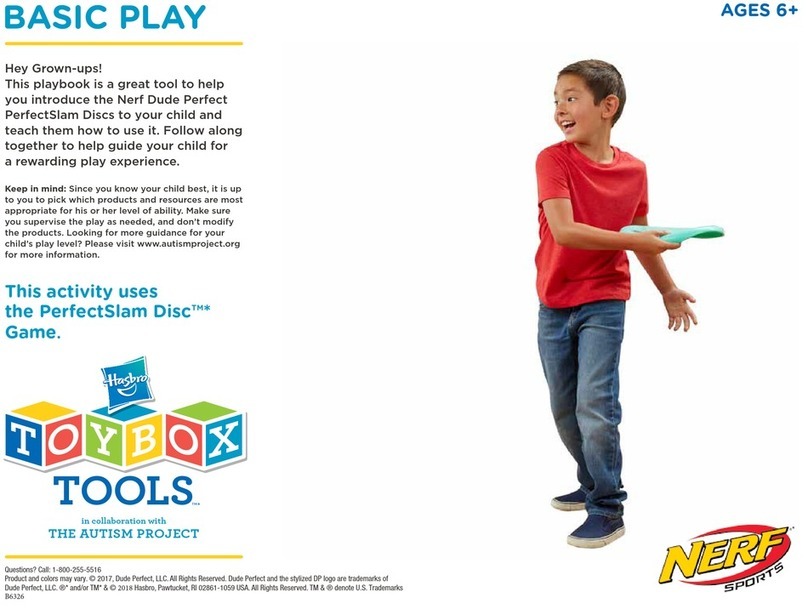

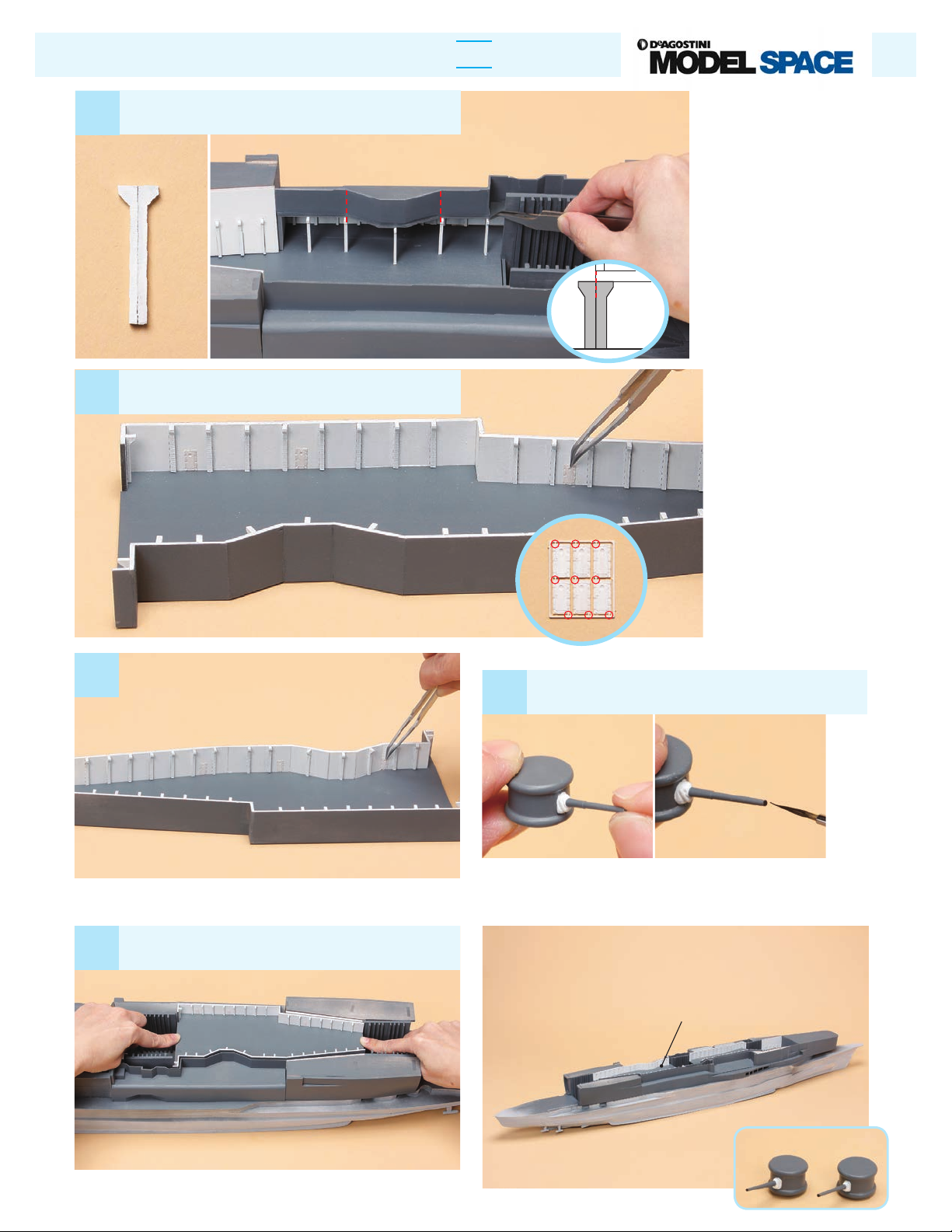

De Agostini Model Space IJN Akagi User manual

Other De Agostini Toy manuals

De Agostini

De Agostini Model Space HUMMER H1 User manual

De Agostini

De Agostini MODEL SPACE Honda CB750 FOUR User manual

De Agostini

De Agostini MODEL SPACE Honda CB750 FOUR User manual

