SB-6-146-K (10/2015) 1 / 4

SERVICE MANUAL

HFRL-508 60 CFM

FILTER-REGULATOR

HAF-502 100 CFM FILTER

Risk of personal injury.

Risk of property damage.

Except as otherwise specified by the manufacturer, this

product is specifically designed for compressed air service

and use with any other fluid (liquid or gas) is a misap-

plication. For example, use with or injection of certain

hazardous gases in the system (such as oxygen or liquid

petroleum gas) could be harmful to the unit or result in a

combustible condition that may cause fire or explosion.

Manufacturer’s warranties are void in the event of misap-

plication and manufacturer assumes no responsibility for

any resulting loss.

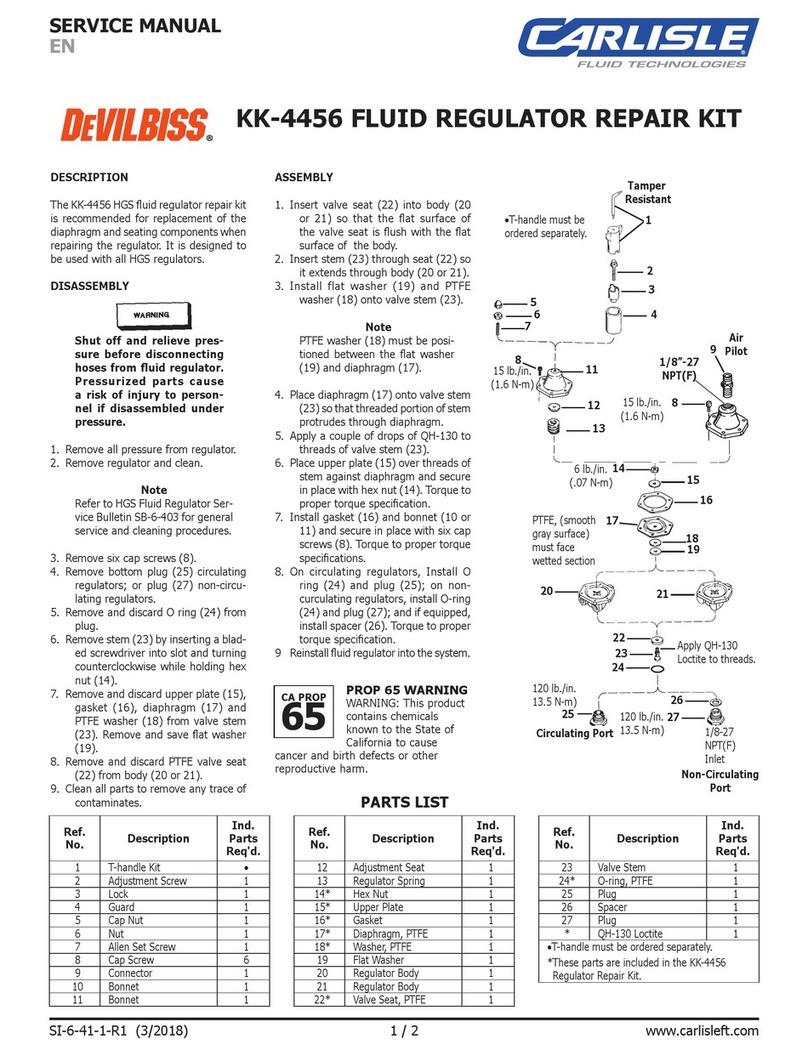

