Detcon X40-08-N4X User manual

Model X40-08-N4X, Model X40-32-N4X

Model X40-32-N1P, Model X40-32-N7

Integrated Alarm and Control System

Integrated Alarm & Control System

Operator’s Installation and Instruction Manual

Covers all Model X40 Control Systems

December 10, 2012• Document #3672 • Revision 3.0

DETCON, Inc.

4055 Technology Forest Blvd.,

The Woodlands, Texas 77381

Ph.713.559.9200 / Fax 281.298.2868

2Hwww.detcon.com

Model X40

Model X40 Instruction Manual Rev. 3.0 ii

This page left intentionally blank

Shipping Address: 4055 Technology Forest Blvd., The Woodlands Texas 77381

Mailing Address: P.O. Box 8067, The Woodlands Texas 77387-8067

Model X40

Model X40 Instruction Manual Rev. 3.0 iii

Table of Contents

1. Introduction............................................................................................................................................1

1.1 Features .......................................................................................................................................................... 1

1.2 LCD Main Display Function .......................................................................................................................... 2

1.3 Modbus™ Communication ............................................................................................................................ 2

1.4 Secure Digital Card (SD Card)....................................................................................................................... 2

1.5 I/O Modules and Connections ........................................................................................................................ 2

1.6 Enclosure Types ............................................................................................................................................. 4

1.7 Alarms and Fault Condition ........................................................................................................................... 5

1.8 System Operation ........................................................................................................................................... 6

1.9 Operator Interface........................................................................................................................................... 7

1.9.1 Magnetic Programming Tool...................................................................................................8

1.9.2 Front Panel User Interface......................................................................................................8

1.10 Main Display Functions ................................................................................................................................. 9

1.10.1 Sensor Group ...........................................................................................................................9

1.10.2 Transceiver Group...................................................................................................................9

1.10.3 RL4/Alarm Stations Group ....................................................................................................10

1.10.4 AO-4 Group ...........................................................................................................................10

1.11 Menu Function ............................................................................................................................................. 10

1.12 Optional Remote Alarm Reset/Acknowledge Switch ..................................................................................11

1.13 Wireless Option............................................................................................................................................ 11

2. Installation............................................................................................................................................13

2.1 Safety Guidelines ......................................................................................................................................... 13

2.2 N1P Enclosure Installation ........................................................................................................................... 13

2.3 N4X Enclosure Installation .......................................................................................................................... 15

2.4 N7 Enclosure Installation ............................................................................................................................. 19

2.4.1 Wireless Radio Module Wiring..............................................................................................22

2.4.2 Model 100 Terminal Board....................................................................................................24

2.4.3 Transient Protection Board ...................................................................................................25

3. I/O Connection Installation.................................................................................................................27

3.1 Analog 4-20mA Sensor Inputs (DA-4)......................................................................................................... 28

3.2 Dry Contact Inputs (DI-4) ............................................................................................................................ 29

3.3 Analog 4-20mA Outputs (AO-4).................................................................................................................. 30

3.4 Alarm Relay Outputs (RL-4)........................................................................................................................ 32

3.5 Serial Output Gas Sensors (RS-485) ............................................................................................................ 34

3.6 General Installation Wiring Notes................................................................................................................ 35

3.7 Initial Start-Up.............................................................................................................................................. 35

4. Secure Digital Card .............................................................................................................................36

5. System Configuration..........................................................................................................................36

5.1 X40 Controller Setup.................................................................................................................................... 36

5.2 Menu Functions............................................................................................................................................ 36

5.2.1 Auto Configure System...........................................................................................................37

5.2.2 Set Channel Alarms ...............................................................................................................38

5.2.3 Set Relay (Alarm) Functions..................................................................................................39

5.2.4 Inhibit and Alarm Test Mode .................................................................................................39

5.2.5 System Diagnostics ................................................................................................................40

5.2.6 Time and Date........................................................................................................................41

5.2.7 View TWA and Peak ..............................................................................................................42

6. Modbus™ Communications ...............................................................................................................42

6.1 Modbus™ Register Map .............................................................................................................................. 43

7. Remote Alarm Reset/Acknowledge Switch Installation...................................................................44

Model X40

Model X40 Instruction Manual Rev. 3.0 iv

8. Troubleshooting Guide........................................................................................................................45

9. Customer Support and Service Policy ...............................................................................................45

10. Warranty Notice ..............................................................................................................................46

11. Appendix...........................................................................................................................................47

11.1 Specifications................................................................................................................................................47

11.2 Utilities .........................................................................................................................................................48

11.2.1 Set Channel Data ...................................................................................................................48

11.2.2 Set RF Silence and RF Sleep (Wireless Function Only) ........................................................50

11.2.3 Set Low Battery Alarms .........................................................................................................50

11.2.4 Set Modbus™ Address...........................................................................................................51

11.2.5 CXT Low Battery Threshold ..................................................................................................51

11.2.6 Module Update Interval.........................................................................................................51

11.2.7 Set COMM Baud Rates ..........................................................................................................52

11.2.8 Set Modbus™ Timeouts .........................................................................................................52

11.2.9 Display Settings .....................................................................................................................53

11.3 Spare Parts and Wireless Accessories...........................................................................................................54

11.4 Revision Log.................................................................................................................................................55

Table of Figures

Figure 1 Model X40-N4X Controller ..............................................................................................................1

Figure 2 Menu Flow Chart...............................................................................................................................7

Figure 3 Magnetic Programming Tool ............................................................................................................8

Figure 4 Front Panel User Interface.................................................................................................................8

Figure 5 N1P Controller Mounting and Dimensional View..........................................................................13

Figure 6 N1P AC/DC Inputs..........................................................................................................................14

Figure 7 N1P RS-485 Port Connections........................................................................................................14

Figure 8 X40-08-N4X Controller Mounting and Dimensional View............................................................15

Figure 9 X40-32-N4X Controller Mounting and Dimensional View............................................................16

Figure 10 N4X Protective Earth Connector...................................................................................................16

Figure 11 N4X AC/DC Inputs .......................................................................................................................17

Figure 12 N4X RS-485 Master Port Connections .........................................................................................17

Figure 13 N4X RS-485 Slave Port Connections............................................................................................18

