DEPURECO RAM Series Instructions for use

RAM 280

RAM 280 MP

RAM 500

RAM 1000

RAM T500

RAM 1000 AV

Page 3 of 38

1. INFORMATIVE SECTION

1.1 Foreword...................................................................................................................4

1.2 Main parts.................................................................................................................6

1.3 Optional parts...........................................................................................................7

1.4 Manufacturer's identification data ....................................................................... 7

1.5 Identification plate................................................................................................... 7

1.6 Permitted Uses........................................................................................................7

1.7 Authorised environmental conditions.................................................................. 8

1.8 Noise level ................................................................................................................8

1.9 Technical data ..........................................................................................................9

1.10 Warranty .................................................................................................................10

2. SAFETY SECTION

2.1 Safety Information ...................................................................................................11

2.2 Safety recommendations..................................................................................... 12

2.3 Safety plates and symbols...................................................................................14

2.4 Residual risks .........................................................................................................14

2.5 Applied Directives .................................................................................................15

3. HANDLING, UNPACKING AND INSTALLATION SECTION

3.1 Handling..................................................................................................................16

3.2 Unpacking ...............................................................................................................16

3.3 Installation ..............................................................................................................22

4. OPERATION SECTION

4.1 Description of the controls ..................................................................................23

4.2 Operating cycle ......................................................................................................24

4.3 Storage –Decommissioning ...............................................................................25

5. MAINTENANCE SECTION

5.1 Informative notes ..................................................................................................26

5.2 General safety regulations................................................................................... 27

5.3Replacing the filter ................................................................................................29

5.4 Cleaning or replacing of the oil proof cartridge................................................31

5.5 Troubleshooting.....................................................................................................33

5.6 Scrapping ................................................................................................................34

Page 4 of 38

1. INFORMATIVE SECTION

IMPORTANT - The DEPURECO term and logo in this document refer to and are the property of

DEPURECO INDUSTRIAL VACUUMS S.r.l.

This document remains the exclusive property of DEPURECO S.r.l. Full or partial reproduction by any

means (graphical, electronic, etc.) is prohibited without prior authorisation from the Company

Management.

1.1 Foreword

Dear Customer

Thank you for having chosen DEPURECO; we hope you will enjoy using your new DEPURECO RAM

series vacuum cleaner. This manual has been drafted in order for our customer to fully appreciate the

quality of this machine. Please read all sections before using the machine for the first time.

It includes information, recommendations and important warnings concerning the use of the vacuum,

which will help fully exploit the technical properties of your machine.

Read messages, warnings and indications preceded by the following symbols carefully:

For the safety of people

For the integrity of the vacuum cleaner

For the safeguard of the environment

This manual forms an integral part of the vacuum cleaner. Read this

manual and the other attachments supplied carefully. Knowledge of

the instructions here contained is indispensable for the safe use

and maintenance of the vacuum cleaner

Page 5 of 38

This manual describes the following models:

RAM 280 MP

The vacuum cleaner is equipped with the following filters:

OIL PROOF CARTRIDGE (P12475)

PPL FILTER (P09679)

GRID BASKET (P09626)

This manual provides all the necessary information for the use and maintenance of the vacuum

cleaner.

This specific model has undergone strict testing to ensure maximum reliability. Its operation and

durability will depend on proper use and maintenance.

This manual is an integral part of the vacuum cleaner and must accompany it at all times, until its

demolition.

In the event it is lost or damaged, you can request another copy from DEPURECO INDUSTRIAL

VACUUMS S.r.l. (henceforth shortened to DEPURECO).

The technical information contained in this manual is exclusive property of DEPURECO and must be

considered confidential. Reproduction, even partial, of graphics, text and illustrations is prohibited by

law.

Some details shown in the figures in this manual may differ from those on your vacuum; this is

because some components may have been removed to ensure maximum illustration clarity.

This manual has been divided into sections for easy consultation and each section has been identified

by a specific graphical symbol.

The topics covered in this manual are those expressly required by Machinery Directive 2006/42/EC

and the technical data are taken from the technical file archived at DEPURECO.

With reference to Regulation 1907/2006/EC (REACH), DEPURECO hereby declares that no

Substances of

Very High Concern

- (SVHC) included in the Candidate List, are contained in its

products.

This manual should be kept in a place accessible to all personnel in charge with operating and

performing maintenance on the vacuum cleaner.

