4

Table of Contents

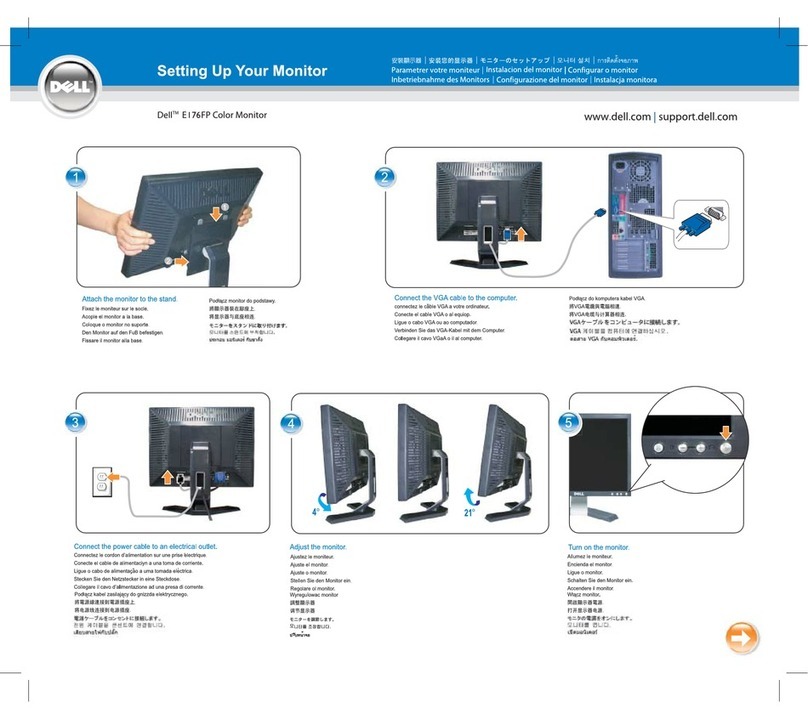

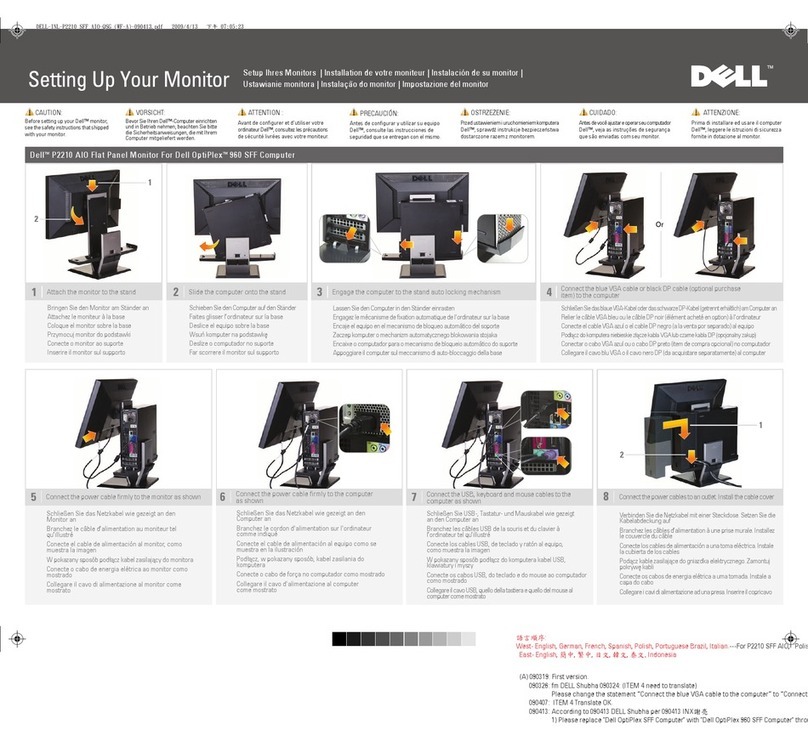

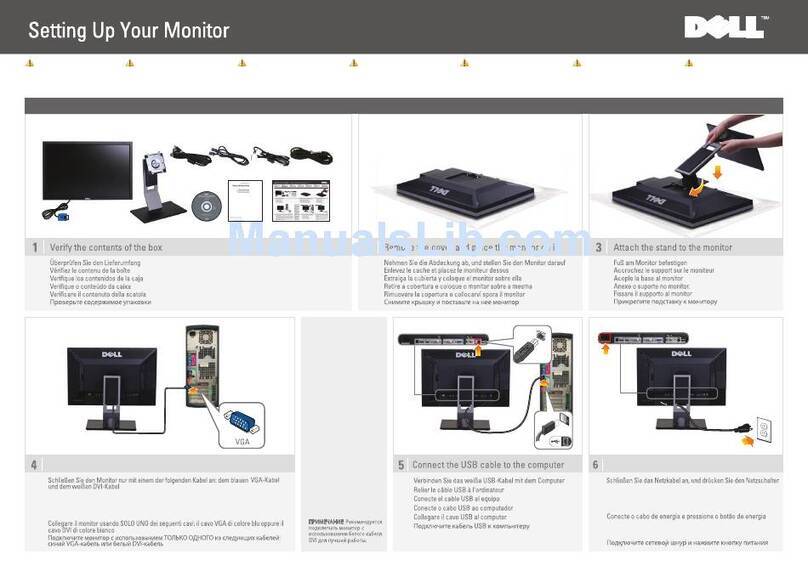

Installation

•Prevent internal heat build up by allowing adequate air

circulation. Do not place the monitor on surfaces (rugs,

blankets, etc.) or near materials (curtains, draperies) that

may block the ventilation holes.

•Do not install the monitor near heat sources such as

radiators or air ducts, or in a place subject to direct

sunlight, excessive dust, mechanical vibration or shock.

•Do not place the monitor near equipment that generates

magnetism, such as a converter, or high voltage power

lines.

Maintenance

•Clean the cabinet, panel and controls with a soft cloth

lightly moistened with a mild detergent solution. Do not

use any type of abrasive pad, scouring powder or solvent

such as alcohol or benzine.

•Do not rub, touch or tap the surface of the screen with