Figure 14 N4X Antenna Connector ...............................................................................................................18

Figure 15 N7 Controller Mounting and Dimensional View ..........................................................................19

Figure 16 N7 Controller Assembly w/Mounting Plate ..................................................................................20

Figure 17 N7 Controller PCA........................................................................................................................20

Figure 18 N7 AC/DC Converter Board Wiring.............................................................................................21

Figure 19 N7 DC Power Wiring ....................................................................................................................22

Figure 20 Wireless Radio Module Assembly for X40 Controller .................................................................22

Figure 21 Wireless 320 Transceiver Assembly w/Mounting Plate Dimensions ...........................................23

Figure 22 Model 100 Terminal Board to X40 Controller Wiring..................................................................23

Figure 23 Model 100 Terminal Board ...........................................................................................................24

Figure 24 Model 100 Terminal Board Rotary Switches................................................................................25

Figure 25 Wiring Diagram to the Master.......................................................................................................25

Figure 26 Wiring Diagram to the Slave.........................................................................................................26

Figure 27 I/O Module Installation .................................................................................................................27

Figure 28 Model DA-4 4-20mA Input Module and 4-20mA Gas Sensor Connections ................................28

Figure 29 Model DA-4 4-20mA Input Module and 4-20mA Gas Sensors....................................................28

Model X40

Model X40 Instruction Manual Rev. 3.0 v

Figure 30 Model DI-4 Contact Input Module................................................................................................29

Figure 31 Model AO-4 4-20mA Output Module...........................................................................................30

Figure 32 Model RL-4 Relay Output Module ...............................................................................................32

Figure 33 Modbus™ Gas Sensor Connections..............................................................................................34

Figure 34 N1P & N4X Remote Switch Input ................................................................................................44

Figure 35 N7 Remote Switch Input ...............................................................................................................44

List of Tables

Table 1 X40 Model 100 Terminal Board Connector Plugs ...........................................................................24

Table 2 AO-4 Modbus™ Addresses..............................................................................................................31

Table 3 RL-4 Relay Modbus™ Addresses ....................................................................................................33

Table 4 X40 Register Map.............................................................................................................................43

Model X40

Model X40 Instruction Manual Rev. 3.0 vi

This page left intentionally blank

Shipping Address: 4055 Technology Forest Blvd., The Woodlands Texas 77381

Mailing Address: P.O. Box 8067, The Woodlands Texas 77387-8067

Model X40

Model X40 Instruction Manual Rev. 3.0 Page 1 of 56

1. Introduction

1.1 Features

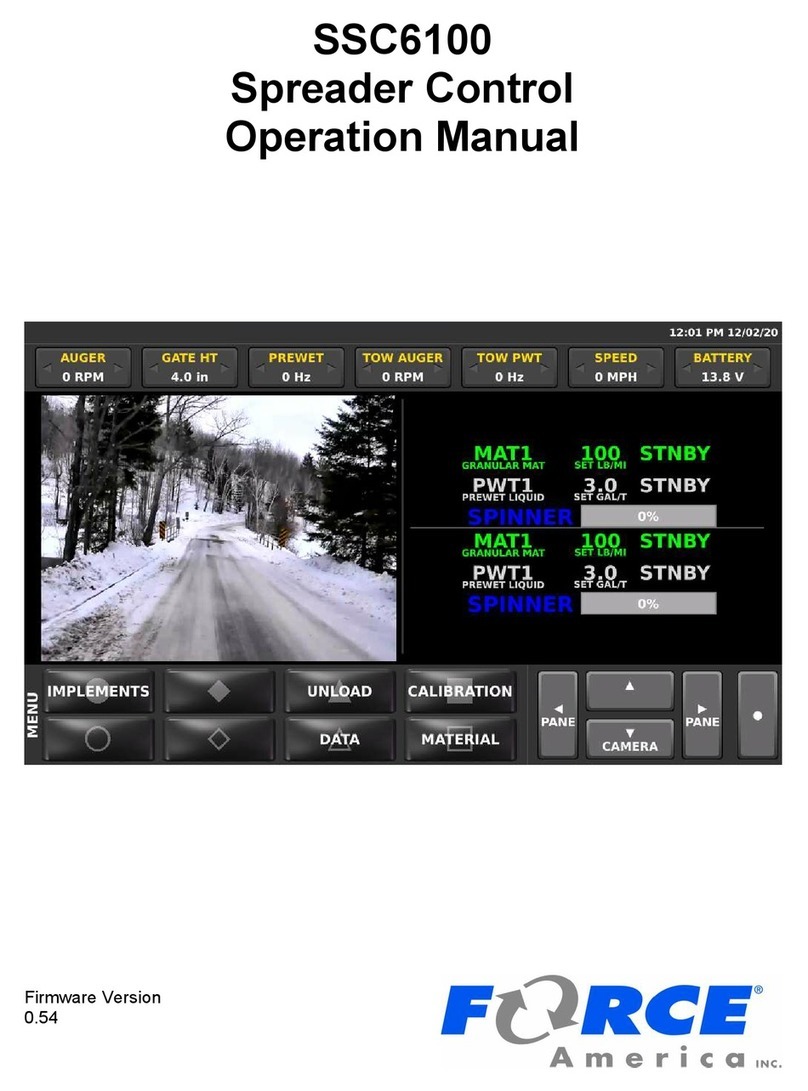

The Detcon X40 controller (Figure 1) is a multi-channel gas detection control system. The X40 serves as a

host monitor/controller for a network of gas detection sensors and various other field devices. The

controller offers a non-intrusive magnetic interface with backlit LCD display and Modbus™ technology

that supports either wireless or a hard wire sensor connection. The X40 is equipped with an auto configure

system to automatically search the Modbus™ addresses of various Detcon equipment associated with the

controller and adds the equipment to the controller without user intervention.

Remote mounted gas detection sensors include any analog 4-20mA or RS-485 (Modbus™) serial output

device such as;

•toxicgas,

•combustiblegas,or

•oxygendeficiencysensors.

Remote field devices include contact closure inputs such as:

•liquidlevel,

•temperature,

•pressure,or

•smokedetectiondevices.

