Delptronics ThunderBell User manual

ThunderBell Module Kit Instructions Page 1 of 8

Important Information

Thank you for your purchase of the Delptronics ThunderBell Eurorack Module Kit!

The most recent version of this document, and the instructions for the ThunderBell Mini Kit can be downloaded from:

http://delptronics.com/thunderbell.php

Before you start, please read the Electronic Kit Soldering Tutorial. It contains important and useful information even

for experienced kit builders. If this is your first electronic kit, the best piece of advice we can give is to take your time

and be careful to put the right part in the right place. The tutorial can be downloaded from:

http://delptronics.com/documents/SolderingTutorial.pdf

In the instructions that follow, each part type is followed by the PCB outline for that part. Refer to the enclosed

photograph of the completed kit for assistance with part identification and placement.

The PCB is marked with the refdes (reference designator) of each part, not its value. For example R1 refers to

resistor number one and C1 refers to capacitor number one. Once the part value is identified, it is easy to find the

refdes on the PCB.

Some parts must be oriented in a particular way, that is, the correct lead goes in the appropriate hole in the PCB. For

example, electrolytic capacitors are polarized (they have a positive lead and a negative lead). Ceramic capacitors are

not polarized, so it does not matter which of the two leads goes in which of the two holes. In these instructions, the

symbol (±) highlights parts that must be inserted with a particular orientation.

When you are ready to begin, separate the parts by type. Then, when you are ready to solder parts of a particular

type, separate them by value. Compare your parts to the bill of materials, which can be found on the last page of this

document. Make sure no parts are missing. These instructions list the parts in the recommended order of assembly.

In general, the order is shortest to tallest.

This manual is separated into two sections: board-mounted parts, which are soldered directly to the PCB, and off-

board parts which are connected to the PCB via wires.

