1Introduction .......................................................................................................................4

1.1 Introduction to PROFINET IO Communication.....................................................................4

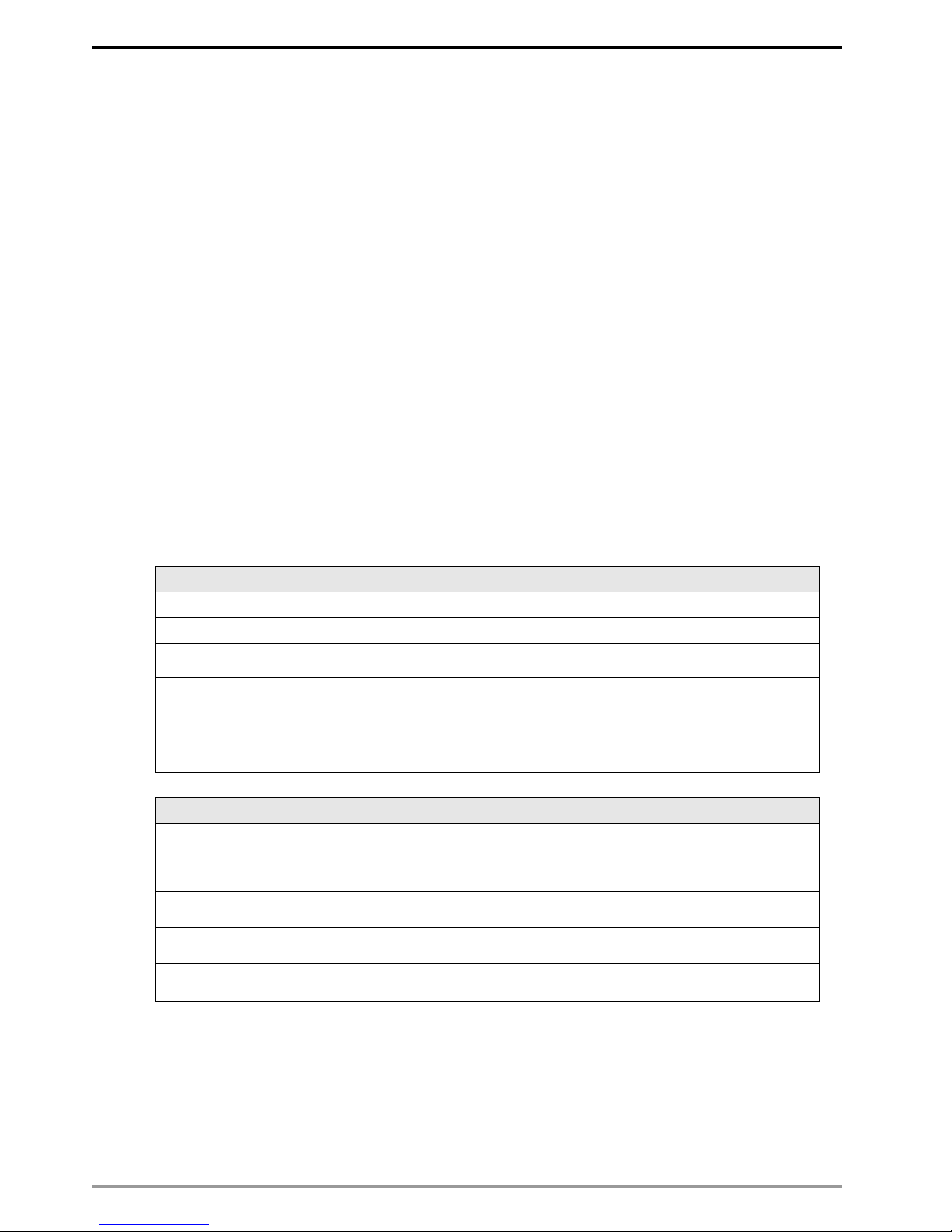

1.2 Features ...............................................................................................................................4

