De Agostini Model Space ROBI Pack 03 Instruction Manual

Other De Agostini Toy manuals

De Agostini

De Agostini Model Space Harley-Davidson FLSTF Fat Boy User manual

De Agostini

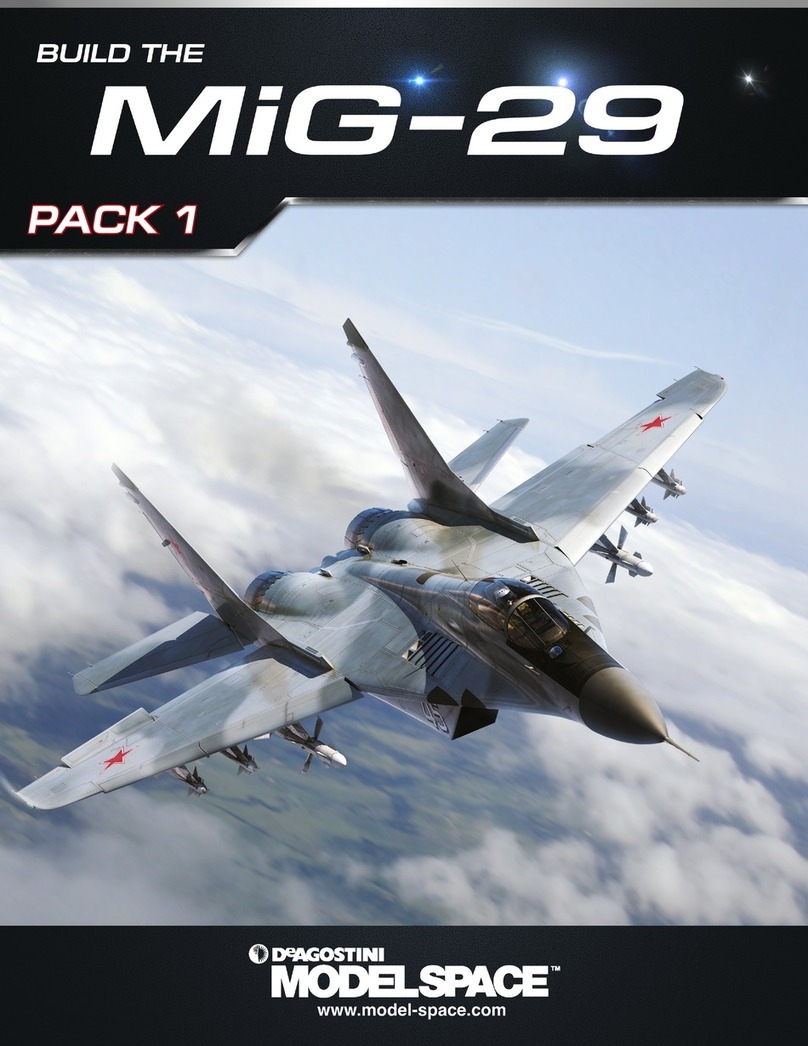

De Agostini Model Space MiG-29 User manual

De Agostini

De Agostini Model Space MiG-29 User manual

De Agostini

De Agostini MODEL SPACE Honda CB750 FOUR User manual

De Agostini

