Instructions provided by the Manufacturer when installing this device.

4-Employ safe blanket loading practices and ensure that no blankets are in contact with the rear surface of the warmer.

5-Do not stack blankets closer than 4” from fan inlet.

6-Do not allow stacked blankets to extend past front lip of shelves to ensure airflow within the cabinet is not restricted.

7-Care should always be taken to ensure the door is closed and latched upon loading or retrieving contents from the cabinet.

8-Use warm water and a mild liquid detergent to remove finger prints and light soil from the stainless steel surfaces.

BLANKET WARMER-SAFE OPERATING INSTRUCTIONS

MODEL

CYCLES

MAX. KWS.

PHASE

SER. NO.

VOLTAGE

MAX. AMPS

EQUIP. NO.

1-800-759-8766

Manufactured by JAMESTOWN METAL PRODUCTS, INC.

12

3

456

9

8

7

PRODUCT SAFETY LABELS

F2-012-81

F2-012-82

Page 3

J2 WARMING CAB. OWNER'S • REV8

LABEL LOCATIONS

Technical Data

•Dimensions-Inches (millimeter)

SS2201-

J2(G)

SS2205-

J2(G)

SS2207-

J2(G)

Exterior

Width 30(762) 30(762) 30(762)

Height 26(660) 74(1880) 74(1880)

Depth 26(660) 26(660) 26(660)

Interior Upper

Width 27(686) 27(686) 27(686)

Height 15(381) 59(1499) 15(381)

Depth 19(483) 19(483) 19(483)

Lower

Width 27(686)

Height 35¼(895)

Depth 19(483)

•Capacity

Cubic capacity (Liter capacity)

SS2201-

J2(G)

SS2205-

J2(G)

SS2207-

J2(G)

Total

Volume

4.37 ft3

(124)

17.5 ft3

(496)

15.72 ft3

(445)

Upper

Chamber

N/A N/A 4.37 ft3

(124 L)

Lower

Chamber

N/A N/A 11.35 ft3

(321)

•Weight

SS2201-

J2(G)

SS2205-

J2(G)

SS2207-

J2(G)

Weight 179 340 404

Page 4

J2 WARMING CAB. OWNER'S • REV8

WARNING

Disconnect (power) supply before

servicing.

WARNING

Explosion Hazard

Donotuseinthepresenceofammable

Anesthetics.

NOTE

This warmer should not be left

unattended

for periods greater than 24

hours. In case of extended absences

disconnect warmer from its power

source.

NOTE

To promote a self closing door swing,

the front door hinge corner leveling foot

should be slightly higher than the others.

NOTE

To insure proper heat distribution, allow

airowspaceonthetopanddoorside

of blankets. DO NOT BLOCKAIR VENT.

NOTE

Avoidusingammablecabinetcleaning

agents, as well as blanket cleaning

agents that cause fabric to become

brittle over time.

Knowledge of proper procedures is essential to the

safe operation of this equipment.

The following precautions should be reviewed

by all personnel prior to operating this

equipment.

WARNING

Indicates a possibility of personal injury.

CAUTION

Indicates a possibility of damage to

equipment.

NOTE

Indicates important facts or helpful hints.

WARNING

Patient Burn Hazard

Temperature of cabinet contents may

differ from display temperature.

WARNING

The temperature of liquids in this cabinet

may not be suitable for certain patient

applications.

Always check the temperature of

contents before using.

SPECIAL USER ATTENTION

Page 5

J2 WARMING CAB. OWNER'S • REV8

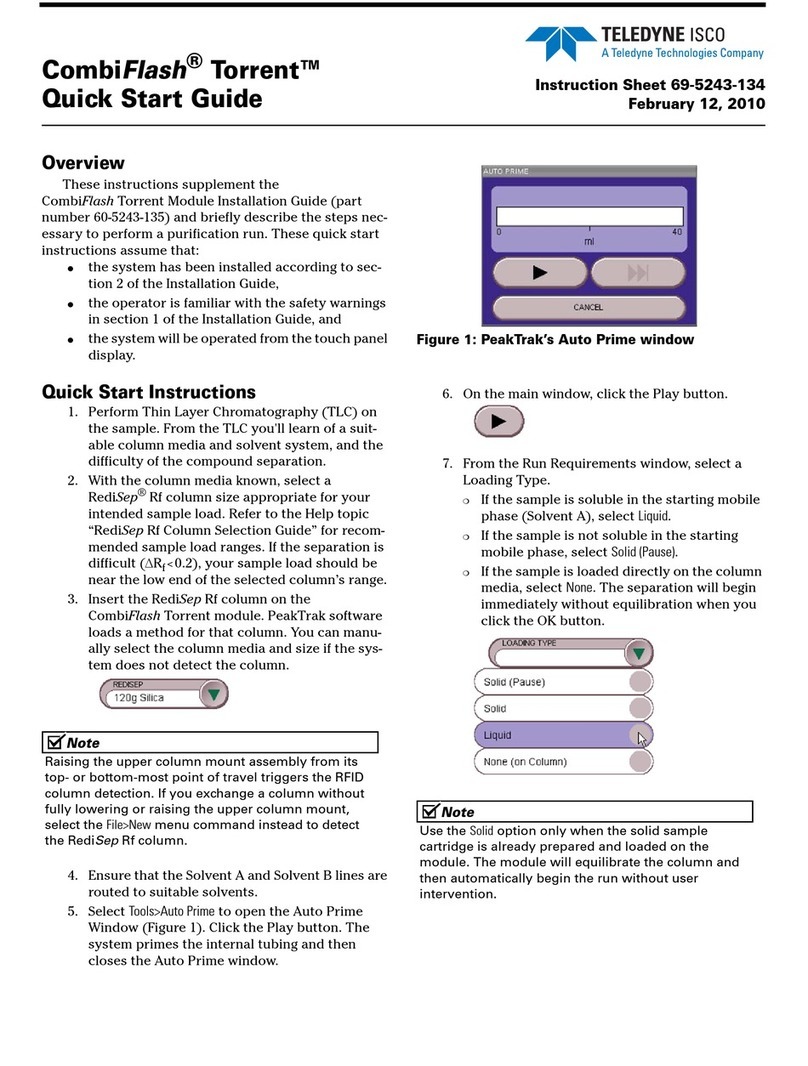

30"