De Agostini

De Agostini MODEL SPACE SUZUKI GSX 1300R HAYABUSA User manual

De Agostini

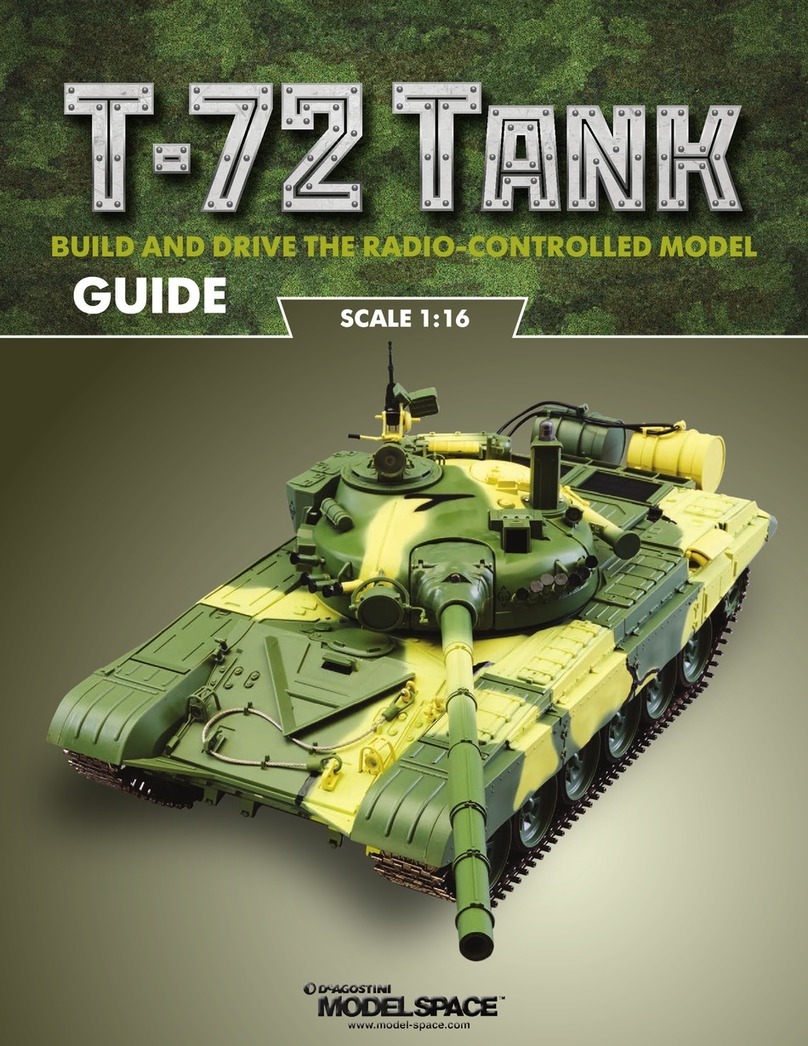

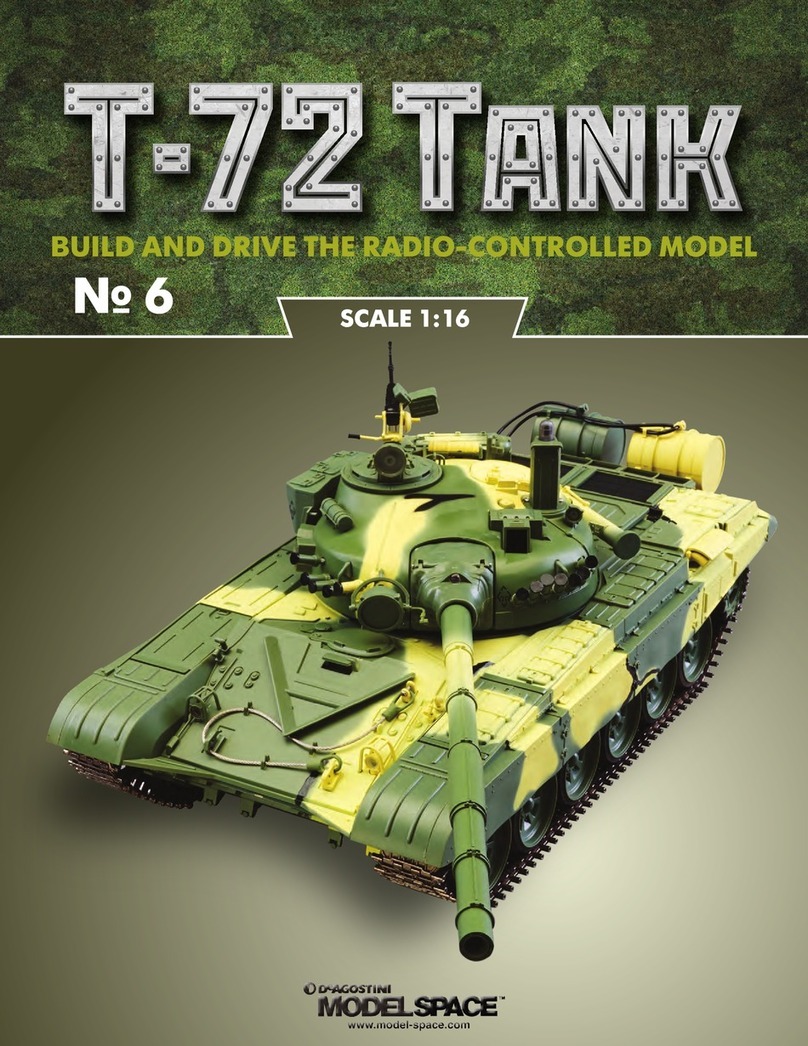

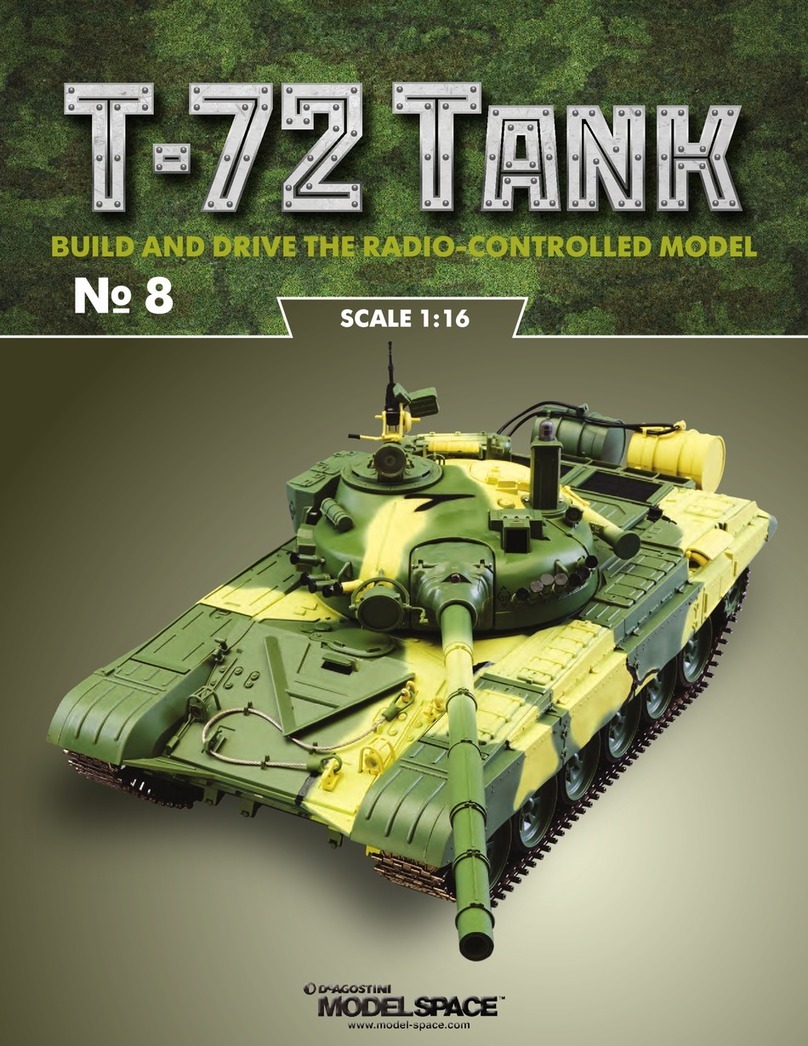

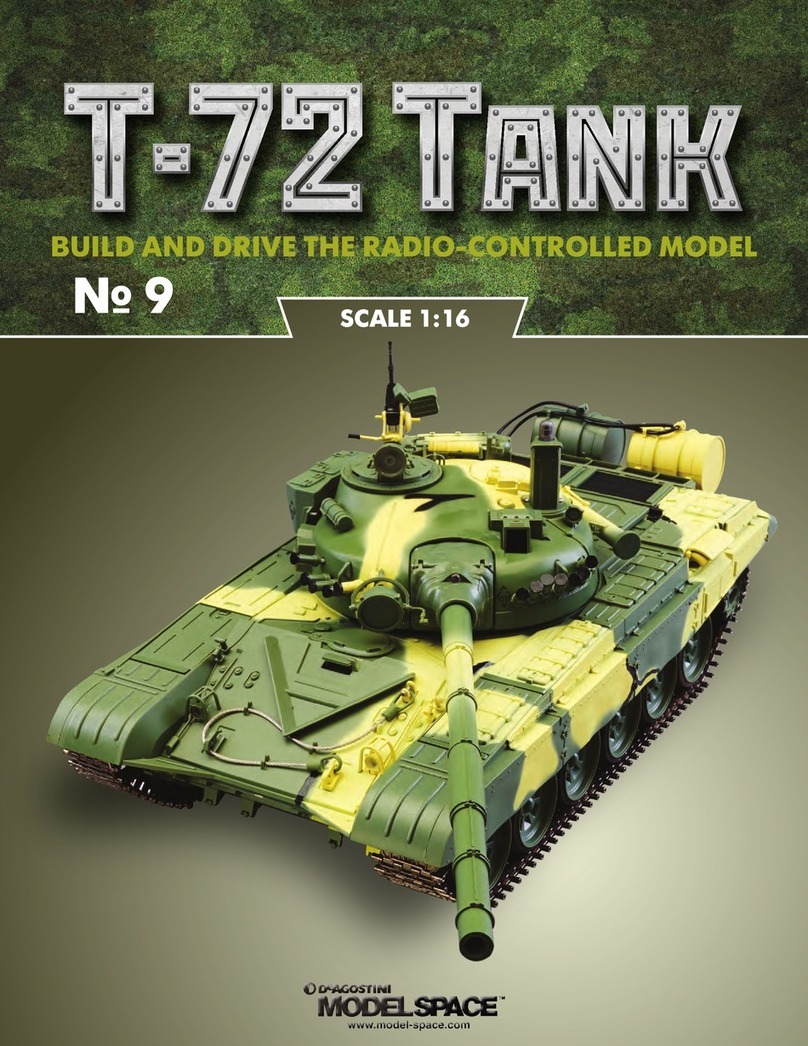

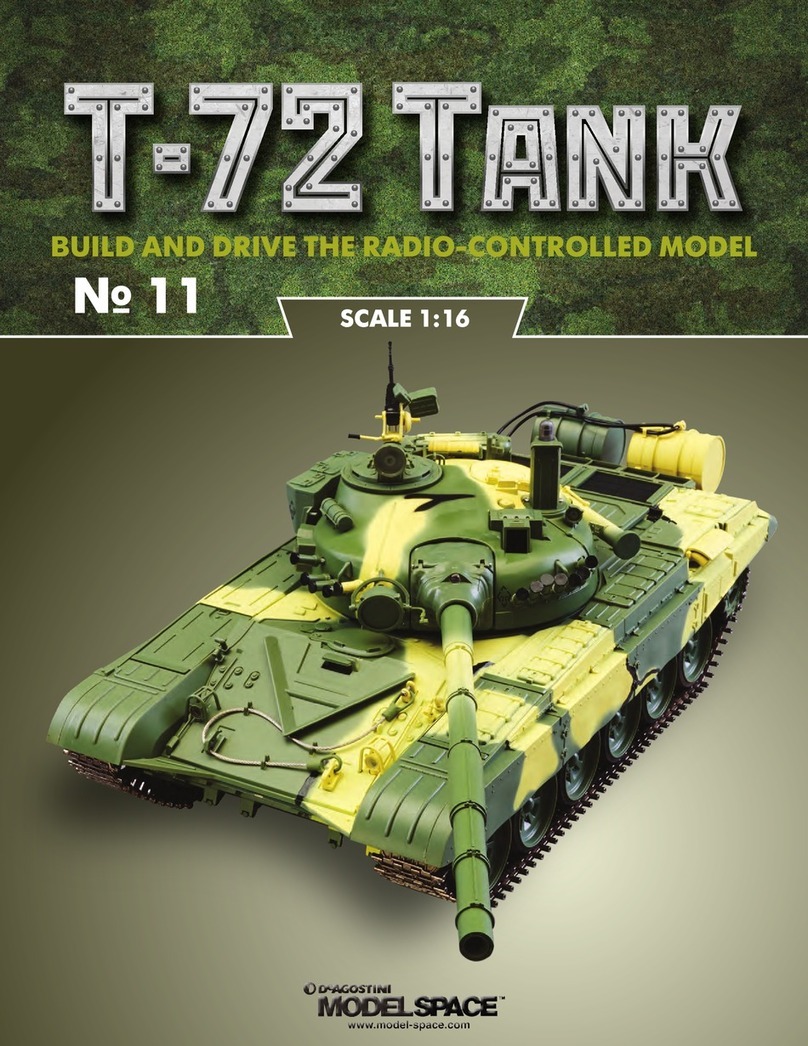

De Agostini Model Space T-72 User manual

De Agostini

