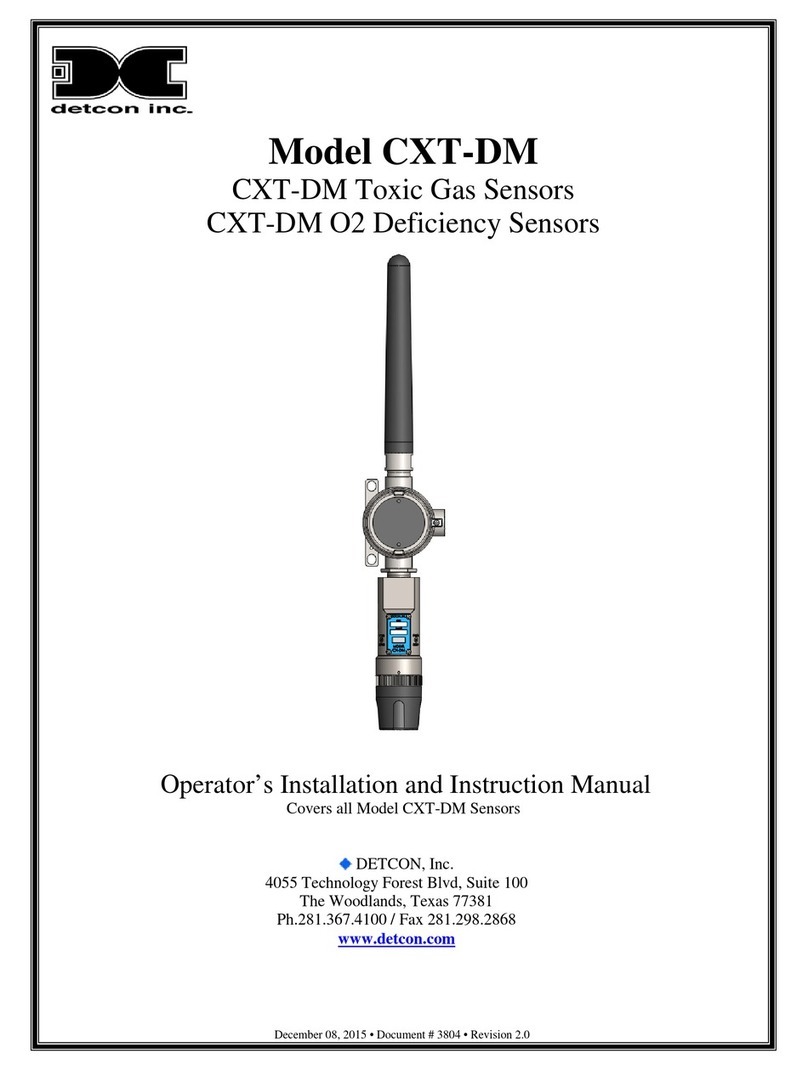

Model DM-100

Model DM-100 iii

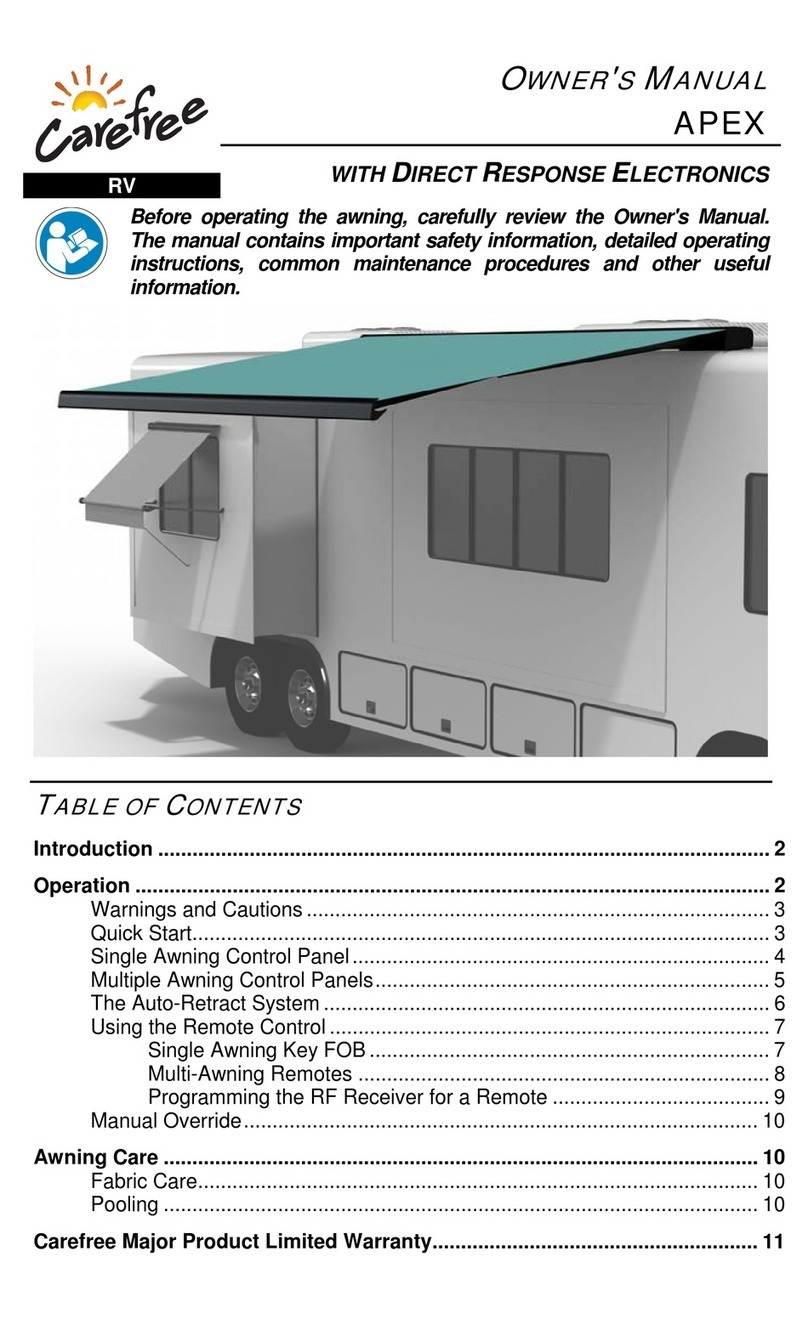

Table of Contents

1. Introduction ..................................................................................................................................................1