762mm

18½"

470mm

6½"

165mm

24"

610mm

2"

50mm

26"

660mm 15"

381mm

19"

483mm

HINGES ARE

REVERSIBLE FOR

OPPOSITE DOOR

SWING

FRONT SIDE

LEVELING FEET (4) ½"

13mm

27"

686mm

26"

660mm

TOP 29¼"

743mm

15"

380mm

23½"

597mm

235°

DOOR SWING

MODELS

SS2201-J2

SS2201-J2G

Page 6

J2 WARMING CAB. OWNER'S • REV8

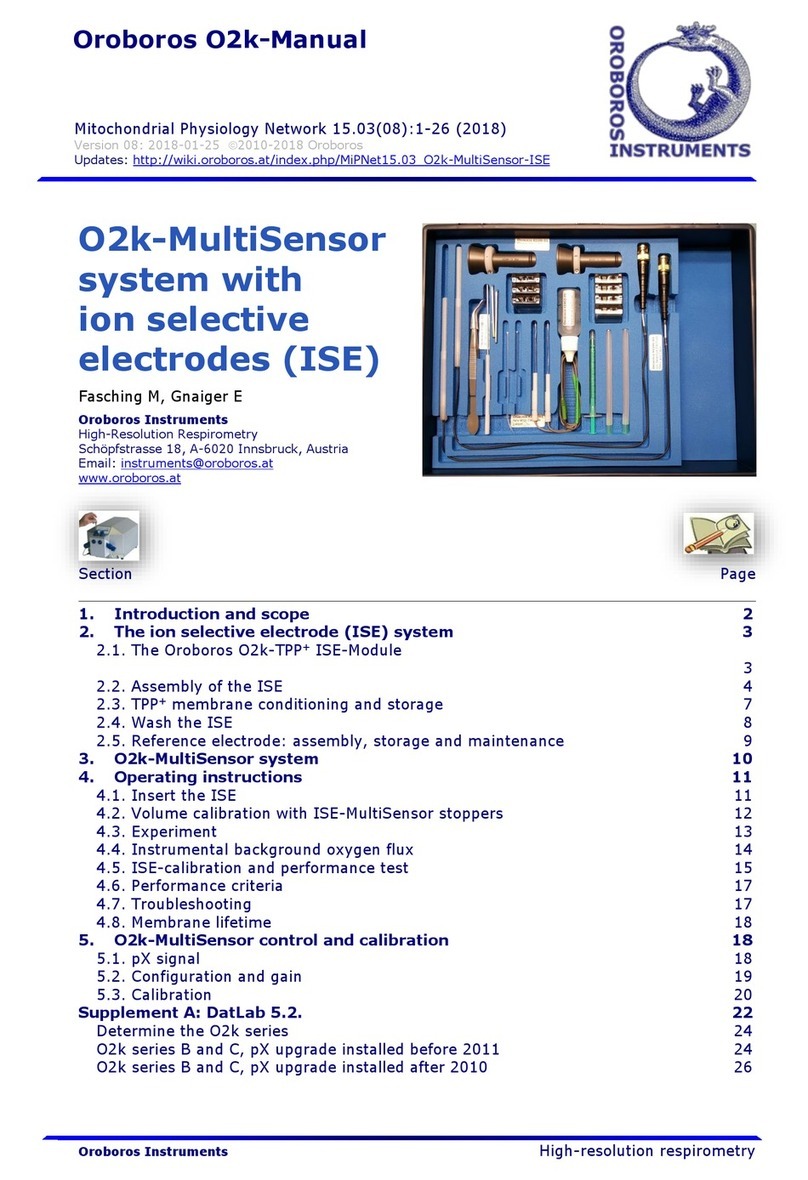

27"

686mm

26"

660mm

TOP 29¼"

743mm

15"

380mm

235°

DOOR SWING

73½"

1867mm

HINGES ARE

REVERSIBLE FOR

OPPOSITE DOOR

SWING

FRONT SIDE

LEVELING FEET (4)

59"

1499mm

½"

13mm

2"

50mm 24"

610mm

19"

483mm

30"

762mm

71½"