De Agostini Model Space C57 User manual

De Agostini

De Agostini MODEL SPACE Honda CB750 FOUR User manual

De Agostini

De Agostini MODEL SPACE SUZUKI GSX 1300R HAYABUSA User manual

De Agostini

De Agostini Model Space MiG-29 User manual

De Agostini

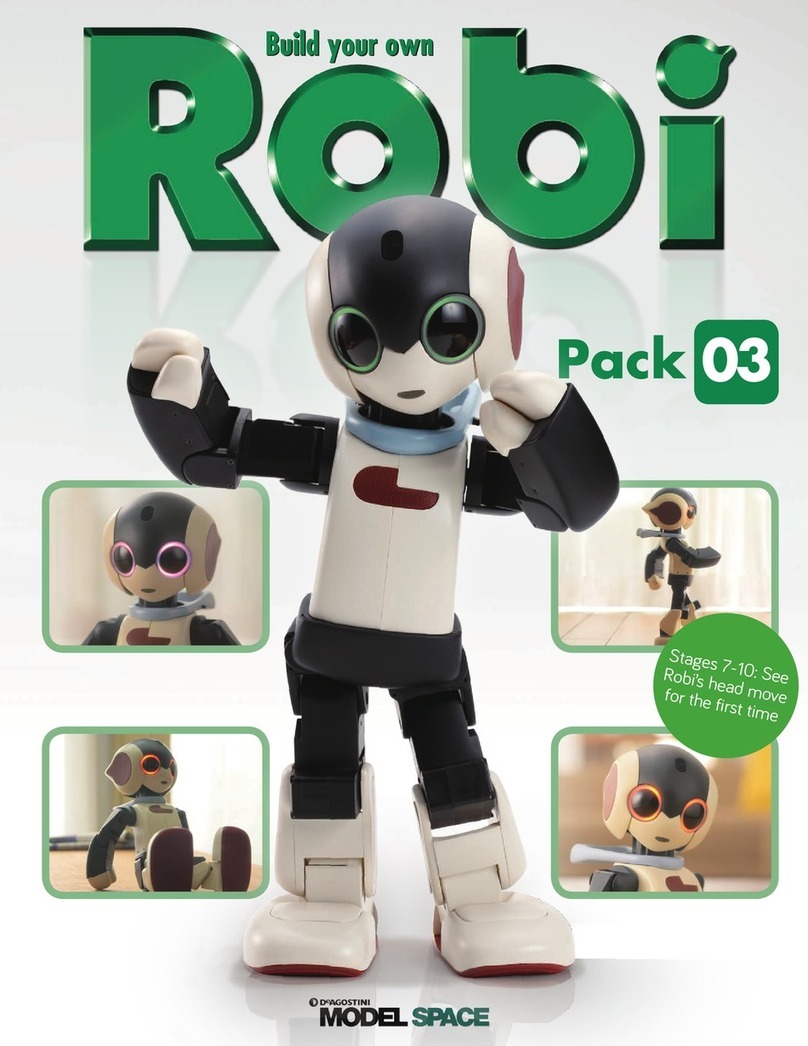

De Agostini Model Space ROBI Pack 03 Instruction Manual

De Agostini