De Agostini MODEL SPACE SUZUKI GSX 1300R HAYABUSA User manual

De Agostini

De Agostini Model Space D51 200 User manual

De Agostini

De Agostini Model Space IJN Akagi User manual

De Agostini

De Agostini Model Space SANTISIMA TRINIDAD User manual

De Agostini

De Agostini Model Space MiG-29 User manual

De Agostini

De Agostini Model Space D51 200 User manual

De Agostini

De Agostini Model Space C57 User manual

De Agostini

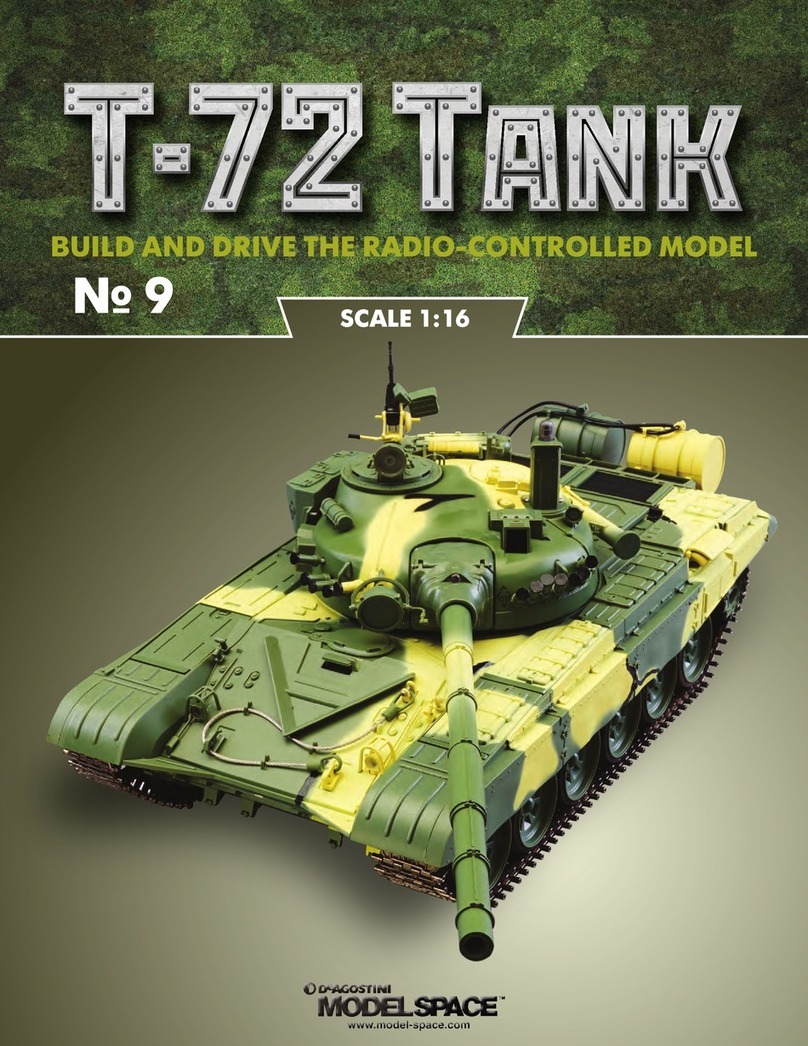

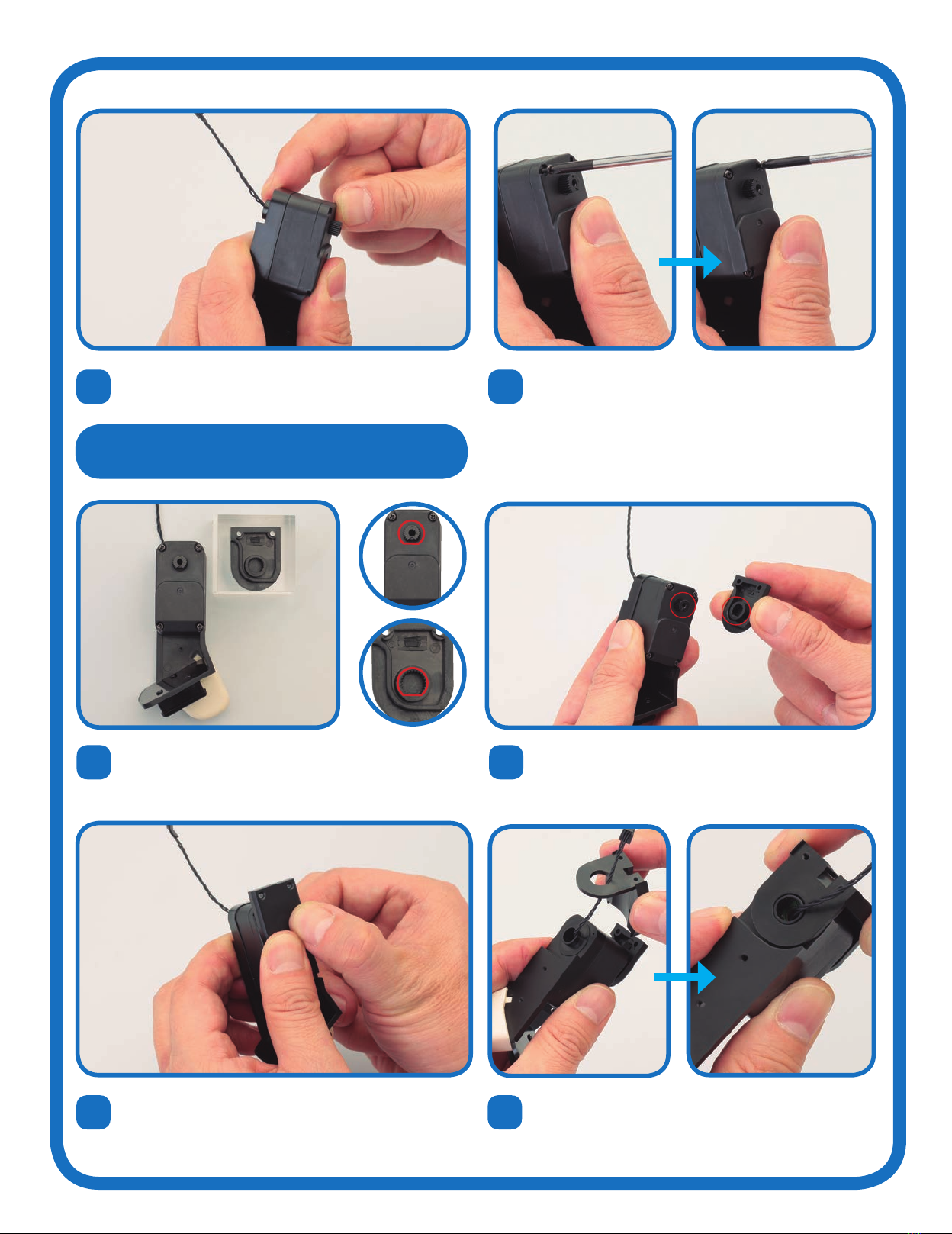

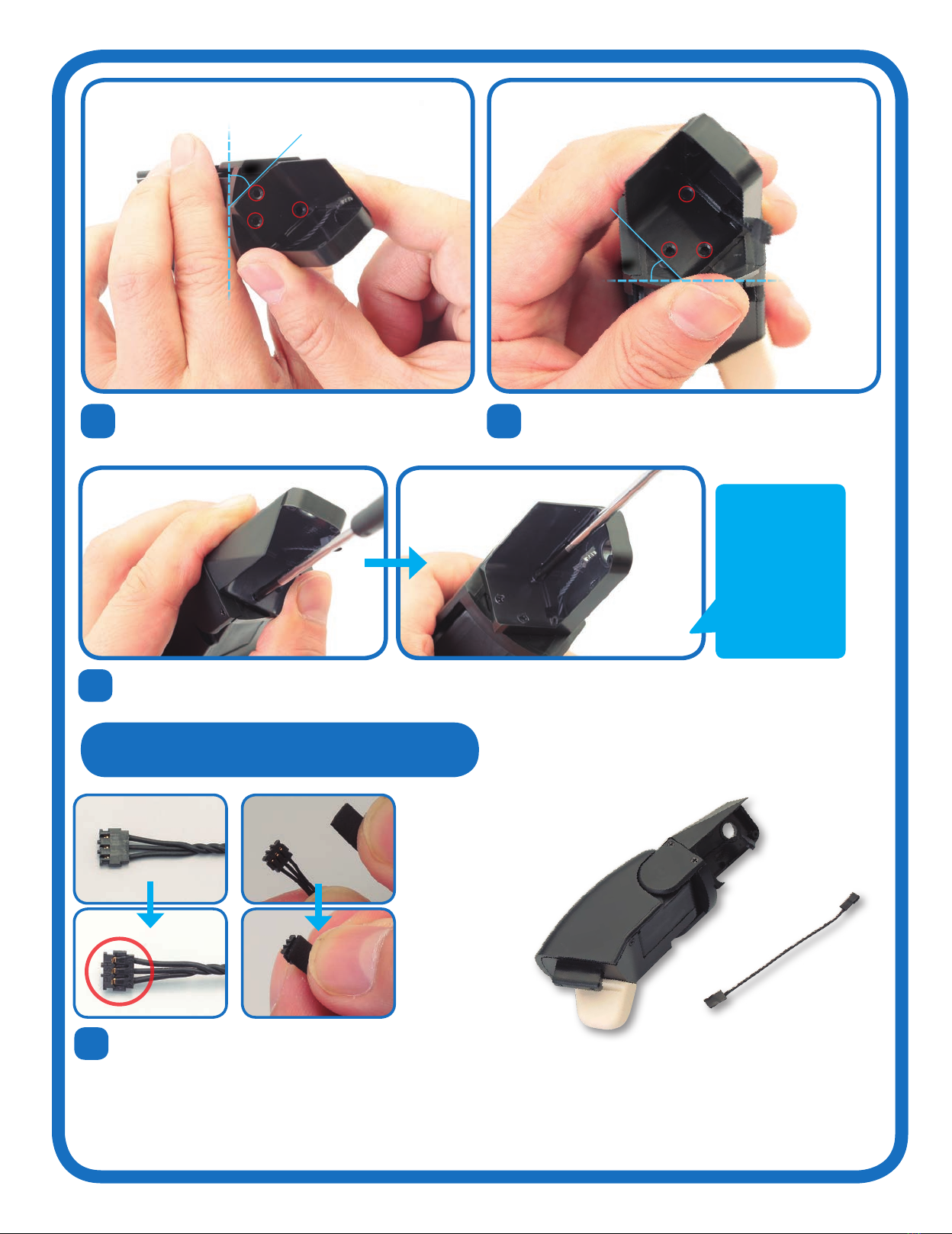

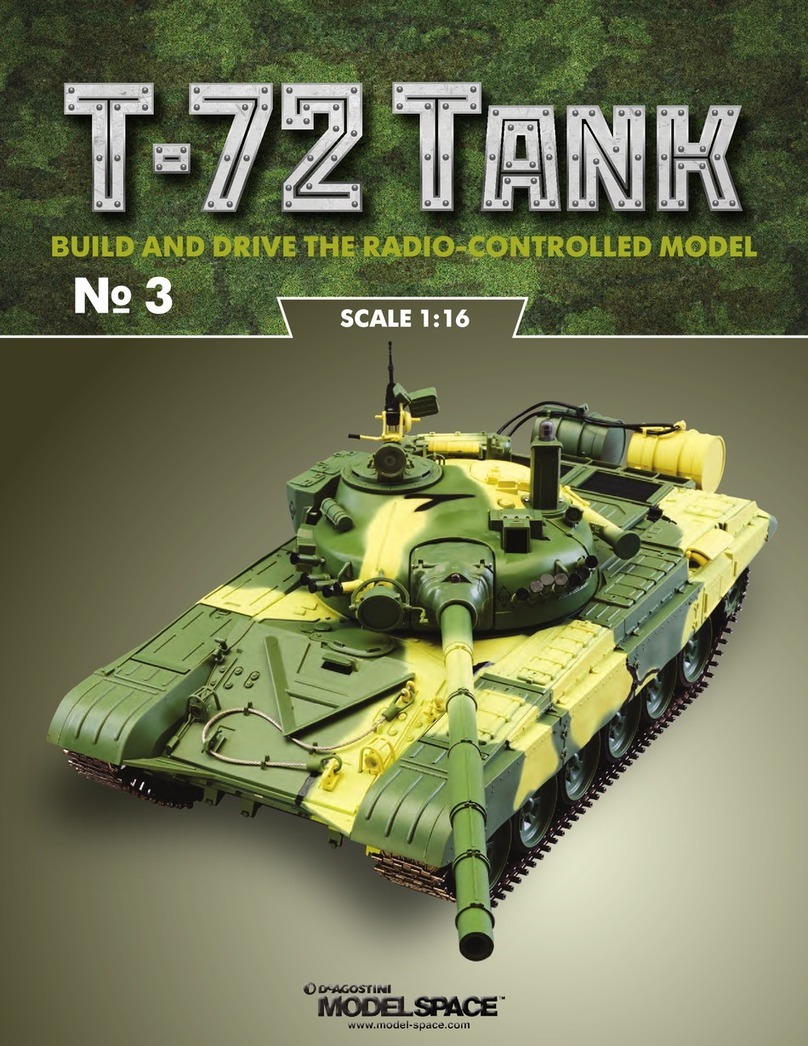

De Agostini Model Space T-72 User manual

De Agostini

De Agostini Model Space T-72 User manual

De Agostini

De Agostini MODEL SPACE Honda CB750 FOUR User manual

De Agostini

De Agostini MODEL SPACE Honda CB750 FOUR User manual