1816mm

MODELS

SS2205-J2

SS2205-J2G

Page 7

J2 WARMING CAB. OWNER'S • REV8

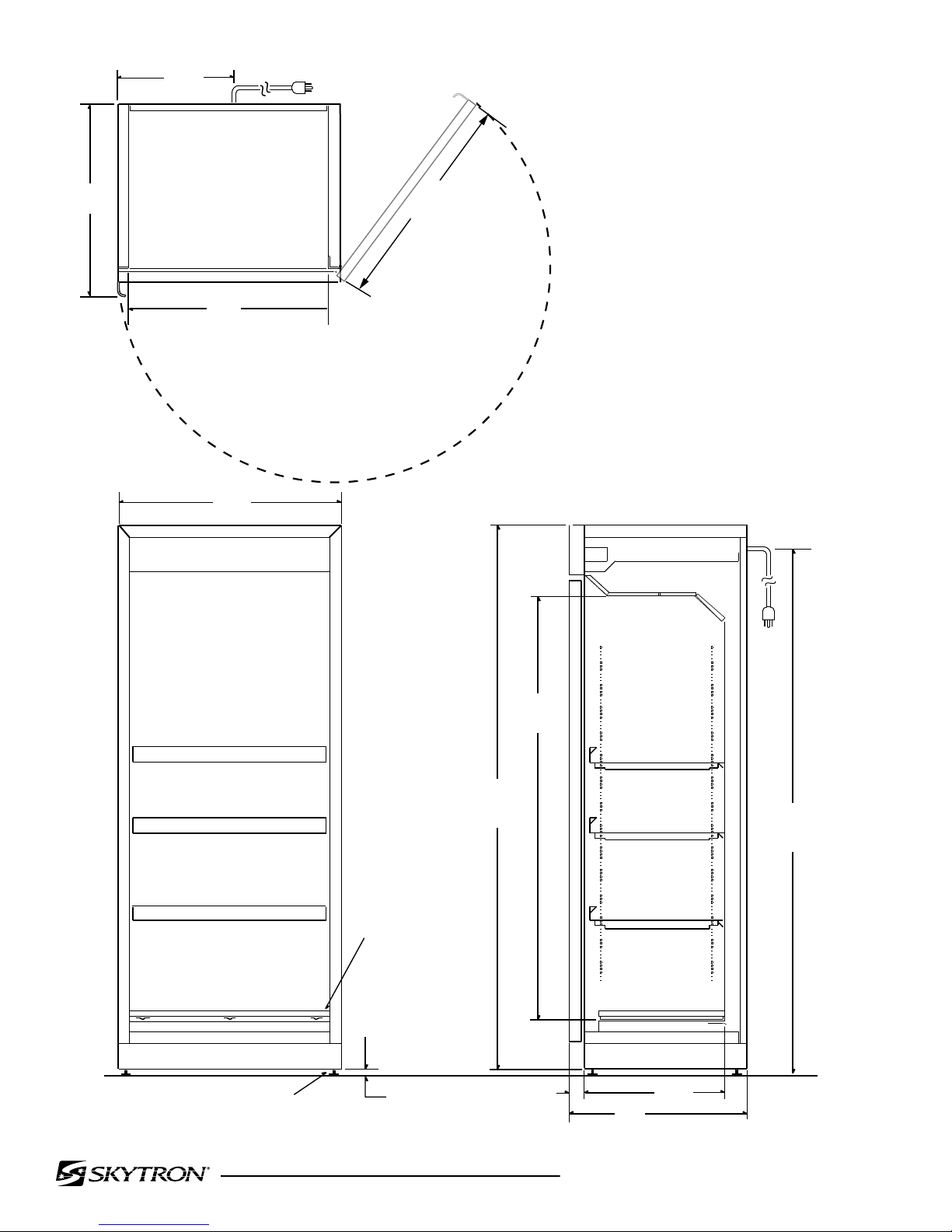

16¼"

413mm

44"

1118mm

15"

381mm

35¼"

895mm

LEVELING FEET (4)

FRONT SIDE

6½"

165mm

HINGES ARE

REVERSIBLE FOR

OPPOSITE DOOR

SWING

73½"

1867mm

½"

13mm

2"

50mm 24"

607mm

19"

483mm

30"

762mm

27"

686mm

26"

660mm

TOP 29¼"

743mm

15"

380mm

235°

DOOR SWING

71½"

1816mm

MODELS

SS2207-J2

SS2207-J2G

Page 8

J2 WARMING CAB. OWNER'S • REV8

users are in-serviced with the use, limitations

and hazards. No other use is authorized or

recommended.

d. Construction

The body of the warming cabinet is double walled

stainless steel construction with insulation for

increased heating efciency. Doors are made

of double paned stainless steel or double paned

tempered glass framed with stainless steel.

e. Servicing

All control components are located in the control

compartment at the top of the warmer and serviced

by removal of the front panel. Servicing of circulation

fans, heating elements and manual temperature

overloads are accessed through the interior of

each heating chamber with the door(s) open only

by SKYTRON Authorized Service Technicians.

f. Features

• Illuminated power on/off switch

• Insulated body and door(s)

• Silicone door gasket(s)

• Independent digital thermostatic controls and

displays

• Reversible door swing

• Front access serviceability

• Leveling feet

• Exterior/interior stainless steel construction

• 8’ power cord

• Adjustable shelves for SS2205 and SS2207

models

• Temperature range of 90° to 160°

g. Installation

SS2201-J2(G) – counter, under counter, or cart

SS2205-J2(G) & SS2207-J2(G) – freestanding

h. Options

• Glass doors (G) on end of model number

• Casters kits

• SS2201-J2(G) – F2-012-58

• SS2205-J2(G) or SS2207-J2(G)

– F1-010-102

• Warmer cart (F1-020-23) for counter top

models

• Warmer stand (F1-020-23-NC) for

counter top models

SECTION I INTRODUCTION

1-1. General

SKYTRON Stainless Blanket and Solution Warming

Cabinets are designed to provide heated storage of

blankets, sterile water and saline solutions used in

the care of patients in surgery, recovery, OB/GYN,

ICU, ER and trauma areas. SKYTRON Model

SS2201-J2(G) offers a compact size with one

warming compartment. Model SS2205-J2(G) offers

a full size cabinet with one warming compartment.

Model SS2207-J2(G) provides upper and lower

compartments.

a. Controls

The controls for each compartment are mounted

in the top section of the warmer and labeled Upper

Chamber and Lower Chamber, with a circuit breaker

providing power to each control.

Each compartment controller:

• Controls on/off of the compartment

• Set point of temperature 90° to 160°

• Temperature display in Fahrenheit

Digital read out provides:

• Chamber temperature

• Temperature set point

• Heating active

• Over heat (alarm)

An audible and visual AL alarm

indicates an overheat condition.