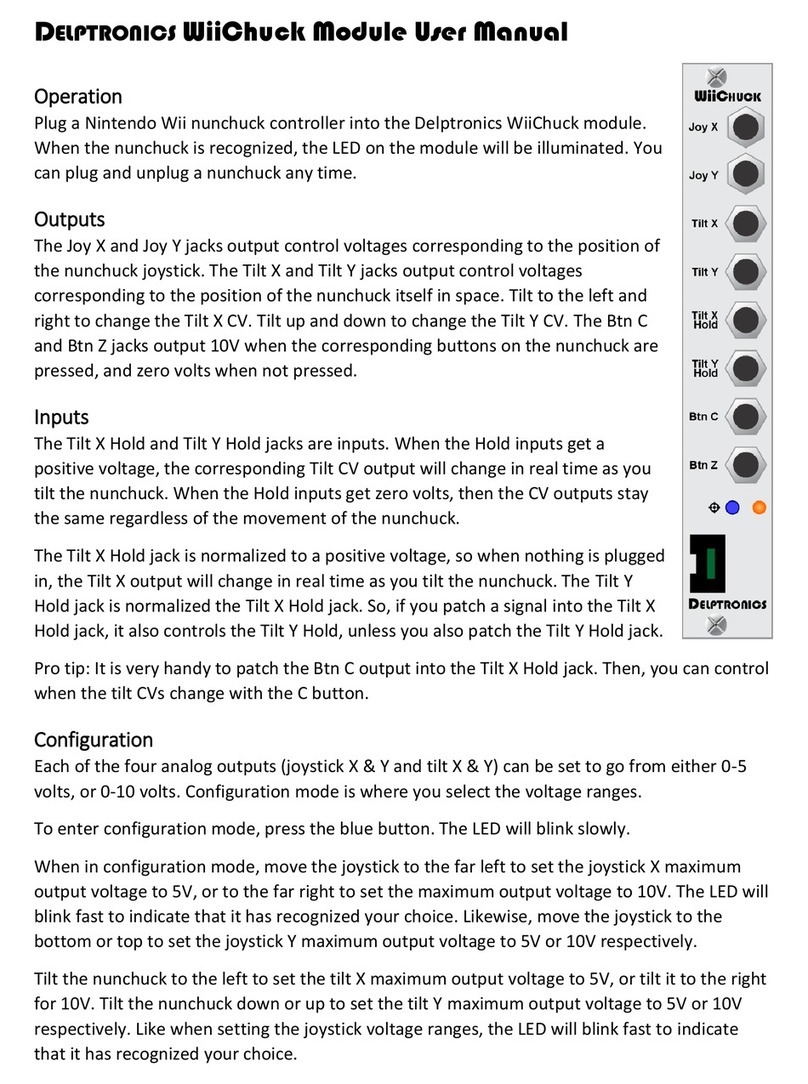

Using the ThunderBell Module

Trigger Button: Press the button to make the bell sound.

Pitch Knob: controls the pitch of the bell.

Decay Knob: controls how long it takes for the bell’s volume to decay from its maximum level down to silence. The

bell can be re-triggered even while the last bell sound is still decaying.

Pitch CV Jack: allows you to control the pitch of the bell with an external control voltage. It accepts 0V to 5V, but has

over-voltage protection. The pitch is determined by the sum of the voltage in the jack and the pitch knob, so the knob

still works when a plug is inserted into the jack.

Decay CV Jack: allows you to control the decay of the bell with an external control voltage. It accepts 0V to 5V, but

has over-voltage protection. The decay is determined by the sum of the voltage in the jack and the pitch knob, so the

knob still works when a plug is inserted into the jack.

Trigger Jack: allows you to trigger the bell sound using an analog trigger or gate signal. It accepts a 2.5 to 15 volt

signal. The trigger button can still be used even when a plug is inserted into the Trigger Jack.

Output Jack: is where the sound comes out. The output signal is about 9V peak-to-peak.

ThunderBell Module Kit Instructions Page 2 of 8

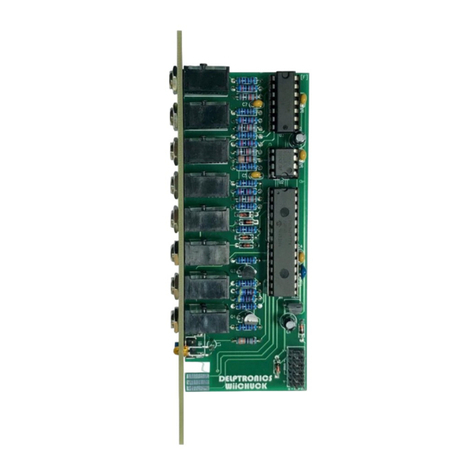

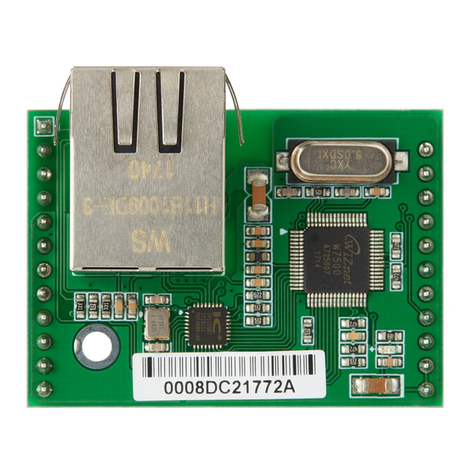

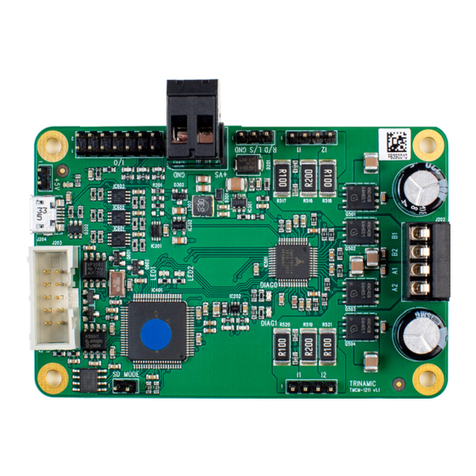

Board-mounted Parts

All of the board-mounted parts are supplied in two little plastics bag to keep them together. You can refer to the

picture below while assembling the printed circuit board. The following pages list each part type and describe how to

assemble it.