Integrated Alarm & Control System

Figure 1 Model X40-N4X Controller

Model X40

Model X40 Instruction Manual Rev. 3.0 Page 2 of 56

1.2 LCD Main Display Function

The main display is an 11/4" x6" backlit LCD that is four lines by forty characters and displays up to eight

configured channels at one time. The four internal magnetic switches are located above the backlit LCD

display and offer basic navigation for a complete configuration of the controller (Section 5.1).

Real time sensor status includes;

•channelnumber,

•gasconcentration,

•devicetag(gastype)and

•alarm/faultstatus.

Each channel displays the current status of three alarm levels and a fault condition on the front panel LED

indicators.

1.3 Modbus™ Communication

The controller uses the RS-485 Modbus™ RTU protocol to communicate with serial sensors (RS-485) and

I/O modules. A secondary Modbus™ port is addressable by a PLC, PC/HMI, DCS or other Modbus™

RTU master-polling devices.

Primary Modbus™ Interface (COMM1 Master)

Uses two-wire half duplex RS-485, 9600 baud, 8 data bits, 1 stop bit, no parity. Communicates directly

with Modbus™ capable sensors and Detconꞌs independently addressable I/O modules that operate on 11.5-

30VDC.

Secondary Modbus™ Interface (COMM2 Slave)

The Modbus™slave interface communicates with the remote display or an additional controller.

1.4 Secure Digital Card (SD Card)

The X40 controller allows data logging when an SD memory card is installed. The card must be installed

on the back of the PCA (printed circuit assembly) before the controller is powered up. The controller will

automatically format the card (Section 4) and create the necessary files for data logging.

1.5 I/O Modules and Connections

A maximum of 32 channels are configurable for the X40 models and are customizable using Detconꞌs I/O

modules. Accommodation for the I/O modules relies on the type of enclosure utilized. Seamless system

expansion is accomplished through DIN rail mounted and stackable modules. The modules communicate

with the controller using Modbus™ technology and are available in four types;

•4‐20mAinputs,

•drycontactinputs,

•4‐20mAoutputs,and

•relayoutputs.

Model X40

Model X40 Instruction Manual Rev. 3.0 Page 3 of 56

The analog sensors/field devices interfaced to the I/O modules communicate with the COMM1 Modbus™

master port on the X40 controller while the serial sensors interface directly with the COMM1 port and do

not require I/O modules. The types of sensors/field devices interfaced will dictate the I/O modules required

for the X40 controller. Configuration inputs are completely field-configurable providing a distinctive

combination of flexibility and expansion for the customer.

I/O modules are factory installed unless specifically instructed otherwise. The number of I/O modules

supported by the X40 controller relies on the enclosure type due to physical space limitations. Additional

modules in excess of the maximum allowed for each enclosure type must be mounted in a separate

enclosure by the customer. The module limits for each enclosure is as follows:

•X40‐32‐N1Penclosure‐maximumoftwoI/Omodulesoutside

•X40‐08‐N4Xenclosure‐maximumofsixI/Omodulesinside

•X40‐32‐N4Xenclosure‐maximumoftwelveI/Omodulesinside

•X40‐32‐N7enclosure‐doesnotaccommodatemoduleinstallations

The X40 controller can be configured for various I/O module combinations at the Detcon factory.

Customer application/site specific information must be provided on the Configuration Form. Information

provided is verified for correct quantity and type of I/O modules to support application/site requirements.

The customer should supply the following site specific information:

1. Number of gas channels.

2. Detcon sensor model number and I/O type (Modbus™ or 4-20mA) for each channel.

3. Range, units, and gas type for each channel.

4. Alarm level(s) for each gas channel.

5. Device Tag for each channel.

6. Assignment and set-up information for each relay contact.

7. Analog output requirements for each channel.

NOTE The set-up configuration is executed by the user in the field (Section 5). Modifications to

are expected to take place on site due to requirement changes and/or system expansions.

Detcon I/O Modules (Purchased Separately)

Analog 4-20mA Sensor Inputs (DA-4)

•Providespowertoanytwoorthreewirefieldsensors

•Receivesstandard4‐20mAsignaloutputsfromthesensors

•Four4‐20mAinputstosupportuptofoursensors

•UsesRS‐485Modbus™RTUprotocoltocommunicatetothecontrollerandmusthaveaunique

Modbus™address.

Dry Contact Inputs (DI-4)

•Relaycontactoutputsfromfielddevicescanbeconnected

•Fourrelaycontactinputs

•CanbeinstalledontheDINrailofthecontroller

•UsesRS‐485Modbus™RTUprotocoltocommunicatethestateofthecontactoutputsfromfield

devicesandmusthaveauniqueModbus™address.

Analog 4-20mA Outputs (AO-4)

•Providea4‐20mAoutputequaltothecurrentconcentrationreadingreportedtothecontroller

fortheassociatedchannel.

•UsesRS‐485Modbus™RTUprotocoltoreceivethe4‐20mAoutputlevels.AO‐4modulesmust

haveauniqueModbus™address.

Model X40

Model X40 Instruction Manual Rev. 3.0 Page 4 of 56

Alarm Relay Outputs (RL-4)

•Alarmscanbeusedtocontrol(fire)annunciatingdevicesorsignalinputstoothercontroldevices.

•FourFormC,SinglePoleDoubleThrow(SPDT),5Amprelaycontactseachassignedspecificallyto

onealarm.

•UsesRS‐485Modbus™RTUprotocoltocommunicatetheoutputsandmusthaveaunique

Modbus™address.

•TheX40controllerisconfiguredwithamaximumofeightseparaterelaybankseachholdingupto

twoRL‐4modules.

•Anytimeaspecificalarm(e.g.Alarm3)isfiredforaparticularmoduleinabank(e.g.Bank2),all

correspondingalarms(e.g.Alarm3ꞌs)forallmodulesinthatparticularbank(e.g.Bank2)arealso

triggered.

Serial Output Gas Sensors (RS-485)

Serial output gas sensors can be interfaced with the X40 controller without I/O modules by connecting the

sensors in a series to the primary RS-485 Modbus™ interface (COMM1).

1.6 Enclosure Types

The X40 controller is available in three enclosure types to accommodate various customer needs. The

number of I/O modules varies depending on the enclosure type.