• Loss of power

b. Performance

Heated air is circulated over the contents by fan(s)

in a convection function providing an even heat

distribution. Each compartment is designed to

hold a quantity of blankets or solutions. Once a

set temperature is selected and obtained it will be

controlled throughout within 10° of the selected

temperature. From a cold start, each compartment's

loaded contents will be evenly heated to set point

within 8 to 12 hours. In the event of power loss the

warmer will resume normal function once power

is restored.

c. Usage

This device is intended for warming 100% cotton

blankets ONLY and non-ammable solutions in

commercial establishments where all operators/

Page 9

J2 WARMING CAB. OWNER'S • REV8

h. Clean all exterior and interior surfaces of

the warming cabinet as needed with a damp

towel and a mild non-abrasive detergent. Rub

surfaces in a back and forth motion in the

direction of the grain, do not wipe in a circular

motion or perpendicular to the grain.

i. Plug the power cord into a properly grounded

120V electrical outlet.

1-3. Service / Principles of Operation

This equipment contains no user serviceable parts.

To avoid injury, refer all repairs to SKYTRON trained

service personnel.

Model SS2201-J2(G) is a single compartment 1/3

size, SS2205-J2(G) is a single compartment full size,

and model SS2207-J2(G) is a dual compartment full

size warmer. Each compartment has independently

controlled temperature regulation by a thermostatic

control unit and independent thermal protection

cut off.

Each warming compartment is designed to circulate

air from the top of the chamber over a heating

source, which cycles on and off by means of a

sensor to maintain set temperature, and back out at

the bottom of the chamber. This process produces

a convection type of heating system.

Dual compartment warmers have an air barrier

between the upper and lower compartments

restricting heat migration to the upper chamber

and affecting the temperature setting.

1-2. Installation / Uncrating

Move the warming cabinet to the location of

installation prior to uncrating.

a. Remove metal banding securing the cabinet

to the pallet.

b. Remove all packing materials covering the

warmer.

c. Remove the warmer from the pallet and position

in desired location.

d. Open the door(s) and remove the shipping

brackets and replace the screws in the body

of the cabinet.

e. Remove the shipping brackets holding the

shelves in the bottom compartment and discard.

f. Install shelf supports as outlined in the Shelf

Adjustment portion of the Operation Section.

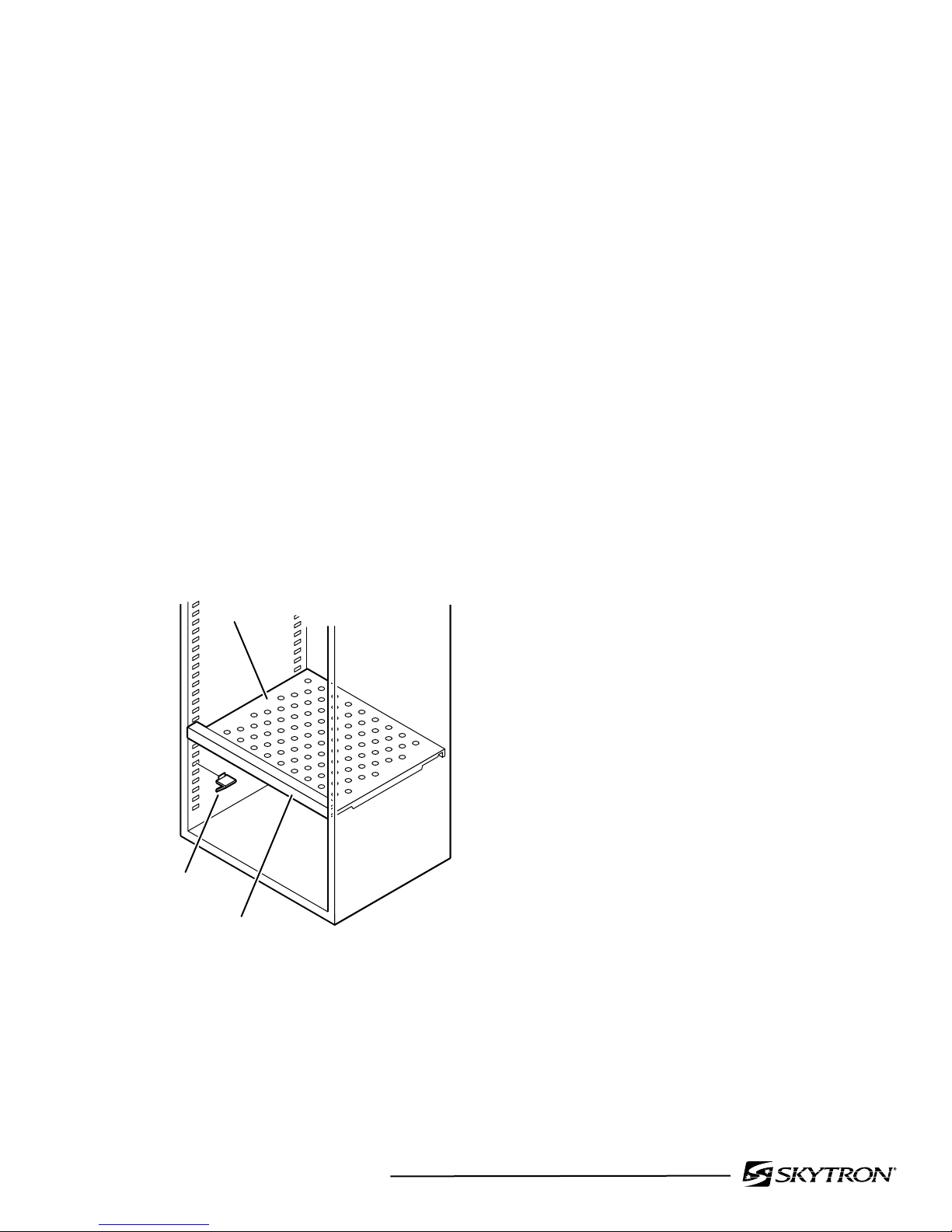

SHELF SUPPORT

(4 per shelf)

FRONT

SHELF

g. Make sure the cabinet is leveled properly

to the floor or counter top by adjusting

the leveling feet at the bottom of the

cabinet. To promote self closing door swing,

the front door hinge corner leveling foot

should be slightly higher than the others.