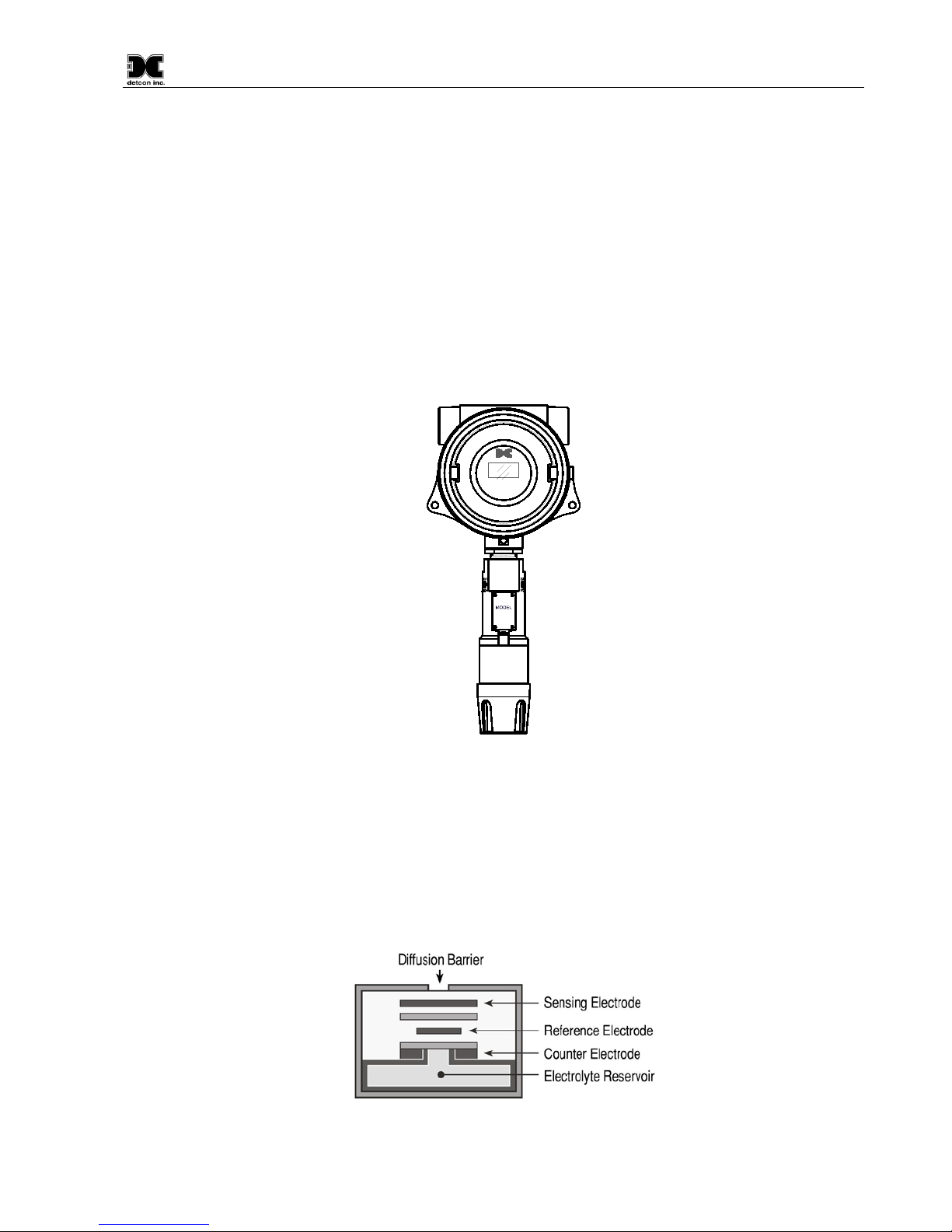

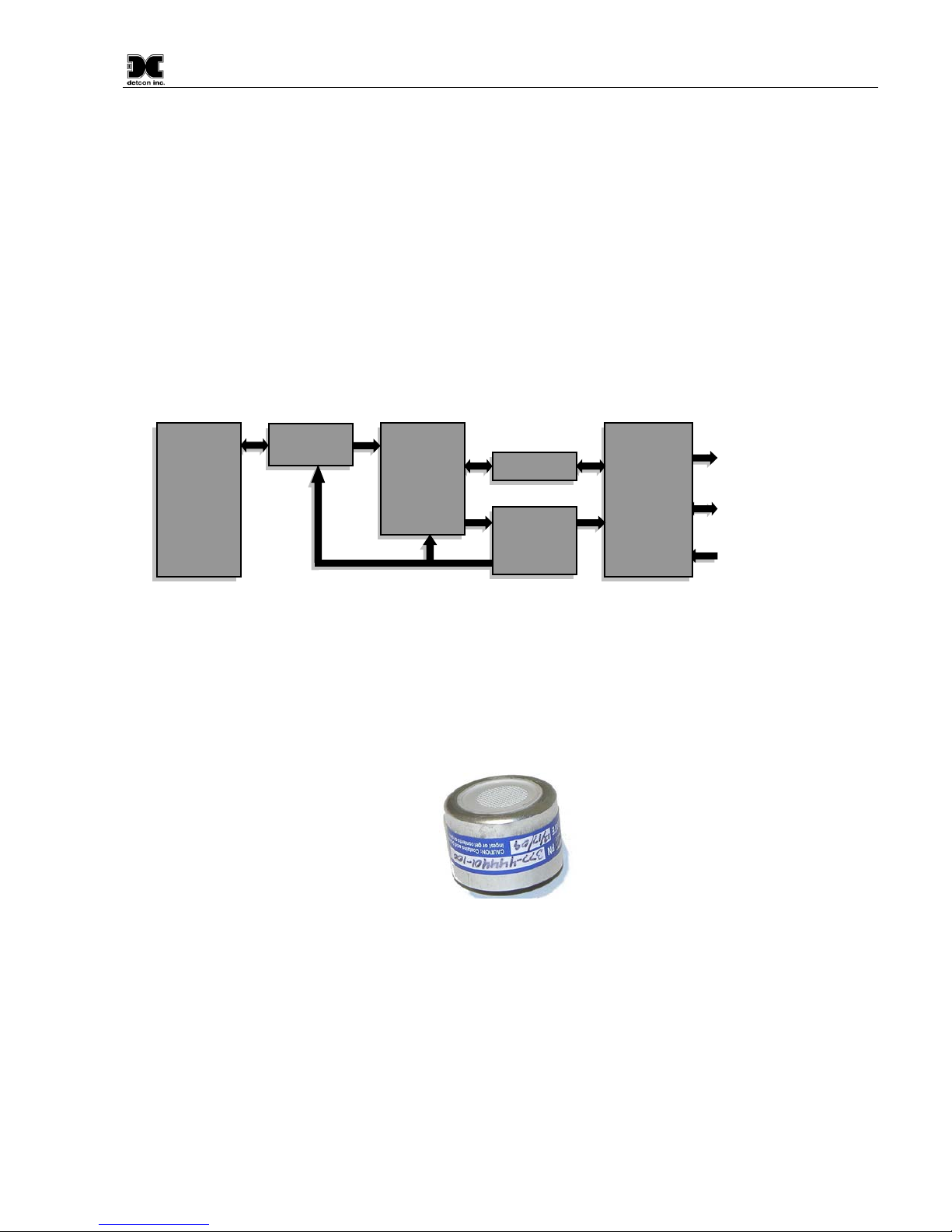

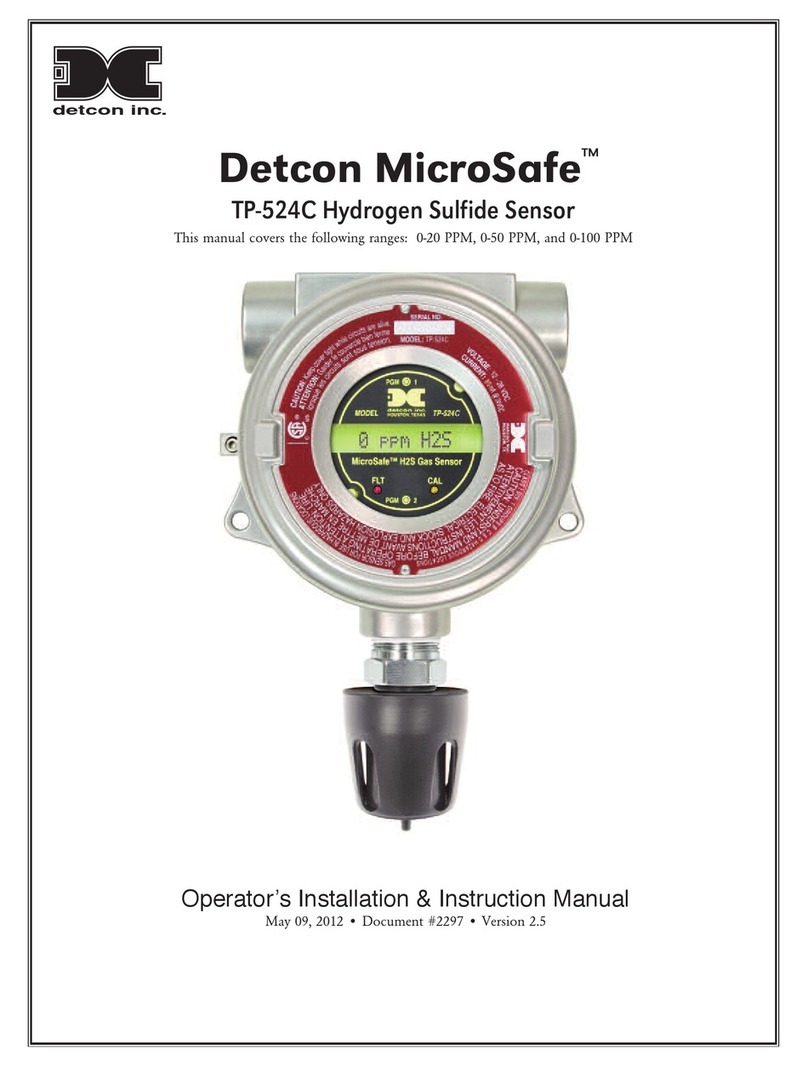

1.1 Description.......................................................................................................................................... 1

