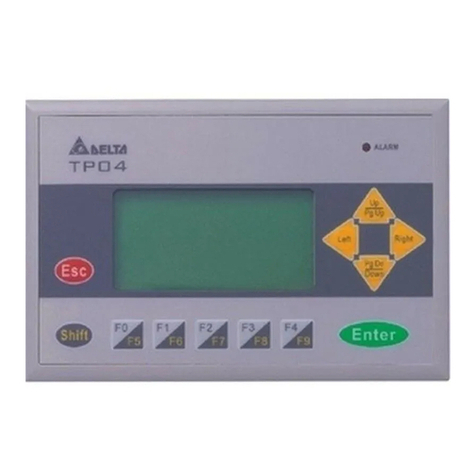

3.2 Function Specification

ITEM TP04G-AS2

Screen STN-LCD

Color Monochromatic

Backlight

The back-light automatic turn off time is 1~99 minutes

(0 = do not turn off)

(back-light life is about 50 thousand hours at 25℃)

Resolution 128X64 Points

Display Range 72mm (W) X 40mm (H); 3.00” (diagonal preferred)

Contrast Adjustment 10-step contrast adjustment

Font

ASCII: characters (including European Fonts)

Taiwan: (BIG 5 code) traditional Chinese character font

China: (GB2324-80 code) simplified Chinese character font

5X 8: 25 words X 8 rows

8X8: 16 words X 8 rows

8X12: 16 words X 5 rows

Maximum words x rows, for

each font size

8X16: 16 words X 4 rows

Font Size ASCII: 5X8, 8X8, 8X12, 8X16

Alarm Indication LED (RED)

1. Power on indication (blink for three times)

2. Will blink for communication error or other alarm

3. Special Indication by user programming

RS-232 Indication LED

(Yellow)

It will blink when transmitting program and communicating by using

RS-232.

Display Screen

RS-485/RS-422 Indication

LED (green) It will blink when communicating by using RS-485/RS-422.

Program Memory 256KB flash memory

Serial Communication Port

RS-232 (COM1)

Unsynchronized transmission method: RS-232

Data length: 7 or 8 bits, Stop bits: 1or 2 bits

Parity: None/Odd/Even,

Transmission speed: 9600bps~115200bps

RS-232: 9 PIN D-SUB male

Extension Communication

Port RS-422/RS-485 (COM2)

Unsynchronized transmission method: RS-485/RS-422

Data length: 7 or 8 bits, Stop bits: 1 or 2 bits

Parity: None/Odd/Even

Transmission speed: 9600bps~115200bps

RS-422: 9 PIN D-SUB male

RS-485: 5-Pin removal terminal

Extension Slot 1. Update program version 2.The slot for program copy card

Battery Cover DC 3V battery for HMI

External Interface

5-Pin Removal Terminal There are DC 24V input and RS-485 input

4 PROGRAM COPY CARD

TP04G provides function of program copy card to copy user program, system function and passwords that is

different from the copy program. It is used to copy the whole HMI environment settings and application programs

to another HMI rapidly. It saves time and manpower. The operation is as follows.

Definition: Program Copy Card ÆPCC, TP Series ÆTP

Step TPÆPCC PCCÆTP

1 Turn the switch on the PCC to TPÆPCC Turn the switch on the PCC to PCCÆTP

2 Insert the PCC into the extension slot of TP Insert the PCC into the extension slot of TP

3 Input the power to TP Input the power to TP

4 It will display “remove PCC” on the screen and power

on again

It will display “remove PCC” on the screen and

power on again

HMI display message

Copy HMI program to PCC (TPÆPCC) Copy PCC program to HMI (PCCÆTP)

If the TP model type does not correspond with the

model type of program of PCC, TP will display “TP

series and PCC is different. Press Enter to Confirm

TP seriesÆPCC. Press Esc to Exit”.

If there is no program in PCC, TP will display “The PCC

is Empty. PCCÆTP series is illegal”.

TP will display “TP ÆPCC series Please wait!” during

transmission.

TP will display “TP ÆPCC series Please wait!” during

transmission.

TP will display “Please Remove the PCC and Reboot”

when transmit complete.

TP will display “Please Remove the PCC and Reboot”

when transmit complete.

5 PASSWORD FUNCTION

1. If you forgot the password, it can be cleared by using the following code: 8888. This universal code will clear the

password and all TP04 internal programs. The TP04 will be reset to the factory settings.

2. Users may use 0~9 and A~Z as characters for the password. But it must use the function keys F0~F4 to input the

password characters.

F0/F5: scrolls in a loop as follows 0 Æ5 ÆA ÆB ÆC ÆD ÆE ÆF Æ0

F1/F6: scrolls in a loop as follows 1 Æ6 ÆG ÆH ÆI ÆJ ÆK Æ1

F2/F7: scrolls in a loop as follows 2 Æ7 ÆL ÆM ÆN ÆO ÆP Æ2

F3/F8: scrolls in a loop as follows 3 Æ8 ÆQ ÆR ÆS ÆT ÆU ÆV Æ3

F4/F9: scrolls in a loop as follows 4 Æ9 ÆW ÆX ÆY ÆZ Æ4

6 HARDWARE OPERATION

After power supplies to TP04G, the alarm indication LED will blink for three times and startup display, on the LCM

display area will show “No User Data in Memory, Press ESC 5 seconds, Return to System”.