Page 10

J2 WARMING CAB. OWNER'S • REV8

SECTION II OPERATION

Control Layout Display Messages

ERROR CODE DESCRIPTION

ER Memory Error

-- Short-Circuit Probe Error

oo

Open Probe Error

Initial Operation

Initial power up

a. Plug the power cord into a properly grounded

120VAC electrical outlet.

b. Turn circuit breaker on the front control panel

to the ON position.

c. Turn the power switch to the ON position for

each compartment.

d. The display should illuminate with the current

chamber temperature.

Alarm Test

a. Press the SET button on the temperature

control. SP will appear on the display.

b. Press the SET button again. The present

temperature setting will appear on the display.

c. Using the Up/Down arrow buttons, set the

new set point to 110° and press SET to lock

the new value.

d. Allow stabilization of the heating chamber.

e. Repeat steps one and two above and press the

down button to 95° and press the SET button.

•Thealarmactivates

f. To silence the alarm, press the SET button and

the DOWN arrow key together.

Description of controls

Each temperature controller and power switch

operates one warming compartment.

Circuit Breaker – main power to the warming

cabinet controllers.

Power Switch – turns on/off the fan, controller and

heating functions of the selected compartment.

Display – normally shows the current interior

chamber temperature.

Up Arrow Button – used to adjust the set point of

the selected chamber.

Down Arrow Button – used to adjust the set point

of the selected chamber.

Set Button - when pressed displays the selected

warming chambers desired set point.

DISPLAY

POWER

SWITCH

CIRCUIT

BREAKER UP ARROW

BUTTON

DISPLAY SET

BUTTON

DOWN

ARROW

BUTTON

Page 11

J2 WARMING CAB. OWNER'S • REV8

Operating Instructions

Turning the warmer on

a. Make sure the power cord is plugged into a

properly grounded 120VAC electrical outlet.

b. Turn circuit breaker on the front control panel

to the ON position.

c. Turn the power switch to the ON position for

each compartment.

The display should illuminate with the current

chamber temperature.

Selecting the temperature set point

a. Press the SET button on the temperature

control. SP will appear on the display.

b. Press the SET button again. The present

temperature setting will appear on the display.

c. Using the Up/Down arrow buttons, set the new

set point to the desired temperature and press

SET to lock the new value.

d. Press SET and DOWN simultaneously to return

back to normal operation.

Note: if the set point is changed to a value 10°

below current temperature the alarm will activate.

Loading of the cabinet

Load only sterile water, saline solutions or 100%

cotton blankets, do not warm synthetic blend fabrics

or items containing plastic, rubber, or metal snaps,

studs, hooks etc. Check for proper placement of

the shelf on shelf supports prior to loading. The

blanket shelf is perforated to facilitate even heating

of blankets placed on the shelf and must be used

to hold blankets.

All loads should be allowed time to stabilize at the

set temperature; Do not raise set temperature to

increase the rate of heating:

• Solutions - Approximately 8 to 12 hours

• Blankets - Approximately 6 to 8 hours

Bottles should be loaded to allow for a minimum of

one half inch from the top of the compartment and

spacing around the back and sides one quarter inch

andnotprotrudepastthefrontedgeoftheuidtray

in the compartment for evenly distributed heating.

Forefciencypurposesbaggedsolutionsshould

be placed on shelves, stacking of uid bags

increases the heating time required to achieve set

temperature.

Blankets must be folded and stacked to allow a

two to three inch open space between the top of

the compartment or shelf, on each side and rear

of the stacked blankets, nor protrude past the front

edge of the shelf. Following the above guidelines

improves the efciency of heating the contents

thoroughly.

Rotatewarmedcontentsonarstinrstoutbasis

failure to do so may present cold or discolored

contents.

Temperature settings for uids vary depending

on use or manufacturer. Always refer to AORN

guidelines and manufacturer’s recommendations

for proper temperature settings.

Flammable agents in the warming cabinet can

causeanexplosionorre.Donotloadthewarming

cabinetwithanyitemthatcouldintroduceammable

agents into the cabinet atmosphere.

In case of power failure the unit will resume normal

operationwhenpowerisrestored.Followtheuid

manufacturer’s guidelines for solutions that have

cooled or been removed from heated storage but

not used.

Page 12

J2 WARMING CAB. OWNER'S • REV8

Unloading of the cabinet

Internal surfaces of the warmer are hot. Avoid

contact when loading and unloading the warming

cabinet.

CAUTION

Glass may shatter when cooled

suddenly, solution bag and bottles may

burst when picked up.

CAUTION

Temperatures over 110° may burn when

exposed for extended periods of time.

Skytron recommends the use of personal protective

equipment while loading and unloading of contents.

Turning the warmer off

a. Move the on/off rocker switch(es) to the OFF

position of the compartment to shut down.

b. Moving the circuit breaker switch to the OFF

position will shut down the entire warmer

Overheat Alarm (A1) Condition

When the chamber temperature exceed the set

point by 8° or more the display will read A1 and

the audible alarm is triggered.

a. To silence the audible alarm press and hold the

SET and DOWN buttons together until silenced.

b. Turn off the warmer chamber and unload the

contents and reload following the loading

guidelines previously outlined.

c. Turn on the chamber and monitor for

performance. If the chamber overheats into an

alarm (A1) condition turn off the chamber and

contact your local authorized service personnel

for troubleshooting.