In the event of any dispute arising, the Court of Turin (Italy) shall have jurisdiction

This manual forms an integral part of the vacuum cleaner. Read this

manual and the other attachments supplied carefully. Knowledge of

the instructions here contained is indispensable for the safe use

and maintenance of the vacuum cleaner

Page 6 of 38

1.2 Main parts

1. Handle

2. Electrical panel

3. Cap

4. Motor head

5. Tank

6. Inlet

7. Outlet

8. Pivoting wheels

9. Fixed wheels

10. Discharge ball valve

1

2

3

4

5

6

7

9

8

10

Page 7 of 38

1.3 Optional parts

A wide range of optional accessories is available from DEPURECO depending on the intended use of

the vacuum.

1.4 Manufacturer's identification data

DEPURECO INDUSTRIAL VACUUMS S.r.l.

Corso Europa 609 - 10088 Volpiano (TO) - ITALY

phone +39 011 98 59 117 - fax +39 011 98 59 326 | VAT NO. 02258610357

e-mail: depureco@depureco.com - website: www.depureco.com

1.5 Identification plate

The data on the vacuum identification plate must be referred to in any correspondence with the

manufacturer or the dealer.

1.6 Permitted Uses

These vacuum cleaners are designed and built according to the 2006/42/CE (Machine Directive) for an

exclusive professional industrial use; either way, for any non-domestic use,

This vacuum cleaner is suitable for the cleaning and the collection of oil, coolants, emulsions and

swarf –non-flammable and non-harmful –and to reintegrate the filtrated liquids inside the machine

tool.

The vacuum cleaner was conceived to be used by only one operator.

In accordance with the Directive 1999/92/EC, whenever in the presence of combustible dust and/or

flammable gas, it’s the responsibility of the employer to carry out the classification of the Zone and to

choose a device in the appropriate category (According to the definition given in the 2014/34/EU

Directive.

Any other use is considered IMPROPER.

Page 8 of 38

1.7 Authorised environmental conditions

To ensure the correct operation, the vacuum cleaner must be kept away from atmospheric agents

(rain, hail, snow, fog, dust in suspension, etc.) in an area with a room temperature range between 0°

and 40°C and a relative humidity no higher than 70%.

The work environment must be clean and suitably lit.

1.8 Noise level

The phonometric tests performed on this specific vacuum cleaner model demonstrate a sound

pressure level of

RAM 280 MP

72 dB(A)

Exposure to noise

WARNING!

Workers exposed to sound pressure levels higher than 85 dB(A) must be

protected by suitable personal protection device (PPE) such as certified ear

muffs.

Under these conditions, workers must be provided with adequate training

and information on risks arising from noise exposure.

Page 9 of 38

1.9 Technical data

U.M.

RAM 280 MP

Weight*

Kg

220

Overall dimensions**

mm

700x1450

Height

mm

1400

Voltage I Frequency

V - Hz

230 –50/60

Power

kW - HP

4,3 / 5,8

Maximum vacuum

mbar

250

Maximum air flow

m³/h

570

Noise level

dB (A)

72

Inlet diameter

mm

50

Liquid capacity

L

280

Solid capacity

L

40

Intake

L/sec

280/63

Discharge

L/sec

280/60

(*) weight without packaging - packaging weight = 20 Kg

(**) machine dimensions without packaging

Page 10 of 38

1.10 Warranty

DEPURECO guarantees this model of vacuum cleaner for a period of 24 months from the date of

purchase, indicated on the receipt at the time of delivery of the product.

The guarantee is null and void in the event that the vacuum is repaired by unauthorised third parties or

by using equipment, accessories or components not supplied or not authorised by DEPURECO, or if

the serial number is removed (during the guarantee period).

For the duration of the guarantee, DEPURECO undertakes to repair or replace free of charge parts and

components which prove to have manufacturing defects.

Repairs will be exclusively executed at a DEPURECO site or in a DEPURECO approved Assistance

Centre and the machine must be sent free of charge (freight cost at user’s charge unless otherwise

agreed).

The guarantee does not cover cleaning of working parts.

The purchase invoice must be shown to the authorised technical personnel carrying out the repair and

must accompany the vacuum during its shipment.

Defects that are not evidently due to materials or manufacturing will be examined solely at our

premises or at a Technical Service Centre of our choosing.

Should the complaint be unjustified, all repair and/or replacement expenses shall be charged to the

purchaser.

In any case, the following items are not covered by the guarantee: accidental damage due to

transport, negligence, abnormal use, improper use, non-compliance with the instructions contained in

this booklet or arising from phenomena that do not depend on normal use/operation of the vacuum.

DEPURECO shall not be held liable for any injuries to persons or damage to objects caused by misuse

or improper use of the vacuum.

