http://www.delta.com.tw/products/plc.asp

DVP-EH DVP04DA-H

Analog Input Module

Instruction Sheet

1 WARNING

Please carefully read this instruction thoroughly prior to use the DVP04DA-H.

The DC input power must be OFF before any maintenance.

This is an OPEN-TYPE built-in DVP04DA-H, and the DVP04DA-H is certified to meet the safety

requirements of IEC 61131-2 (UL 508) when installed in the enclosure to prevent high

temperature, high humidity, exceessive vibration, corrosive gases, liquids, airbome dust or

metallic particles. Also, it is equipped with protective methods such as some special tool or key to

open the enclosure, in order to prevent the hazard to users and damage DVP04DA-H.

Do not connect the AC power to any of the input/output terminals, or it may damage to the

DVP04DA-H. Make sure that all the wiring is well conducted prior to power on.

Do not touch the internal circuit for at least 1 minute after the power supply is OFF.

Make sure that the DVP04DA-H is properly grounded , to prevent any electromagnetic noise.

2 INTRODUCTION

2.1 Model Explanation and Peripherals

Thank you for choosing DELTA’s PLC DVP Series. The analog output module of DVP04DA-H

series can read/write the data of analog output module by using instructions FROM / TO via

DVP-PLC EH Series MPU program. The analog output module receives 12-bit digital data of 4

groups from PLC MPU and converts it into 4 points analog output signal either in voltage or in

current.

Software version of DVP04DA-H analog output module can be updated via RS-485.

Users can select output from voltage or current via wiring. Voltage output range is 0V ~ +10V DC

(resolution is 2.5 mV). Current output range is 0mA ~ 20mA (resolution is 5 µA).

Nameplate Explanation

20.4VDC ~ 28.8VDC

VX.XX 04DA-H0T4130001

0 ~ +10V or -0 ~+20mA

2.5mV or 5 A

Model Name

Input power supply spec.

Analog input/output module spec.

Barcode

Model Explanation

Serial Number

Model

Product Series

Input+Output point

Model type

AD: Analog input module

DA: Analog output module

PT: Platinum temperature sensors(PT-100)

TC: Thermocouple sensors(Type J/K)

S: for SS series MPU

P: for EP series MPU

H: for EH series MPU

Production week

Production place (Taoyuan)

Production year (2004)