De Agostini

De Agostini Model Space MiG-29 User manual

De Agostini

De Agostini MODEL SPACE Honda CB750 FOUR User manual

De Agostini

De Agostini Model Space T-72 User manual

De Agostini

De Agostini Model Space HUMMER H1 User manual

De Agostini

De Agostini Model Space C57 User manual

Popular Toy manuals by other brands

Smoby

Smoby 7600220376 quick start guide

Eduard

Eduard Nashorn quick start guide

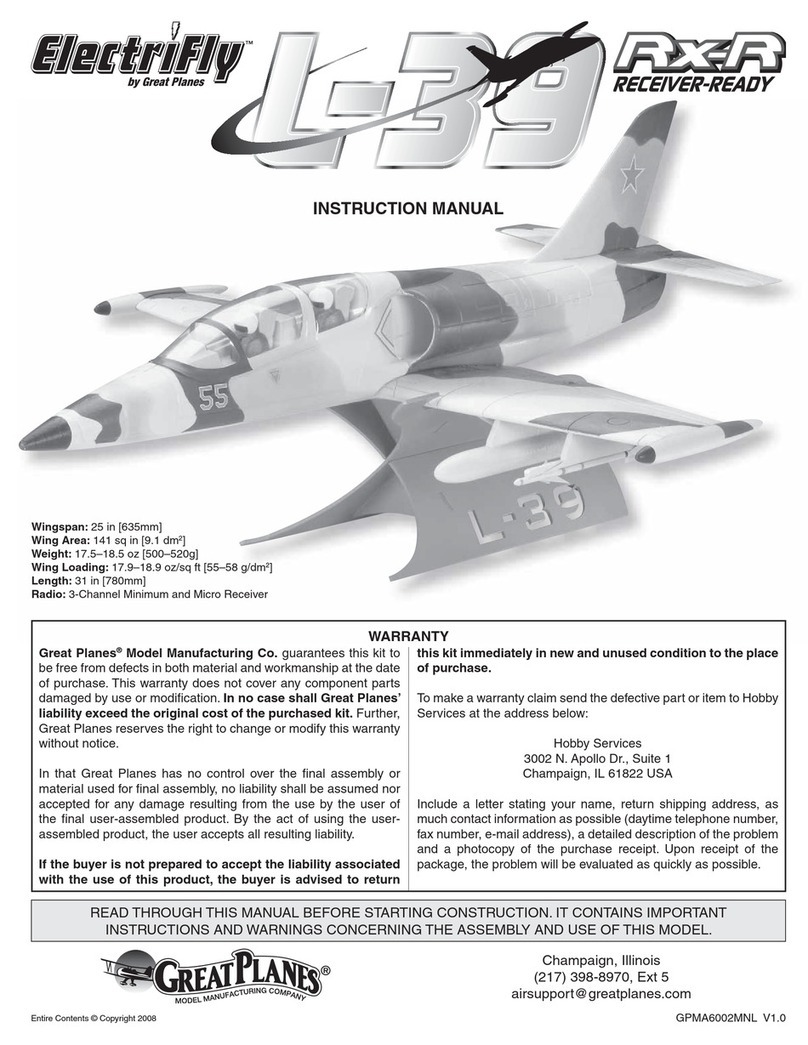

electrifly

electrifly L-39 instruction manual

Agora Models

Agora Models JAGUAR E-TYPE Build instructions

TP active fun

TP active fun TP295 Instructions for assembly, maintenance and safe use

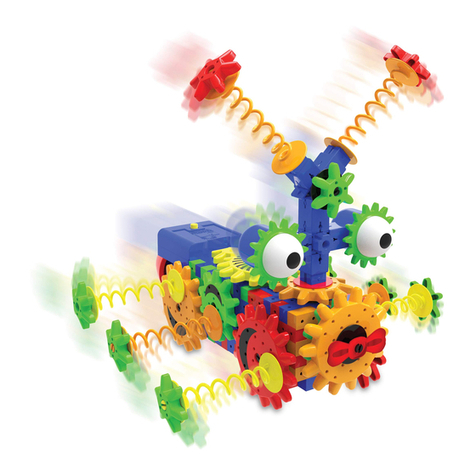

The Learning Journey

The Learning Journey Techno Gears Bionic Bug instruction manual