Off-Board Parts

Refer to the photo below when installing the pots, 3.5mm jacks and trigger button wires. Try to keep the wires short

so that you don’t end up with a mess of spaghetti behind the panel.

ThunderBell Module Kit Instructions Page 3 of 8

1N4148 Diode (±)

Diodes are red and black glass cylinders. There are four diodes, and they all look similar, but D2 is different. D2 is a

switching diode and has “1N4148” printed on it in very small type. An easier way to tell D2 apart is that D2 is loose,

while the other three diodes are connected together on a piece of tape.

Diodes are polarized, so it is important that the right lead goes in the right hole. When inserted into the PCB, the

black stripe on the diode must line up with the stripe on the part outline on the PCB. The diode leads need to be bent

into a U shape in order to insert them into the PCB. Bend the leads by holding the diode body and pressing down on

each lead close to the body.

Schottky Diodes (±)

D1, D3, and D4 are Schottky diodes and have “BAT85” printed on it in very small type. When inserted into the PCB,

the black stripe on the diode must line up with the stripe on the part outline on the PCB.

Resistors

Resistors are cylindrical parts with colored stripes indicating their value. The resistor leads need to be bent into a U

shape in order to insert them into the PCB. Bend the leads by holding the resistor body and pressing down on each

lead close to the body.

Quantity

Description

Marking

Refdes

5

1K Resistor

brown

black

black

brown

brown

R10, R11, R14, R15, R16

1

4.7K Resistor

yellow

violet

black

brown

brown

R20

2

10K Resistor

brown

black

black

red

brown

R9, R17

1

22K Resistor

red

red

black

red

brown

R13

3

47K Resistor

yellow

violet

black

red

brown

R4, R12, R22

1

68K Resistor

blue

gray

black

red

brown

R18

2

100K Resistor

brown

black

black

orange

brown

R1, R21

1

220K Resistor

red

red

black

orange

brown

R2

3

470K Resistor

yellow

violet

black

orange

brown

R3, R5, R19

1

1M Resistor

brown

black

black

yellow

brown

R6

2

2.2M Resistor

red

red

black

yellow

brown

R7, R8

Ceramic Capacitors

Ceramic capacitors are very small tan or blue blobs. Their value is marked on them with a three digit code. The

marking is rather small, so you may have to use a magnifying glass to read them.

Quantity

Description

Marking

Refdes

2

0.01 µF Ceramic Capacitor

103

C6, C7

3

0.1 µF Ceramic Capacitor

104

C3, C9, C10

1

0.68 µF Ceramic Capacitor

684

C5

2

1 µF Ceramic Capacitor

105

C4, C8

ThunderBell Module Kit Instructions Page 4 of 8

Chip Sockets (±)

There are two 8-pin sockets. Sockets are marked with a small notch on one end that must line up with the notch in

the PCB outline. Once the socket is soldered in place, the PCB outline will not be visible, so it is important that the

socket is oriented correctly in order to ensure that the chip is oriented correctly when it is inserted into the socket.

Electrolytic Capacitors (±)

Electrolytic capacitors look like little tin cans with two wires sticking out of the bottom. The value is clearly printed on

the capacitor. Both electrolytic capacitors in this kit are the same value (10 µF).

Electrolytic capacitors are polarized, so it is important that the right lead goes in the right hole. The negative lead on

the capacitor is the shorter one and it is marked with a gray stripe on its body. The positive lead is longer. The

positive hole on the PCB has a square pad and is marked with a plus sign.

Voltage Regulator (±)

There is one voltage regulator chip in the kit. The voltage regulator has the same basic shape as a transistor. There

are several ways to tell them apart. First and foremost, the voltage regulator is marked with the part number 78L05.

Second, the voltage regulator is loose and the three transistors are taped together. When in doubt, read the marking

on the part.

The voltage regulator’s PCB outline is labeled REG1. The outline is similar to that of a transistor, so make sure you

put the regulator in the right place. Make sure that the flat side of the voltage regulator lines up with the flat side of the

outline on the PCB. The regulator will not sit flush against the PCB. Do not force it down any further than it will go with

a gentle pressure.