N1P Enclosure

The Model X40-32-N1P controller is housed in a NEMA 1 panel mount enclosure for indoor use. The

internal power supply of the N1P controller converts 90-264VAC to 24VDC (up to 7.5 Amps) and can

power a maximum of 32 sensors and associated I/O modules. A maximum of two I/O modules can be

installed on the outside of the controller. Additional modules need to be mounted separately by the

customer.

The power supply for the N1P is capable of handling AC inputs from 90-264VAC, 50-60Hz without

degradation. The X40 controller can be powered by an external DC source that meets the input

requirements (11.5-30VDC) of the unit if AC power is not preferred or available. DC power can be used

for primary or back-up power in the event of an AC power failure. RS-485 and power out are provided for

connection to sensors attached to the unit.

N4X Enclosure

The X40 controller is available in two different size models for the N4X enclosure type. Both the X40-08-

N4X and X40-32-N4X controllers are housed in a NEMA 4X water/corrosion proof enclosure for

indoor/outdoor use. The power supplies for both enclosure types are capable of handling AC inputs from

90-264VAC, 50-60Hz without degradation. The X40-N4X can be powered by an external DC source that

meets the input requirements (11.5-30VDC) of the X40 if AC power is not preferred or available. This

input can be used for primary power or back-up power in the event of an AC power failure. The DC output

voltage is capable of delivering a minimum of:

•2.5Ampsofcurrenttotheload(60Watts@24VDC)fortheX40‐08‐N4X,uptoeightsensors.

•7.5Ampsofcurrenttotheload(200Watts@24VDC)fortheX40‐32‐N4X,upto32sensors.

RS-485 master port and power out are provided for connection to serial sensors attached to the unit.

The X40-08-N4X enclosure houses a maximum of six I/O modules inside of the controller and is capable

of communicating with a maximum of 32 devices. The enclosure can incorporate integral alarms such as an

8" strobe mounted on the top of the enclosure, horn, or both.

Model X40

Model X40 Instruction Manual Rev. 3.0 Page 5 of 56

The X40-32-N4X enclosure houses a maximum of twelve I/O modules inside of the controller and

communicates with up to 32 devices.

N7 Enclosure

The X40-32-N7 controller is housed in an explosion proof NEMA 7 enclosure for indoor/outdoor use. The

N7 enclosure does not accommodate module installations. Modules must be mounted externally by the

customer. Any sensors and associated I/O modules will need to be powered separately by the customer.

The X40 controller can be powered directly by an external DC source provided by the customer, which

meets the input requirements (11.5-30VDC) of the unit. A plug-in male connector is provided for input

wiring terminations. A plug-in male connector provides quick disconnect convenience during replacement

or servicing.

An optional AC/DC converter board inside a condulet/J-Box is available from Detcon to only power the N7

controller with an AC voltage source. The converter uses AC inputs between 90-264VAC and provides a

24VDC (up to 167mA) output. Power to I/O modules or sensors must be provided by the customer.

Detcon offers an optional mounting plate for mounting the X40-32-N7 controller to a pole.

1.7 Alarms and Fault Condition

The alarms (Alarm 1, Alarm 2, Alarm 3, and Fault) can be used to control annunciating devices or as signal

inputs to other control devices. The field configurable magnetic user interface permits alarm values and

fault condition to cause an assigned relay or bank of relay outputs to fire, triggering external alarm devices.

The assigned relay outputs will return to normal state when a gas alarm or a fault condition clears.

Additionally, an external manual switch can be wired to the X40, acting as an acknowledge/reset switch

(Section 1.12).

When the X40 is in alarm, the display will remain on the channel group with the alarm. When there is more

than one alarm/fault, the controller will cycle through group pages with alarms/faults including the

transceiver, RL-4/alarm station, and AO-4 group pages. The user can manually cycle to any group page that

exists using the arrow switches. After a time out period, the X40 will resume page cycle protocols based

upon the existence of alarms/faults. Four LED indicators on the front panel show alarm/fault alarm output

status and are labeled respectively as ALM 1 (yellow), ALM 2 (yellow), ALM 3 (red), and FAULT (blue).

All alarms can be configured Energized/De-Energized, Latching/Non-Latching and Silenceable/Non-

Silenceable for the relays.

Energized Mode

The normally open contact is closed if the alarm level has not been reached or if the sensor is not in fault.

Energized mode provides for fail-safe operation since a loss of power or cable failure will cause the contact

to be open.

De-Energized Mode

The normally open contact is open if the alarm level has not been reached or if the sensor is not in fault.

Silenceable

The corresponding alarm LED and relay can be deactivated by acknowledging the Alarm Silence function

on the front panel of the X40 controller or by activating the external acknowledge switch if installed

(Section 0 and 7).

Model X40

Model X40 Instruction Manual Rev. 3.0 Page 6 of 56

Non-Silenceable

The corresponding alarm LED and relay will remain activated until the cause of the alarm or fault is clear.

Latching Mode

The relay can be deactivated after the alarm condition has cleared by acknowledging the Alarm Reset

function on the front panel of the X40 controller or by activating the external reset switch if installed

(Section 0 and 7).

Non-Latching Mode

The relay is deactivated as soon as the sensor alarm or fault condition is clear.

1.8 System Operation

The setup of the controller is critical for proper operation. Modbus™ addresses must be correct on all the

devices connected to the controller before the controller will acknowledge the devices. Each wireless

sensor must have a unique Modbus address (refer to sensor manual for details). The number of sensors is

determined during auto configure if the addresses on the sensors and modules are set correctly.

The operator interface of the X40 utilizes four internal magnetic switches located above the controllerꞌs

backlit LCD display. The four switches provide a non-intrusive interface and allow for complete

configuration of the controller and are labeled as follows:

•PROG,

•u(UpArrow),

•v(DownArrow)and

•ENTER.

The ENTER switch also doubles as a RESET/ACK switch from the Main Display only (not in Menu

Mode).

Model X40

Model X40 Instruction Manual Rev. 3.0 Page 7 of 56

1.9 Operator Interface

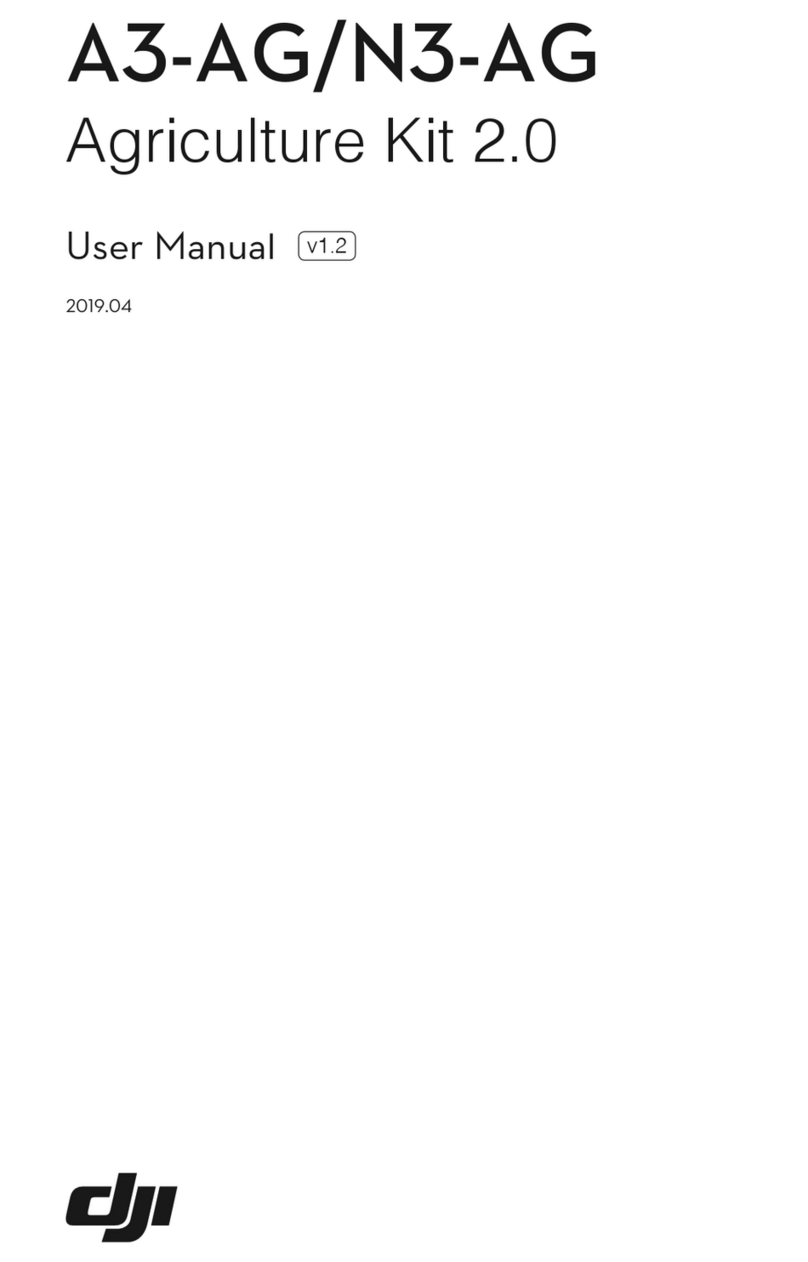

Reference the Menu Flow Chart (Figure 2) to learn how to easily navigate the menus and make changes.

MAIN DISPLAY

NORMAL OPERATION

UTILITY MENU

SET RF SILENCE

AND RF SLEEP

UTILITY MENU

SET COMM BAUD RATES

UTILITY MENU

SETUP CHANNEL DATA

MAIN MENU

SET CHANNEL ALARMS

UTILITY MENU

SET MODBUS TIMEOUTS

RF SILENCE: ON/OFF

RF SLEEP: ##:##

RF SLEEP: ON/OFF

COMM1 BAUD RATE: ####

COMM2 BAUD RATE: ####

RESPONSE TIMEOUT: ####

INTERPOLL DELAY: ####

SLAVE ID: ## in hex

DEVICE TYPE: XXXXXX

ANALOG INPUT: #

DECIMAL POINT: #

RANGE: #####

TYPE: XXXXXXXXX

RL4 BANK: XXX

ALM1 LEVEL: ##

ALM1 ASCENDING: Y/N

ALM2 LEVEL: ##

ALM2 ASCENDING: Y/N

ALM3 LEVEL: ##

ALM3 ASCENDING: Y/N

UTILITY MENU

SET MODBUS ADDRESS

MAIN MENU

SET RELAY FUNCTION

MAIN MENU

INHIBIT & ALARM TEST MODE

MAIN MENU

SYSTEM DIAGNOSTICS

UTILITY MENU

DISPLAY SETTINGS

MODBUS ADDRESS: ###

LATCHING (Bank1): Y/N

ENERGIZED (Bank1): Y/N

SILENCEABLE (Bank1): Y/N

LATCHING (Bank2): Y/N

ENERGIZED (Bank2): Y/N

SILENCEABLE (Bank2): Y/N

INHIBIT MODE: #:##

INHIBIT MODE: START/STOP

ALARM TEST MODE: ON/OFF

BRIGHTNESS: ###

BACKLIGHT TIMEOUT: #:##

CONTRAST: ###

Multiple Channels

Multiple Channels

Multiple Relays

(Fault, Alm1, Alm2, Alm3)