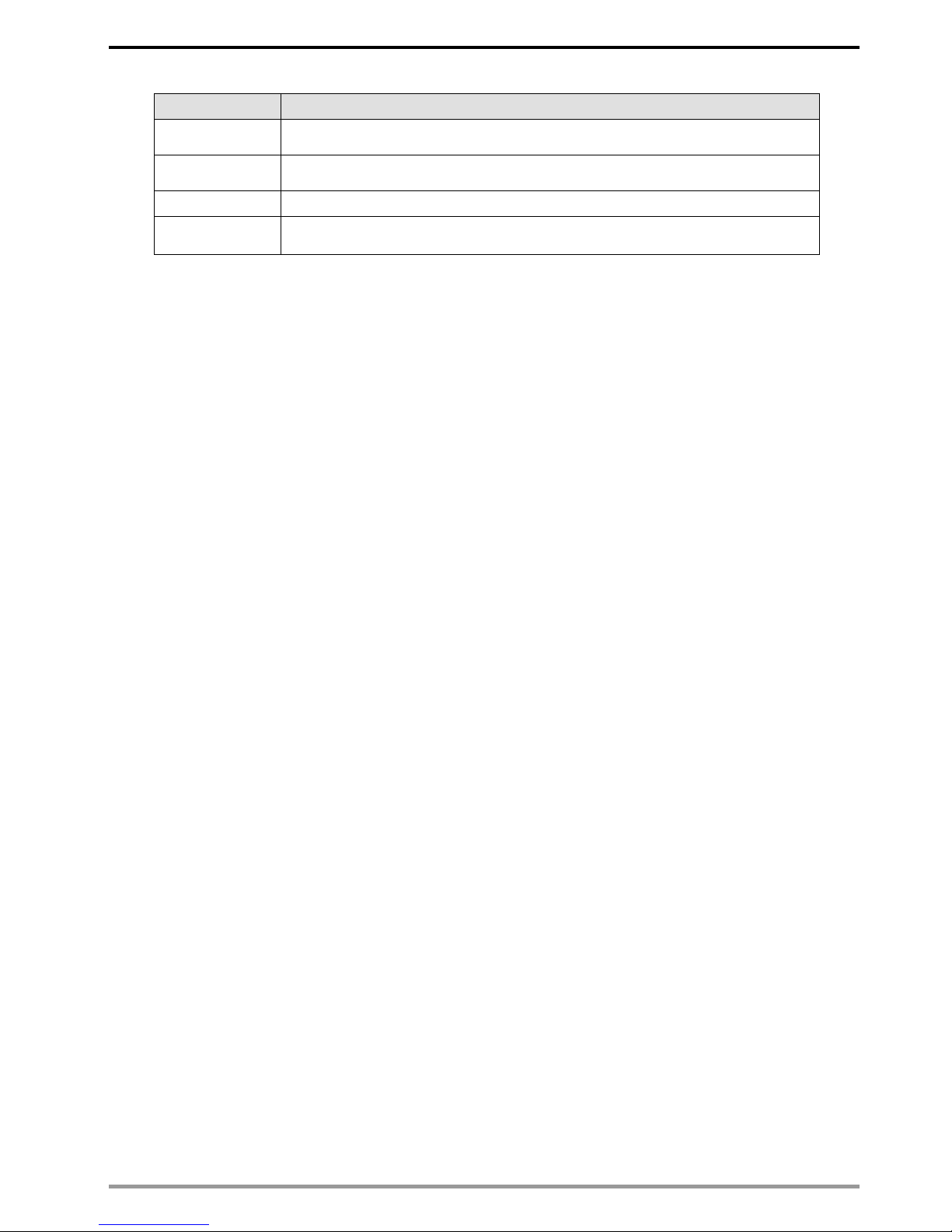

1.3 Network Functions and Specifications..................................................................................4

2Product Appearance and Components...........................................................................6

2.1 Exterior Dimensions .............................................................................................................6