If lowering the set temperature of the chamber

more than 10° of current internal temperature the

alarm will activate. Follow the procedure above

to silence the alarm.

Shelf Adjustment

a. Turn off the power to the heating chamber

where the adjustment is needed.

b. Allow the chamber to cool and unload the

contents.

c. Remove the shelf

d. Determine the new position of the shelf

e. To remove the shelf supports pull the bottom of

the support toward the interior of the chamber

to approximately a 90° angle and out toward

the center of the chamber.

f. Install the shelf support into the new location

by inserting the top of the support into the new

position and rotating down toward the bottom

of the cabinet until the bottom tab locks in.

g. Count the empty holes in the pilaster at each

of the corners to be sure that the shelf will be

level in the new position.

h. Reinstall the shelf with the raised edge toward

the front of the cabinet.

i. Align notches in bottom of the shelf with the

shelf supports.

j. Pull outward on shelf to insure it is locked

properly on the supports.

SHELF SUPPORT

(4 per shelf)

FRONT

SHELF

Page 13

J2 WARMING CAB. OWNER'S • REV8

3-1. Troubleshooting

If your unit is not operating properly, check the following before calling your authorized service agent.

Do not attempt to repair or service beyond this point. Contact SKYTRON for nearest authorized service

agent.

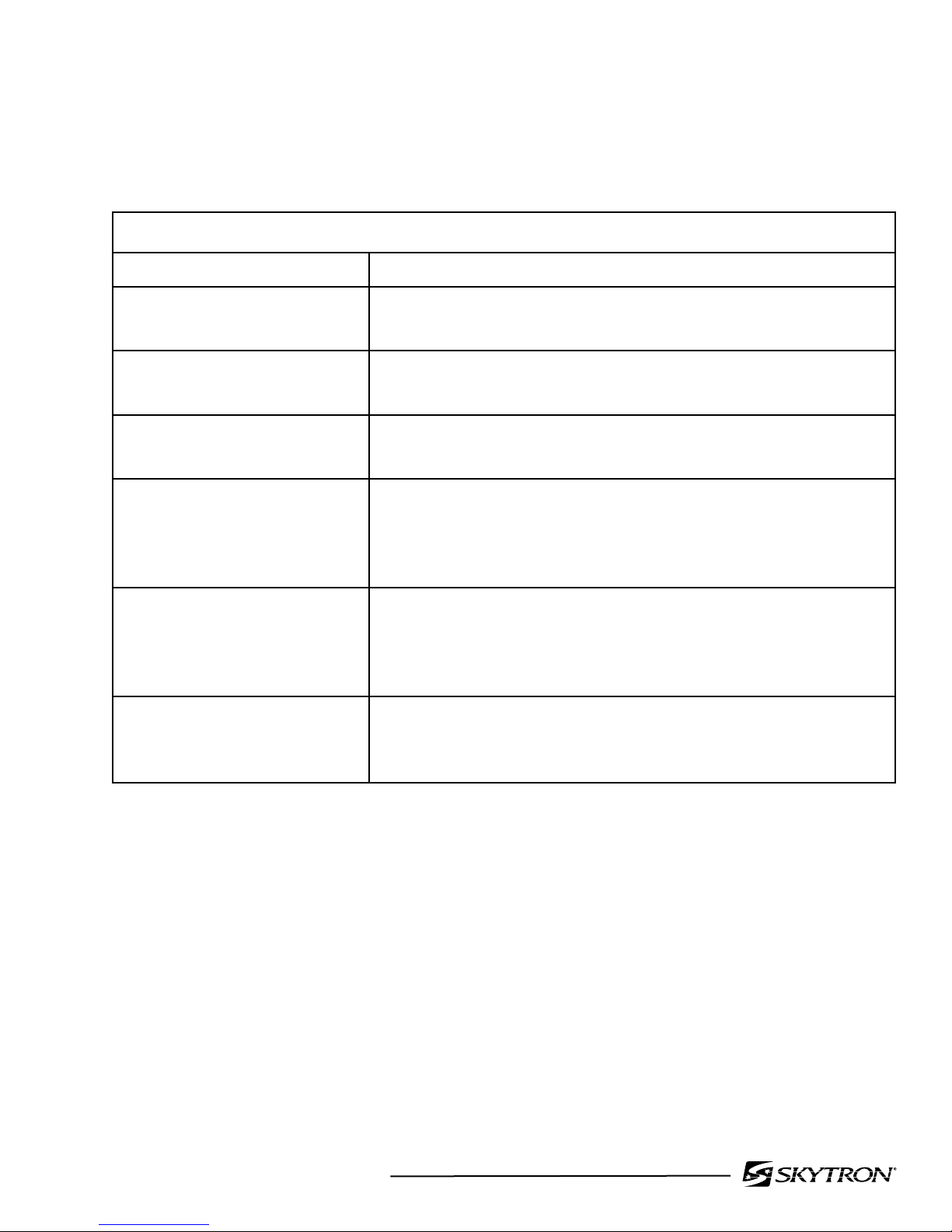

TROUBLESHOOTING GUIDE

DESCRIPTION ACTION REQUIRED

ER - Memory Error Controller Defective, Replace - Contact SKYTRON

representative

--- Short Circuit Probe Error Temperature Probe Defective, Replace - Contact SKYTRON

representative

oo

- Open Probe Error Temperature Probe Defective, Replace - Contact SKYTRON

representative

Unit Will Not Power Up • Check Outlet for Power

• Check if warmer is plugged into 120VAC outlet

• Check if circuit breaker is turned on

• Check if the power switch is turned on

Chamber does not Heat • Is the power turned on

• Is temperature set above Chamber Ambient Temperature

• Is the Circulation Fan Operational

• Is the Limit Thermostat reset

Over Temperature Alarm

"A1" is Activated

• Is the Circulating Fan Operational

• Are the Contents Loaded Properly

• Has the Chamber Set Temperature been lowered

Onlyfacilityauthorized,SKYTRONtrained&certied,maintenancepersonnelshouldfurther

troubleshoot or attempt repairs.