LCD DISPLAY TEST

LED DRIVER TEST

EXT RESET SWITCH TEST

RELAY DRIVER TEST

MODBUS DRIVER TEST

MAIN MENU

AUTO CONFIGURE SYSTEM

CHANNELS: ##

AO4S: #

RXT-320S:##

RL4/ALM BANK 1: #

RL4/ALM BANK 2: #

MAIN MENU

TIME AND DATE

TIME: HH:MM:SS

DATE: MM/DD/YY

MAIN MENU

VIEW TWA & PEAK

DATE,TIME,CHANNEL,

TWA:######,PEAK: ######

UTILITY MENU

UTILITY MENU

SET LOW BATTERY ALARMS

TTE(DD:HH:MM): ##:##:##

SOC(%): ###%

UTILITY MENU

SET CXT LOW BATTERY

THRESHOLD

THRESHOLD: 5-7 VDC

UTILITY MENU

SET MODBUS UPDATE INTERVAL

UPDATE INTERVAL: 0-5 mins

Figure 2 Menu Flow Chart

Model X40

Model X40 Instruction Manual Rev. 3.0 Page 8 of 56

1.9.1 Magnetic Programming Tool

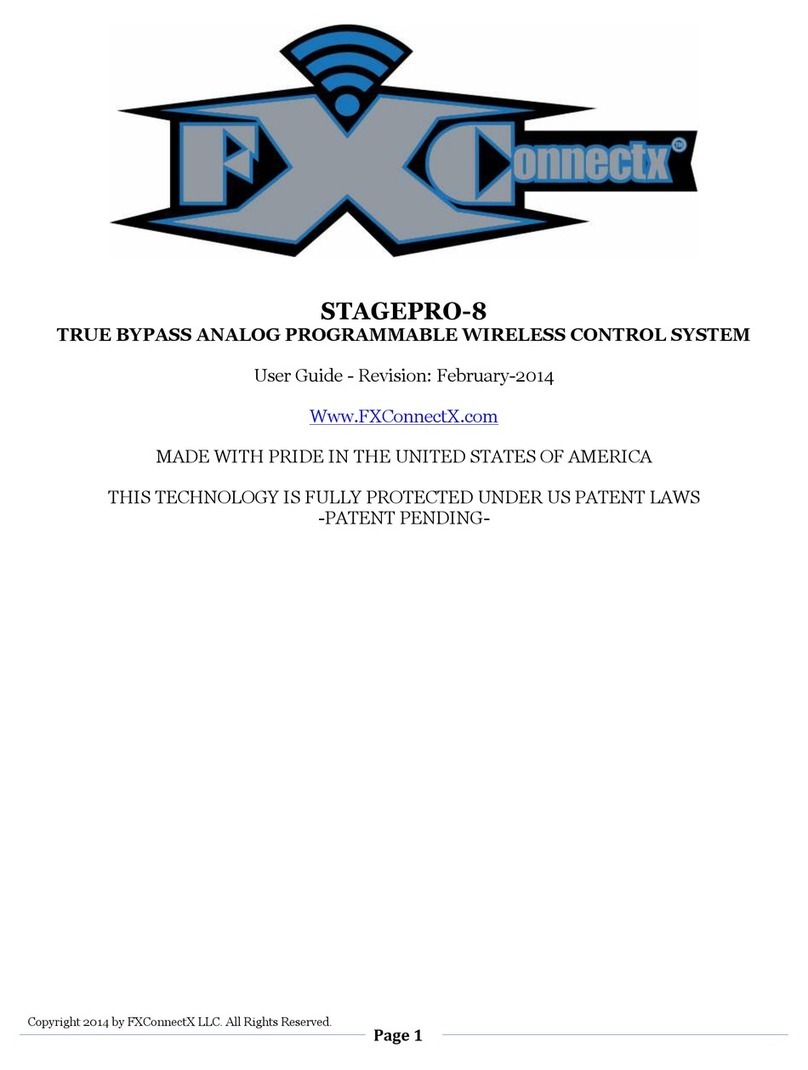

The magnetic programming tool (Figure 3) is used to operate the magnetic switches. For switch activation,

the programming magnet is briefly held on the switch marker (⊗) and then removed. This action will be

referred to as a "swipe" for the remainder of this manual.

Figure 3 Magnetic Programming Tool

1.9.2 Front Panel User Interface

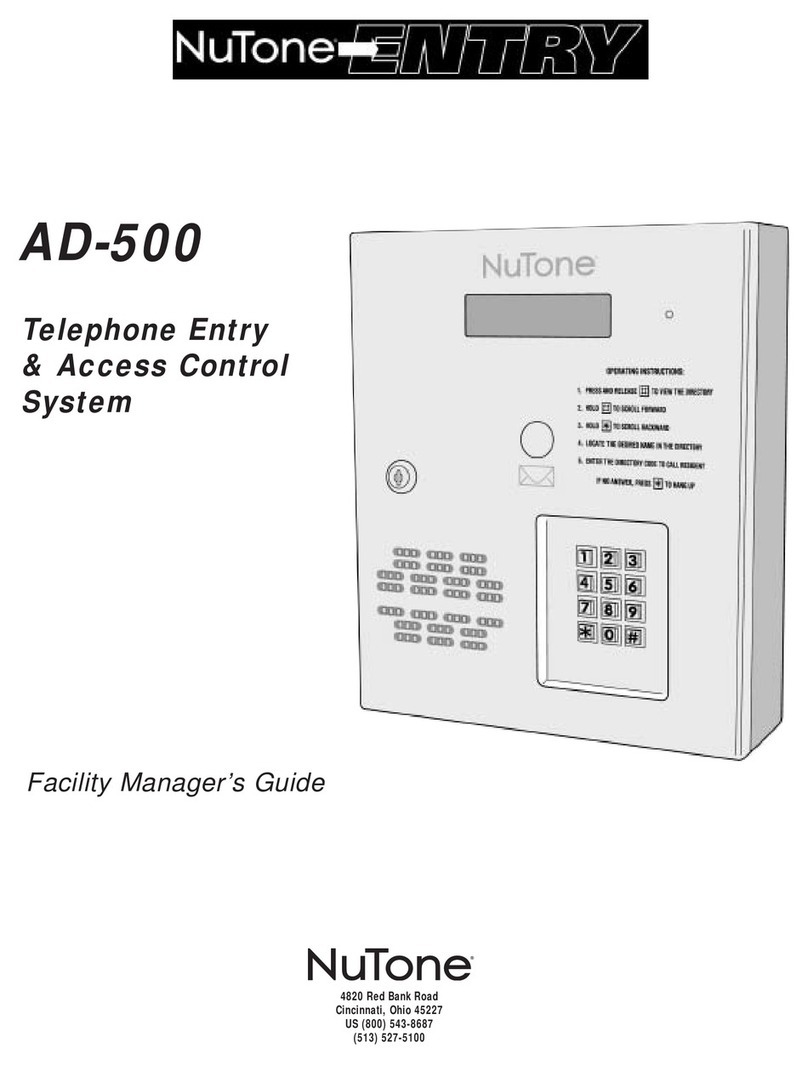

The front panel user interface (Figure 4) contains four switches necessary to configure the X40 controller.