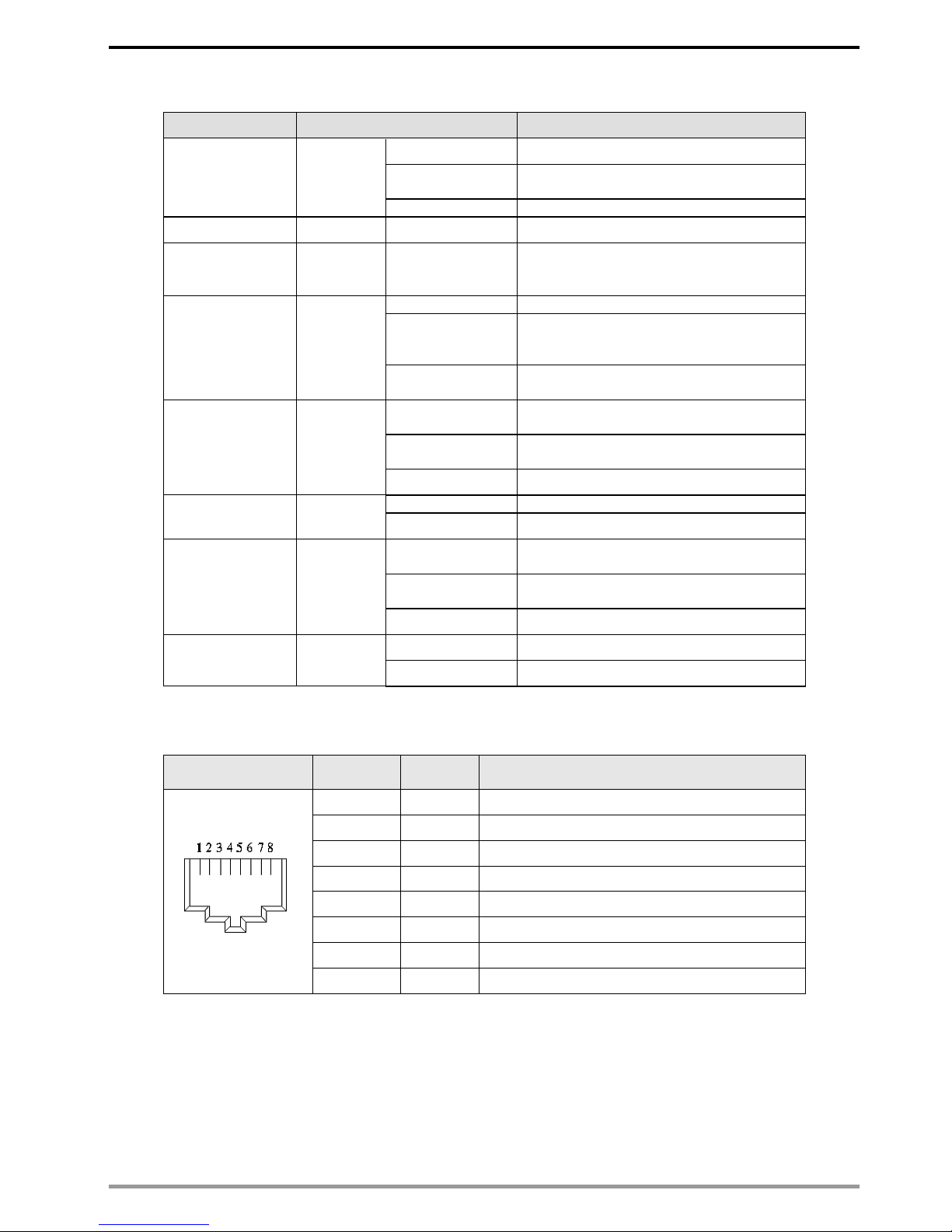

2.2 Introduction to Each Component..........................................................................................6

2.3 LED Indicators......................................................................................................................7

2.4 Definition of RJ45 Pin...........................................................................................................7