In the event of any dispute arising, the Court of Turin (Italy) shall have jurisdiction.

To use the warranty, visit www.depureco.com or photocopy the form

available on the last page of this manual, fill it in all its parts (in capital

letters would be recommended), and send it via fax to Depureco at the

number + 39 011 98 59 117

In the event of doubts, avoid interpreting the information!

Call your reseller immediately!

Page 11 of 38

2. SAFETY SECTION

2.1 Safety Information

As per Italian Legislative Decree 81/08 and subsequent modifications, the Safety

Manager must train and inform workers about the risks involved with using the

vacuum cleaner so that they may be able to avoid injury to themselves and others.

The use of device by people (including children) with limited physical and mental capacities or lacking

in experience and knowledge is strictly forbidden, unless they are supervised by a person who is

experienced in the use and safe handling of the device.

Children must be supervised to make sure they will not play with the device.

Failure to comply norms, laws or basic safety precautions, may cause accidents during operation,

maintenance and repair of the vacuum cleaner. Accidents can frequently be avoided by recognising

potentially hazardous situations before they occur. Adequate training is crucial to this end.

DEPURECO shall not be held liable for accidents or damage due to the improper use of the vacuum

by untrained personnel or to failure to comply, even partially, with the occupational safety standards

and intervention procedures contained in this manual.

Safety warnings and precautions are indicated in this manual as well as on the product itself.

Operators must pay special attention to these hazard warnings to prevent accidents with serious

consequences for themselves and other people.

DEPURECO designs and manufactures its equipment and accessories with care, identifying and

compensating possible risks related to their use. In the event of equipment, procedures, work

methods or techniques not expressly provided for by DEPURECO being used, it is crucial to ensure

beforehand that there are no dangers for oneself and the others. Nevertheless, DEPURECO shall not

be held liable.

Use exclusively Depureco original spare parts.

Depureco disclaims any liability in case spare parts other

than original have been used.

Page 12 of 38

2.2 Safety recommendations

WARNING!

The following information is essential in view of preventing all hazards that may occur

while the vacuum cleaner is running. However, they cannot replace the expertise and

common sense of operators as an overall framework for the prevention of accidents.

Structural damage, alterations or improper repairs can modify the protective capacity

of the vacuum, thereby nullifying this certification and releasing DEPURECO from any

liability.

Each section lists further safety measures specific to the various functions.

WARNING!

Setting to work –connection to the power supply

Make sure there is no evident sign of damage to the vacuum cleaner before starting work.

Before plugging the vacuum cleaner into the electrical mains, make sure the voltage rating

indicated on the data plate corresponds to that of the electrical mains.

Plug the vacuum cleaner into a socket with a correctly installed ground

contact/connection.

Make sure that the vacuum cleaner is turned off.

The plugs and connectors of the connection cables must be protected against splashes of

water.

Check that the vacuum cleaner is properly connected to the electrical mains.

Use the vacuum cleaner only when the cables that connect to the electrical mains are in

perfect condition (damaged cables could lead to electric shocks!).

Regularly check there are no signs of damage, excessive wear, cracks or ageing on the

electric cable.

WARNING!

When the vacuum cleaner is operating, do not:

Crush, pull, damage or tread on the cable that connects to the electrical mains.

Only disconnect the cable from the electrical mains by removing the plug (do not pull the

cable).

Only replace the electric power cable with one of the same type as the original: H07 RN -

F. The same rule applies if an extension is used.

The cable must be replaced by the manufacturer’s Service Centre staff or by equivalent

qualified personnel.

CAUTION!

Page 13 of 38

It is absolutely forbidden;

•For underage and non-trained people to use this vacuum cleaner.

•To connect the vacuum cleaner to mains without suitable earthing.

•To operate the vacuum cleaner outdoors in the presence of atmospheric precipitations.

•To operate the vacuum cleaner without locking the swivelling wheel through the special brake

located on it.

•To operate the vacuum cleaner on uneven ground or in non-horizontal positions.

•To operate the vacuum cleaner in corrosive environments.

•To operate the vacuum cleaner in working environments not classified according to the directions

given on the device’s plate.

•To vacuum the following materials:

1. Flaming materials (embers, hot ashes, lit cigarettes etc…)

2. Open flames

3. Combustible gases

4. Flammable, combustible or aggressive liquids (gasoline, solvents, acids,

alkaline solutions etc…)

5. Dusts/Substances and/or spontaneously combusting explosive mixtures

of them (magnesium or aluminium dusts etc…)

•To tamper with or modify the return valve set up by the manufacturer

•The use of the JETCLEAN system in the presence of potentially explosive clouds in the

atmosphere.

