Service Bulletin

SB-6-371-1

Replaces SB-6-371-H

The Right Way To Finish-

Important: Before using this equip-

ment, read all safety precautions and in-

structions. Keep for future use.

See" ACCESSORIES" section for connections

for riser, gauge, tee, inlet swivel and ball

valves.

4. Periodically clean exterior of regulator

with solvent soaked cloth.

PARTS REPLACEMENT

The HGB regulator may be serviced without

removing it from the line.

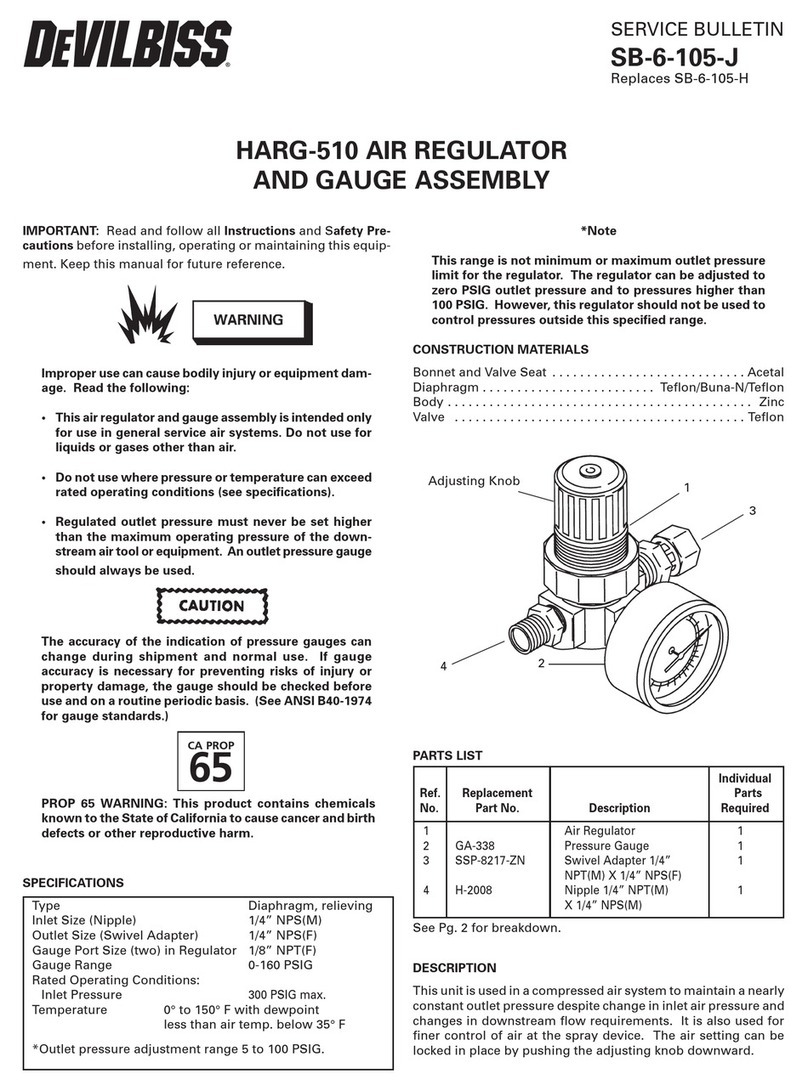

OPERATION

Fluid pressure adjustment is done with a re-

movable key (1). Insert large end of key into

top of regulator. Turn clockwise to increase

fluid pressure, counterclockwise to decrease

fluid pressure.

~

Note

Relieve line pressure before servic-

ing regulator.

Model HGB-502

Regulator Assembly

Only

Fluid pressure adjustment can also be accom-

plished remotely with air control: Remove six socket head cap screws (2) with

a 5/32" Allen wrench. The small end of the

adjusting key (1) may be used for this pur-

pose.

