This product is certificated to meet RoHS

Directive and Lead-Free produced definition.

Using approved critical components only is

recommended when the situation to replace

defective parts. Vender assumes no liability

express or implied, arising out of any unauthorized

modification of design or replacing non-RoHS

parts. Service providers assume all liability.

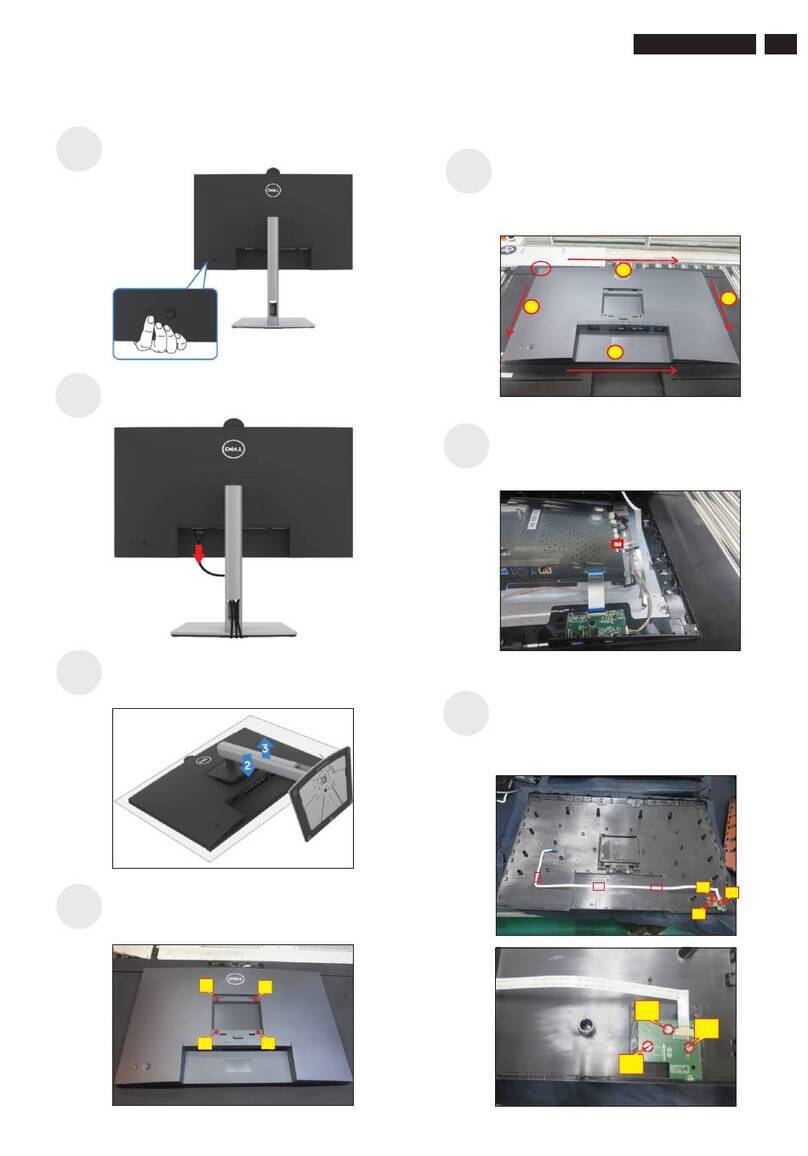

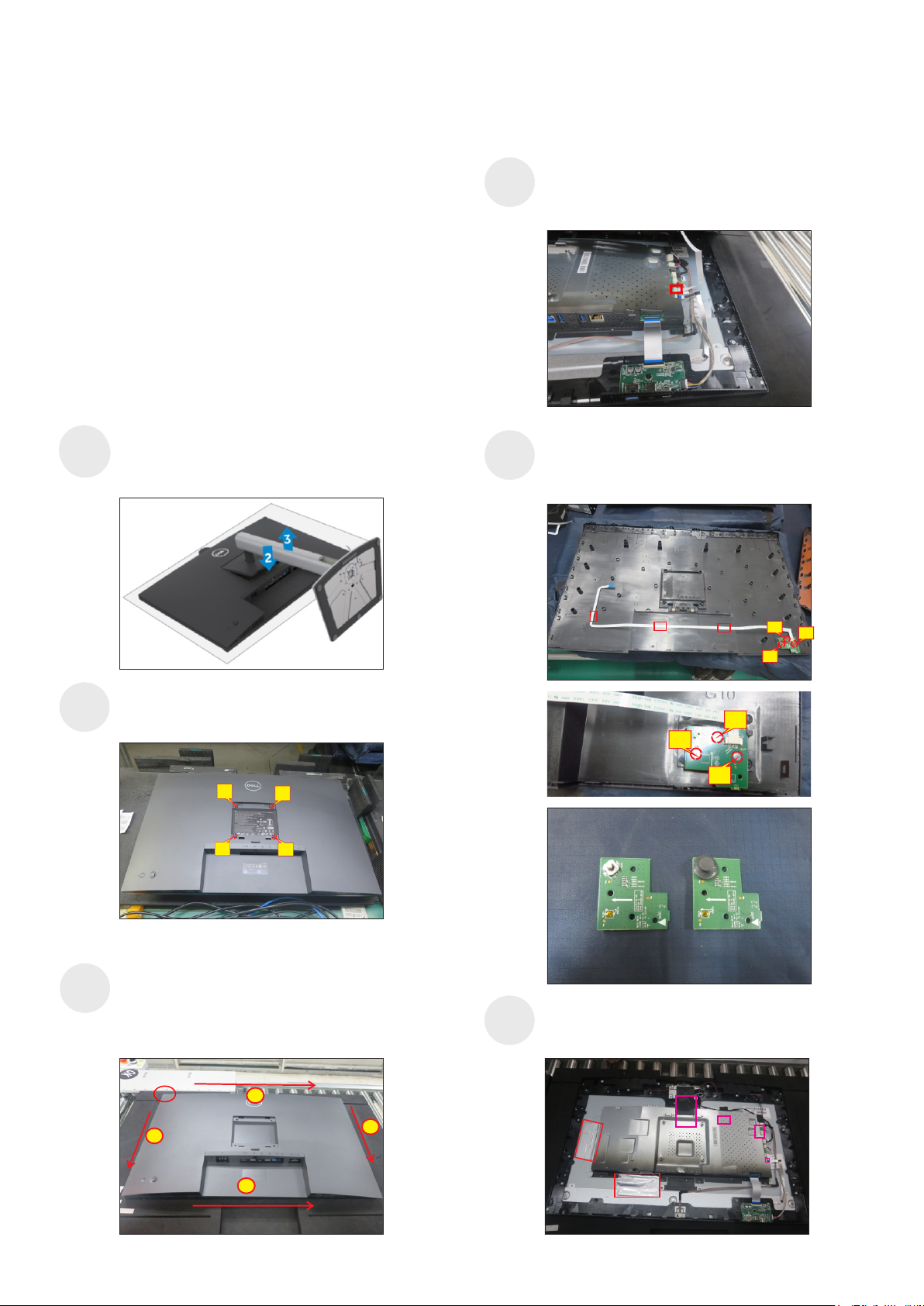

Proper service and repair is important to the safe,

reliable operation of all series products. The

service providers recommended by vender should

be aware of notices listed in this service manual in

order to minimize the risk of personal injury when

perform service procedures. Furthermore, the

possible existed improper repairing method may

damage equipment or products. It is recommended

that service engineers should have repairing

knowledge, experience, as well as appropriate

product training per new model before performing

the service procedures.