De Agostini Model Space SANTISIMA TRINIDAD User manual

De Agostini

De Agostini Model Space Harley-Davidson FLSTF Fat Boy User manual

De Agostini

De Agostini Model Space C57 User manual

De Agostini

De Agostini MODEL SPACE Honda CB750 FOUR User manual

De Agostini

De Agostini Model Space MiG-29 User manual

De Agostini

De Agostini MODEL SPACE Honda CB750 FOUR User manual

De Agostini

De Agostini Model Space H.M.S. Bounty Admiralty User manual

De Agostini

De Agostini Model Space T-72 User manual

De Agostini

De Agostini Model Space MiG-29 User manual

De Agostini

De Agostini MODEL SPACE Honda CB750 FOUR User manual

Popular Toy manuals by other brands

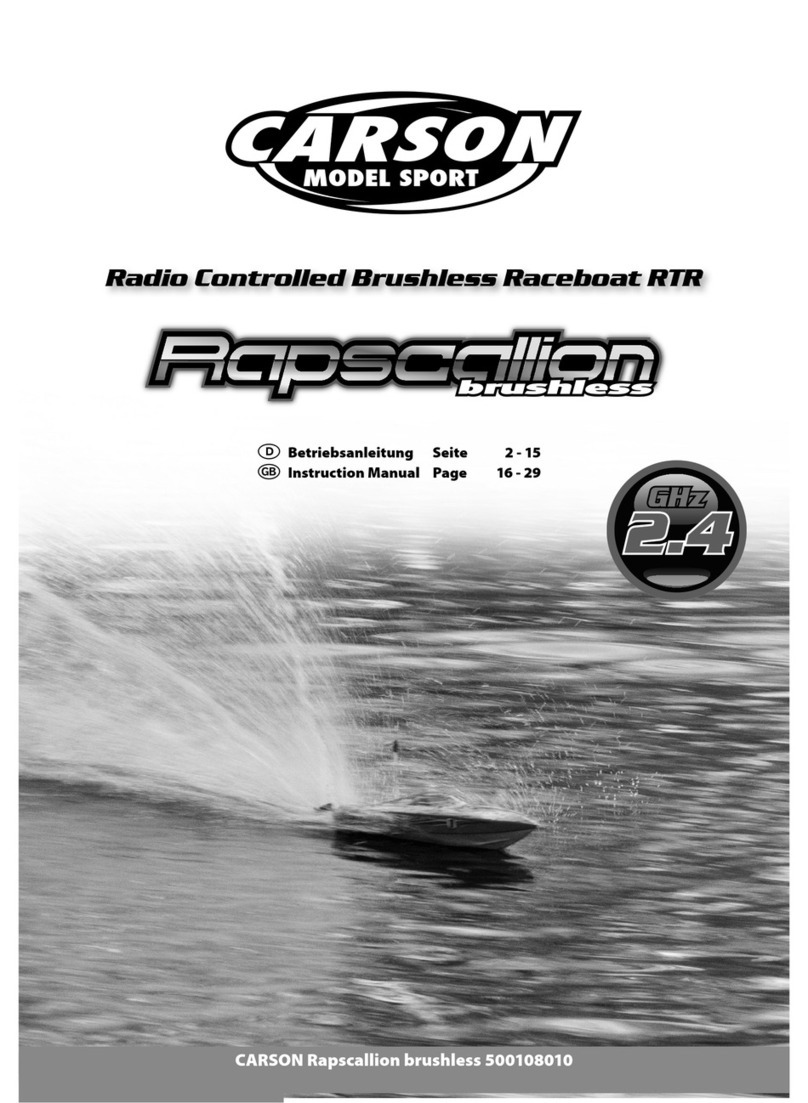

Carson