Model HGB-508

Includes HGB-502 regulator

plus gauge, riser tube and

fittings.

1. Turn adjusting key (1) fully counterclock-

wise turning the regulator off.

2. Remove adjusting key (1).

3. Install a 1/4" NPT(M) fitting H-2008 for air

hose connection.

4. Use a regulated air supply to adjust fluid

pressure regulator.

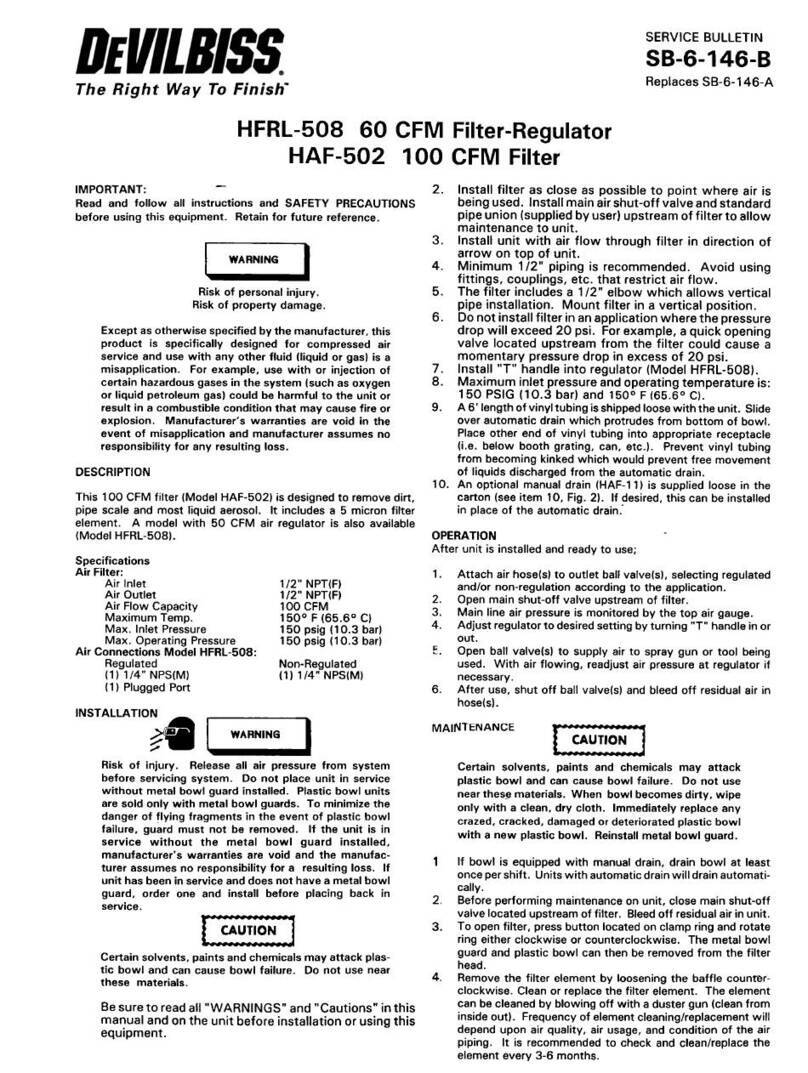

PREVENTIVE MAINTENANCE

Periodic cleaning of regulator with a solvent

compatible with the material being used is

recommended.

~

rTo clean material from the regulated mate-

rial line and the regulator, these steps should

be followed:

.SPECIFICATIONS:

Height: 5" (excluding adjusting key)

Width: 2-7/8"

1. Relieve supply line pressure.

2. Using the small end of the adjusting key

(1), engage the regulator and screw it

down tight. This holds the valve off its

seat. Also, the key may be used in this

position to prevent waste from entering

the regulator when spray booth is cleaned.