Product Announcement:

Qualified Repairability:

NOTICE:

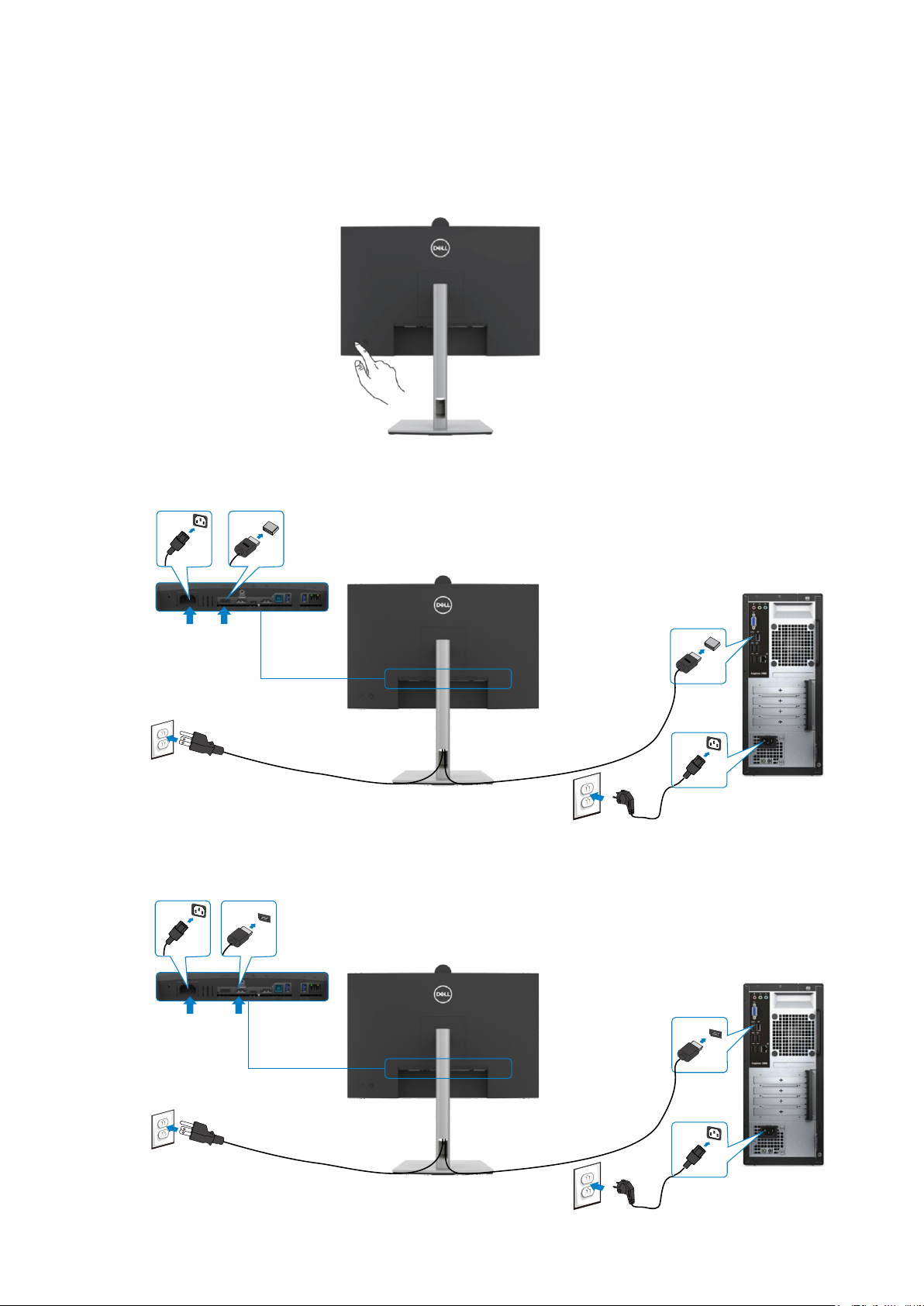

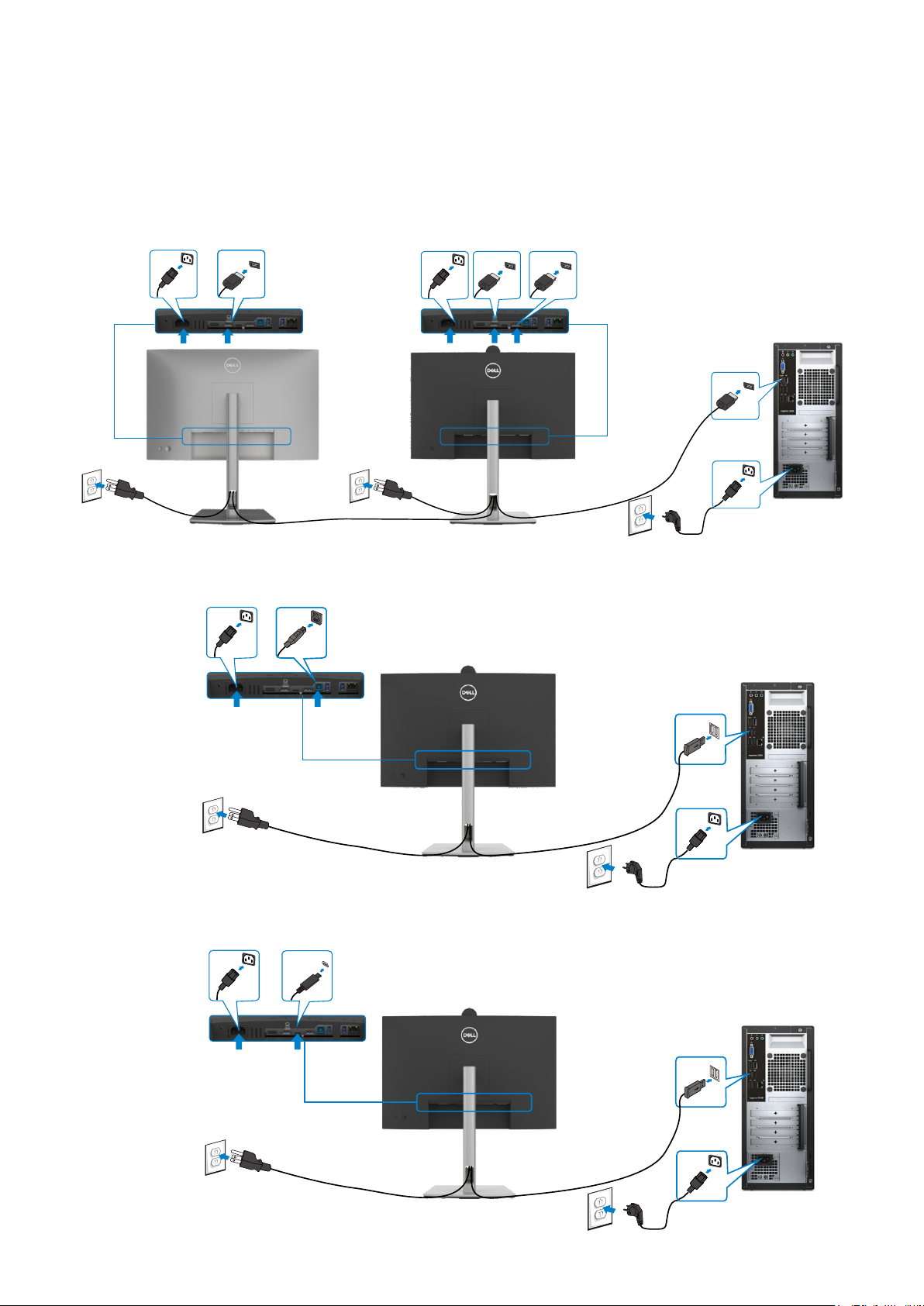

! To avoid electrical shocks, the products should be

connected to an authorized power cord, and turn

off the master power switch each time before

removing the AC power cord.

! To prevent the product away from water or

expose in extremely high humility environment.

! To ensure the continued reliability of this

product, use only original manufacturer’s

specified parts.

! To ensure following safety repairing behavior, put

the replaced part on the components side of

PWBA, not solder side.

! To ensure using a proper screwdriver, follow the

torque and force listed in assembly and

disassembly procedures to unscrew screws.

! Using Lead-Free solder to well mounted the

parts.

! The fusion point of Lead-Free solder requested in

the degree of 220°C.

1. Important Safety Notice