De Agostini MODEL SPACE Honda CB750 FOUR User manual

Other De Agostini Toy manuals

De Agostini

De Agostini Model Space D51 200 User manual

De Agostini

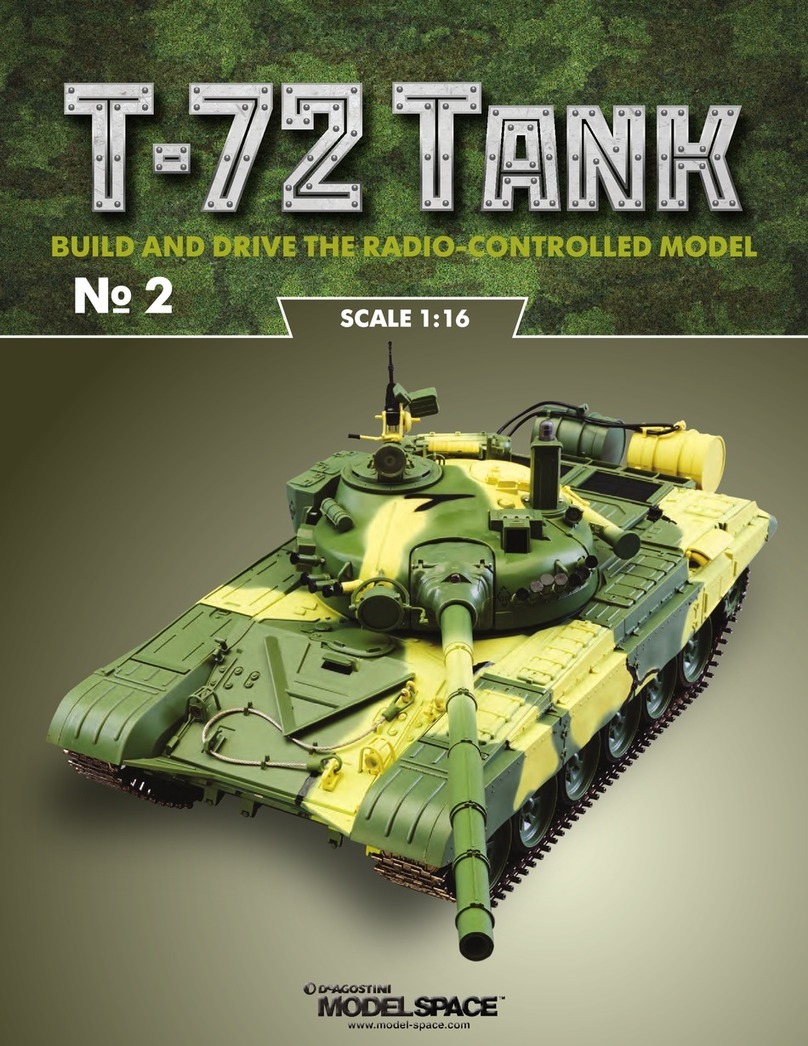

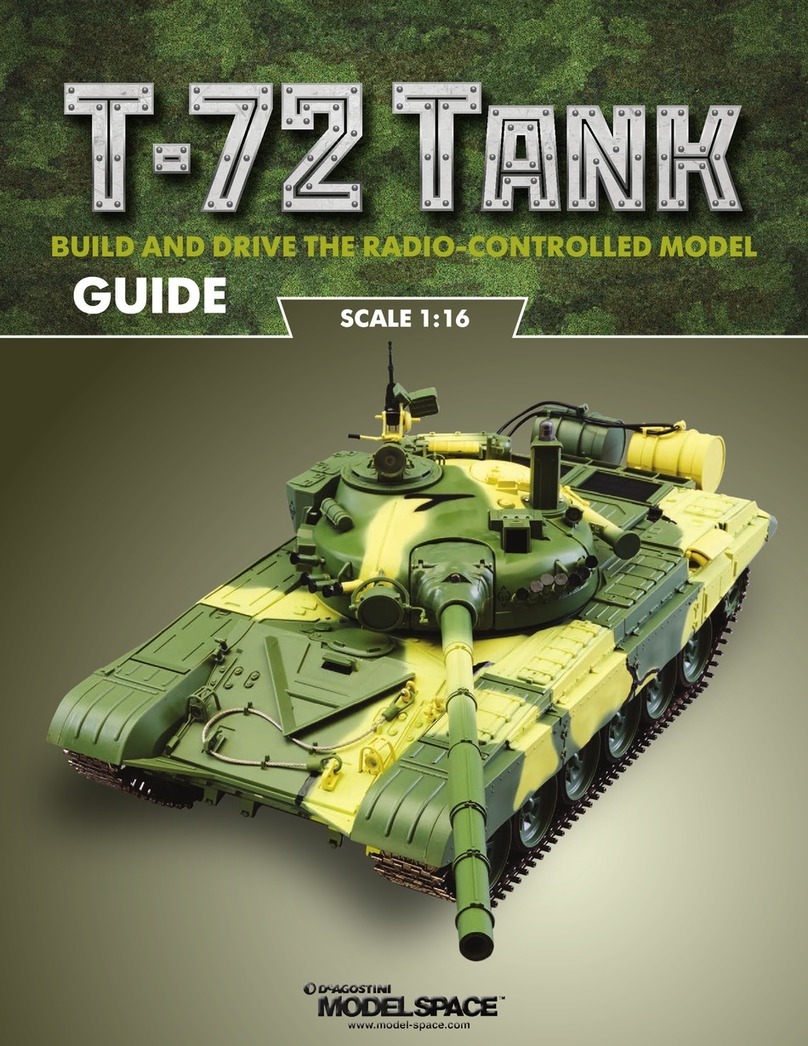

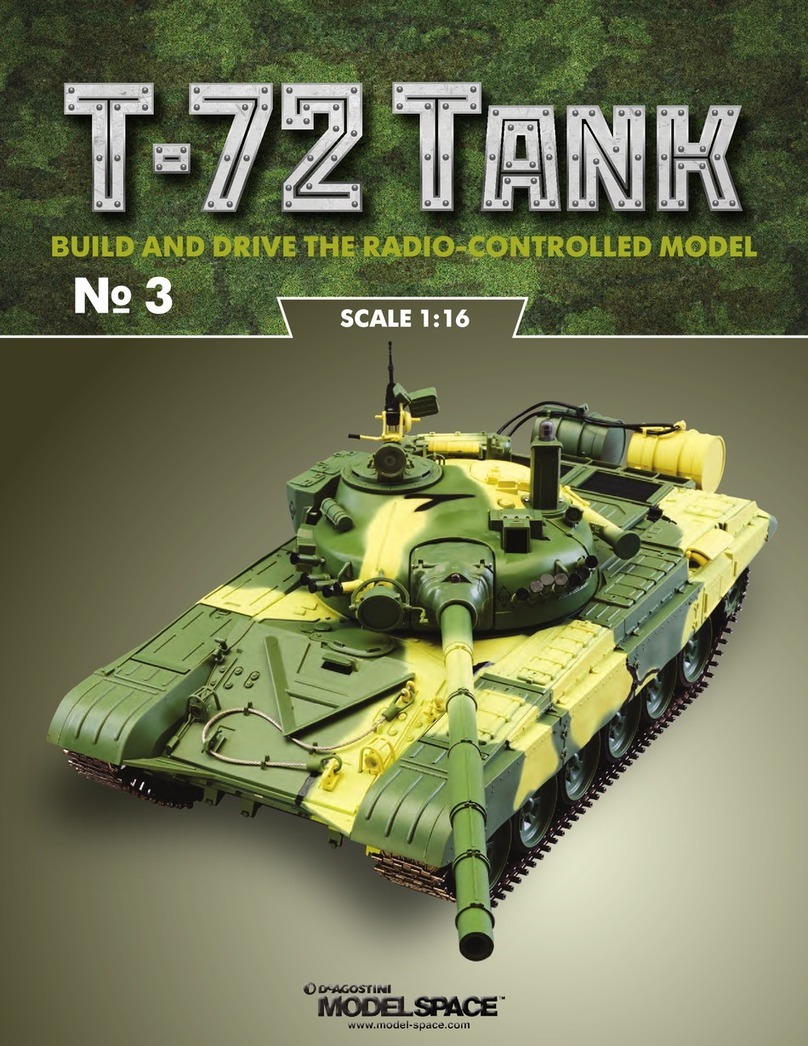

De Agostini Model Space T-72 User manual

De Agostini

De Agostini Model Space T-72 User manual

De Agostini

De Agostini MODEL SPACE Honda CB750 FOUR User manual

De Agostini

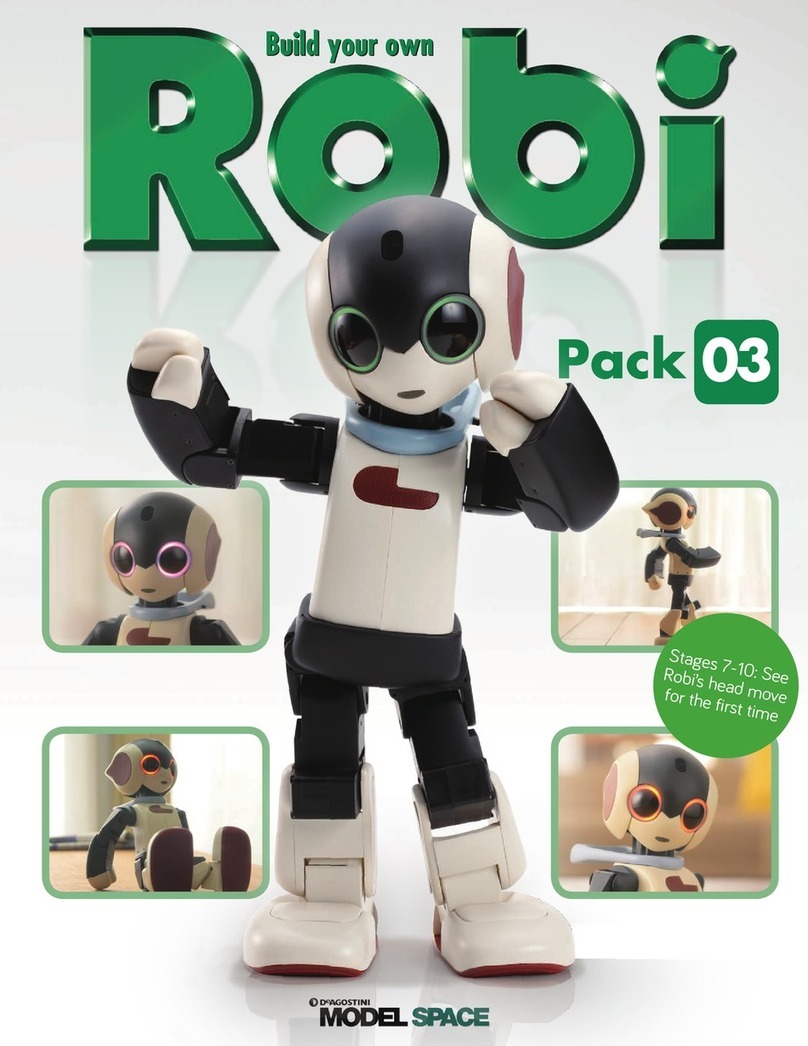

