SAFETY

is not qualied to operate the machine. An untrained

operator exposes himself and bystanders to possible

serious injury or death.

• Never exceed limits of a piece of machinery. If its

ability to do a job or to do so safely is in question, DON’T

TRY IT.

• Do not use unit until you are sure that area is clear,

especially around children and animals.

PREPARATION

• Always wear relatively tight and belted clothing to

avoid getting caught in moving parts. Wear sturdy,

rough-soled work shoes and protective equipment for

eyes, hair, hands, hearing, and head; and respirator or

lter mask where appropriate.

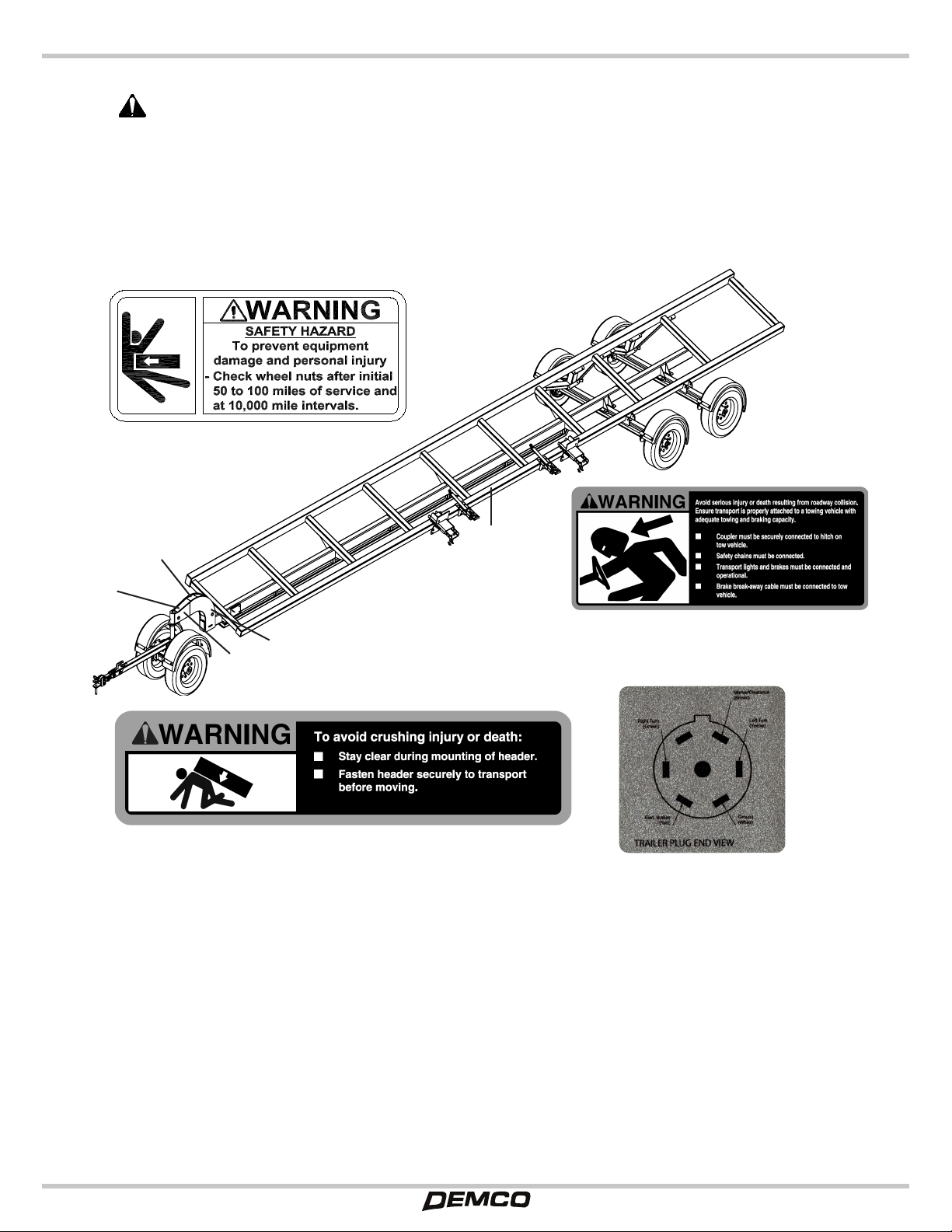

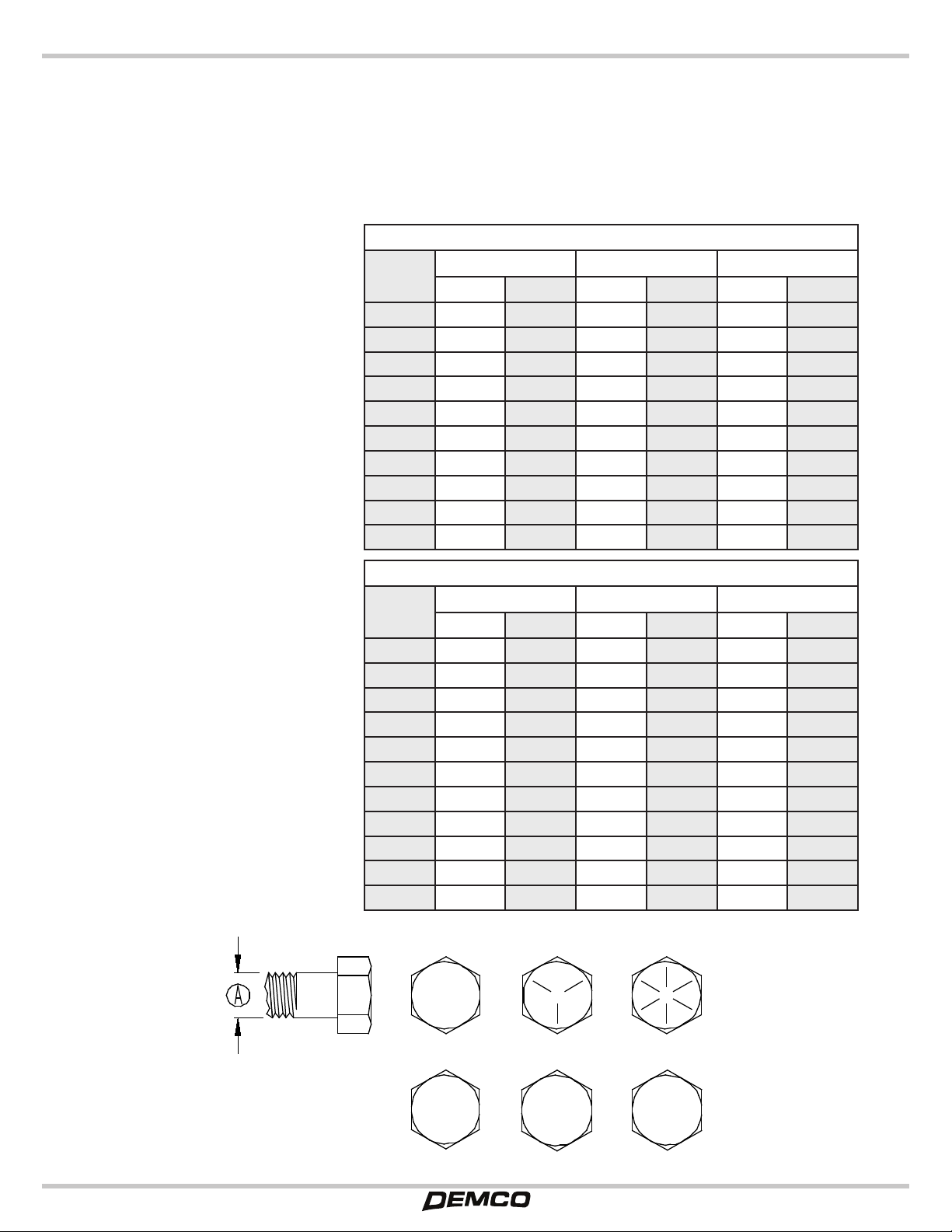

• Keep wheel and lug nuts tightened to specied torque.

Assure that tires are inated evenly.

• Give unit a visual inspection for any loose bolts, worn

parts, or cracked welds, and make necessary repairs.

Follow maintenance safety instructions in this manual.

• Make sure there are not tools lying on or in equipment.

• Make sure that brakes are evenly adjusted (if equipped

with brakes).

• Do not allow anyone to stand between tongue or hitch

and towing vehicle when backing up to equipment.

TRANSPORTATION

• Always comply with all state and local laws governing

highway safety and movement of farm machinery on

public roads. Local laws should also be checked for all

highway lighting and marking requirements.

• If equipment is going to be transported on a public

highway, always follow state and local regulations

regarding safety chains. Be sure to check with local

law enforcement agencies for your own particular

regulations. If required safety chains should be obtained

and installed, only safety chains (not elastic or nylon/

plastic tow straps) should be used to retain connection

between towing and towed machines in event of

separation of primary attaching system. Use a high

strength, appropriate size hitch pin with a mechanical

retainer and attach safety chains. Crisscross chains

under tongue and secure to draw bar cage, mounting

loops, or bumper frame.

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our eorts

to provide safe equipment can be wiped out by an

operator’s single careless act.

Every year many accidents occur which could have been

avoided by a few seconds of thought and a more careful

approach to handling equipment. You, the operator,

can avoid many accidents by observing the following

precautions in this section. To avoid personal injury,

study the following precautions and insist those working

with you, and you yourself, follow them.

In addition to the design and conguration of equipment,

hazard control and accident prevention are dependent

upon the awareness, concern, judgment, and proper

training of personnel involved in the operation, transport,

maintenance and storage of equipment.

