Denios PolySafe-Depot PSR 8.8 User manual

BA_Batterie-Ladeschrank_002 May 2012

Batterie-Ladeschrank

Original

Operating instruction

BA_Batterie-Ladeschrank_002 page 2 May 2012

Table of contents

1General Instructions ........................................................................................................................................3

1.1 Legend, Explanation of symbols.................................................................................................................3

2Safety instructions...........................................................................................................................................4

3Correct use in accordance to the instructions..............................................................................................4

4Product description .........................................................................................................................................5

4.1 Technical Data............................................................................................................................................5

5Assembly...........................................................................................................................................................6

6Commissioning ................................................................................................................................................6

6.1 Connecting the fan and the external chargers ...........................................................................................7

7Operation...........................................................................................................................................................7

8Fault...................................................................................................................................................................8

9Maintenance and repair...................................................................................................................................8

10 Disposal.............................................................................................................................................................8

11 Attachments/Installed components .............................................................................................................10

11.1 Circuit diagram of battery charging cabinet..............................................................................................10

11.2 Declaration of conformity for radial ventilator...........................................................................................11

11.3 Manufacturer's test certificate of differential pressure sensor..................................................................12

BA_Batterie-Ladeschrank_002 page 3 May 2012

1 General Instructions

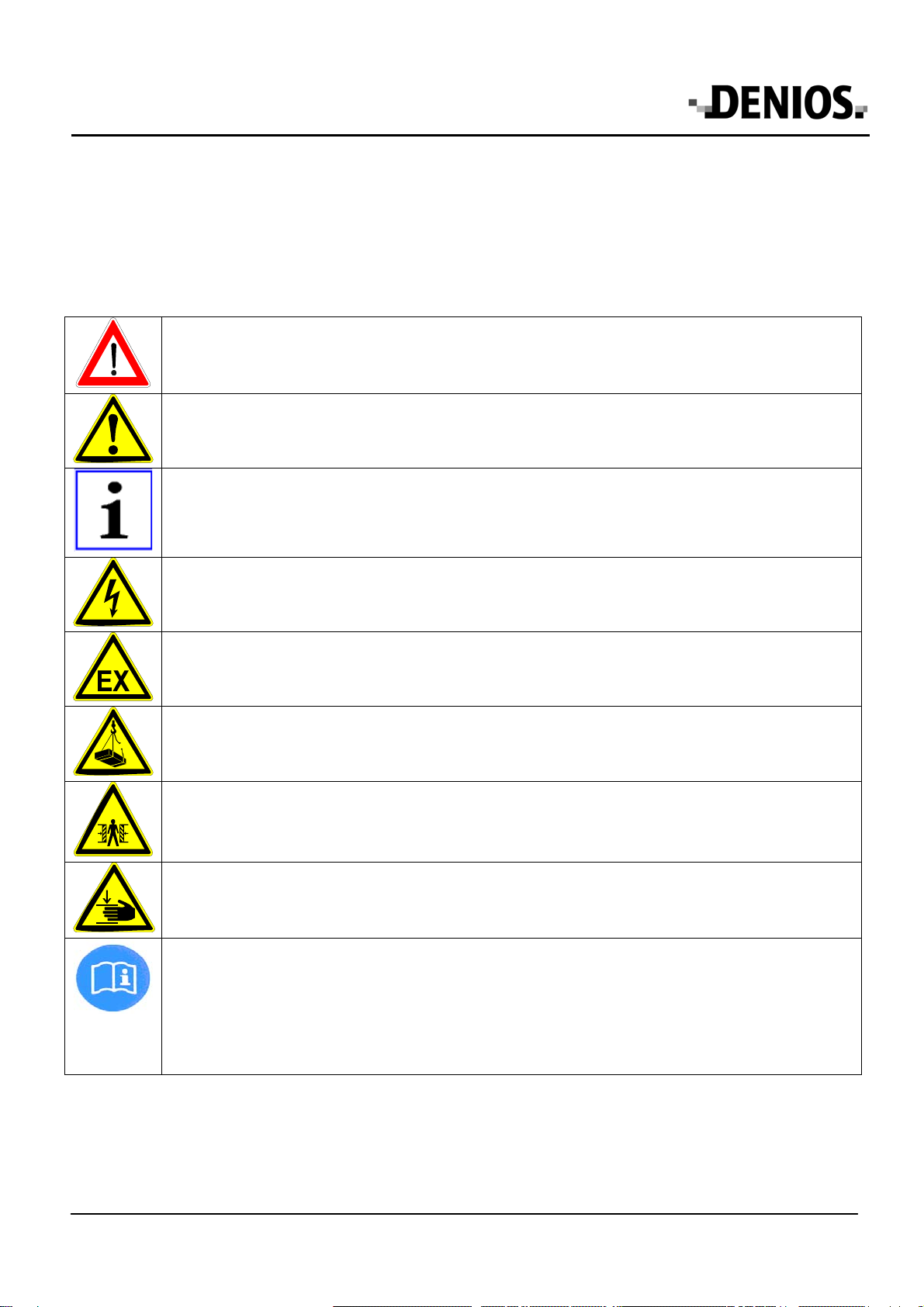

1.1 Legend, Explanation of symbols

The following safety symbols are used in these operating instructions. Above all, these symbols are intended to

draw the attention of the reader to the adjacent safety instructions.

This symbol indicates that there are hazards to the life and health of persons.

The symbol indicates that there are hazards for the machine, material or environment.

This symbol identifies information provided to improve understanding of the product and correct

handling of the product.

This symbol warns of dangerous electrical voltage within the working area (e.g. electrical

distributors, terminal boxes, etc.)

This symbol warns of hazards caused by explosive atmospheres.

This symbol indicates suspended loads and their concomitant dangers.

This symbol indicates a possible risk of crushing

This symbol indicates a possible risk of crushing body parts (especially hands) by moving machine

parts or machine parts that are closing.

SEPARATE

INSTRUCTIO

NS

This point refers to additional operating instructions or regulations (enclosed or delivered

separately) required for operation or maintenance of accessories; these must be read and carefully

observed.

(safety instructions referring to these must always be observed).

BA_Batterie-Ladeschrank_002 page 4 May 2012

Keep these operating instructions stored in a safe place. They are for practical use and should be

available to the user at the location of the equipment.

These operating instructions apply to Batterie-Ladeschrank. It contains all the information needed

regarding correct startup, trouble-free operation, maintenance, removal from service and disposal.

The instructions in this user manual must be carefully followed and adhered to. The operating

personnel must be informed and sufficiently trained regarding the content of these operating

instructions.

No changes, extensions or modifications may be made to the product without the manufacturer's

written authorization.

National regulations and safety regulations have to be adhered to.

2 Safety instructions

Any damages to the battery charging cabinet must be remedied immediately in full observance of

the required safety measures.

Make sure the charging cable is disconnected before starting to charge!

Caution! Risk of short-circuit!

The device must be horizontal and be placed firmly on a suitable surface.

An obstruction of the air exhaust ducts must be checked before starting to charge!

Special safety instructions are contained in the following chapters.

3 Correct use in accordance to the instructions

The battery charging cabinet is used for safe charging of batteries from automobiles and lorries. Two different

battery chargers can be connected (chargers not supplied).

The operational temperature range is between -20°C and +40°C.

The charging cabinet must not be used as a storage facility.

The battery charging cabinet must not be transported with batteries installed in it! The charging

cabinet is not suitable for storing and transporting storing units.

The battery charging cabinet must never be exposed to direct sunlight or high temperatures for long

periods of time as otherwise this may lead to a reduction in inherent stability and strength in the

material.

BA_Batterie-Ladeschrank_002 page 5 May 2012

4 Product description

The design and configuration of the battery charging cabinet is based on the specifications of the German BGI

5017 "Charging facilities for vehicle batteries". The battery charging cabinet is fitted with the required control unit

for safe monitoring of the charging procedure. This control unit is positioned on the cabinet. The battery charging

cabinet is fitted with an automatic ventilation system with a follow-up time of 1 hour, as specified by the BGI 5017.

The batteries can only be charged when ventilation is switched on. The follow-up time of the fan is monitored by

the control unit

Compliant to BGI 5017 Chapter 3.3 "Planning aid for ventilation and explosion protection", the spaces/areas are

deemed to be non-explosive when the technical ventilation accords to the set requirements. No explosion-

protection is required for the technical ventilation when the fan is not within the gas-air current (min. device group

II, category 3G Ex).

The cabinet is fitted with transparent plexiglass doors so that the charging procedure can be easily monitored.

Additionally, there are connections for all commonly available battery chargers. The chargers can be placed on the

charging cabinet. There are connection terminals in the charging cabinet to simultaneously connect 2 batteries

each. There is an integrated sump with grate covering in the cabinet to catch any escaping liquids if necessary.

Additionally, the cabinet is comprised of a robust, acid and alkali proof polyethylene (PE) casing, coloured blue

and grey.