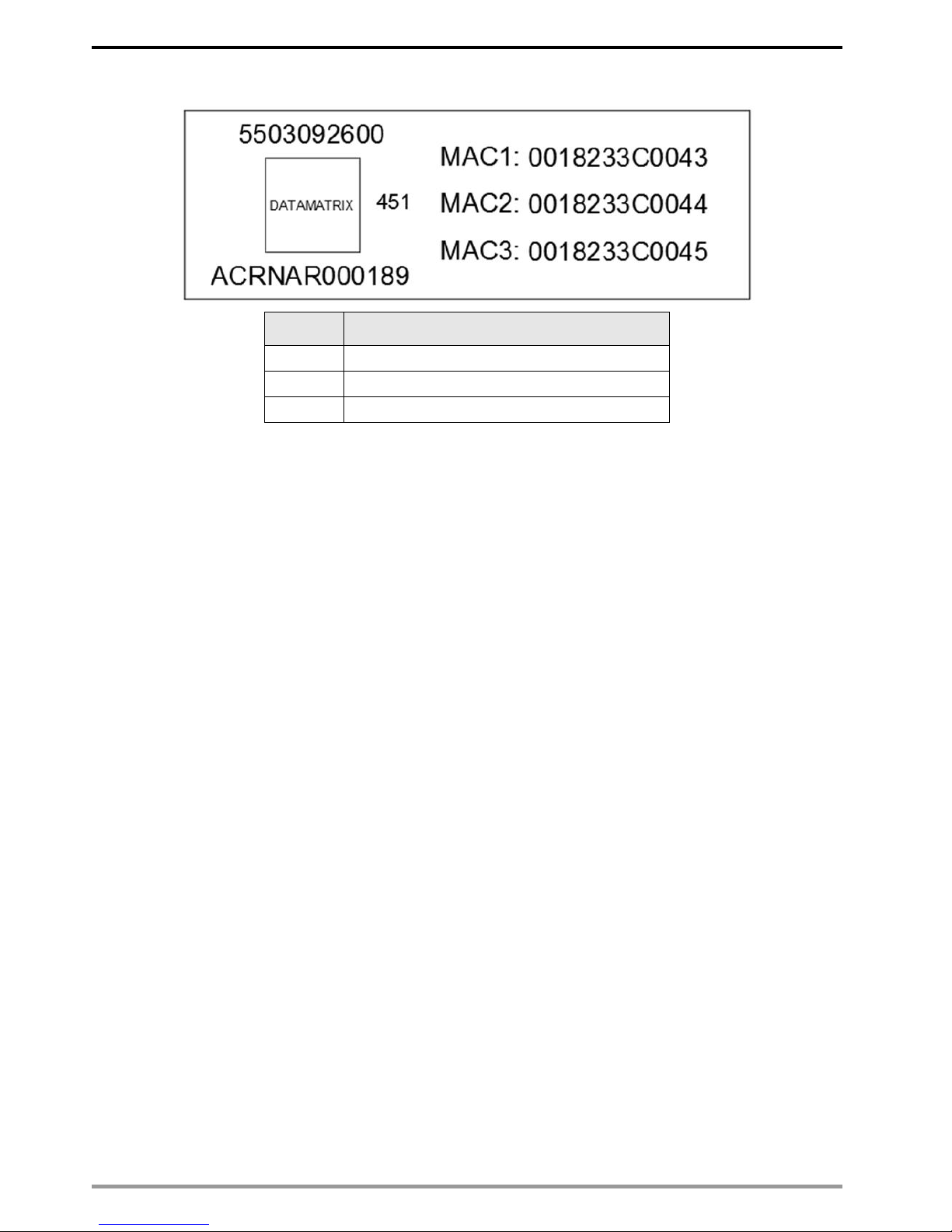

2.5 MAC Address Label..............................................................................................................8

3Installation and Wiring......................................................................................................9

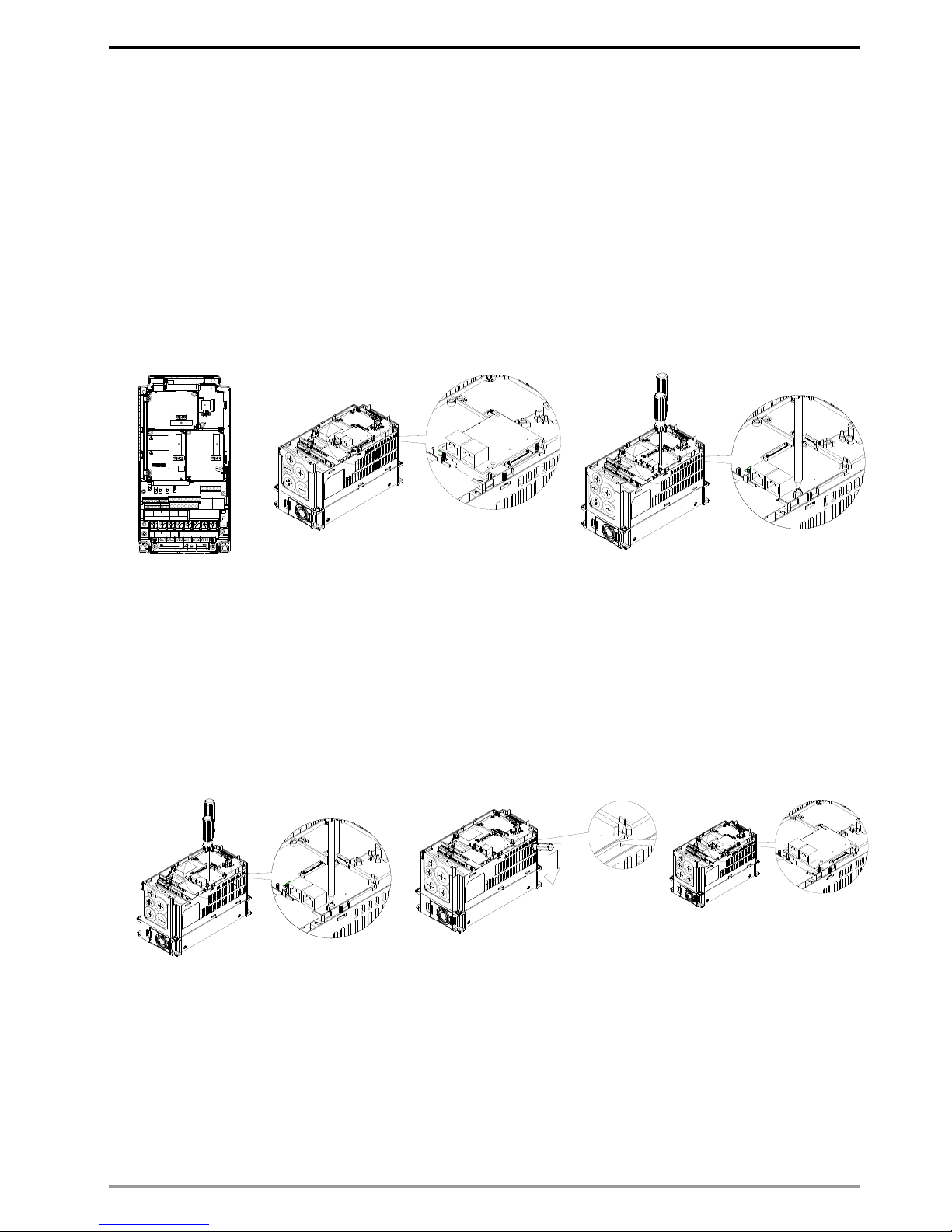

3.1 Installation ............................................................................................................................9

3.2 Unloading .............................................................................................................................9

3.3 Connecting to the Network .................................................................................................10

4VFD-C2000 Drive Settings ..............................................................................................11

5PROFINET Communication Profile................................................................................12

5.1 Synchronous Parameter Access in Delta-specific Mode (Tables for Control Word and Status

Word)..................................................................................................................................12

5.2 Asynchronous Parameter Access.......................................................................................16

5.3 Identification and Maintenance Functions (I&M) ................................................................17

5.4 Disconnection Treatment....................................................................................................17

6Connection Configuration to Host Controller...............................................................18

6.1 Basic Configuration ............................................................................................................18

6.2 Speed Mode DEMO (S7-300 + STEP 7)............................................................................23

6.3 Speed Mode DEMO (S7-1500 + TIAPORTAL)..................................................................33

6.4 Demonstration of Reading/Wrting Synchronous and Asynchronous Parameters (S7-300 +

TIA PORTAL)......................................................................................................................42