Troubleshooting or repairs by unauthorized personnel could result in personal injury or equipment

damage.

SECTION III MAINTENANCE & REPAIR

Page 14

J2 WARMING CAB. OWNER'S • REV8

3-2. Preventative Maintenance

a. Every 6 months - Cleaning

It is recommended to perform preventative

maintenance on the Skytron model warming

cabinets every six months or when any service is

performed.

1. Turn off the power and unplug the warmer

from the power source.

2. Using a damp cloth and mild non abrasive

detergent rub surfaces in a back and forth

motion in the direction of the grain, do not

wipe in a circular motion or perpendicular to

the grain.

• Clean all exterior surfaces

• Remove all contents and clean all shelving

• Cleanallinteriorchamberwalls,oorand

ceiling starting at the top and working down

3. Restore power to the warmer and allow

temperatures to stabilizer prior to reloading

solutions and blankets.

b. Every year - Internal Cleaning

Removal of the interior plenum panels:

1. Remove the bottom spill pan with the four

Phillips head retaining screws two in each side.

2. Remove the bottom plenum by removal of the

four Phillips head screws at the front edge.

3. Supporting the ceiling panel remove the four

Phillips head screws that hold the rear plenum

to the ceiling plenum.

4. Support the ceiling plenum and pull the rear

plenum at the bottom toward the front of the

warmer to remove.

5. Remove the ceiling plenum by disconnecting

the fan power wires.

6. Clean all exposed surfaces with a damp cloth

and mild non abrasive detergent.

7. Assemble plenum panels in the reverse order

of removal.

8. Plug the warmer in and turn the power on.

c. Yearly - Temperature Controller Calibration

1. Place an independent accurate thermometer

in the chamber and close the door.

2. Set the temperature to a setting between 90°

and 160°.

3. Allow chamber to acclimate to the selected

temperature.

4. Compare controller reading with independent

thermometer

5. Adjust controller program value P1 up or down

to correct any offset in readings. (see control

settings section)

Page 15

J2 WARMING CAB. OWNER'S • REV8

3-3. Limit Thermostat Reset

It may be necessary to reset the Limit Thermostat

of a chamber due to a malfunction or a faulty

controller. This is a safety cutout switch installed

in each plenum area that is designed to interrupt

power to the heating element if the temperature

exceeds 180° F during operation. To reset the

Limit Thermostat the following instructions should

be followed.

a. For models SS2201-J2(G), SS2205-J2(G)

and upper chamber of SS2207-J2(G):

1. Disconnect the power to the warmer by

unplugging the unit.

2. Remove the top cover from the warming

cabinet by removal of four Phillips head screws

and place to the side.

3. The Limit Thermostat is located at the rear

center of the cabinet.

4. Pressrmlyonthecenterredbuttonuntilan

audible snap is heard.

5. Replace the top cover and install the fastening

screws.

6. Plug the warmer back into a power source.

7. Monitor the warmer for normal operation.

b. For lower chamber of SS2207-J2(G):

1. Disconnect the power to the warmer by

unplugging the unit.

2. Remove the fan assembly from the ceiling

plenum by removal of four Phillips head

screws and unplug the power cord and place

to the side.

3. The Limit Thermostat is located at the rear

center of the cabinet.

4. Pressrmlyonthecenterredbuttonuntilan

audible snap is heard.

5. Replace the fan assembly and install the

fastening screws.

6. Plug the warmer back into a power source.

7. Monitor the warmer for normal operation.

3-4. Fan Replacement

Failure of a circulation fan can cause the warming

chamber to overheat and enter an alarm mode.

The following procedure should be followed to

replace the circulation fan.

1. Disconnect the power to the warmer by

unplugging the unit.

2. Remove the fan assembly from the ceiling

plenum by removal of four Phillips head

screws and unplug the power cord and place

to the side.

3. Remove the four screws that secure the fan

to the fan panel.

4. Install the new fan paying attention to the

direction of ow; there are arrow markings

onthefantoindicateow.Thefanshould

have the arrow pointing away from the fan

mounting panel (UP).

5. Replace the fan assembly and install the

fastening screws.

6. Plug the warmer back into a power source.

7. The fan should start to operate as soon as the

power is turned on to the chamber repaired.

Note: It may be necessary to reset the Limit

Thermostat if the chamber heated to a temperature

greater than 180° F.

Page 16

J2 WARMING CAB. OWNER'S • REV8

3-5. Heating Element and/or Temperature

Probe Replacement:

The Heating Element and Temperature Probe are

located in the heating plenum and positioned close

to each other. The following procedure will allow

for exchange of either or both parts.

1. Disconnect the power to the warmer by

unplugging the power cord from the 120V

outlet.

2. Removal of the interior plenum panels.

• Remove the bottom spill pan with the four

Phillips head retaining screws two in each

side.

• Remove the bottom plenum by removal of the

four Phillips head screws at the front edge.

• Supporting the ceiling panel remove the

four Phillips head screws that hold the rear

plenum to the ceiling plenum.

• Support the ceiling plenum and pull the rear

plenum at the bottom toward the front of the

warmer to remove.

• Remove the ceiling plenum by disconnecting

the fan power wires.

3. The heating element is located on the rear wall.

• Remove the electrical connections from the

element.

• Disconnect the heating element from the

mounting location.

• Install the new element and replace the

electrical connections.

• Proceed to step 5.

4. The temperature probe is located above the

heating element and held in place with a hold

down tab and secured with a Phillips head

screw.

• Loosen the Phillips head screw and slide

the probe out from under the hold down tab.