3. Blow material back through the regulated

line by introducing air pressure into the

line down stream from the regulator. With

spray gun attached, this can be done by

loosening air cap ring on gun, holding

cloth over air cap and pulling trigger. This

forces air in a reverse path through spray

gun and air forces material back through

regulated material line.

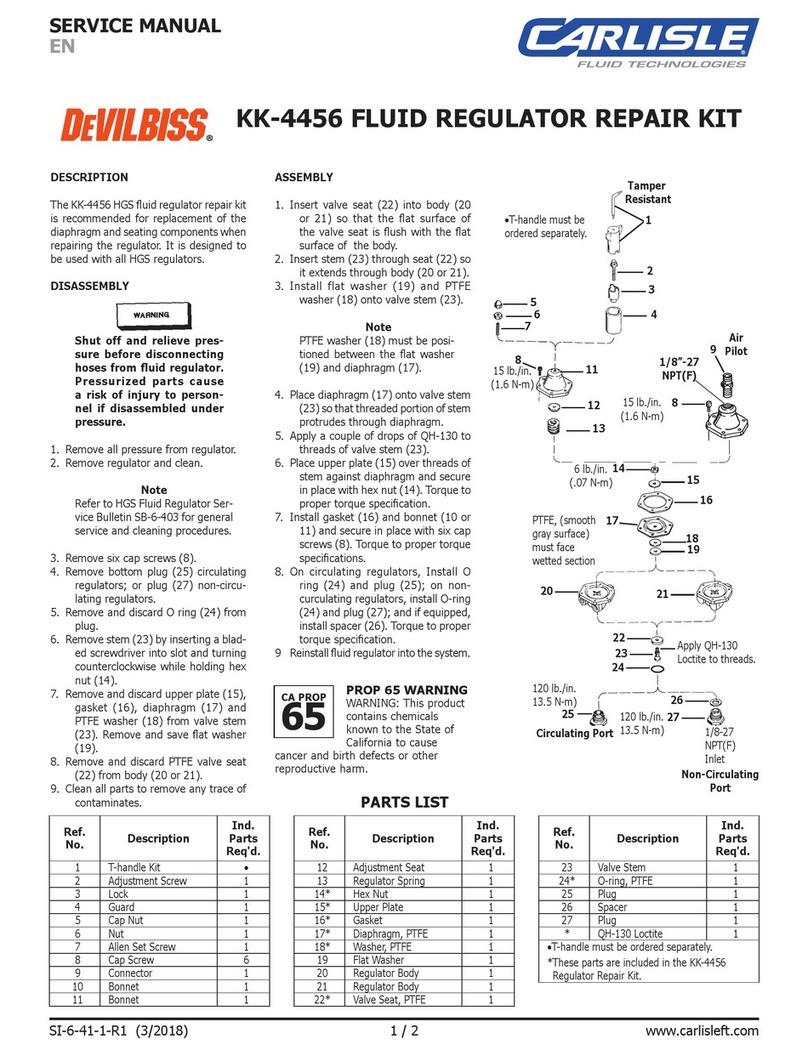

To Replace Diaphragm:

1. The diaphragm socket (8) has an arrow

stamped on top. Curl the edge of

the diaphragm up where the arrows point.

2. Slip the diaphragm assembly out from

under the valve stem nut (C) so the nut is

released from the socket (8).

3. Remove nut (A) and pull off diaphragms

(7). Install 2 new diaphragms over

threaded end of the socket (8). Convex

sides of each diaphragm must be toward

threaded end.

4. Apply retaining compound to male

threads as shown and install nut (A).

5. Install diaphragm into body by again curl-

ing the edges of the diaphragms.

6. Slip socket (8) under valve stem nut (C).

7. Reassemble regulator body. Tighten all six

cap screws evenly to 65 to 75 in./lbs.

torque.