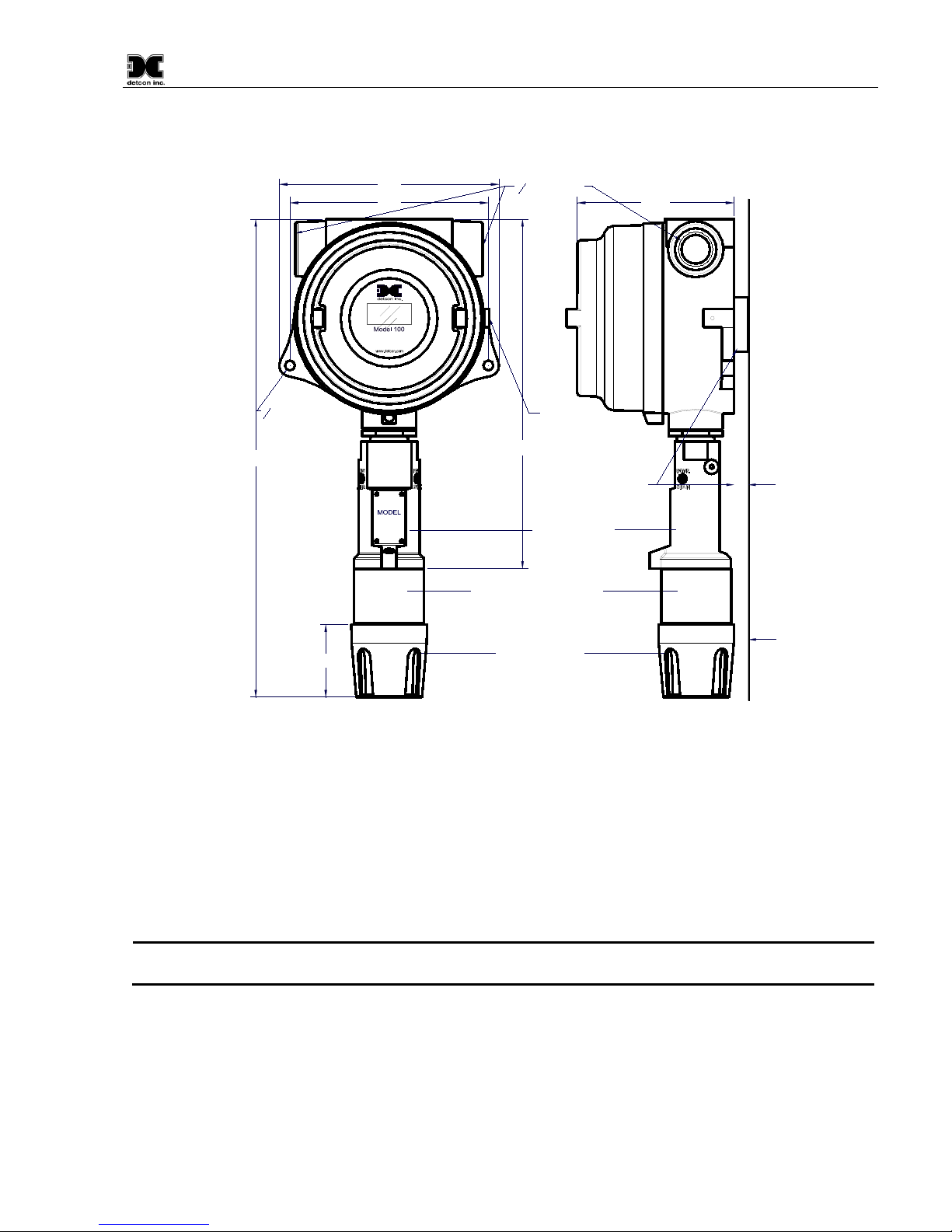

1.2 Modular Mechanical Design............................................................................................................... 2

1.3 Model 100 Standard Terminal Board (Optional)................................................................................ 4

1.4 DM-100 Display Terminal Board (Optional) ..................................................................................... 4

1.5 DM-100 Series Display (Optional)..................................................................................................... 5

1.6 Wireless Transceiver and Battery Pack (Optional)............................................................................. 5

2. Installation....................................................................................................................................................6

2.1 Hazardous Locations Installation Guidelines for Safe Use................................................................. 6

2.2 Sensor Placement................................................................................................................................ 7

2.3 Sensor Contaminants and Interference ............................................................................................... 8

2.4 Sensor Mounting................................................................................................................................. 8

2.5 Electrical Installation.......................................................................................................................... 9

2.6 Field Wiring...................................................................................................................................... 10

2.6.1 DM-100 Display Terminal Board Settings................................................................................... 11

2.7 Initial Start Up................................................................................................................................... 11

2.7.1 Toxic Gas Sensors........................................................................................................................ 11

2.7.2 O2Deficiency Sensors.................................................................................................................. 13

3. Operation....................................................................................................................................................14

3.1 Normal Operation ............................................................................................................................. 14

3.2 Auto Span Level Adjustment............................................................................................................ 14