Carson Rapscallion brushless instruction manual

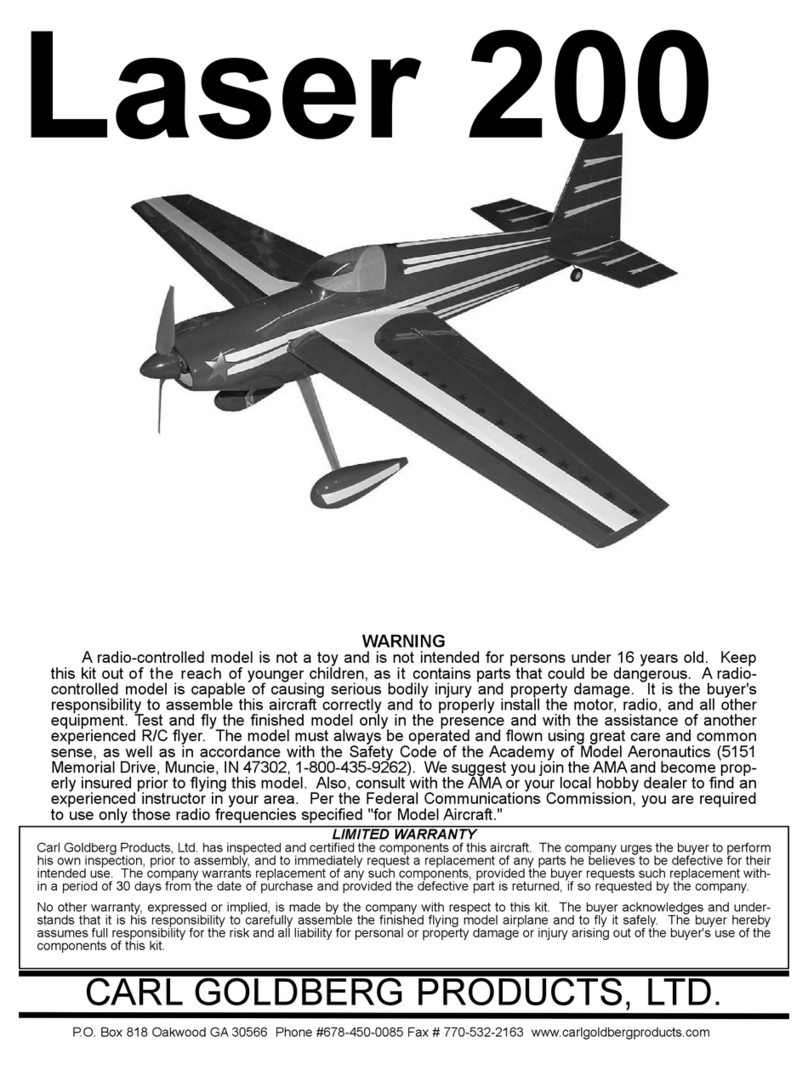

Carl Goldberg Products

Carl Goldberg Products Laser 200 instruction manual

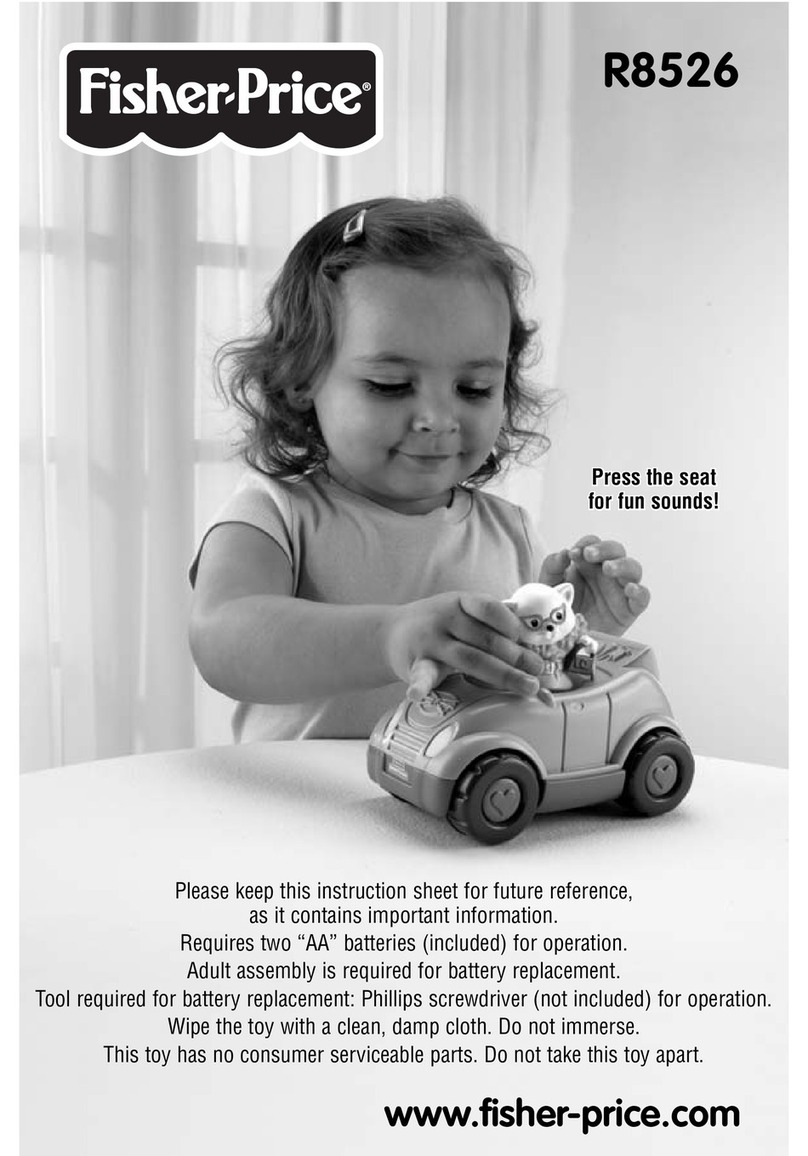

Fisher-Price

Fisher-Price R8526 instruction sheet

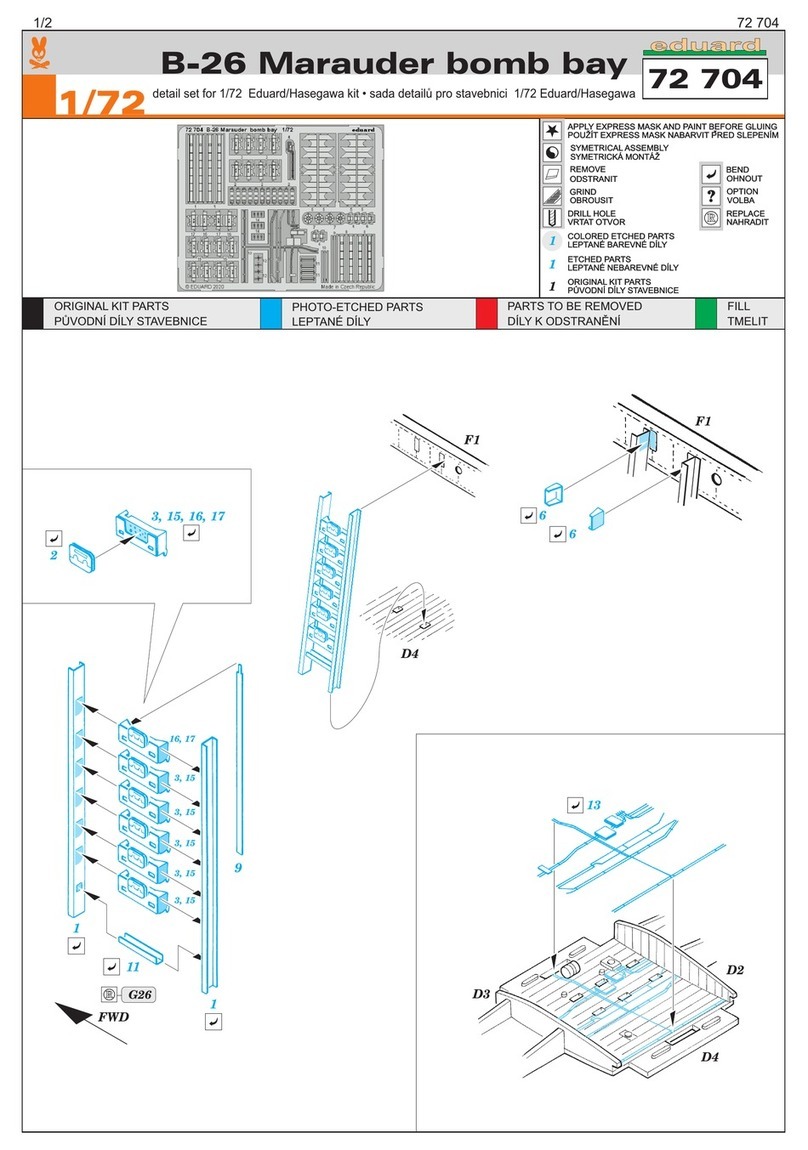

Eduard

Eduard B-26 Marauder manual

Fisher-Price