•To carry out maintenance on the vacuum cleaner in ATEX classified areas

•To carry out maintenance on the vacuum cleaner without first having switched the device off and

disconnected the plug from the socket.

•To keep foreign materials such as debris, oil, tools or other objects in the bin which could disrupt

the functioning and cause harm to people.

•To use flammable or toxic solvents such as gasoline, benzene, ether or alcohol for cleaning.

•To operate the vacuum cleaner without the filtering unit provided for by the manufacturer.

•To operate the vacuum cleaner without safety devices.

•To wear loose or flowing apparel such as ties, scarves, or torn clothing that could get caught on

the vacuum cleaner or vacuumed by the device.

•To open the waste bin while the vacuum cleaner is working.

•To open the waste bin in an area which has been classified potentially explosive.

•To use extension leads, plug-in connection devices and adapters.

•To climb on the vacuum cleaner.

•To touch electrical wires, switches, buttons, etc. with wet hands.

Page 14 of 38

•To touch some components which could reach high temperatures (such as the motor’s terminal

box and the motor housing in particular) while operating the vacuum cleaner.

WARNING!

This vacuum cleaner could contain oil mists that may be hazardous to your health.

The emptying out and maintenance procedures must be carried out exclusively by specialized

personnel wearing suitable safety clothing.

The manual must be available at all times to be consulted about the operation cycle or any

time a doubt may arise on how to handle the machine.

Never switch the machine on in the absence of a complete filtering system.

2.3 Safety plates and symbols

Plates with safety symbols and/or messages are applied to the vacuum and its packaging.

These pages show their precise location and the nature of the hazard.

Warning!

Ensure that all safety messages are perfectly legible.

Clean them using a cloth with water and soap. Do not use solvents, naphtha or petrol.

Request replacements for damaged plates from DEPURECO.

If a plate is located on a component that is being replaced, make sure to fit the old plate to

the new component.

2.4 Residual risks

Read the instructions on the packaging

carefully before handling the vacuum cleaner

Attention! Do not carry out maintenance

operations in presence of voltage.

Warning! High Voltage.

Page 15 of 38

DEPURECO recommends complying with the instructions, procedures and recommendations in this

manual and with the safety standards in force. DEPURECO also recommends using suitable personal

protective equipment as well as the protection devices integrated in the vacuum.

The residual risks analysed on the vacuum and/or its components could be:

Electrical risks during maintenance due to the requirement to work on live parts

Pursuant to Italian Legislative Decree 81/08 –articles 80 to 87 –it is prohibited to operate on live

parts, notwithstanding the exceptions set forth by said Legislative Decree.

Risks associated with incorrect use in presence of explosive and inflammable liquid substances

The vacuum must not be used in environments containing liquid substances or liquids that can

evaporate at room temperature, inflammable powders and gas.

Risks related to operation in humid environments

Respect the limitations indicated in this manual, in section 1.5 “Authorised environmental

conditions”.

Risk of incorrect interpretation of the safety pictograms

With reference to risk analysis and identification, DEPURECO has installed hazard labels on the

vacuum, in compliance with the standards concerning graphical symbols.

The user must immediately replace any safety plate rendered illegible due to wear or damage.

Warning!

The removal of safety plates from the vacuum and/or its components and packaging is

strictly prohibited.

DEPURECO shall not be held liable for the vacuum's safety in the event of failure to

comply with this prohibition.

2.5 Applied Directives

The following directives apply to the vacuum cleaner described in this manual:

- 2006/42/EC Machinery Directive

- 2014/30/EU Electromagnetic compatibility directive

- 2011/65/EU - ROHS - Directive on the restriction of the use of certain hazardous substances

in electrical and electronic equipment

- 2014/35/UE –Low tension directive

The reference standards, including their binding requirements, are managed within the DEPURECO

Quality Management System and archived by DEPURECO.