The regulator is more heat sensitive than most of the parts in this kit, so take care not to let the soldering iron linger

too long. If you are unsure, then solder one lead at a time and let the part fully cool off before soldering the next lead.

Transistors (±)

There are four 2N3904 transistors in the kit. The transistor PCB outlines are labeled Q1 through Q4. The outline is

similar to that of the voltage regulator, so make sure you put everything in the right place. Make sure that the flat side

of the transistor lines up with the flat side of the outline on the PCB. The transistors will not sit flush against the PCB.

Do not force them down any further than they will go with a gentle pressure.

Transistors are more heat sensitive than most of the parts in this kit, so take care not to let the soldering iron linger

too long. If you are unsure, then solder one lead at a time and let the part fully cool off before soldering the next lead.

ThunderBell Module Kit Instructions Page 5 of 8

Power Connector

The power connector is a black plastic block with ten pins sticking out of it. The shorter pins get inserted into the PCB

and soldered. Make sure that the plastic body of the connector is flush against the PCB. A good technique is to solder

only one pin. Then press down on the long pins while heating that first solder joint. If the connector was not seated

flush, it will click into place. Remove the soldering iron and let the joint cool for two seconds before releasing

pressure on the connector. Then, solder the remaining nine pins.

Chips (±)

There are two chips in the kit. Note the direction of the chip before inserting it. The notch on the chip must line up with

the notch on the socket. Make sure that the right chip is in the right socket. U1 is a PIC12F1822, and U2 is a TL072.

The chip pins come from the factory a little bit splayed out, not pointing straight down. You may need to bend them

inward a little before you insert them. Hold the body of the chip and rest all of the pins on one side against the table

top and gently press down just a little bit. Then do the other side. If the pins do not line up well with the socket, repeat

the straightening procedure.

Make sure not to bend any of the pins while inserting the chips. If a pin gets bent, remove the chip by inserting a

small flat head screwdriver between the chip and the socket, then slowly and gently prying the chip out. Straighten

the bent pin and reinsert.

PCB Inspection

At this stage, pause to inspect your work. Compare your PCB to the photo.

Make sure that:

All parts have been soldered in place.

Polarized parts are oriented correctly.

All of your solder joints look good.

There are no solder bridges (blobs of solder covering two leads/pins).

The leads are clipped off short –right above the solder.

This is a good point to take a break before assembling the off-board parts.

ThunderBell Module Kit Instructions Page 6 of 8

Connecting Off-Board Parts via Wires

The placement of pots, jacks, and switches in the panel or enclosure determines how and when they are connected

to the PCB as well as the length of wire needed. Cut a piece of wire to the appropriate length. Measure carefully, and

give yourself a little extra wire to work with. Strip about ¼ inch (6mm) of insulation off of each end of the wire. Twist

the exposed strands of wire together. Insert the wire into the appropriate hole on the top side of the PCB, and solder

it on the bottom, just like you did with the board-mounted parts. Wrap the other end of the wire around the appropriate

pin on the potentiometer, jack, or button, and solder it in place.

Potentiometers

The potentiometers (pots) can either be soldered directly to the PCB, or they can be connected to the PCB via wires.

You can even do a combination where one pot is board-mounted and the others are connected with wires. Board-

mounting the pots is most convenient because it means that the PCB will be supported by the pots behind the panel.

When viewed with the shaft pointing toward you, as in the picture to the right, the pot’s

value is printed at the top. The pins are, from left to right, counterclockwise (anticlockwise),

wiper, and clockwise. The holes on the PCB are labeled CW and CCW to indicate which pin

on the pot gets connected to which hole on the PCB. If you are soldering one or more pots

directly to the PCB, the shafts will point away from the PCB.

There is a tab on the pots that must be removed or it will get in the way when you try to

mount them in the enclosure or panel. Hold the pot in one hand and grab the tab with a

small pair of pliers. Rotate the pliers away from the pot, and the tab will snap right off.