Fisher-Price Laugh & Learn Learning Bunny K0468 quick start guide

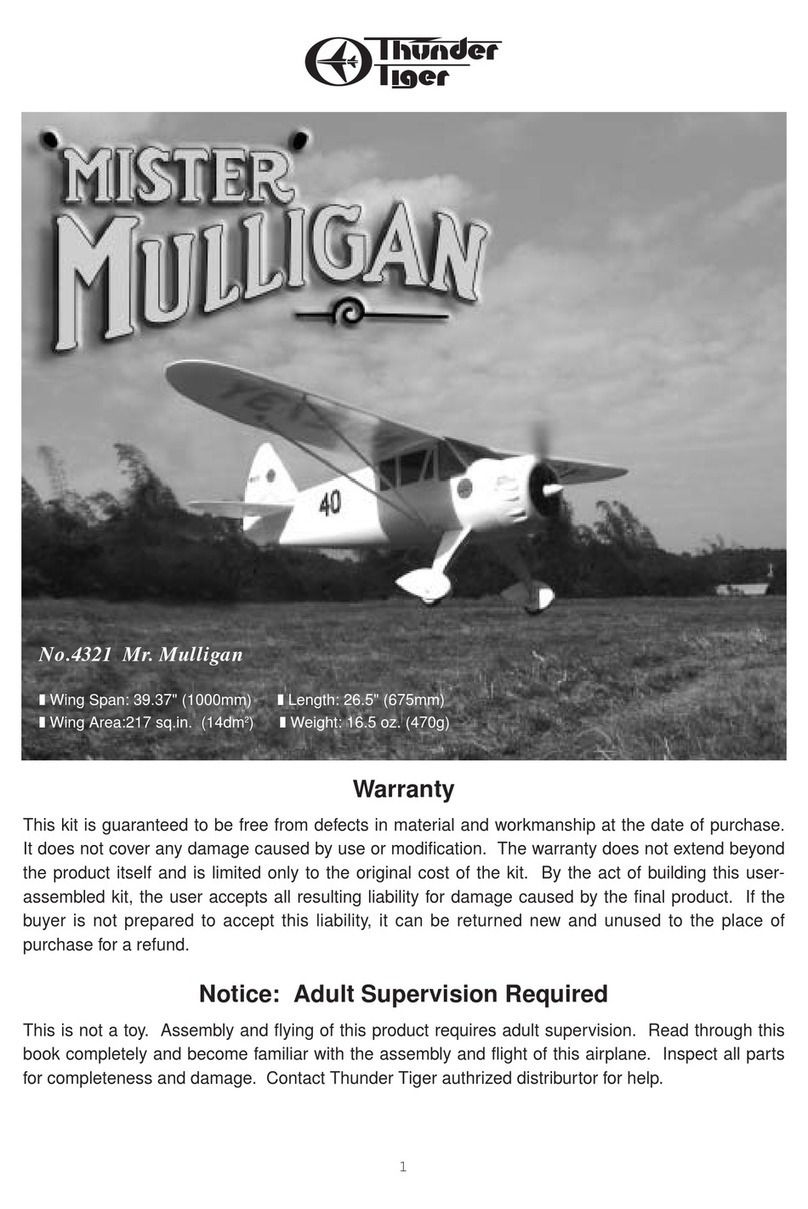

THUNDER TIGER

THUNDER TIGER Mister Mulligan 4321 manual

Aircraft Modelers Research

Aircraft Modelers Research Extra 300 Mid-Wing manual

Eduard

Eduard M-ATV OGPK overhead cover manual

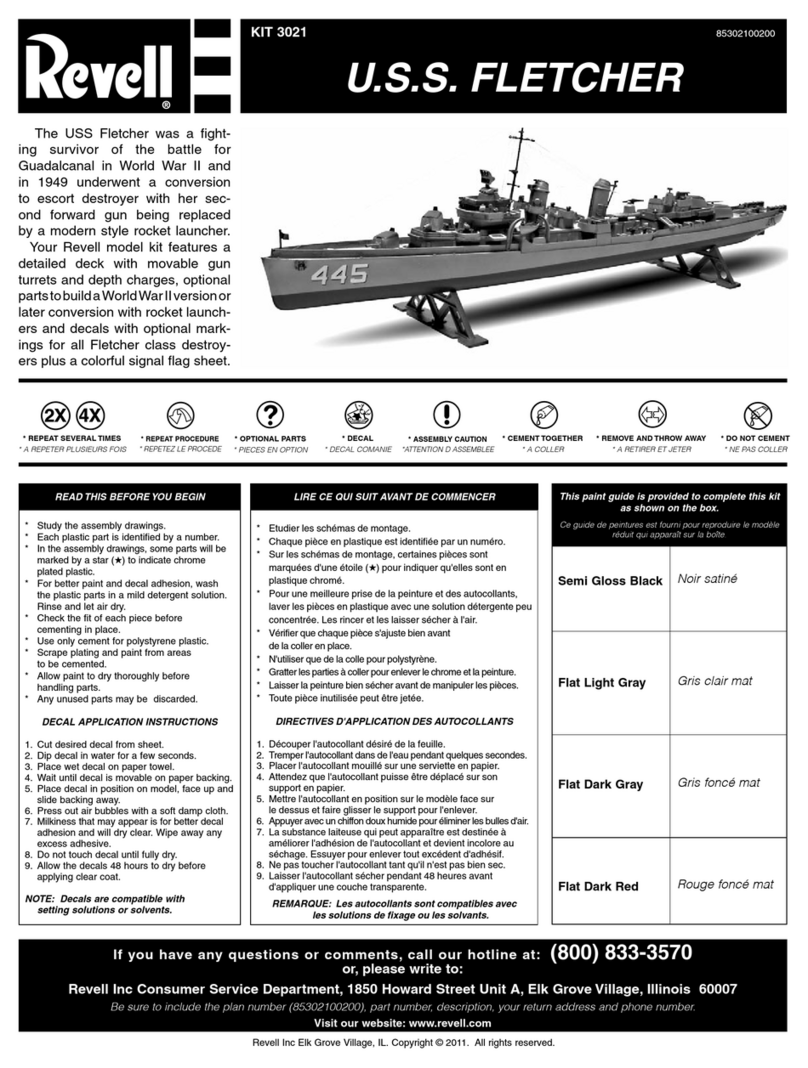

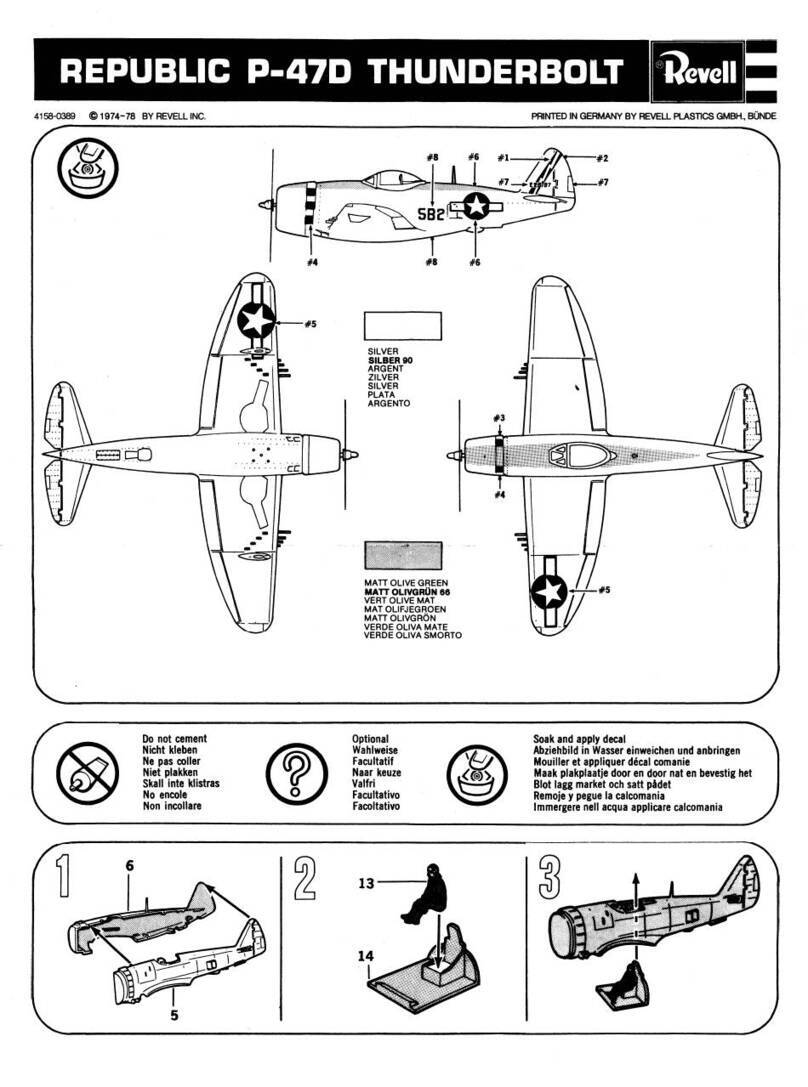