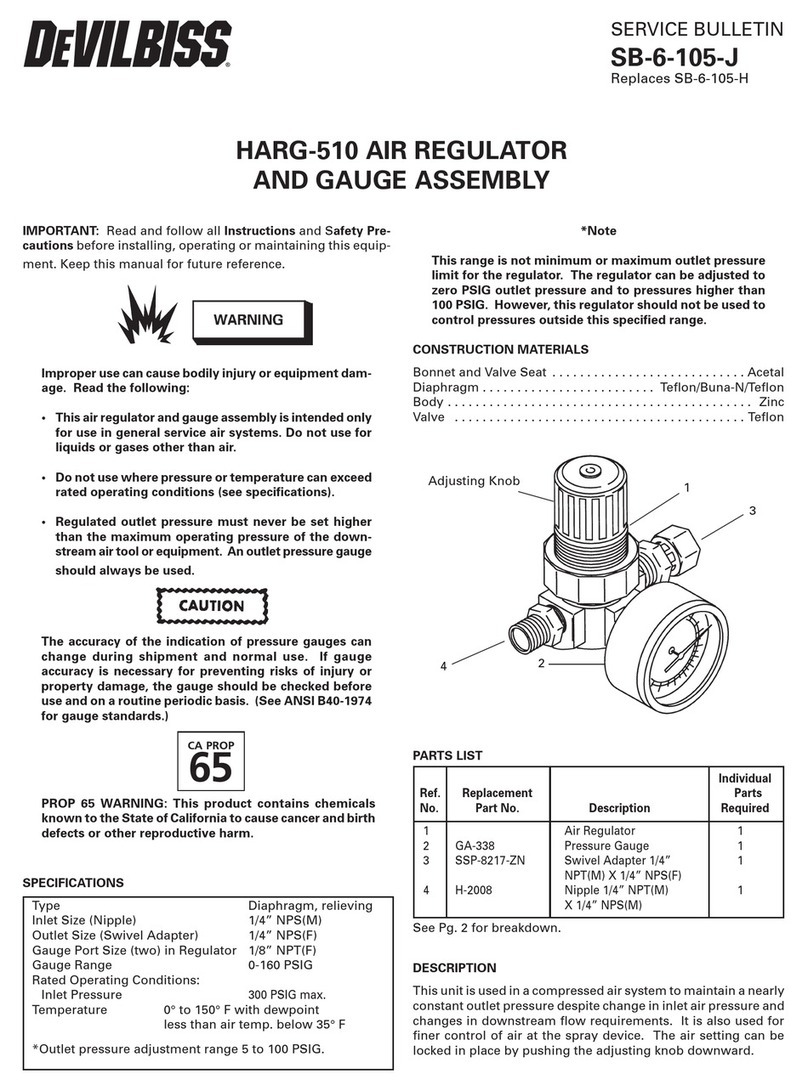

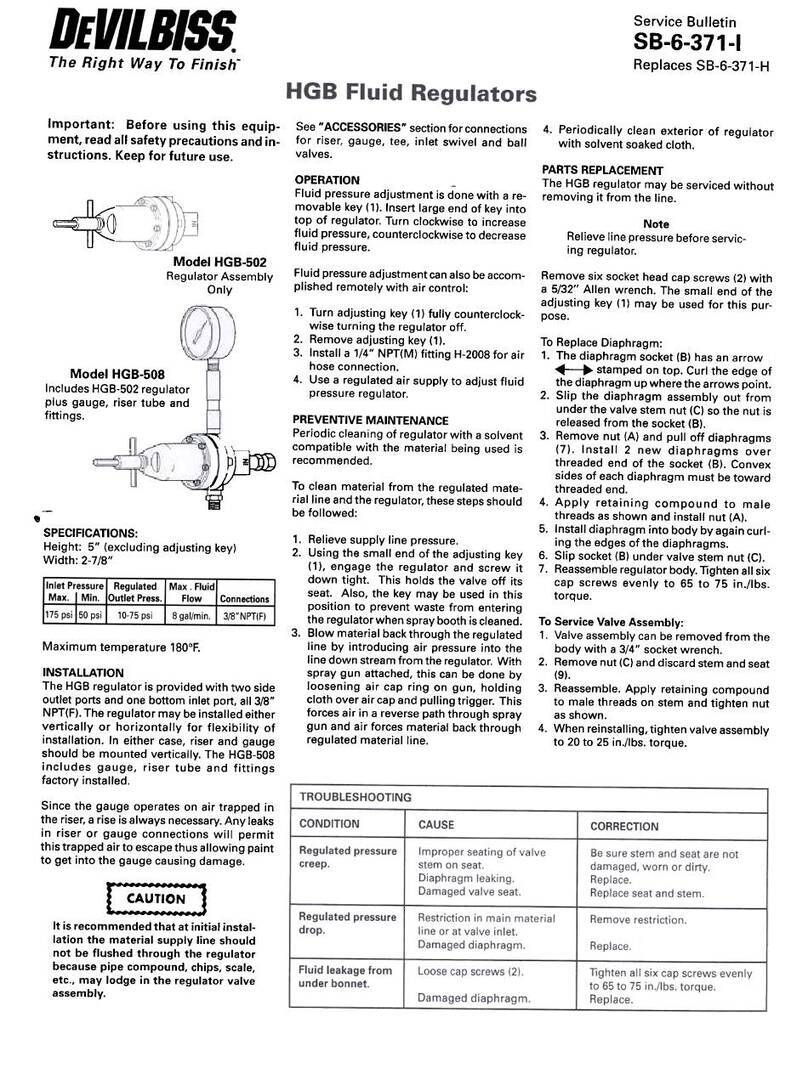

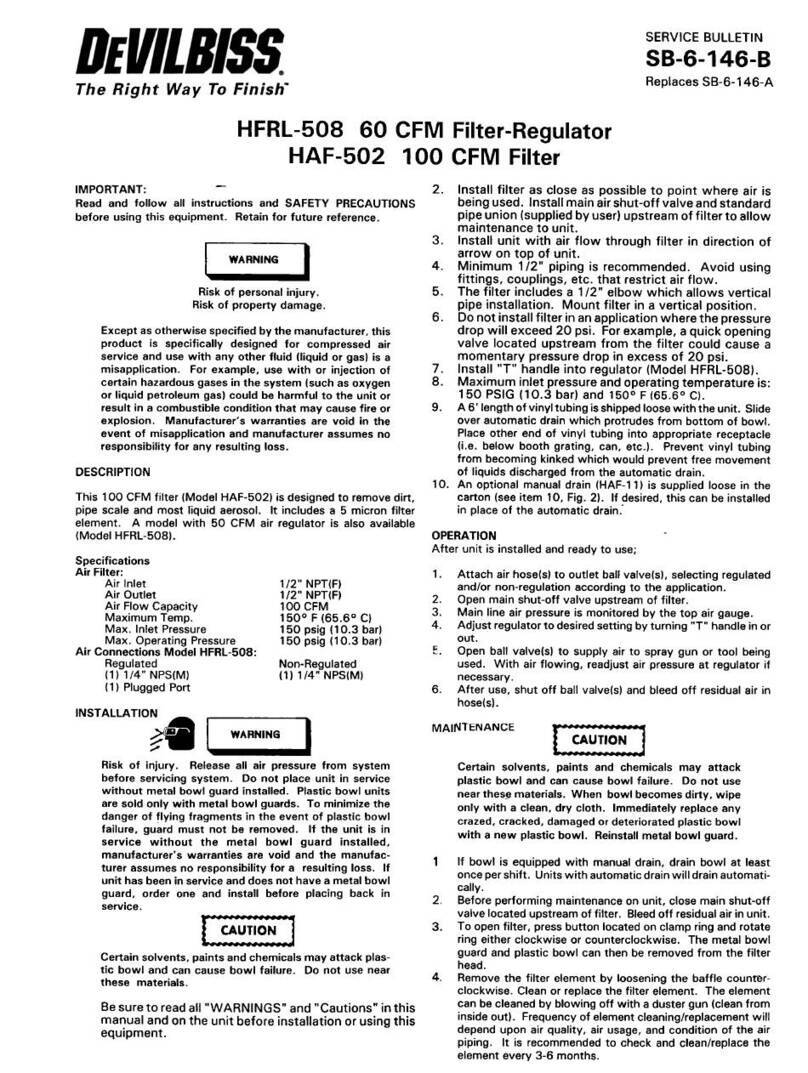

DESCRIPTION

This 100 CFM filter (Model HAF-502) is designed to remove dirt, pipe

scale and most liquid aerosol. It includes a 5 micron filter element. A

model with 50 CFM air regulator is also available (Model HFRL-508).