3. HANDLING, UNPACKING AND INSTALLATION SECTION

Page 16 of 38

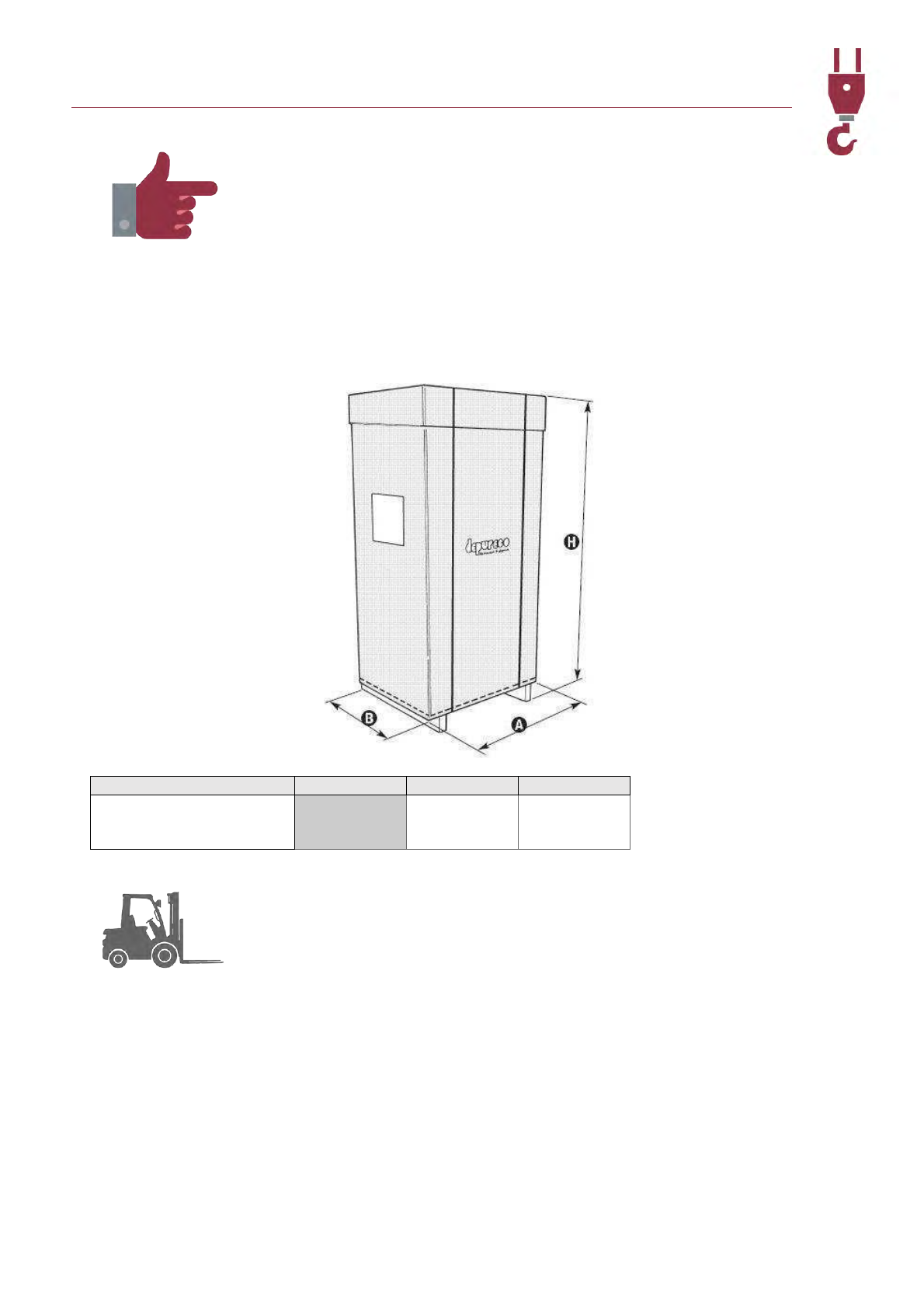

3.1 Handling

Warning!

The instructions for transporting and unpacking the vacuum correctly are

shown

on the packaging as well.

The following instructions also indicate the operations to be undertaken should the vacuum need to

be re-packed or unpacked after subsequent transportation.

Dimensions of packed vacuum cleaner:

A

B

H

RAM 280 MP

75 cm

145 cm

160 cm

When using a forklift, lift the load 200 mm off the ground and swing backwards.

Always keep the height of the working environment in mind when lifting loads.

Before starting any movement, ensure that the area is cleared and that there are no moving objects

on the packaging. For lifting and handling, apply operating safety laws and normal instructions for

fork-lift truck driving.

3.2 Unpacking

The vacuum cleaner must be lifted and handled exclusively using a forklift having

suitable load bearing capacity.

The vacuum cleaner must be lifted and handled exclusively using a forklift having

suitable load bearing capacity.