Production Model

XA: A/D , D/A Functions

RT: Resistor Thermocouple

HC: High speed count input module

PU: single axis positioning unit

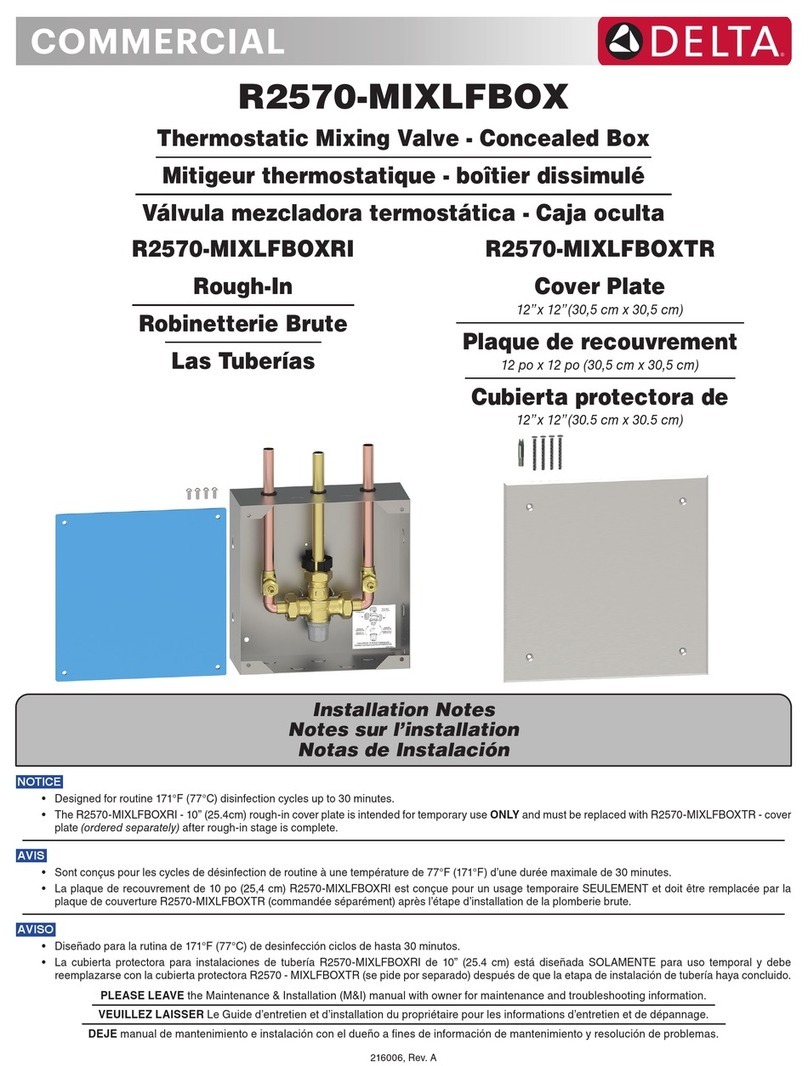

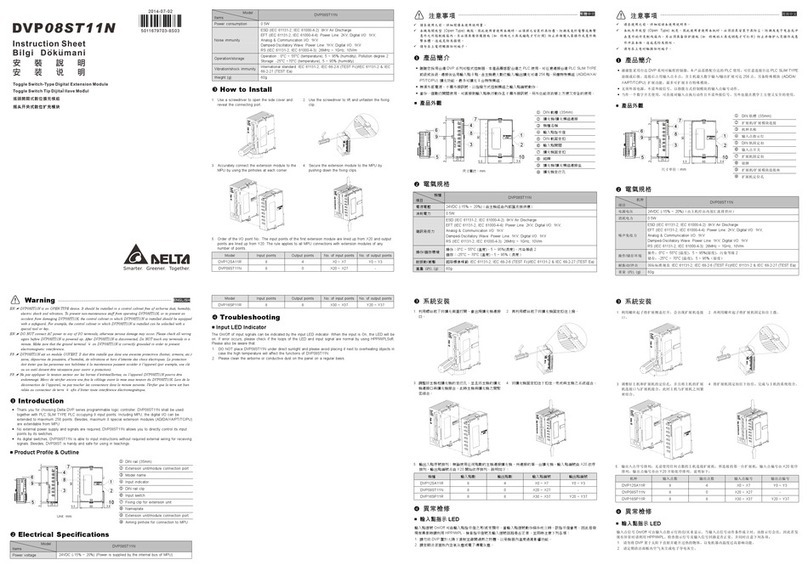

2.2 Product Profile and Outline

Unit:mm

1. DIN rail track (35mm) 6. Terminals

2. Mounting hole for wire to connect extension

unit/extension module 7. Mounting hole

3. Model name 8. Terminal layout

4. Indicator for power, error and run status 9. Mounting port to connect extension

unit/extension module

5. DIN rail clip

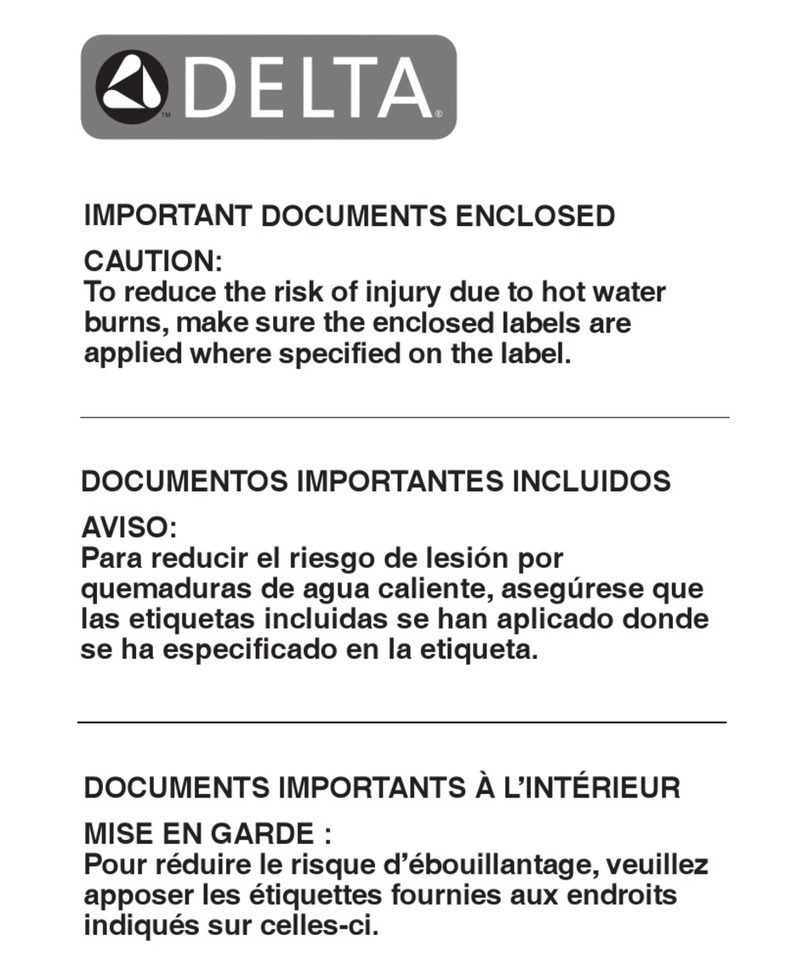

2.3 External wiring

V+

I+

COM

V+

I+

COM

24+

24-

DC/DC +15V

-15V

AG

FG

FG

CH1

CH1

0V~+10V

*2

*3 DC24V

CH2 CH2

AC drive, recorder,

scale valve...

AC drive, recorder,

scale valve...

voltage output

shielding cable *1

shielding cable *1

current output

converter

terminal of

power module

system grounding

class 3 grounding

(100 or less)

Note 1: Please isolate analog output and other

power wiring.

Note 2: If the noise interference from loaded wiring

input terminal of is significant, please

connect a capacitor with 0.1~0.47µF 25V

for noise filtering.

Note 3: Please connect terminal of power

module and terminal of analog output

module to system earth point and make

system earth point be grounding or

connects to machine cover.

Warning: DO NOT wire to the No function terminal

●.

3 STANDARD SPECIFICATIONS

3.1 Specifications

Digital/Analog (4D/A) Module Voltage Output Current Output

Power Supply Voltage 24 VDC(20.4VDC~28.8VDC) ( –15%~+20%)

Analog Output Channel 4 channels / each module

Analog Output Range 0~10V 0~20 mA

Digital Data Range 0~4000 0~4000

Resolution 12 bits (1LSB=2.5 mV) 12 bits (1LSB=5 µA)

Output Impedance 0.5Ωor lower

Overall Accuracy ±0.5% of full scale of 25℃(77℉)

±1% of full scale during 0~55℃(32~131℉)

Response Time 3 ms ×channels

Max. Output Current 20 mA(1KΩ~2MΩ) -

Tolerance Carried Impedance -0〜500Ω

Digital Data Format 2’s complementary of 16-bit, 13 Significant Bits

Isolation Method It has isolation between digital area and analog area. There is no

isolation among channels.

Protection

Voltage output has short circuit protection but short circuit for a long

period short circuit may cause inner wiring damage and current

output break.