sharp or abrasive items such as a ball point pen or

screwdriver. This type of contact may scratch the picture

tube.

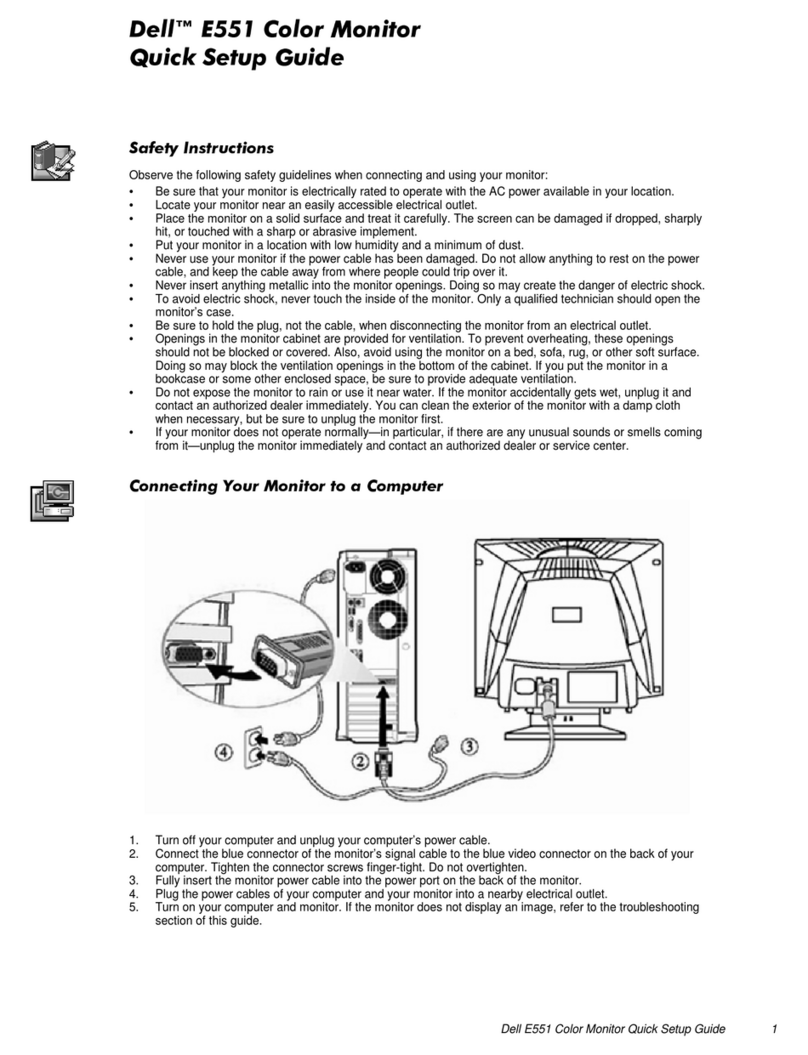

Warning on Power Connection

•Use an appropriate power cord for your local power

supply.

For customers in the U.S.A.

If you do not use an appropriate power cord, the monitor

will not conform to mandatory FCC standards.

for 220 to 240 V ACfor 100 to 120 V AC

•Before disconnecting the power cord, wait for at least 30

seconds after turning off the power to allow the static

electricity on the CRT display surface to discharge.

•After the power has been turned on, the CRT is

demagnetized (degaussed) for about 5 seconds. This

generates a strong magnetic field around the metal frame,

which may affect the data stored on magnetic tapes and

disks near the monitor. Place magnetic recording

equipment, tapes and disks away from this monitor.