Page 17 of 38

- Cut and unwind the two packaging fixing belts

- remove the staples that fix the carton packaging to the pallet with the aid of a screwdriver

- remove the carton completely

Page 18 of 38

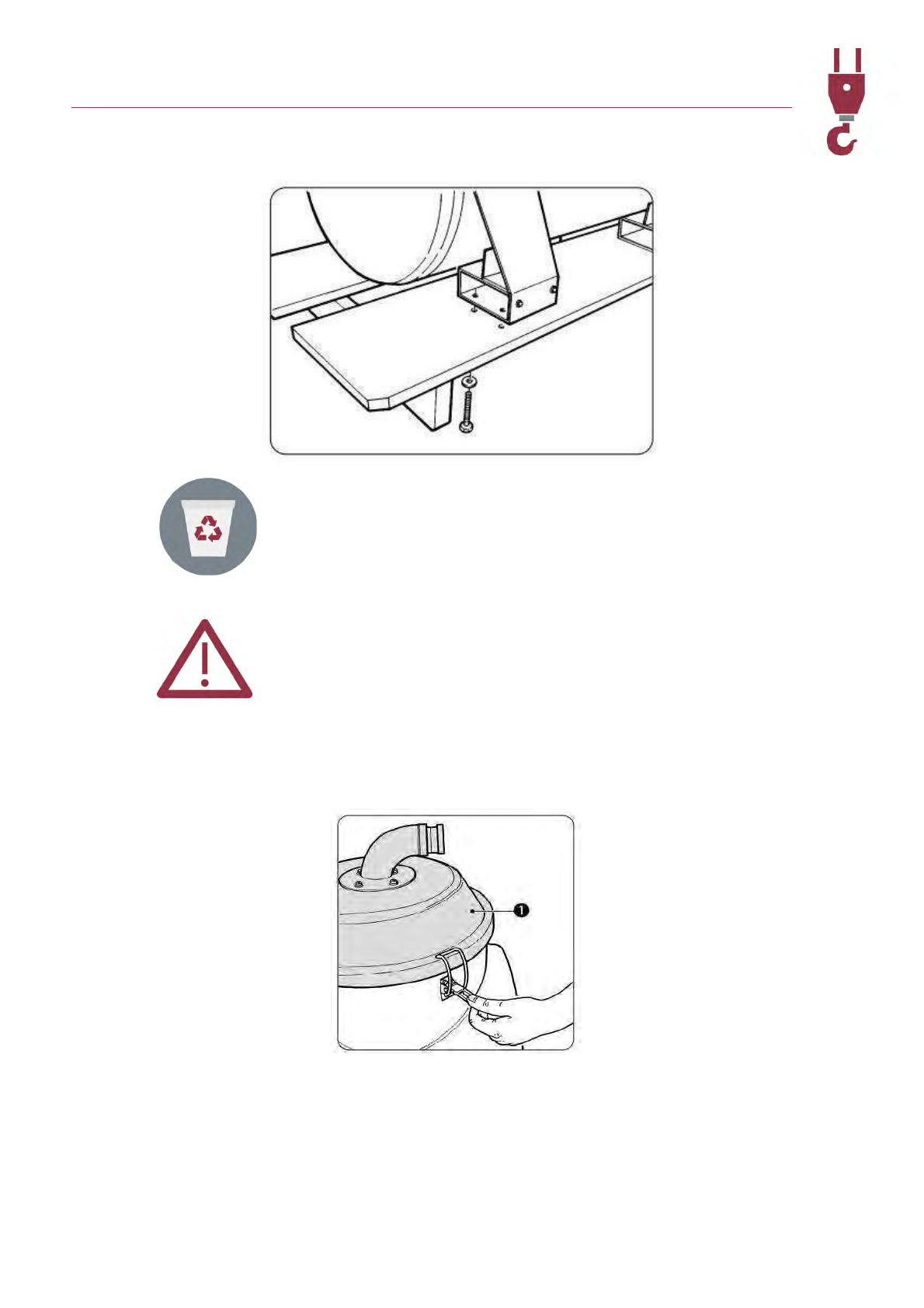

- After removing the protection wrapper, unscrew and remove, from both sides, the screws fixing the

machine to the pallet.

-Unlock and remove the cap (1)

The cardboard packaging can be recycled. To protect the

environment, make sure to dispose it off in specialised collection

centres.

Warning!

Keep the pallet.

In the event of subsequent transport, the vacuum must be secured

to the pallet using the same fastening system.