Communication mode (RS-485)

Yes, there are ASCII/RTU modes, communication rate can be 4800

/9600 /19200 /38400 /57600 /115200. Communication format of

ASCII mode is 7Bit, even bit, 1 stop bit (7 E 1). Communication

format of RTU mode is 8Bit, even bit, 1 stop bit (8 E 1). Can’t use

RS-485 if PLC MPU connection is in series.

Connect to DVP-PLC MPU in

series

If DVP04DA-H modules are connected to MPU, the modules are

numbered from 0 – 7. 0 is the closest and 7 is the furthest to the

MPU. 8 modules is the max and they do not occupy any digital I/O

points of the MPU.

3.2 Other Specification

Power Specification

Max. Rated Consuming Power 24 VDC (20.4VDC~28.8VDC) (–15%〜+20%), 2W, supply from

external power

Environment Condition

Environment Condition Follow the DVP-PLC MPU

Spec. of Prevent Static

Electricity All places between terminals and ground comply with the spec

4 CR (Control Register)

DVP04DA-H Analog Output Module Explanation

CR

No.

RS-485

Parameters

Address

Latched Register Name b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

#0 H 4032 ○R Model type System used, DVP04DA-H model code=H 0401

Reserved CH4 CH3 CH2 CH1#1 H 4033 ○R/W Output mode setting

Output mode setting: factory setting is H0000.

Mode 0: output voltage mode (0V~10V).

Mode 1: output voltage mode (2V~10V).

Mode 2: output current mode (4mA~20mA).

Mode 3: output current mode (0mA~20mA).

Mode 4: none use.

#2 ~ #5 Reserved

DVP04DA-H Analog Output Module Explanation

CR

No.

RS-485

Parameters

Address

Latched Register Name b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

#6 H 4038 ○R/W CH1 output value

#7 H 4039 ○R/W CH2 output value

#8 H 403A ○R/W CH3 output value

#9 H 403B ○R/W CH4 output value

The output setting range of channel CH1~CH4 is K0~K4000. Factory setting is K0

and unit is LSB.

#10~#17 Reserved

#18 H 4044 ○R/W To adjust OFFSET

value of CH1

#19 H 4045 ○R/W To adjust OFFSET

value of CH2

#20 H 4046 ○R/W To adjust OFFSET

value of CH3

#21 H 4047 ○R/W To adjust OFFSET

value of CH4

It is used to set the OFFSET value of CH1~CH4. The setting range is

K-2000~K2000. The factory setting is K0 and unit is LSB.

#22 ~ #23 Reserved

#24 H 404A ○R/W To adjust GAIN

value of CH1

#25 H 404B ○R/W To adjust GAIN

value of CH2

#26 H 404C ○R/W To adjust GAIN

value of CH3

#27 H 404D ○R/W To adjust GAIN

value of CH4

It is used to set the GAIN value of CH1~CH4. The setting range is K-1600~K8000.

The factory setting is K2000 and unit is LSB.

#28~#29 Reserved

#30 H 4050 ╳R Error status Data register used to save all error status. Please refer to fault code chart for details.

#31 H 4051 ○R/W Communication

address setting

It is used to set RS-485 communication address. The setting range is from 01 to 255

and the factory setting is K1.

#32 H 4052 ○R/W Communication

Baud Rate setting

It is used to set communication baud rate (4800, 9600, 19200, 38400, 57600,

115200bps). Communication format: ASCII mode is 7Bit, even bit, 1 stop bit (7 E 1).

Communication format of RTU mode is 8Bit, even bit, 1 stop bit (8 E 1).

b0: 4800 bps (bit/sec). b1: 9600 bps (bit/sec). (factory setting)

b2:19200bps(bit/sec). b3:38400bps(bit/sec).

b4: 57600 bps (bit/sec). b5: 115200 bps (bit/sec).

b6-b13:reserved.

b14: exchange low and high byte of CRC check code (only for RTU mode)

b15: ASCII / RTU mode selection

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

Reserved CH4 CH3 CH2 CH1

#33 H 4053 ○R/W Reset to factory

setting and set

characteristics

adjustable priority

Factory setting H0000.