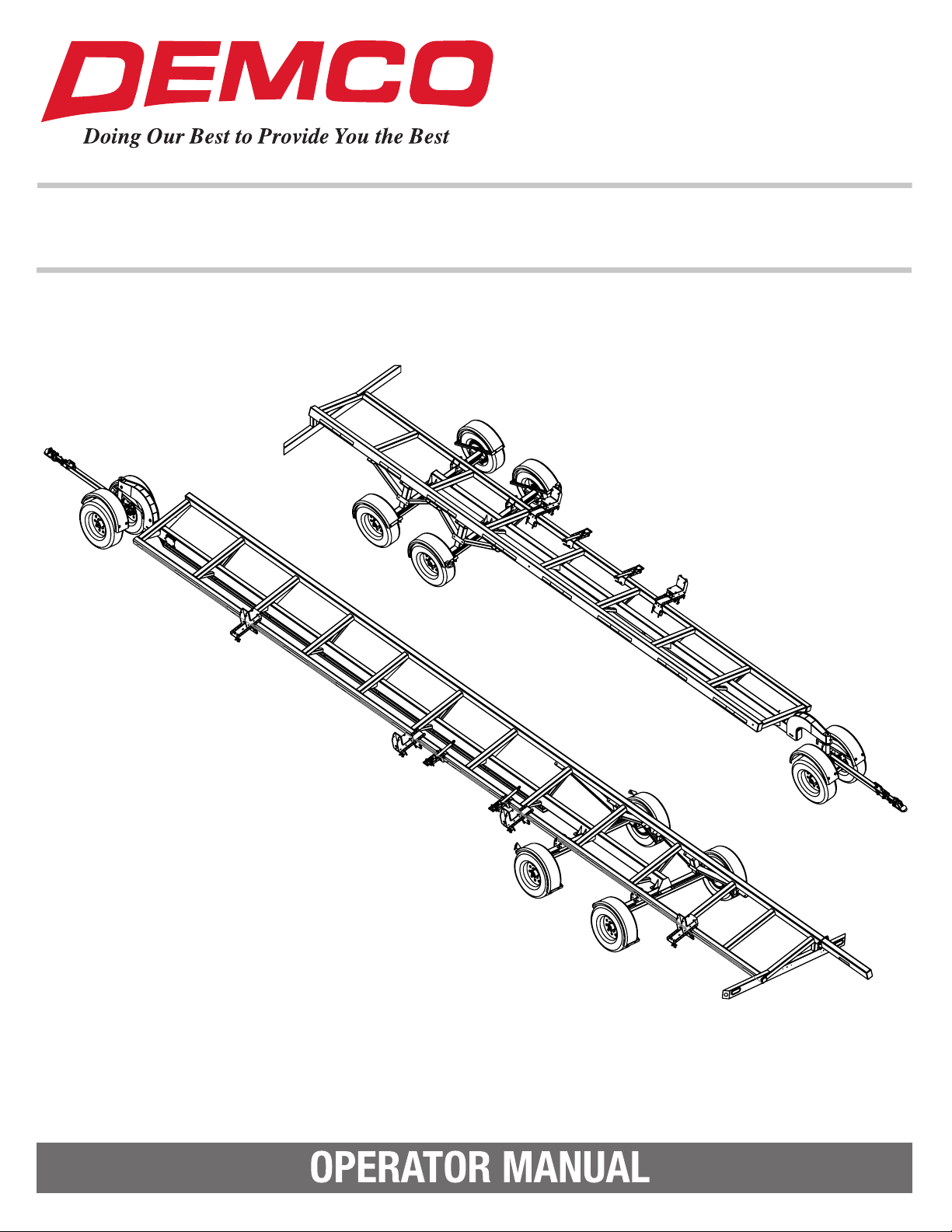

In order to provide a better view, certain illustrations

in this manual may show an assembly with a safety

shield removed. However, equipment should never be

operated in this condition. Keep all shields in place. If

shield removal becomes necessary for repairs, replace

shield prior to use.

It has been said “The best safety device is an informed,

careful operator.” We ask you to be that kind of operator.

TRAINING

• Safety instructions are important! Read all attachment

manuals; follow all safety rules and safety decal

information. Failure to follow instructions or safety rules

can result in serious injury or death

• Don’t hurry the learning process or take unit for granted

in becoming familiar with your new equipment.

• If you do not understand any part of this manual

and need assistance, see your dealer. (Replacement

manuals are available from selling dealer.)

• Operators must be instructed in and be capable of the

safe operation of the equipment, its attachments, and all

controls. Do not allow anyone to operate this equipment

without proper instructions.

• Never allow children or untrained persons to operate

equipment.

• Train all new personnel and review instructions

frequently with existing workers. A person who has not

read and understood all operating and safety instructions

SAFETY...YOU CAN LIVE WITH

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Page 4 8H000019