Page 19 of 38

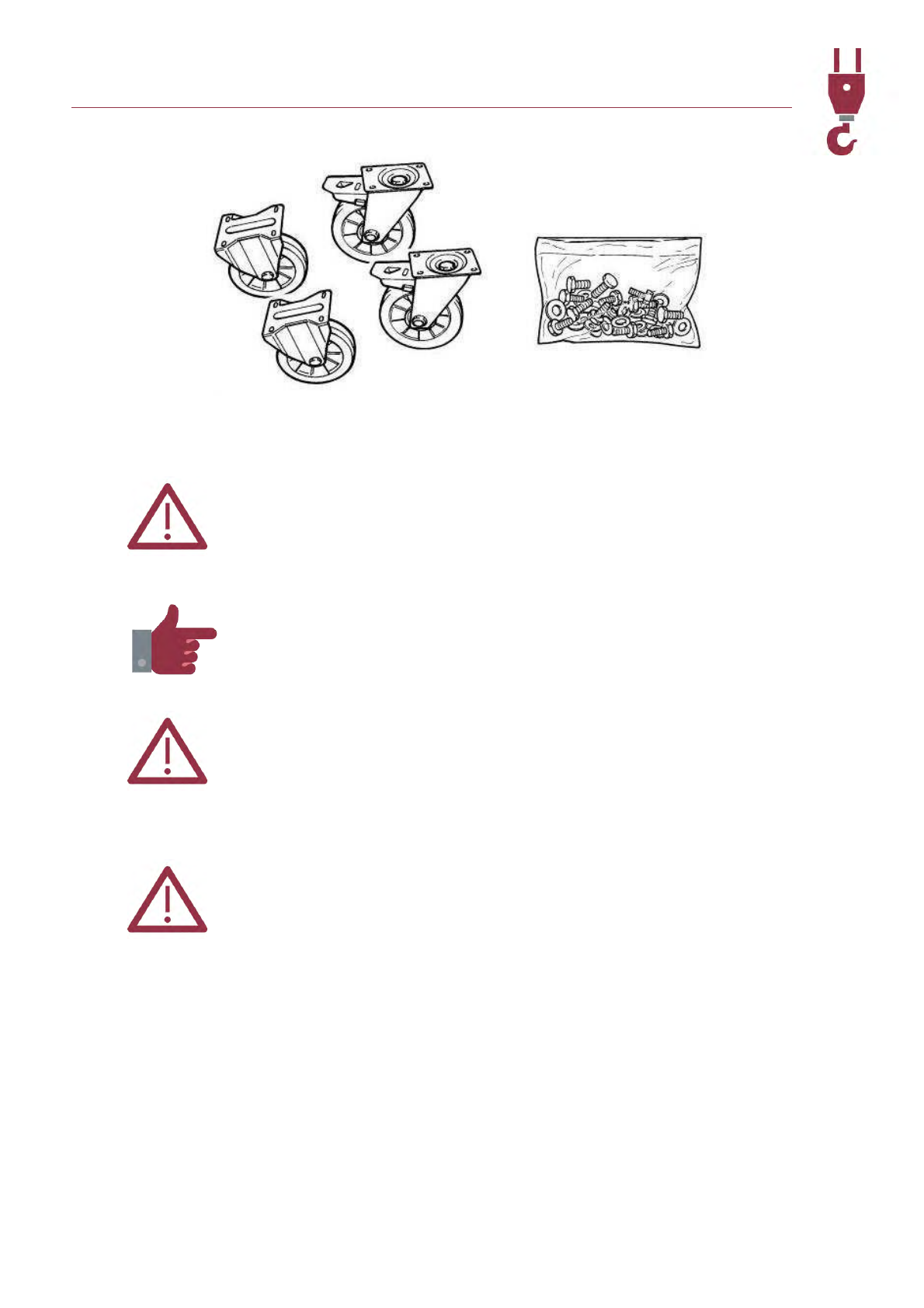

-Find the 4 wheels and the bag containing the screws

-Close and lock the cap again

Attention!

The following operation must be carried out on a flat terrain by a forklift operator

and a second person.

Warning!

Insert the forklift’s forks in the appropriate mountings.

Attention!

The forks must go completely inside the mountings.

-Lift the vacuum cleaner 1.5 Mt.

Attention!

Block the forklift’s movements, switch it off and pull the handbrake. The operator

must monitor while the second person is operating.