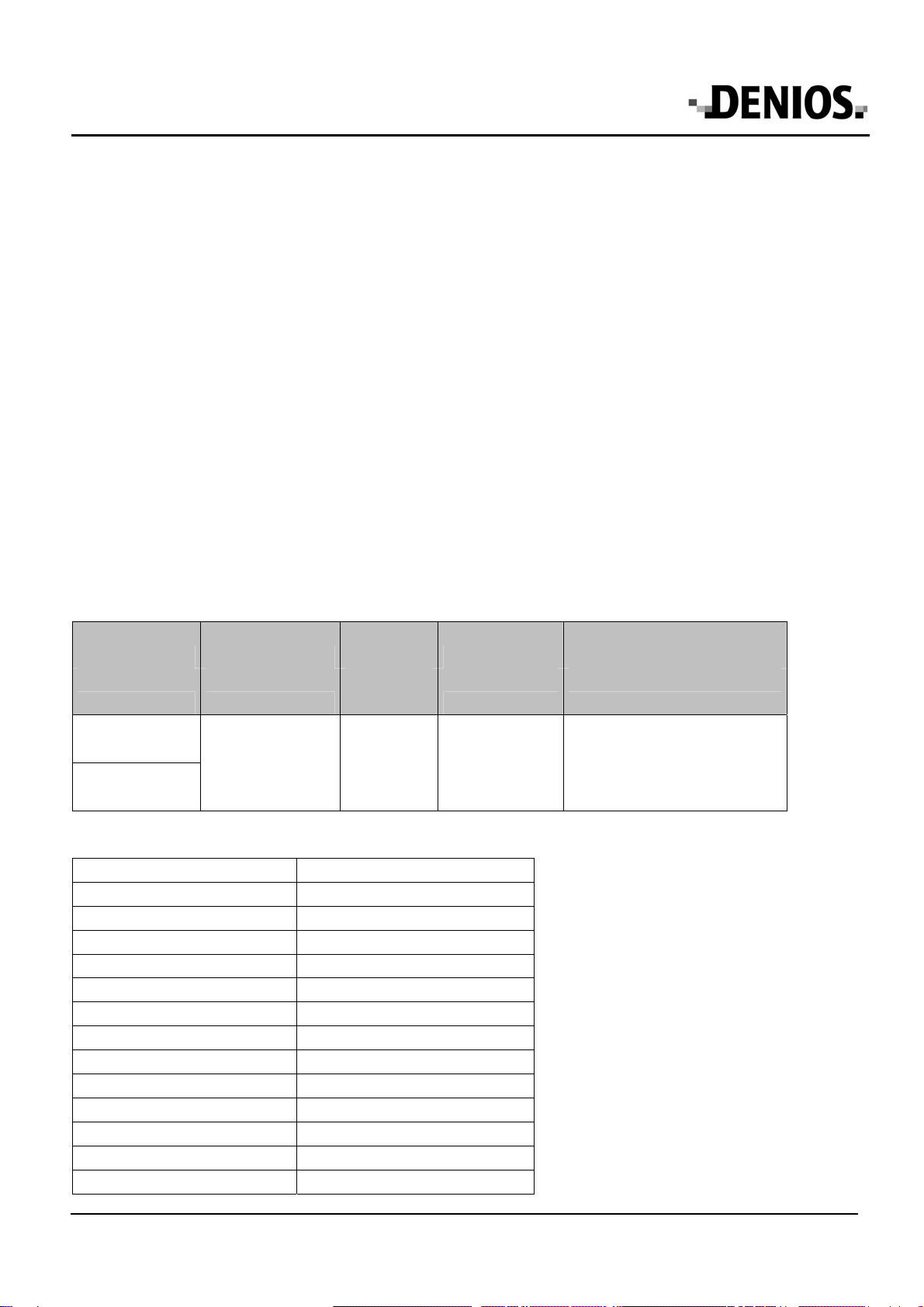

4.1 Technical Data

Type Dimensions Sump Bearing load bearing capacity of each

shelf

Art. No. w x d x h (mm) Capacities

(l) Grates (kg) (kg) UDL

PSR 8.8 in blue

186 933

PSR 8.8 in grey

186939

910 x 760 x 1300 25 400 80/50*

*wall-mounted

Weight 75 kg

Electrical connection 1/N/PE 230V~, protection class 1

Pre-fuse max. 10A

Power consumption max. 2kW

Fan

Type EP.VE.18610

Volumetric flow 0-140 m³/h

Total pressure 200-20 Pa

Voltage 230V

Current consumption 0.35A

ATEX-marking CE II 3 G T4

Differential pressure sensor

Type DBK-2G-20/300

ATEX-marking II2G EEx ia IIC T6

Other manuals for PolySafe-Depot PSR 8.8

2

Table of contents