• Cut the wires off from the probe approximately

8” to 10” from the probe.

• Strip the wires back and attach the new

probe wires to the old probe.

• Secure the new probe under the hold down

tab and tighten the retaining screw.

• Remove the front control panel from the

warmer by removing the four Phillips head

screws, one on each corner.

• Pull the control panel out until all attached

components are clear of the warmer body.

• Roll the panel upward and place on top of

the warming cabinet.

• Find the Temperature probe wires previously

cut and pull the new probe wires through

the wire chase.

• Remove the old probe wires from the

controller and attach the new wires.

5. Reassemble the plenum panels.

• Assemble plenum panels in the reverse order

of removal in step 1.

• Plug the warmer in and turn the power on.

Note: It may be necessary to calibrate the probe to

the chamber by adjusting the offset in the controller,

value P1. See Preventative Maintenance Section

2 on Calibration of the temperature controller to

the chamber.

Page 17

J2 WARMING CAB. OWNER'S • REV8

15. Install the upper door and install upper hinge

pin. Follow step 14.

16. Replace the control panel using the 4 Phillips

head screws previously removed.

17. Plug the warmer back into the power source.

b. Door latch adjustment

1. Slowly close the door and adjust the height

of the keeper to provide between 1/8" to

1/16" clearance between the KEEPER and

the LATCH PAWL. Mark the location, open

the door and tighten the (2) screws. Test and

readjust as required to insure proper operation.

2. If the proper clearance cannot be achieved

with the available adjustment of the keeper

to the latch pawl, it may be necessary to add

additional washers to the bottom hinge pin of

the door. (Follow DoorAdjustment/Orientation

procedure instructions.)

3-6. Door Adjustment/Orientation

a. The following procedure can be used to change

the orientation of the door swing or to make

adjustments to the latch alignment.

1. Disconnect the power to the warmer by

unplugging the power cord from the 120v

outlet.

2. Remove the front control panel from the

warmer by removing the four Phillips head

screws, one on each corner.

3. Pull the control panel out until all attached

components are clear of the warmer body.

4. Roll the panel upward and place on top of the

warming cabinet.

5. Remove the hinge pin from the top bracket

while supporting the door.

6. Tilt the door out and lift off the lower hinge pin

and set aside.

7. For dual compartment warmers remove the

center hinge bracket while supporting the

lower door.

8. Lift the door up and set to the side.

9. Remove the lower hinge bracket and secure

to the opposite side of the warmer at the top

and remove the hinge pin from the bracket.

10. Replace the hinge pin in the original top hinge

bracket and remove from the cabinet and install

at the opposite side lower position.

11. Remove the door latch keepers and mounting

plate and secure to the opposite side of the

cabinet. Removal/Replacement of the door

Latch Pawl is recommended.

12. Rotate the door 180° and position on the

lower hinge pin.

13. Install the center hinge bracket and secure to

the cabinet if dual chamber.

14. Check for alignment of the latch keeper to

the latch pawl. Adjust the keeper up or down

to proper clearance. If the proper clearance

cannot be achieved, washers (Skytron part

number F1-010-93) or hinge bushings (Skytron

part number F1-010-92) may be added to the

lower hinge pin of the door to help raise the

door to align with the keeper.

Page 18

J2 WARMING CAB. OWNER'S • REV8

3-7. Temperature Controller

a. Replacement

If a fault is determined in the temperature controller

and replacement is required follow the steps

below to replace the controller. It may also require

additional programming once the control has been

changed.

1. Disconnect the power to the warmer by

unplugging the power cord from the 120v

outlet.

2. Remove the front control panel from the

warmer by removing the four Phillips head

screws, one on each corner.

3. Pull the control panel out until all attached

components are clear of the warmer body.

4. Roll the panel upward and place on top of the

warming cabinet.

5. Disconnect the heating element, power, and

temperature sensor wires from the control.

6. Release the retaining ring that holds the control

to the front panel.

7. Insert the new control and secure with retaining

ring.

8. Connect the heating element, power, and

temperature sensor wires to the new controller.

9. Secure the control panel to the warmer with the

four Phillips head screws removed in step 2.

10. Plug the warming cabinet back into a 120volt

power source.

b. Programming

Access to all code protected parameters.

1. Press SET for 8 seconds. The access code

value 00 is shown on the display. (Unit comes

with code set at 00 from factory).

2. With the UP and DOWN arrows, code can be

set to user needs.

3. Press SET to enter the code. If code is

correct,therstparameterlabelisshownon

the display (SP).

4. Move to the desired parameter with the UP

and DOWN keys.

5. Press SET to view the value on the display.

6. ThevaluecanbemodiedwiththeUPand

DOWN arrows.

7. Press SET to enter the value and exit to next

parameter.

8. Repeat until all necessary parameters are

modied.

9. Press SET and DOWN at the same time to

exit programming or wait one minute and the

display will automatically exit programming

mode.

Parameter Description Value

SP Set point User

Dened

r0 Differential or

Hysteresis 1

r1 Lower Value Set Point 90

r2 Higher Value Set

Point 160

d0 Heating or Cooling

Control Ht

c0 Min. stop time for

Load 0

c2 Load Status during

Probe Error off

P1 Ambient Probe

Adjustment -3

P5 Ambient Probe Type TCJ or K *

H5 Parameter Access

code 0

A0 Alarm 1 Hysteresis 10

A1 Alarm 1 Threshold 10

A2 Alarm 1 Exclusion

Time 0

A3 Alarm 1

Conguration HI

A4 Alarm 2 Hysteresis 1

A5 Alarm 2 Threshold 0

A6 Alarm 2 Exclusion

Time 0

A7 Alarm 2

Conguration off

* See page 21, item 16 for Thermocouple

This manual suits for next models

5

Table of contents