SB-6-403-J Page 3

TECHNICAL DATA

PSI (bar)

Fluid Inlet Pressure Min. 50 (3.5)

Max. 300 (20.7)

Regulated Fluid Min. 2 (0.14)

Pressure Range Max. 100 (6.9)

*Typical Flow Rates 150 to 2500 cc's/minute

oz's (grams)

Average Unit Weight

Models - Swivel 7.3 (210)

- Tamper Resist 7.9 (225)

- Standpipe 9.3 (265)

- Bayonet 9.7 (275)

Fluid oz's (ml)

Static Content

Models - Circulating 0.25 (7)

- Non-circulating 0.20 (5)

Wetted Parts 303 and 416 Stainless Steel,

Teflon ®

Models 17 models offered as standard

* Dependent upon viscocity and specific

gravity of material. Above information

based upon testing with mineral oil with

viscosity of 24 seconds #4 Ford, and

specific gravity of 0.84.

®Registered trademark of Dupont.

INSTALLATION

Risk of hazardous bursting or

equipment damage. Do not ex-

ceed 300 PSI (21 bar) maximum

fluid inlet pressure to regulator.

These regulators may be used

with most common coating and

finishing materials. However,

they are not designed for use

with highly abrasive materials.

If used with abrasive materials,

frequent and thorough clean-

ing will be required, and replace-

ment of parts will be increased.