Specifications

Air Filter:

Air Inlet 1/2" NPT(F)

Air Outlet 1/2" NPT(F)

Air Flow Capacity 100 CFM

Maximum Temp. 150° F (65.6° C)

Max. Inlet Pressure 150 psig (10.3 bar)

Max. Operating Pressure 150 psig (10.3 bar)

Air Connections Model HFRL-508:

Regulated Non-Regulated

(1) 1/4" NPS(M) (1) 1/4" NPS(M)

(1) Plugged Port

INSTALLATION

Risk of injury. Release all air pressure from system

before servicing system. Do not place unit in ser-

vice without metal bowl guard installed. Plastic bowl

units are sold only with metal bowl guards. To minimize the

danger of flying fragments in the event of plastic bowl failure,

guard must not be removed. If the unit is in service without

the metal bowl guard installed, manufacturer's warranties

are void and the manufacturer assumes no responsibility

for a resulting loss. If unit has been in service and does not

have a metal bowl guard, order one and install before plac-

ing back in service.

Certain solvents, paints and chemicals may attack plastic bowl

and can cause bowl failure. Do not use near these materials.

IMPORTANT:

Read and follow all instructions and SAFETY PRECAUTIONS before

using this equipment. Retain for future reference.

1. Be sure to read all "WARNINGS"and "CAUTIONS"in

this manual and on the unit before installation or using this

equipment.

2. Install filter as close as possible to point where air is

being used. Install main air shut-off valve and standard

pipe union (supplied by user) upstream of filter to allow main-

tenance to unit.

3. Install unit with air flow through filter in direction of arrow on

top of unit.

4. Minimum 1/2" piping is recommended. Avoid using

fittings, couplings, etc. that restrict air flow.

5. A 1/2" street elbow will be needed to allow vertical pipe instal-

lation. Mount filter in a vertical position.

6. Do not install filter in an application where the pressure drop

will exceed 20 psi. For example, a quick opening valve located

upstream from the filter could cause a momentary pressure drop

in excess of 20 psi.

7. Install "T" handle into regulator (Model HFRL-508).

8. Maximum inlet pressure and operating temperature is:

150 PSIG (10.3 bar) and 150° F (65.6° C).

9. A 6' length of vinyl tubing is shipped loose with the unit. Slide

over automatic drain which protrudes from bottom of bowl. Place

other end of vinyl tubing into appropriate receptacle (i.e. below

booth grating, can, etc.). Prevent vinyl tubing from becoming

kinked which would prevent free movement of liquids discharged

from the automatic drain.

10. An optional manual drain (HAF-11) is supplied loose in the

carton (see item 10, Fig. 2). If desired, this can be installed

in place of the automatic drain.

OPERATION

After unit is installed and ready to use:

1. Attach air hose(s) to outlet ball valve(s), selecting regulated and/

or non-regulation according to the application.

2. Open main shut-off valve upstream of filter.

3. Main line air pressure is monitored by the top air gauge.

4. Adjust regulator to desired setting by turning "T" handle

in or out.

5. Open ball valve(s) to supply air to spray gun or tool being

used. With air flowing, readjust air pressure at regulator

if necessary.

6. After use, shut off ball valve(s) and bleed off residual air in hose(s).

MAINTENANCE

Certain solvents, paints and chemicals may attack plastic

bowl and can cause bowl failure. Do not use near these ma-

terials. When bowl becomes dirty, wipe only with a clean, dry

cloth. Immediately replace any crazed, cracked, damaged or

deteriorated plastic bowl with a new plastic bowl. Reinstall

metal bowl guard.

1. If bowl is equipped with manual drain, drain bowl at least once

per shift. Units with automatic drain will drain automatically.

2. Before performing maintenance on unit, close main

shut-off valve located upstream of filter. Bleed off residual air

in unit.

3. To open filter, press button located on clamp ring and

rotate ring either clockwise or counterclockwise. The metal bowl

guard and plastic bowl can then be removed from the filter head.