Give CH1 setting for example:

1. When b0=0, user can set OFFSET and GAIN value of CH1 (CR#18, CR#24).

When b0=1, inhibit user to adjust OFFSET and GAIN value of CH1 (CR#18,

CR#24).

2. b1 means if characteristic register is latched. b1=0 (factory setting, latched), b1=1

(not latched).

3. When b2 is set to 1, all settings will reset to factory setting.

#34 H 4054 ○R Software version. It is hexadecimal to display software version. For example: H 010A means 1.0A.

#35~#48 System used

○means latched.

╳means not latched.

R means can read data by using FROM instruction or RS-485.

W means can write data by using TO instruction or RS-485.

LSB (Least Significant Bit): 1. Voltage output: 1LSB=10V/8000=2.5mV. 2. Current output: 1LSB=20mA/4000=5µA.

Explanation:

1. The content of CR#0 is model type, user can read the data from program to know if there is extension

module.

2. CR#1 is used to set two inner channels working mode of analog output module. Every channel has

four modes to set and can be set individually. For example: if setting CH1 to mode 2 (b2~b0=010),

CH2 to mode 1(b5~b3=001). It needs to set CR#1 to H000A. The factory setting of CR#1 is H0000.

3. CR#2 ~ CR#5, CR#10 ~ CR#17, CR#22, CR#23, CR#28, CR#29 Reserved.

4. CR #6 ~ CR#9 display CH1~CH4 output signal. The setting range is K0~K4000. Factory setting is K0

and unit is LSB.

5. CR#18 ~ CR#21 means the value of adjusting OFFSET value of CH1~CH4. The factory setting is K0

and unit is LSB. If output value equal to 0 after calculating, the adjustable range of analog output

voltage or current is -2000~+2000.

Voltage adjustable range: -5V~+5V(-2000LSB~+2000LSB).

Current adjustable range: -10mA~+10mA (-2000LSB~+2000LSB).

6. CR#24 ~ CR#27 means the value of adjust GAIN value of CH1~CH4. The factory setting is K2000 and

unit is LSB. If output value equal to 2000 after calculating, the adjustable range of analog output

voltage or current is -1600~+8000.

Voltage adjustable range: -4V~+20V(-1600LSB~+8000LSB).

Current adjustable range: -8mA ~+40mA (-1600LSB~+8000LSB).

Please be noticed that GAIN VALUE – OFFSET VALUE = +400LSB ~+6000LSB (voltage or current). If the

value difference comes up small (within range), the output signal resolution is then slim and the

variation is definitely larger. On the contrast, if the value difference exceeds the range, the output

signal resolution becomes larger and the variation is definitely smaller.

7. CR#30 is fault code. Please refer to the following chart.

Fault Description Content b15~b8 b7 b6 b5 b4 b3 b2 b1 b0

Power Source Abnormal K1(H1) 0 0 0 0 0 0 0 1

Analog Input Value Error K2(H2) 0 0 0 0 0 0 1 0

Setting Mode Error K4(H4) 0 0 0 0 0 1 0 0

Offset/Gain Error K8(H8) 0 0 0 0 1 0 0 0

Hardware Malfunction K16(H10) 0 0 0 1 0 0 0 0

Digital Range Error K32(H20) 0 0 1 0 0 0 0 0

Average Times Setting Error K64(H40) 0 1 0 0 0 0 0 0

Instruction Error K128(H80)

Reserved

1 0 0 0 0 0 0 0

Note: Each fault code will have corresponding bit (b0~b7). Two or more faults may happen at the same time. 0

means normal and 1 means having fault.

8. CR#31 is used to set RS-485 communication address. The setting range is from 01 to 255. The factory

setting is K1.

9. CR#32 is used to set RS-485 communication baud rate: 4800, 9600, 19200, 38400, 57600, 115200