De Agostini Model Space ROBI Pack 03 Instruction Manual

De Agostini

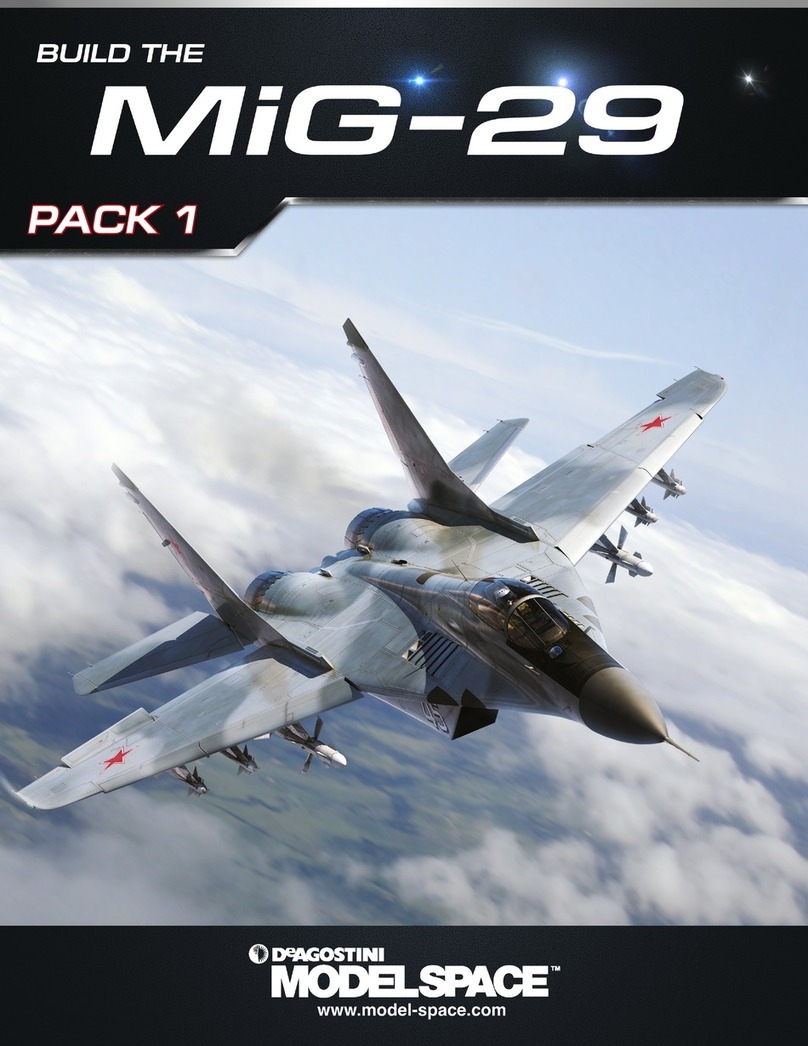

De Agostini Model Space MiG-29 User manual

De Agostini

De Agostini Model Space MiG-29 User manual

De Agostini

De Agostini Model Space MiG-29 User manual

De Agostini

De Agostini Model Space T-72 User manual

De Agostini

De Agostini Model Space C57 User manual

De Agostini

De Agostini Model Space C57 User manual

De Agostini

De Agostini Model Space H.M.S. Bounty Admiralty User manual

De Agostini

De Agostini Model Space MiG-29 User manual

De Agostini

De Agostini Millennium Falcon 3 Series User manual

De Agostini

De Agostini Model Space MiG-29 User manual

De Agostini

De Agostini MODEL SPACE Soleil Royal User manual

De Agostini

De Agostini Model Space D51 200 User manual

De Agostini

De Agostini MODEL SPACE Honda CB750 FOUR User manual

De Agostini

De Agostini Model Space T-72 User manual

De Agostini

De Agostini Model Space T-72 User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions