1. Introduction

1.1 Symbols for hazard statements......................................................................................................................................................................................... 3

1.2 About the operator's manual...............................................................................................................................................................................................3

1.3 Warnings and safety.................................................................................................................................................................................................................4

1.4 Legal information....................................................................................................................................................................................................................... 4

2. About the AGC 150 Stand-alone

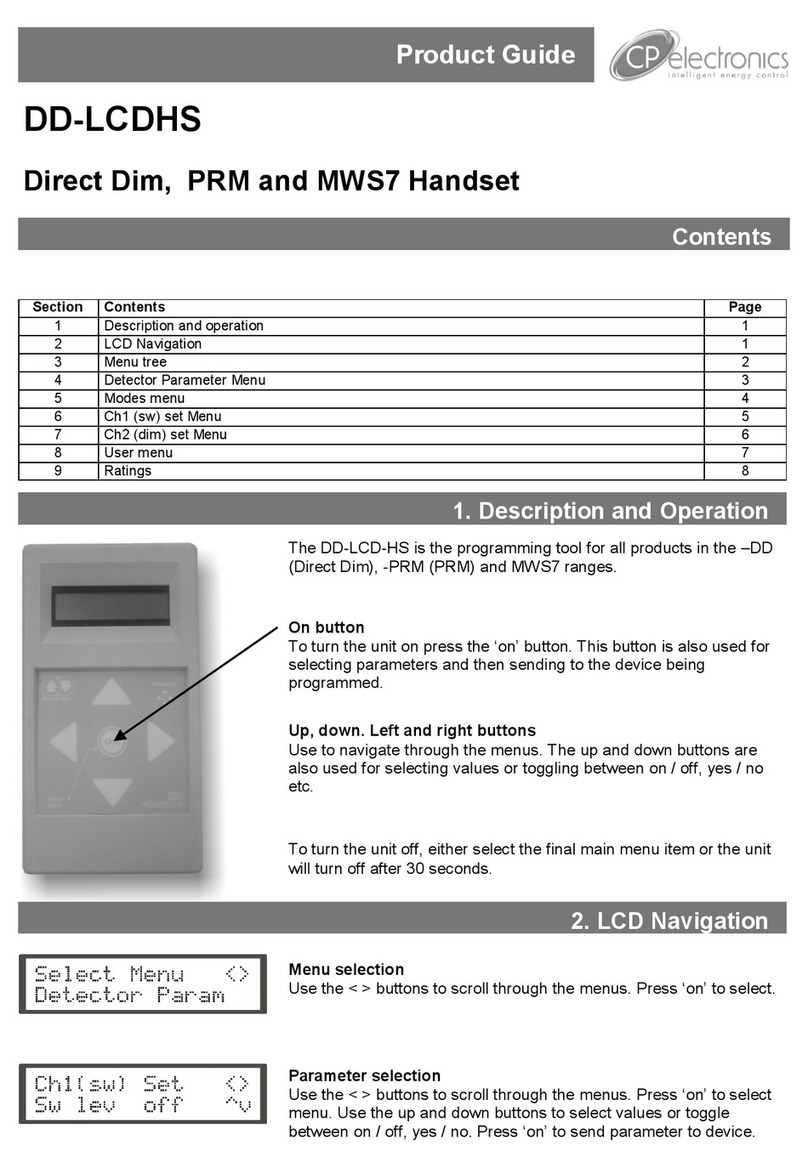

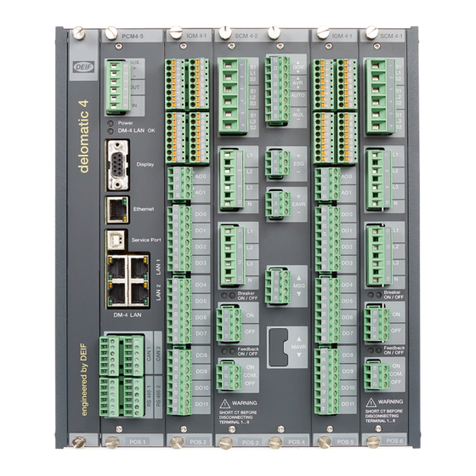

2.1 Display, buttons and LEDs.....................................................................................................................................................................................................5

2.2 Display settings..........................................................................................................................................................................................................................6

2.3 Mimic function.............................................................................................................................................................................................................................6

2.4 Running modes........................................................................................................................................................................................................................... 7

3. Menus

3.1 Menu structure.............................................................................................................................................................................................................................9

3.2 Parameters menu...................................................................................................................................................................................................................... 9

3.2.1 Menu numbers..................................................................................................................................................................................................................10

3.2.2 The jump to parameter function............................................................................................................................................................................ 10

3.3 View menu...................................................................................................................................................................................................................................10

3.3.1 Display views......................................................................................................................................................................................................................11

3.3.2 Display text........................................................................................................................................................................................................................ 12

3.4 Status texts.................................................................................................................................................................................................................................13

3.5 Service view...............................................................................................................................................................................................................................14

3.6 I/O Setup menu.........................................................................................................................................................................................................................16

3.7 Engine shortcuts......................................................................................................................................................................................................................16

3.7.1 ECU Diagnose and Force Regeneration...............................................................................................................................................................16

3.8 General shortcuts....................................................................................................................................................................................................................17

3.9 Exhaust after-treatment (Tier 4/Stage V)...............................................................................................................................................................18

4. Alarm handling and log list

4.1 Alarm handling...........................................................................................................................................................................................................................21

4.2 Logs menu...................................................................................................................................................................................................................................22

Operator's manual 4189341311B EN Page 2 of 22