Read First! ................................................................................. 3

Damper Wire ............................................................................ 3

Setup .......................................................................................... 3

Quick Specifications ................................................................ 3

Precautions ............................................................................... 4

Plug and Play ........................................................................... 4

Parts and Controls ................................................................... 5

The OSD (On-screen Display) System ................................. 6

Resetting the Adjustments ..................................................... 9

Plug and Play

This monitor complies with the DDC

TM

1and DDC2B Display

Data Channel (DDC) standards of VESA.

When a DDC1 host system is connected, the monitor

synchronizes with the V. CLK in accordance with the VESA

standards, and outputs the EDID (Extended Display

Identification Data) to the data line.

When a DDC2B host system is connected, the monitor

automatically switches to the appropriate standard.

DDC

TM

is a trademark of Video Electronics Standard

Association.

•Your monitor operates according to DDC2B. Only

computers that support the same guidelines and operate

at the same or higher level can make use of this feature.

•If your computer does not support the relevant

guidelines, you can still use your monitor and computer.

You may need to manually specify the appropriate

resolution in the computer.

•The highest resolution automatically selected may not

give the best result. You may need to manually select the

most suitable resolution in the computer.

Precautions

Examples of plug types:

for 240 V AC only

The socket should be installed near the equipment and

be easily accessible.

Graphic Enhancement Mode (GEM) .................................. 10

Specifications .......................................................................... 10

Monitor Information ............................................................. 11

Power Saving Function and LED Indicators .................... 11

Preset and User Modes ......................................................... 11

Warning Messages................................................................. 12

Troubleshooting..................................................................... 12

Dell Computer Corporation’s Environmental Program . 14

Appendix .............................................................................. 109

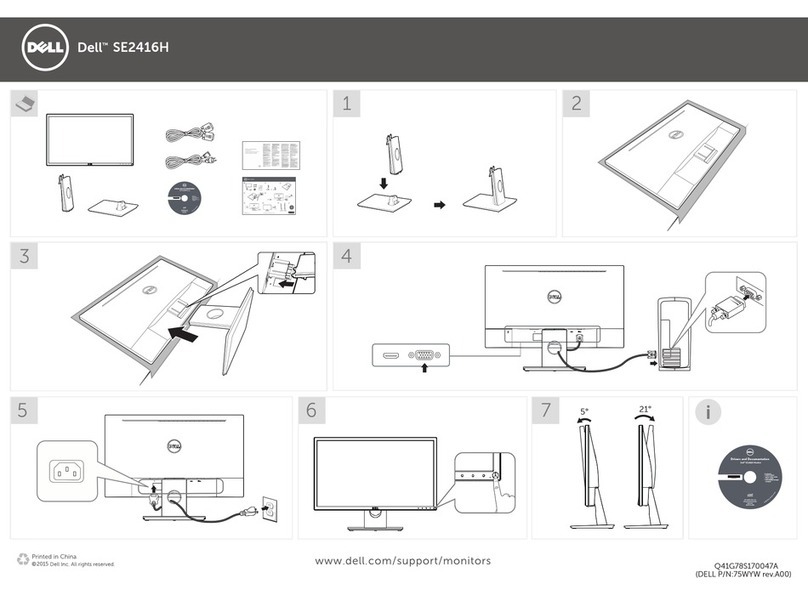

Getting Started

5

Getting Started

EN

F

ES

D

J

C s

C t

PL

Video Connector

Pin No. Signal

1 Red

2 Green (Composite

Sync on Green)

3 Blue

4 Ground

5 CPU Sense

6 Red Ground

7 Green Ground

Pin No. Signal

8 Blue Ground

9 Not used

(no pin)

10 Ground

11 Ground

12 SDA

(serial data)

13 Horizontal Sync

14 Vertical Sync

15 SCL

(serial clock)

Use of the Tilt/Swivel

With the tilt/swivel, you can adjust this monitor to any desired

angle within 180° horizontally and 20° vertically.

To turn the monitor vertically and horizontally, hold it at the

bottom with both hands as shown below.

Parts and Controls

Rear

1(RESET) button (pages 6 and 9)

Resets the adjustments to the factory settings.

2(GEM) button (page 10)

Selects the Graphic Enhancement Mode.

3¨(BRIGHTNESS) ./>buttons (page 6)

Adjust the picture brightness.

Operate as the ./>buttons when adjusting other

items.

4(MENU) button (pages 6 and 11)

Displays the MENU OSD.

5>(CONTRAST) ?//buttons (page 6)

Adjust the contrast.

Operate as the ?//buttons when adjusting other

items.

6u(POWER) switch and indicator (page 11)

Turns the monitor on and off.

The indicator lights up green when the monitor is on,

and lights up orange when the monitor is in Power

Saving mode.

7AC IN connector

Provides AC power to the monitor.

8Video input connector (HD15)

Inputs RGB video signals and SYNC signals

Front

Getting Started