De Agostini Model Space C57 User manual

Other De Agostini Toy manuals

De Agostini

De Agostini Model Space T-72 User manual

De Agostini

De Agostini Model Space T-72 User manual

De Agostini

De Agostini Model Space T-72 User manual

De Agostini

De Agostini Millennium Falcon 3 Series User manual

De Agostini

De Agostini Model Space IJN Akagi User manual

De Agostini

De Agostini MODEL SPACE Honda CB750 FOUR User manual

De Agostini

De Agostini Model Space H.M.S. Bounty Admiralty User manual

De Agostini

De Agostini Model Space MiG-29 User manual

De Agostini

De Agostini Model Space MiG-29 User manual

De Agostini

De Agostini MODEL SPACE Honda CB750 FOUR User manual

De Agostini

De Agostini MODEL SPACE Soleil Royal User manual

De Agostini

De Agostini MODEL SPACE Honda CB750 FOUR User manual

De Agostini

De Agostini MODEL SPACE Honda CB750 FOUR User manual

De Agostini

De Agostini Model Space T-72 User manual

De Agostini

De Agostini Model Space MiG-29 User manual

De Agostini

De Agostini MODEL SPACE Honda CB750 FOUR User manual

De Agostini

De Agostini Model Space T-72 User manual

De Agostini

De Agostini Model Space MiG-29 User manual

De Agostini

De Agostini Model Space MiG-29 User manual

De Agostini

De Agostini MODEL SPACE SUZUKI GSX 1300R HAYABUSA User manual

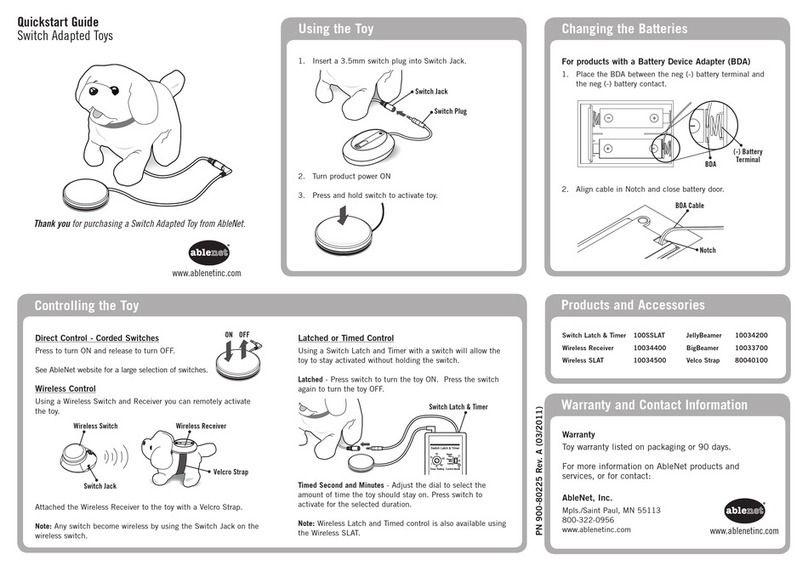

Popular Toy manuals by other brands

Betzold

Betzold 58833 instructions

Fisher-Price

Fisher-Price VOICE TECH RESCUE HEROES Wendy Waters... instructions

Fisher-Price

Fisher-Price POWER WHEELS H4803 Owner's manual & assembly instructions

LGB

LGB 90313 instruction manual

Menuett

Menuett 012134 operating instructions

REVELL

REVELL Tornado GR1 RAF Assembly manual