Page 20 of 38

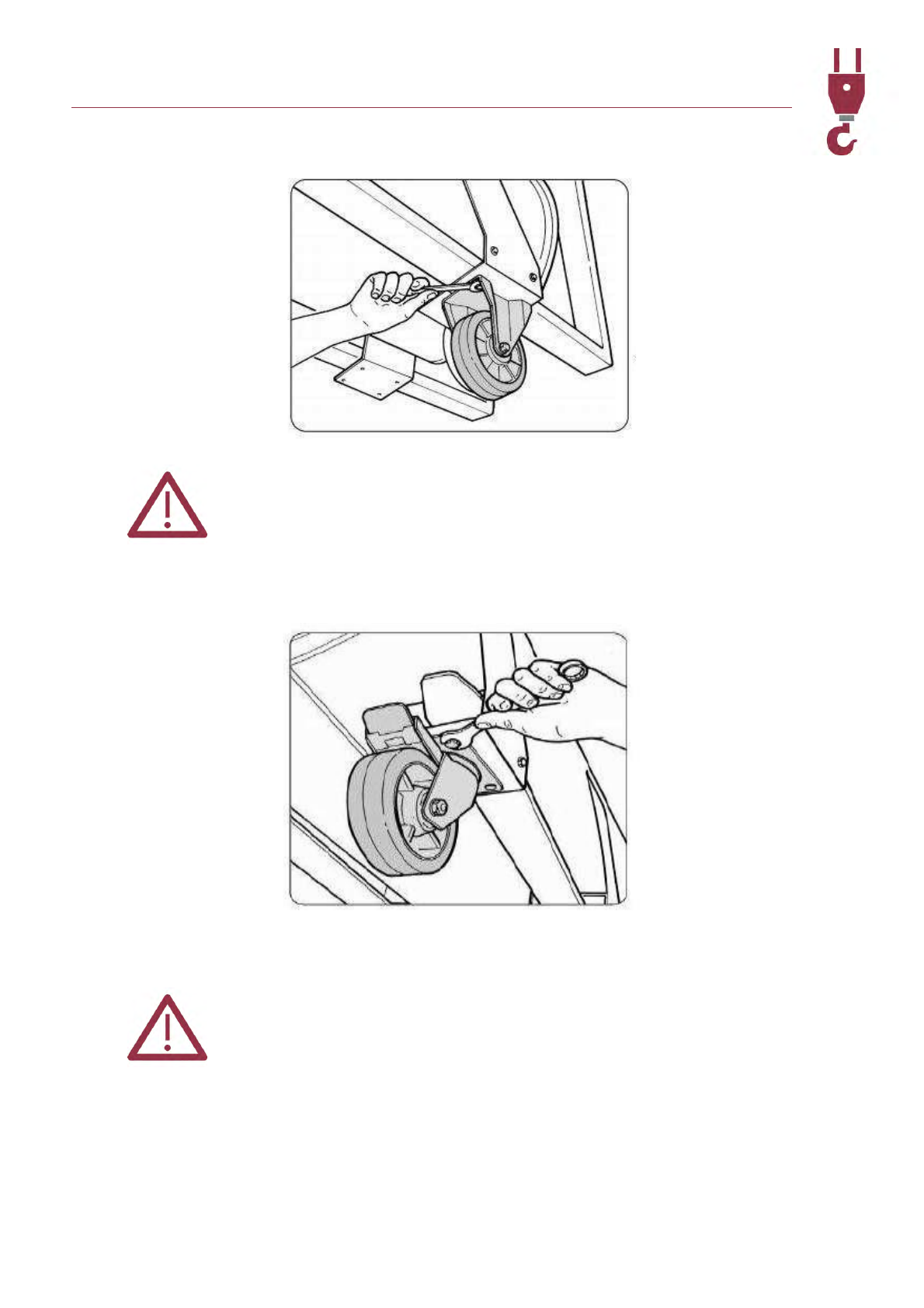

-Install the two fixed wheels on the opposite side of the vacuum’s handle

Attention!

The second person must operate outside from under the forklift

-Install the two pivoting wheels at the other end on the machine as shown in the picture

-Put the machine back on the ground

Attention!

Never stand under the forklift while the machine is being lowered.

Page 21 of 38

-Connect the discharge hose directly to the dedicated nozzle and fix it by using a clamp as

shown in the picture

This manual suits for next models

6

Table of contents

Other DEPURECO Industrial Equipment manuals

DEPURECO

DEPURECO CLEAN AIR User manual

DEPURECO

DEPURECO miniAIR Series User manual

DEPURECO

DEPURECO ECOBULL Instructions for use

DEPURECO

DEPURECO M 100 OIL Series User manual

DEPURECO

DEPURECO AIRWELD Instructions for use

DEPURECO

DEPURECO TX Series User manual

DEPURECO

DEPURECO PUMA Series Instructions for use

DEPURECO

DEPURECO RAM OIL T500 Series User manual

DEPURECO

DEPURECO CLEAN OIL Series User manual