Integrated Alarm & Control System

Figure 4 Front Panel User Interface

PROG Switch

From the Main Display, the PROG switch enters into the Main Menu. Once inside the Main Menu, the

PROG switch acts as an "Escape" switch that moves backwards in the menu flow chart.

NOTE While in Main Menu mode there are no updates to gas readings and hence no alarms will

take place.

uUp Arrow Switch

This switch moves the user up the Main Menu flow chart. It is also used to change selected entries in

the menu selections in the upward direction.

vDown Arrow Switch

This switch moves the user down the Main Menu flow chart. It is also used to change selected entries

in the menu selections in the downward direction.

Model X40

Model X40 Instruction Manual Rev. 3.0 Page 9 of 56

ENTER and RESET/ACK Switch

This switch has multi-purpose use:

•TheENTERfunctionisusedtoacceptselectionsinallmenuscreensandtoexecutetheReset

andAcknowledgefunctions.

•TheResetfunctionreleasesalllatchedrelaysoncethealarm/faultconditionhascleared.

•TheAcknowledgefunctionwilldisengageanysilenceablerelaysthatareinanactivestate.

Thisisusedtosilencealarmsoncetheend‐userhasassessedthealarmcondition.

•TheRESET/ACKNOWLEDGEfunctionoftheswitchisonlyapplicablefromtheMainDisplay

andnotwhileinMainMenumode.

1.10 Main Display Functions

When the X40 is in alarm, the LCD display will stay on the channel group with the channel in alarm. If

more than one alarm/fault exists, the X40 will cycle through group pages with alarms/faults including the

transceiver, RL-4/alarm station, and AO-4 group pages. At any time the user can manually cycle to any

group page using the arrow switches. After a time out period (15 seconds), the X40 will resume page cycle

protocols based upon the existence of alarms/faults. Four LED indicators on the front panel show alarm and

fault alarm output status. The LEDs represent ALM 1 (yellow), ALM 2 (yellow), ALM 3 (red) and FAULT

(blue).

NOTE The X40 only cycles through sensor group pages when no alarms/faults exist.

1.10.1 Sensor Group

XX> YYY "Device Tag"

XX – represents the corresponding channel number

YYY – the gas concentration value

"Device Tag" – Either user enter tag or:

•INALARM#=Ifanychannelisinanygasalarmcondition,#isthealarmlevel.

•INFAULT=Ifanygaschannelisinfault.

•COMMERR=Ifanychannelisnotappropriatelycommunicatingwiththedevice.

1.10.2 Transceiver Group

WTXX ‘Status’ YYY%

XX – represents the transceiver Modbus™ slave address.

‘Status’ – Status message of the alarm station.

•OFFLINE=Notcommunicating.

•DCPOWER=Communicating;linepowered.

•BATTERR=Communicating;cannotreadsmartbatterypack.

•LOWBATT=Communicating;smartbatterytimetoemptybelowthesetthreshold.

•45+DAYS=Communicating;smartbatterypackhasmorethan45daysbeforeempty.

•0‐45DAYS=Communicating;thenumberofdaysuntilsmartbatterypackisempty.

YYY% - represents the link quality of the transceiver.

Model X40

Model X40 Instruction Manual Rev. 3.0 Page 10 of 56

1.10.3 RL4/Alarm Stations Group

Hardwired RL4 Module

RMXX> ‘Status’

XX – represents the RL4 Modbus slave address.

‘Status’ – Status message of the RL4 module.

•COMMERR=Notcommunicatingwithmodule.

•RL4MODULE=Communicatingwithmodule.

Wireless Alarm Stations

ASXX ‘Status’ YYY%

XX – represents the alarm station Modbus slave address.

‘Status’ – Status message of the alarm station.

•OFFLINE=Notcommunicating.

•DCPOWER=Communicating;linepowered.

•BATTERR=Communicating;cannotreadsmartbatterypack.

•LOWBATT=Communicating;smartbatterystateofchargebelowthesetthreshold.

•0–100%=Communicating;currentstateofchargeofthesmartbatterypack.

YYY% - represents the link quality of the alarm station.

1.10.4 AO-4 Group

AMXX> ‘Status’

XX – represents the AO-4 module Modbus slave address

‘Status’ – Status message of the AO - 4 module

•COMMERR=Notcommunicatingwithmodule

•AO‐4MODULE=Communicatingwithmodule

1.11 Menu Function

The X40 controller setup is accomplished through the Main Menu and consists of seven menu items:

1. Auto Configure System

2. Set Channel Alarms

3. Set Relay Function

4. Inhibit & Alarm Test Mode

5. System Diagnostics

6. Time and Date

7. View TWA & Peak

Auto Configure System

The Auto Configure System automatically configures the X40 controller when other Detcon devices are

installed as part of the control system. When activated, the controller searches for Detcon serial sensors,

RL-4 modules/alarm stations, AO-4 modules and wireless radio modules.

Set Channel Alarms

All sensors have three alarm settings ALM1 (Alarm 1), ALM2 (Alarm 2) and ALM3 (Alarm 3). The user

establishes the alarm levels for each sensor depending on the range. The values represent the alarm level set

points and entered in 5% increments of the full-scale range selected for that channel. In ascending mode the

Model X40

Model X40 Instruction Manual Rev. 3.0 Page 11 of 56

relay is activated when the concentration is above the alarm threshold. In descending mode, the alarm relay

is activated when the concentration is below the alarm threshold. Alarms are usually ascending, with the

exception of oxygen sensors. The alarm ascending level can be either Y (Yes) or N (No).

Set Relay (Alarm) Functions

The Set Relay Functions menu enables configuration (Latching, Energized and Silenceable) of the relays in

Bank1-8. Each relay bank has three relay outputs for ALM1, ALM2 and ALM3 and the fourth relay output

is the Fault condition. All relays in the bank must be configured for the following three settings:

•LatchingorNon‐Latching,

•EnergizedorDe‐Energized,and

•SilenceableorNon‐Silenceable.