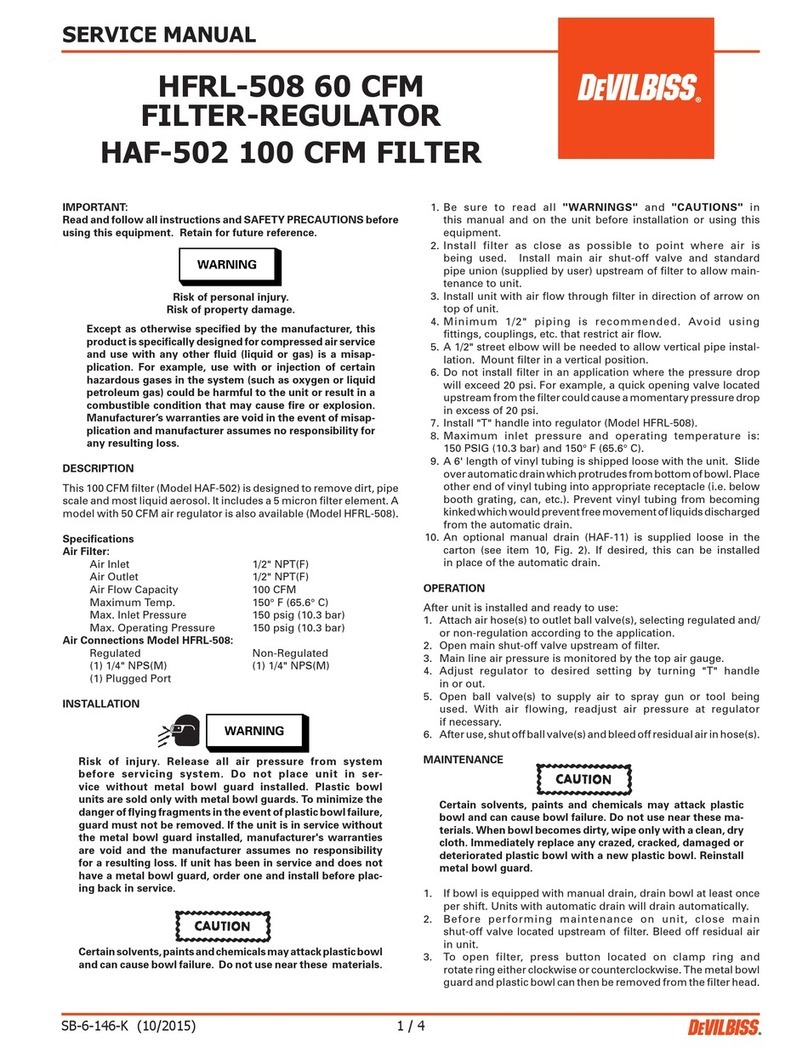

Inlet Pressure IRegulated IMax. FlUid/Max. I Min. Outlet Press. Flow Connectio~s

175ps~l~psi I 10-75psi I 8gal/min.I ~~PT(FI

Maximum temperature 180°F.

INSTALLATION

The HGB regulator is provided with two side

outlet ports and one bottom inlet port, all 3/8"

NPT(F). The regulator may be installed either

vertically or horizontally for flexibility of

installation. In either case, riser and gauge

should be mounted vertically. The HGB-508

includes gauge, riser tube and fittings

factory installed.

To Service Valve Assembly:

1. Valve assembly can be removed from the

body with a 3/4" socket wrench.

2. Remove nut (C) and discard stem and seat

(9).

3. Reassemble. Apply retaining compound

to male threads on stem and tighten nut

as shown.

4. When reinstalling, tighten valve assembly

to 20 to 25 in./lbs. torque.

Since the gauge operates on air trapped in

the riser, a rise is always necessary. Any leaks

in riser or gauge connections will permit

this trapped airto escape thus allowing paint

to get into the gauge causing damage.

~]

It is recommended that at initial instal-

lation the material supply line should

not be flushed through the regulator

because pipe compound, chips, scale,

etc., may lodge in the regulator valve

assembly.