AG20003 Page 7

• Whenhaltingoperation,evenperiodically,settractorortowingvehiclesbrakes,disengagePTO,shutoff

engine, and remove ignition key.

• Beespeciallyobservantofoperatingareaandterrain.Watchforholes,rocks,orotherhiddenhazards.Always

inspect area prior to operation.

- DO NOT operate near edge of drop-off or banks.

- DO NOT operate on steep slopes as overturn may result.

- Operate up and down (not across) intermediate slopes. Avoid sudden starts and stops.

• Pickthemostlevelpossibleroutewhentransportingacrosselds.Avoidedgesofditches,gullies,andsteep

hillsides.

• Beextracarefulwhenworkingoninclines.

• Maneuvertractorortowingvehicleatsafespeeds.

• Avoidoverheadwiresorotherobstacles.Contactwithoverheadlinescouldcauseseriousinjuryordeath.

• Avoidloosegravel,rocks,andholes;theycanbedangerousforequipmentoperationormovement.

• Allowforunitlengthwhenmakingturns.

• Donotwalkorworkunderraisedcomponentsorattachmentsunlesssecurelypositionedandblocked.

• Keepallbystanders,pets,andlivestockclearofworkarea.

• Operatetowingvehiclefromoperatorsseatonly.

• Neverstandalongsideofunitwithenginerunningorattempttostartengineand/oroperatemachinewhile

standing alongside of unit.

• Neverleaverunningequipmentunattended.

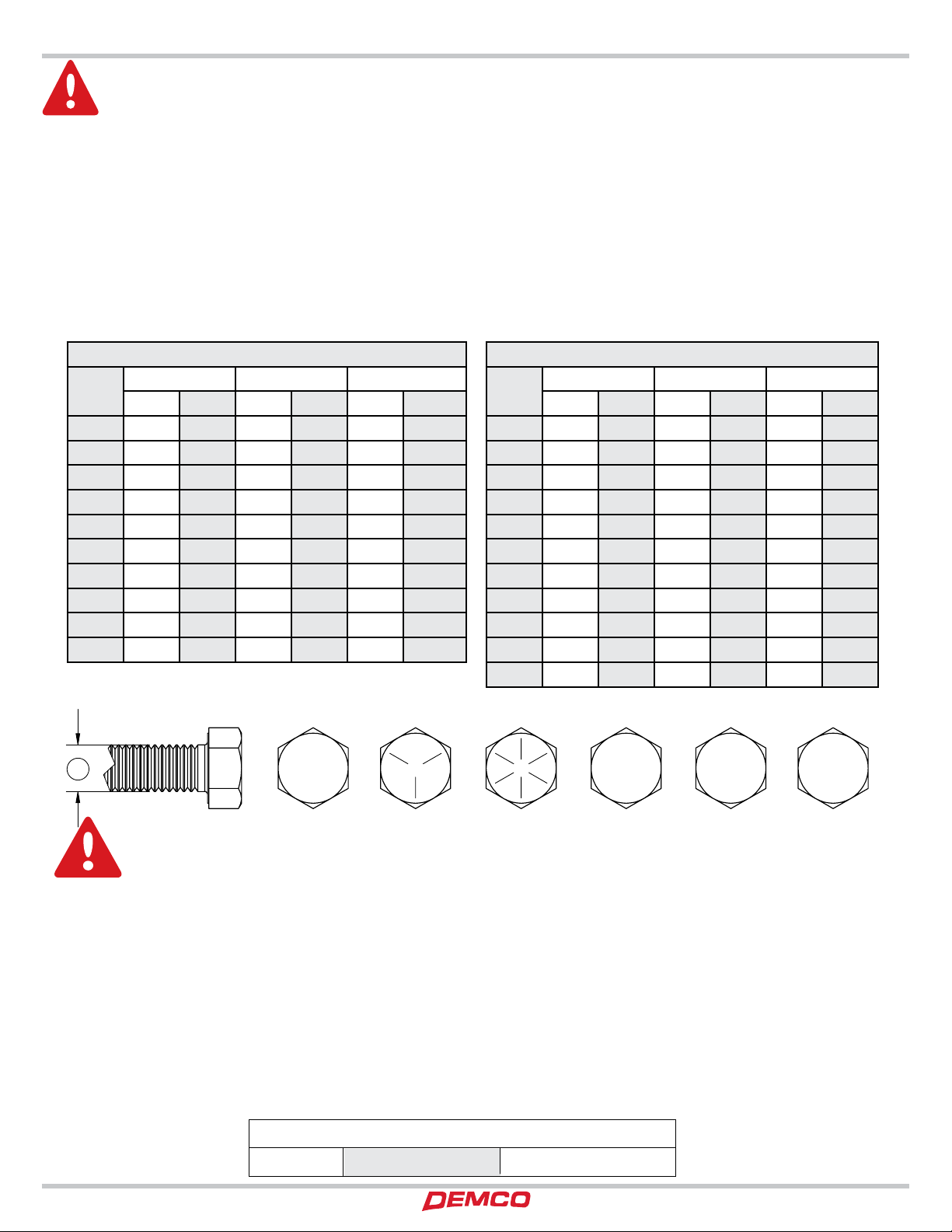

• Asaprecaution,alwaysrecheckhardwareonequipmentfollowingevery100hoursofoperation.Correctall

problems. Follow maintenance safety procedures.

FOLLOWING OPERATION

• Followingoperation,orwhenunhitching,stoptractorortowingvehicle,setbrakes,shutoffengineandremove

ignition key.

• Storeunitinanareaawayfromhumanactivity.

• Donotparkequipmentwhereitwillbeexposedtolivestockforlongperiodsoftime.Damageandlivestock

injury could result.

• Donotpermitchildrentoplayonoraroundstoredunit.

• Makesureallparkedmachinesareonahard,levelsurfaceandengageallsafetydevices.

• Wheelchocksmaybeneededtopreventunitfromrolling.

HIGHWAY AND TRANSPORT OPERATIONS

•SAFETY CHAINS: If equipment is going to be transported on a public highway, always follow state and local

regulations regarding safety chains and auxiliary lighting. Be sure to check with local law enforcement agen-

cies for your own particular regulations. Only safety chains (not elastic or nylon/plastic tow straps) should be

used to retain connection between towing and towed machines in event of separation of primary attaching

system. Use a high strength, appropriately sized hitch pin with a mechanical retainer and attach safety chains.

Criss cross chains under tongue and secure to draw bar cage, mounting loops, or bumper frame.

• Adoptsafedrivingpractices:

- Keep brake pedals latched together at all times. NEVER USE INDEPENDENT BRAKING WITH

MACHINE IN TOW, LOSS OF CONTROL AND/OR UPSET OF UNIT CAN RESULT.

- Always drive at a safe speed relative to local conditions, ensure that your speed is low enough for an

emergency stop. Keep speed to a minimum.

SAFETY