Inhibit and Alarm Test Mode

The Inhibit and Alarm Test Mode permits the user to inhibit functionality of alarms in the network,

simulate alarm conditions and verify relay contacts. The Inhibit mode disables alarm outputs while sensor

are being calibrated or tested. The Alarm Test Mode simulates alarm conditions by increasing the gas

readings from zero for all active gas channels at increments of 5% full scale then decrease back to zero and

exit the test mode.

System Diagnostics

The System Diagnostics menu performs complete functionality tests for;

•LCDdisplay,

•PanelLEDꞌs,

•Externalresetswitch,

•Relays,and

•Modbus™interface.

Time and Date

The Time and Date menu enables the user to effortlessly establish the time and date. The time will be

displayed as military time (24hrs) in hours, minutes and seconds. The date will be displayed as the month,

day and two digit year. If the time and/or date are not correct, they can be updated.

View TWA and Peak

The View TWA and Peak menu permits viewing the recorded time weighted average (TWA) and peak

readings for each channel represented by its assigned gas sensor. The data is recorded on the SD card with

the date, time, channel number, TWA and peak readings each time the controller polls a sensor. Data on the

SD card is viewed by using the Detcon Log File Viewer application on a computer.

1.12 Optional Remote Alarm Reset/Acknowledge Switch

An optional remote Alarm Reset/Acknowledge switch enables the user to reset or acknowledge alarms

without having to open the X40 enclosure. The switch is a normally open push button mounted on the

bottom or side of the NEMA 4X enclosure. For the N1P and N7 enclosures, the switch must be mounted

externally (e.g. bottom of the J-Box).

1.13 Wireless Option

Wireless Option

The Model X40 controller offers a wireless option that uses Modbus™ technology to connect the controller

and other devices to a wireless platform. The local Modbus™ communication uses a wireless grid of

transceivers to broadcast information throughout the wireless network, creating a seamless network of

Modbus™ devices that are not physically connected.

Model X40

Model X40 Instruction Manual Rev. 3.0 Page 12 of 56

Detconꞌs wireless radio module is factory installed inside of the X40 enclosure, transmits signal data

(analog 4-20mA DC or serial Modbus™) and can support up to 32 devices. The transceiver operates at

2.4GHz and conforms to non-licensed radio frequency usage worldwide. Spread spectrum technology

supports integrity and security for the wireless network.

Wireless applications can be a single field device communicating with a host controller or multiple field

devices forming a network of subscribers. Each device in the network is assigned a Network ID and a

Modbus™ address. If radio communication is impossible due to distance or obstruction, each slave device

is capable of locating an alternate route using an additional radio to communicate with the designated

device. This innovative technology is designed to create a robust network that automatically routes around

congestion and line-of-sight obstacles while improving throughput as subscriber device density increases.

Refer to the Wireless Radio Module instruction manual for detailed information.

Wireless Radio Module Mounting

The wireless radio module for the X40 controller is factory mounted on a J-Box. Detcon offers an optional

mounting plate that can be used for mounting the wireless assembly on a pole near the controller. Remote

separation distances of up to 2000 feet are probable with the recommended cable.

The radio module is factory installed in the N4X enclosure. The antenna can be installed (Section 2.3) on

the top of the enclosure or separated up to 50m using Detconꞌs remote antenna mounting kit. For the N7,

the antenna is mounted to the attached J-Box or can be remotely mounted (Section 2.4).

Model X40

Model X40 Instruction Manual Rev. 3.0 Page 13 of 56

2. Installation

2.1 Safety Guidelines

If equipment is used in a manner not specified by Detcon, the protection provided by the equipment may be

impaired.

CAUTION

The user must consult this manual for more information about any location marked

with this symbol.

DANGER

Danger of electrical shock. User must ensure that power has been disconnected

prior to installation or servicing of the equipment.

2.2 N1P Enclosure Installation

CAUTION

The X40-32-N1P unit can power a maximum of 32 sensors. Damage to the power

supply may result if the maximum number of sensors is exceeded.

1. Provide a panel opening that is 9.25" wide by 7.5" high for the controller.

2. Securely mount the X40-32-N1P controller at an indoor location using the mounting dimensions

provided in Figure 5.

3.5" 8" 7"

7"

1.69" 12"

0.218"

0.375"

R0.109"

Slot Detail

I/O Modules

(Qty. of 2 Max)

9.75"

10.5"

Figure 5 N1P Controller Mounting and Dimensional View

3. Ensure that the AC signal/wiring is not housed in the same conduit as the DC signal/wiring.

NOTE The power supply for the X40-32-N1P is capable of handling AC inputs between 90-

264VAC, 50-60Hz without degradation.

Model X40

Model X40 Instruction Manual Rev. 3.0 Page 14 of 56

4. Install AC or DC power as follows (Figure 6):

a. Install AC power by connecting the 90-264VAC input wiring to the terminals labeled VAC

(L1), NEU (L2), and GROUND.

b. Install DC power by connecting the 11.5-30VDC to the terminals of the DIN rail mounted

terminal block labeled 24VDC and DC Comm.

NOTE The DC input voltage should be capable of delivering at least 8 Amps of current to the load

(200 Watts @ 24VDC).

NOTE The supply of power should be from an isolated source with over-current protection and an

input voltage range between 11.5-30VDC.

I ON

C3A

WMS1C03

240V- 10000

I ON

C3A

WMS1C03

240V- 10000

O

I

5A

24VDC

GROUND

VAC (L1)

NEU (L2)

Figure 6 N1P AC/DC Inputs

5. Connect the external Modbus™ sensors at the RS-485 connections labeled RS-485 Master and A

BShld (Figure 7).

RS-485

SLAVE

AB

RS-485 VDC

Out

A

B

+

Figure 7 N1P RS-485 Port Connections

6. If 24VDC is required to power external sensors, connect the sensors to the power terminals labeled

VDC Out and +–.

7. If linking the X40 enclosure to an RD-64X remote display unit, connect the unit to the terminals

labeled RS-485 Slave and ABShld.

Other manuals for X40-08-N4X

1

This manual suits for next models

3

Table of contents

Other Detcon Control System manuals