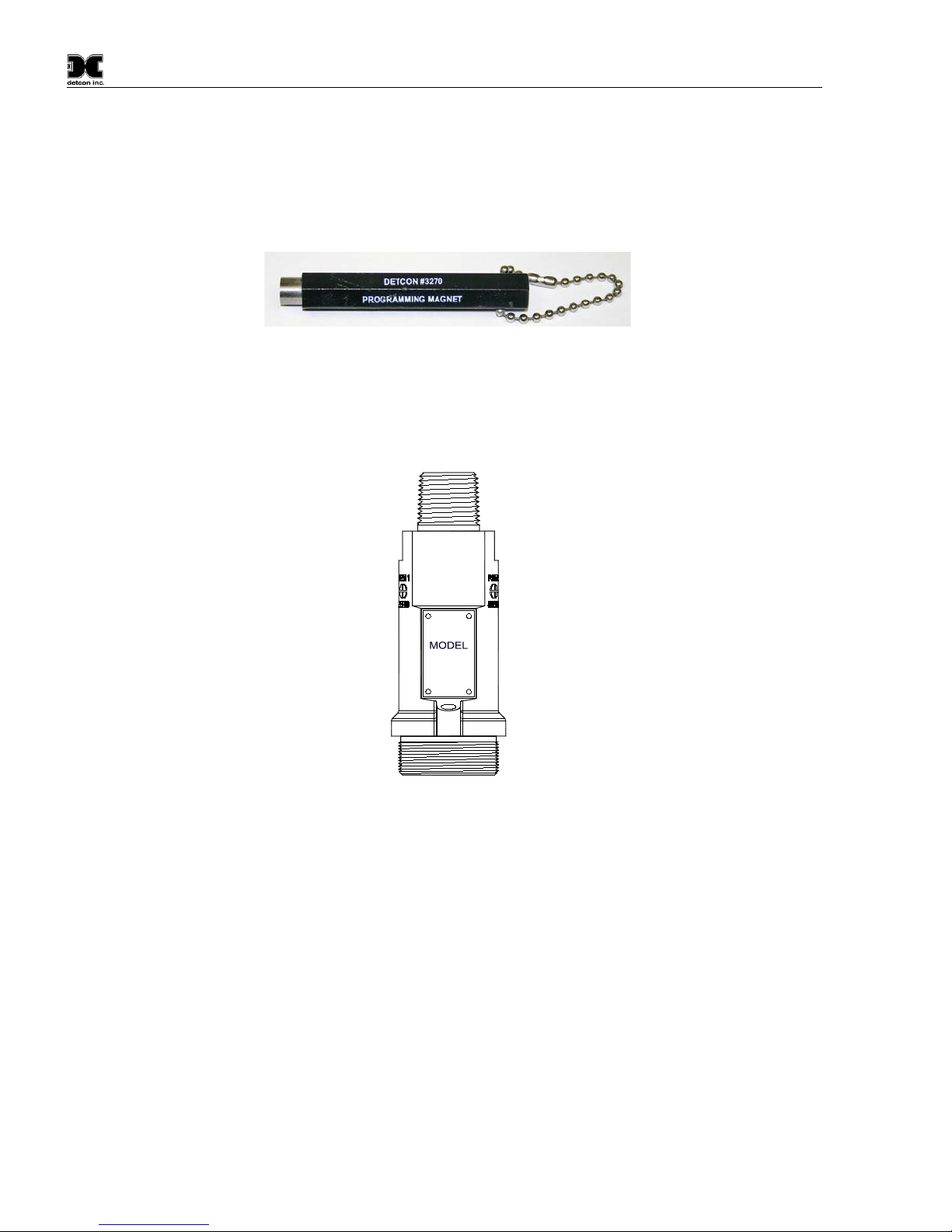

3.3 Calibration ........................................................................................................................................ 15

3.3.1 Zero Calibration............................................................................................................................ 15

3.3.2 Span Calibration........................................................................................................................... 17

3.4 Fault Diagnostic/Failsafe Feature ..................................................................................................... 19

4. Service and Maintenance............................................................................................................................20

4.1 Replacement of Plug-in Sensor......................................................................................................... 20

4.2 Replacement of ITM......................................................................................................................... 21

4.3 Replacement of the Model 100 Terminal Board............................................................................... 21

5. Troubleshooting Guide...............................................................................................................................23

5.1 Smart Display Error Codes............................................................................................................... 25

6. Customer Support and Service Policy........................................................................................................26

7. DM-100 Sensor Warranty ..........................................................................................................................27

8. Appendix ....................................................................................................................................................28

8.1 Specifications.................................................................................................................................... 28

8.2 Sensor Specific Data......................................................................................................................... 29

8.3 Interference Table............................................................................................................................. 31

8.4 Proper Application and Maintenance of Acrylonitrile Sensor.......................................................... 37

8.5 Intrinsically Safe Installation Guidelines, Control Drawing #3993.................................................. 38

8.6 Spare Parts, Sensor Accessories, Calibration Equipment................................................................. 39

8.7 Revision Log..................................................................................................................................... 40