REVELL

REVELL P-47D Thunderbolt Razorback manual

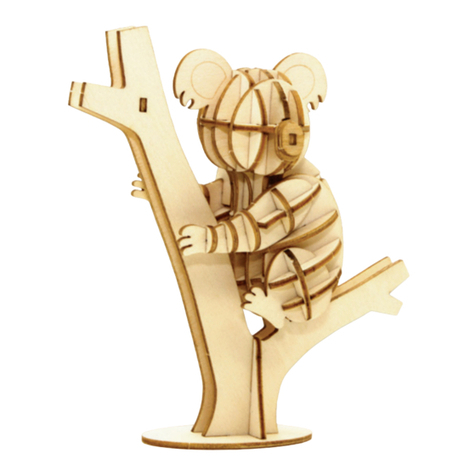

IncrediBuilds

IncrediBuilds Animal Collection Koala Building instructions

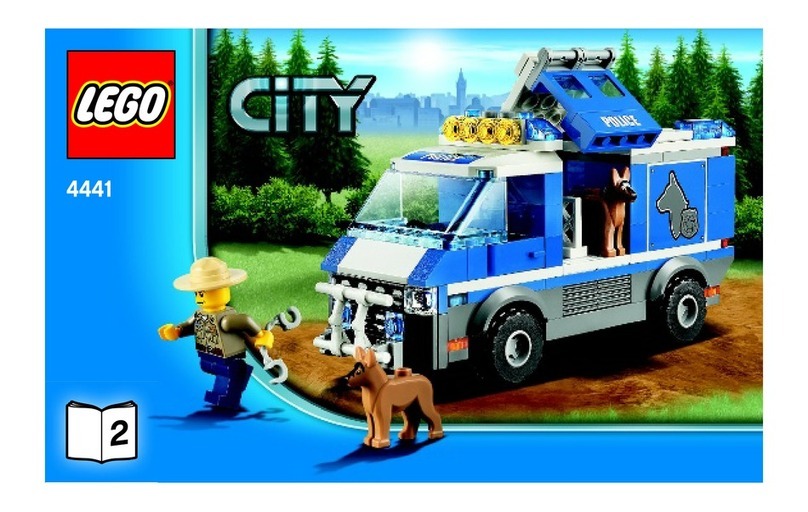

LEGO

LEGO City 4441 Building instructions

Fisher-Price

Fisher-Price Thomas & Friends Take-n-Play Daring Dragon... instructions