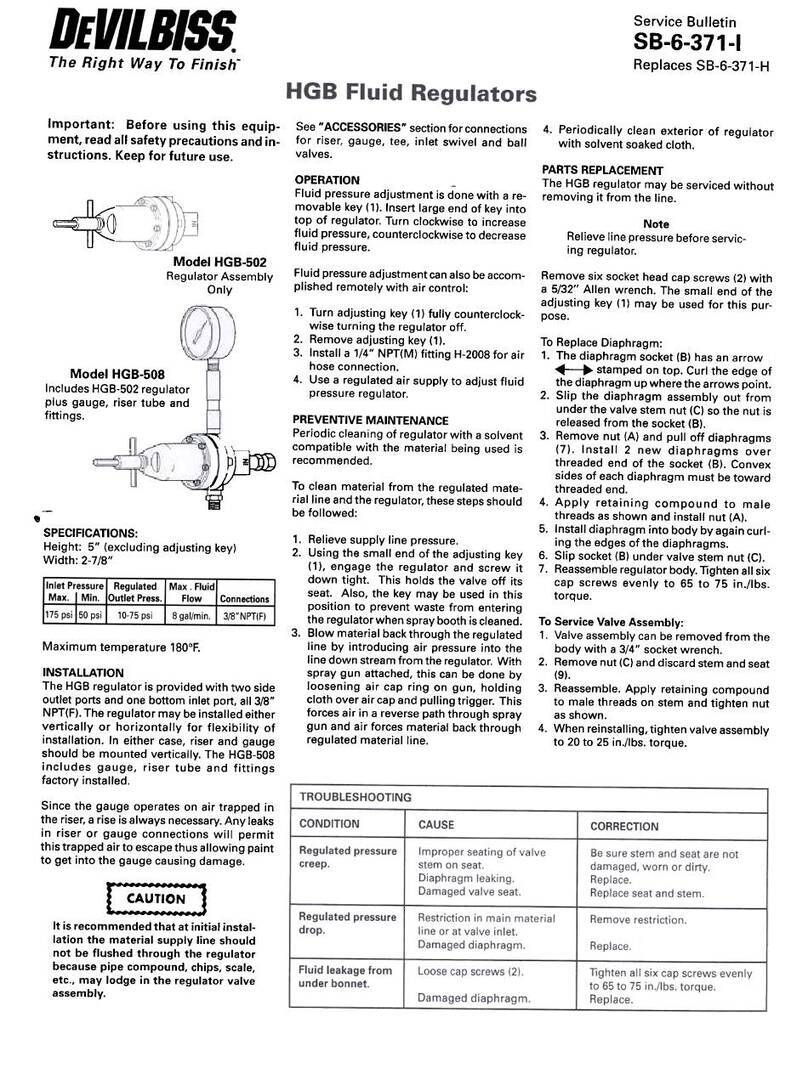

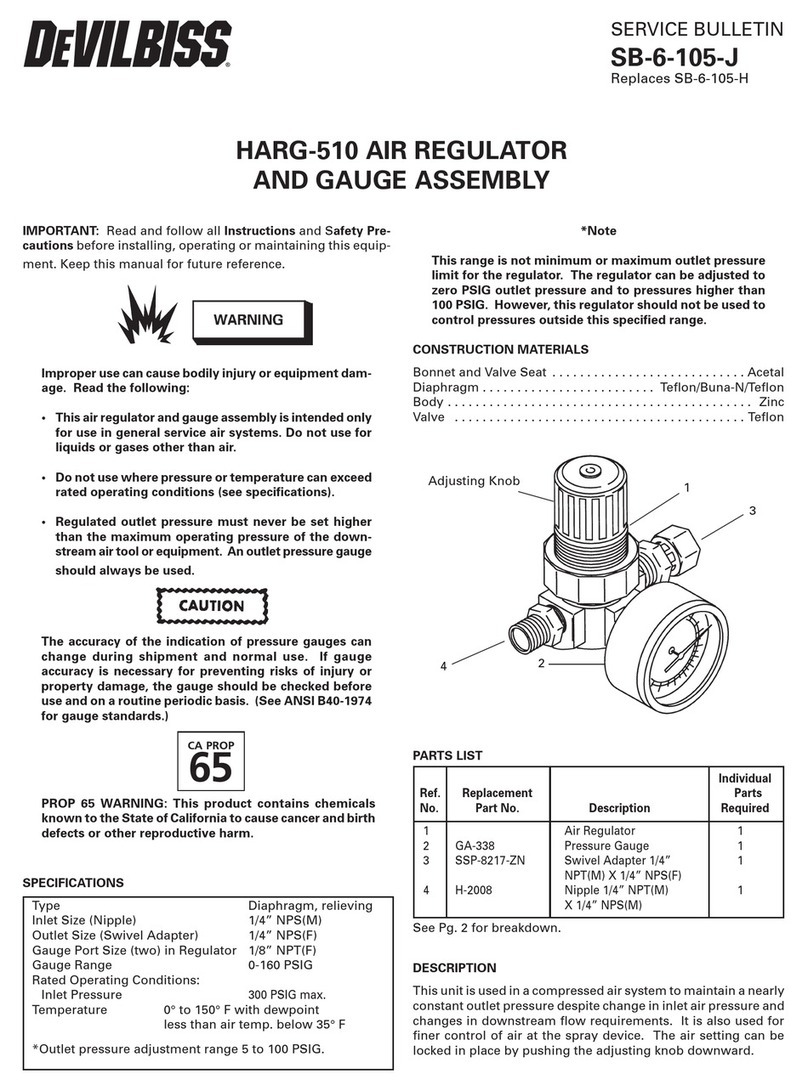

1 . Where possible, mount the HGS regu-

lator as shown below with the fluid

outlet facing up. This will prevent

trapped air from causing erratic op-

eration. Trapped air can result from

an "air push" during a color change

cycle, or entrapped air in the paint.

2. Connect fluid inlet supply hose.

Circulating Models

Connect the fluid supply hose to ei-

ther fluid inlet adapter (53 or 54).

Connect the return line to the other

adapter (53 or 54).

Non-Circulating Models

Connect the fluid supply hose to

inlet of plug (23 or 40).

3. Connect fluid outlet.

Bayonet Regulators

Attach the bayonet lock body (41) to

the bayonet quick disconnect stem at

the spray gun fluid inlet.

3/8" Swivel Regulators

Thread swivel nut (49) onto fluid inlet

of spray gun body.

Standpipe Regulators

Attach fluid supply hose from spray

gun to bulkhead fitting (52).

4. Connect air inlet.

Air Pilot Regulators

Attach regulated air supply to

connector (25).

OPERATION

Risk of hazardous bursting or

equipment damage. Do not ex-

ceed 300 PSI (21 bar) maximum

fluid inlet pressure to regulator.

Fluid pressure adjustment range is from

2 psi to 100 psi (0.1 bar to 6.9 bar).

Fluid pressure to regulator inlet is

300 psi (20.7 bar) maximum and 50 psi

(3.5 bar) minimum.

To Regulate Fluid Pressure on Manual

Adjust Models

1. Remove cap nut (1) and loosen lock

nut (2).

2. With a 3/32 inch hex key allen

wrench, adjust hex key allen set

screw (3) for desired pressure set-

ting. Turn set screw (3) clockwise to

increase and counterclockwise to

decrease pressure.

3. Retighten lock nut (2) after desired

pressure setting has been established.

Replace and tighten cap nut (1).

To Regulate Fluid Pressure on Tamper

Resistant Models

1. Using T-handle (4B), loosen lock (6).

2. Engage adjusting screw (5) with torx

key (4A) and turn adjusting screw

until desired pressure setting is

reached. Turn torx key clockwise to

increase pressure and counterclock-

wise to decrease pressure.

3. Using the torx key, hold adjusting

screw (5) from turning and tighten

lock (6) with the T-handle (4B).

To Regulate Fluid Pressure on Air Pilot

Models

Fluid pressure is controlled by means of

air pressure. To actuate fluid flow, a

minimum of 12-14 psi air pressure must

be applied to the bonnet.Attach one end

of regulated air line to connector (25)

and the other end of the air line to a

remote regulator. Increase air pressure

to increase fluid pressure, and decrease

air pressure to decrease fluid pressure.

Fluid pressure remains constant unless air

pilot regulator setting is altered.

PREVENTIVE MAINTENANCE

Cleaning

Total submersion of the fluid

regulator in solvent for clean-

ing purposes will shorten the

life expectancy of the dia-

phragm.

The frequency with which the fluid

regulator should be cleaned will be the

same as the rest of the system in which

it is being used.

Bayonet Models

When spray gun is removed from service

and fluid regulator is not going to be used

for a period of time, the bayonet end

should immediately be soaked in solvent.

Do not submerge the entire regulator.

This will avoid hardening of material

around the ball and seat which may cause

leakage when regulator is put back in

service. The soaking container should be

an approved closed container if hazard-

ous solvents are used.

Fluid outlet should

face upward.