The steps to Startup the TP04G:

1. Connect power line,

2. Apply 24V DC power,

3. Enter into the startup display,

4. Enter the user-designed program,

5. Press Esc key and hold on for 5 seconds to return to system menu.

There are five selections in the system menu and are described below.

SELECTIONS EXPLANATION

Download

Program

Use the connection cable (DVPACAB530) to connect the TP04 serial communication port

RS-232 to a PC. Then use the TPEdit software to download an application program to

TP04.

Upload Program

Use the connection cable (DVPACAB530) to connect the TP04 serial communication port

RS-232 to a PC. Then use the TPEdit software to upload an application program from

TP04.

Copy Program

Transfer a program between two TP04 units.

1: transmit programs

2: receive programs

When transmit programs and data between two TP04 units. Set one TP04 to “Receive

Program” mode and the other TP04 to “Transmit Program” mode. Please use twisted pair

wires to connect the two units via the RS-485 ports.

TP04 Settings

There are 9 items that used to modify TP04 system settings:

1. Communication protocol: Setting the address of TP04, the control port of PLC, and the

communication string for either RS-232 or RS-485.

2. Contrast: Adjust the contrast of LCM display screen.

3. Back-light: adjust the automatic turn off time of LCM. Setting range is 00~99 seconds. If

set to 00, the LCM Back-light will not turn off.

4. Date and Time: It is used to set the TP04 built-in RTC including year, month, day, hour,

minute, second and week. Also the internal battery capacity display is shown here.

5. Buzzer: Used to set the buzzer sound, normal mode or quiet mode.

6. Language Setting: Used to set the displayed language. English, Traditional Chinese,

simplified Chinese or user defined language.

7. Password setting: Used to set, enable, and disable the password function. If the

password function is enabled, it will require the user to input a password before entering

any system menu. The factory password is 1234.

8. Startup display: Used to select the TP04 startup display. User can select “user defined”

to use the file that designed by TPEdit and download to TP04.

9. Comm. indicator: The user can determine if the RS-232 and RS-485 LEDs will blink or

not during communication.

PLC Connection

There are three methods to connect to PLC:

1. Using TP04 serial communication port (COM1) RS-232: set 8-pin DIP switch to RS-485

mode and connect the cable (DVPACAB215 or DVPACAB230) to program

communication I/O RS-232C of PLC.

2. Using extension communication port (COM2): set 8-pin DIP switch to RS-485 mode

and connect 5-pin removal terminal of extension communication port to RS-485 of PLC

with twisted pair.

3. Using extension communication port (COM2): set 8-pin DIP switch to RS-422 mode

and connect four pins (6, 7, 8, 9) of 9 PIN D-SUB male to RS-422 of PLC with 4-wire

cable.

Execution

Execute the internal program that download from TPEdit or transmitted from other TP04

units. When program is in execution, you can return to system menu by pressing

Escape/Exit (Esc) key for 5 seconds.

7 COMMUNICATION CONNECTION

TP04G may connect to a PC by using connection cable DVPACAB530

1

5

6

9

9 PIN D-SUB

ON PC (RS-232) ON TP02/04G

5

1

9

6

9 PIN D-SUB

9 PIN D-SUB female

Rx 2

GND 5 5 GND

PC COM Port

9 PIN D-SUB female

3 Tx

2 Rx

TP02/04G COM Port

Tx 3

TP04G may connect to a DVP-PLC by using connection cable DVPACAB215/ DVPACAB230 /

DVPACAB2A30

DVPACAB215/ DVPACAB230

PC or TP02/04G

1

13

14

1

5

6

9

25 PIN D-SUB

9 PIN D-SUB

8 PIN MINI DIN

ON PLC

DVPACAB2A30

8 PIN MINI DIN25 PIN D-SUB female

PC/HMI COM Port PLC COM1 Port

Tx 2

GND 7

8 PIN MINI DIN9 PIN D-SUB female

PC/HMI COM Port PLC COM1 Port

4 Rx

8 GND

Rx 2

GND 5

1,2 5V

1

2

3

4

5

6

7

8

12

3

4

5

6

7

8

4 Rx

8 GND

1,2 5V

6

8

20

4

5

1

4

6

7

8

5 TxRx 3

Tx 3

5 Tx

The Pin definition of 9 PIN D-SUB

1. RS-232 2. RS-422

3 Tx

5 GND

RS-232 9 PIN D-SUB male

TP04G-AS2 COM Port

2 Rx

8 Tx +

RS-422 9 PIN D-SUB male

9 Tx -

TP04G-AS2 COM Port

7 Rx -

6 Rx +

DVPACAB630 (RS-422)

8 PIN MINI DIN

9 PIN D-SUB female

HMI COM Port MITSUBISHI FX-PLC

Rx - 7

Tx+ 8

1

2

3

4

5

6

7

8

7 Tx+

2 Rx+

Tx - 9 3 SG

GND 5

Rx+

COM1 Port RS-422

6

4 Tx -

1 Rx -

Switch between RS-422 / RS-485 (by using 8-PIN DIP switch)

8-PIN DIP switch RS-485 RS-422

SW1~SW4 On Off

SW5~SW8 Off On

8 BATTERY LIFE AND PRECISION OF CALENDAR TIMER

Battery life

Temperature (°C) -20 0 20 60

Life (year) 1.972 2.466 2.712 2.835

Precision of calendar timer

At 0°C/32°F, less than –117 seconds error per month.

At 25°C/77°F, less than 52 seconds error per month.

At 55°C/131°F, less than –132 seconds error per month.