The pot values are as follows:

VR1 (Pitch) 10K linear taper potentiometer

VR2 (Decay) 1M linear taper potentiometer

VR3 (Volume) 20K linear taper potentiometer

Trigger Button

Buttons are not polarized, so it does not matter which terminal on the button goes to which hole in the PCB. Make a

note of where the retaining nut is on your button. The supplied button is inserted into the panel from the back and the

nut goes on the front of the panel. So, you can solder the button via wires to the PCB before inserting it into the

panel.

If you are using a different button with the nut on the inside of the panel, then the button must be inserted into the

panel before it can be connected to the PCB. It is easiest if you do it in this order: solder the button wires onto the

PCB first, then put the button through its hole in the enclosure, then tighten the button retaining nut, then solder the

wires to the button.

ThunderBell Module Kit Instructions Page 7 of 8

Jacks

The jacks are connected to the PCB via wires. All of the jacks have one ground pin and

one signal pin, which is pretty normal for module jacks. The signal holes are all square.

In the picture to the right, the holes for the jack wires are shown in bold. The ground

pads are all highlighted. If you wish, you can connect the grounds from part to part and

using fewer ground wires to the PCB. If that last sentence was not entirely clear to you,

then use a separate wire from each jack pin to the appropriate hole in the PCB.

Jacks (±)

The jacks are Output, Pitch CV, Decay CV, and Trigger (or gate). They are all 3.5 mm mono jacks. Connect the tip

terminal of the jack to the square hole in the PCB, and the sleeve terminal to the round hole. If you are using ¼"

jacks, the same process applies, just make sure you correctly identify the tip and sleeve terminals on the jacks.

Panel Assembly

Insert the pots (usually mounted on the PCB) through the holes in the panel. Put the pot washers and nuts on and

hand tighten them. Then do the same with the jacks and button. When all the parts are in place, tighten the nuts.

Take care not to scratch the front of your panel.

The last thing to do is to put knobs on the pots.

Finished

Congratulations, your ThunderBell module is ready to make sweet music!

ThunderBell Module Kit Instructions Page 8 of 8

Bill of Materials

Board-mounted Parts:

Quantity

Description

Marking on part

Refdes

3

BAT85 Schottky Diode

BAT85

D1, D3, D4

1

1N4148 Diode

1N4148

D2

5

1K Resistor

brown

black

black

brown

R10, R11, R14, R15, R16

1

4.7K Resistor

yellow

violet

black

brown

R20

2

10K Resistor

brown

black

black

red

R9, R17

1

22K Resistor

red

red

black

red

R13

3

47K Resistor

yellow

violet

black

red

R4, R12, R22

1

68K Resistor

blue

gray

black

red

R18

2

100K Resistor

brown

black

black

orange

R1, R21

1

220K Resistor

red

red

black

orange

R2

3

470K Resistor

yellow

violet

black

orange

R3, R5, R19

1

1M Resistor

brown

black

black

yellow

R6

2

2.2M Resistor

red

red

black

yellow

R7, R8

2

0.01 µF Ceramic Capacitor

103

C6, C7

3

0.1 µF Ceramic Capacitor

104

C3, C9, C10

1

0.68 µF Ceramic Capacitor

684

C5

2

1 µF Ceramic Capacitor

105

C4, C8

2

10 µF Electrolytic Capacitor

10 µF

C1, C2

4

2N3904Transistor

2N3904

Q1, Q2, Q3, Q4

1

5V Voltage Regulator

78L05

REG1

1

PIC12F1822 MCU Chip

PIC12F1822

U1

1

TL072 Op Amp Chip

TL072

U2

2

8 Pin DIP Socket

U1, U2

1

10 Pin Power Connector

Off-board Parts:

Quantity

Description

Marking on part

Marking on PCB

1

10K Linear Taper Potentiometer

B10K

VR1 PCH

1

20K Linear Taper Potentiometer

B20K

VR3 VOL

1

1M Linear Taper Potentiometer

B1M

VR2 DCY

3

Knobs

4

3.5mm (1/8") Jacks

1

Pushbutton

1'

Hookup Wire

Table of contents

Other Delptronics Control Unit manuals